I-ASTM A519Amapayipi kufanele akhiqizwe ngenqubo engenamthungo futhi kufanele aqedwe ngokushisa noma ngokubandayo njengoba kuchaziwe.

Kumashubhu ayindilinga anobubanzi bangaphandle obungadluli ku-325 mm (12 3/4 in).

Amapayipi ensimbi angakhiwa futhi ngesimo esiyisikwele, esingunxande, noma ezinye izimo njengoba kudingeka.

I-ASTM A519 ingahlukaniswa ngokwezinto ezenziwe ngensimbi:Insimbi Yekhabhonikanye neNsimbi Ehlanganisiwe.

Insimbi yekhabhoniihlukaniswe yabaI-MT ephansi ye-Carbon(Umshini Wokushuba),Insimbi Ephezulu YekhabhonifuthiKususwe isibabule noma kuphinde kufakwe i-phosphor, noma kokubiliInsimbi Yekhabhoni, ukuze ivumelane nezidingo ezahlukene zezimboni kanye nezimo zokusetshenziswa.

Uma kungekho sigaba esichaziwe, abakhiqizi banenketho yokunikelaI-MT1015 noma i-MTX1020amamaki.

Ububanzi bangaphandle: 13.7 - 325 mm;

Ubukhulu bodonga: 2-100mm.

Insimbi ingenziwa nganoma iyiphi inqubo.

Insimbi ingaphonswa ngama-ingot noma iphonswe ngentambo.

Amapayipi kufanele enziwe yi-inqubo engenamthungofuthi kufanele kube okuqediwe ngokushisa noma okubandayo, njengoba kuchaziwe.

Amashubhu ensimbi angenamthungo angamashubhu angenazo izithungo ezihlanganisiwe kuyo yonke indawo.

Amapayipi aqediwe ngokubandayoKunconywa ngezidingo eziphezulu zokunemba kobukhulu kanye nekhwalithi yobuso.

Okukhathaza kakhulu ukusebenza kahle kwezindleko kanye nokuqina kwezinto ezibonakalayo,ipayipi lensimbi eliqediwe ngokushisakungaba ukukhetha okufaneleka kakhulu.

Okulandelayo inqubo yokukhiqiza ipayipi lensimbi elingenamthungo eligoqwe ngokushisa.

Umenzi wensimbi kufanele ahlaziye ukushisa kwensimbi ngayinye ukuze anqume iphesenti lezinto ezicacisiwe.

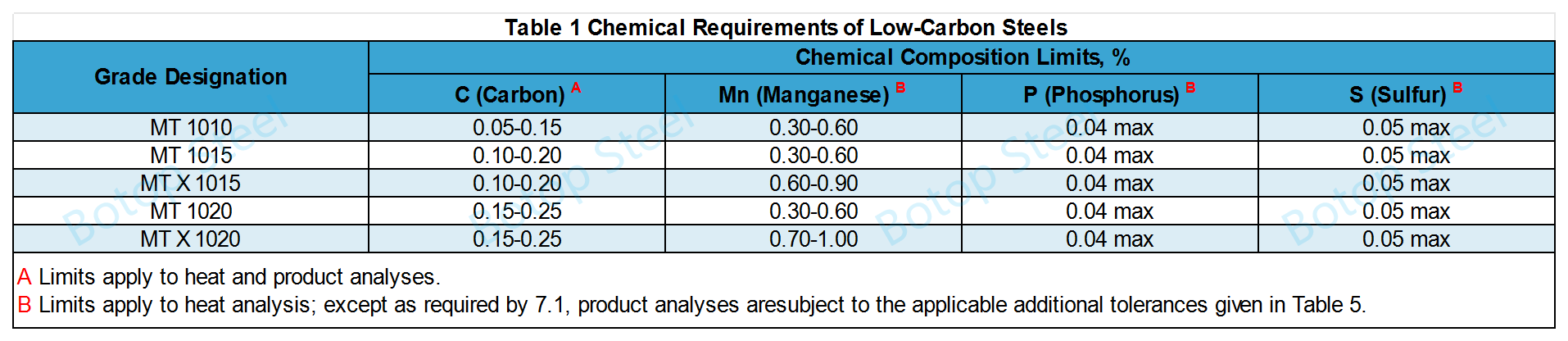

Ithebula 1 Izidingo Zamakhemikhali Zezinsimbi Ezinekhabhoni Ephansi

Insimbi encane iyinsimbi enokuqukethwe kwekhabhoni ngokuvamile okungadluli ku-0.25%. Ngenxa yokuqukethwe kwayo okuphansi kwekhabhoni, le nsimbi inokuguquguquka okungcono kanye nokuguquguquka futhi ayiqinile kangako uma iqhathaniswa nensimbi enekhabhoni ephezulu.

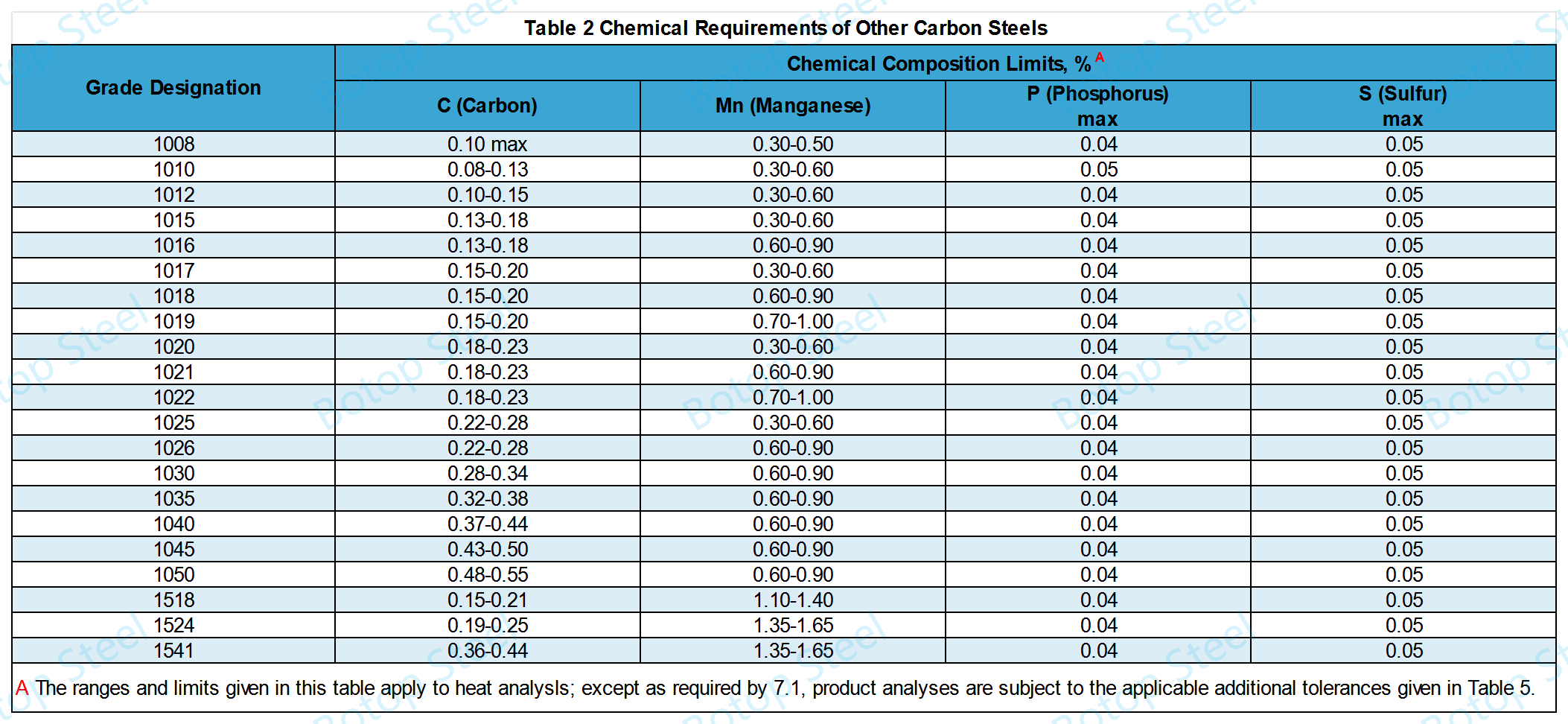

Ithebula 2 Izidingo Zamakhemikhali Zezinye Izinsimbi Zekhabhoni

Izinsimbi zekhabhoni eziphakathi nendawo: Njengoba ziqukethe ikhabhoni ephakathi kuka-0.25% no-0.60%, zinikeza ubulukhuni namandla aphezulu futhi zidinga ukwelashwa ngokushisa ukuze kuthuthukiswe izakhiwo.

Insimbi yekhabhoni ephezulu: Iqukethe phakathi kuka-0.60% no-1.0% noma ngaphezulu kwekhabhoni, futhi inikeza ubulukhuni namandla aphezulu kakhulu, kodwa ukuqina kwayo kuphansi.

Ithebula 3 Izidingo Zamakhemikhali Zezinsimbi Ze-Alloy

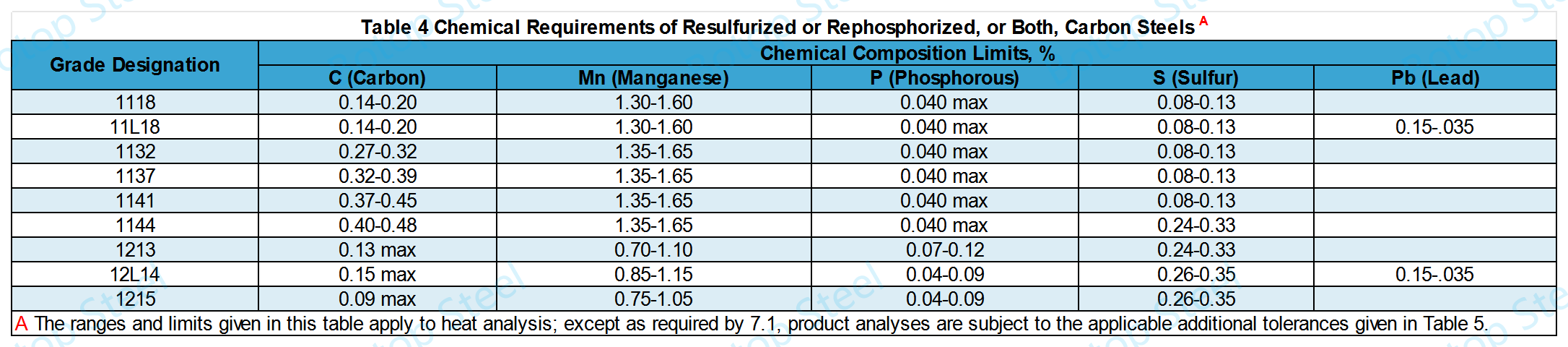

Ithebula 4 Izidingo Zamakhemikhali Zensimbi Zekhabhoni Ezivuselelwe Noma Ezivuselelwe, noma Zombili

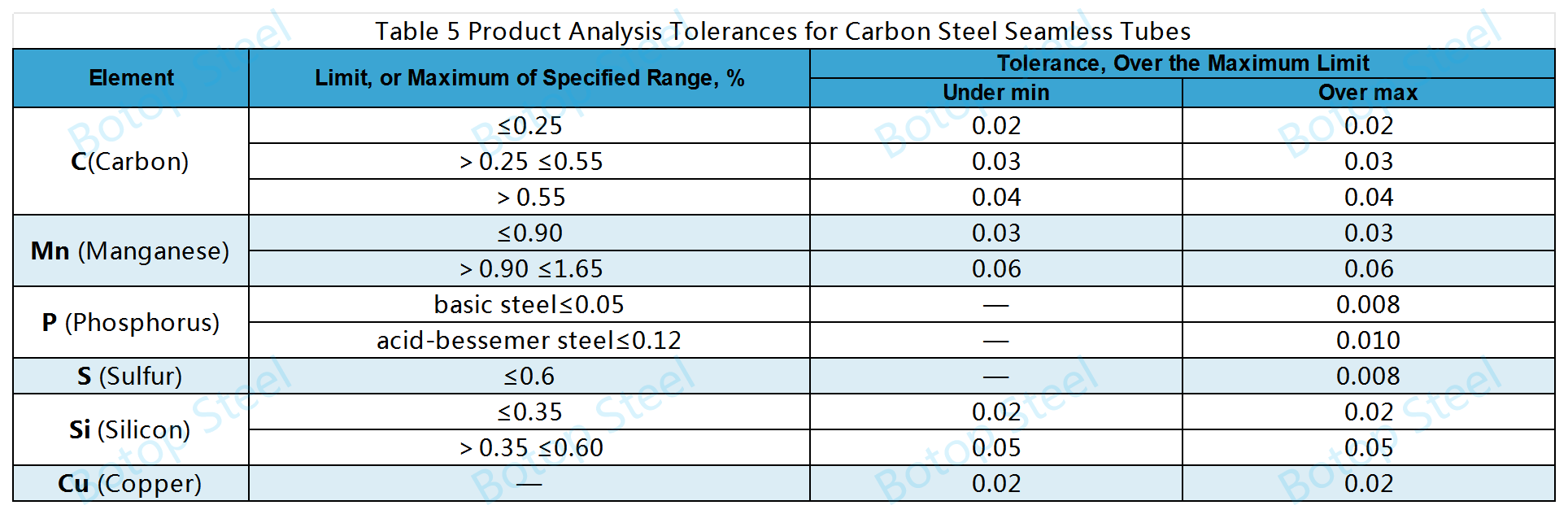

ITHEBULA 5 Ukuhlaziywa Komkhiqizo Ukubekezelela Ububanzi Obubekiwe Noma Obungaphansi Kobubanzi Obubekiwe

Umenzi kufanele acelwe kuphela ukuthi ahlaziye umkhiqizo uma kudingeka nge-oda.

I-ASTM A519 ihlanganisa izinto ezilandelayo zokuhlola:

Ukuhlolwa Kokuqina; Ukuhlolwa Kokucindezeleka; Ukuhlolwa Okungabhubhisi; Ukuhlolwa Kokuvutha; Ukuhlanzeka Nokuqina Kwensimbi.

| Ukuqokwa Kwebanga | Uhlobo Lwepayipi | Isimo | Amandla Aphelele | Amandla Okukhiqiza | Ukwelulwa ngamasentimitha angu-2.[50mm],% | uRockwell, Isikali Sobunzima B | ||

| ksi | I-Mpa | ksi | I-Mpa | |||||

| 1020 | Insimbi Yekhabhoni | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Insimbi Yekhabhoni | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Insimbi Yekhabhoni | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Insimbi Yekhabhoni | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Insimbi Yekhabhoni | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Kuvuselelwe kabusha noma i-Rephosphorized, noma kokubili, Izinsimbi Zekhabhoni | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Kuvuselelwe kabusha noma i-Rephosphorized, noma kokubili, Izinsimbi Zekhabhoni | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Izinsimbi Zengxubevange | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Izinsimbi Zengxubevange | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

I-HR-Egoqekile Ngokushisayo, Isebenza Ngokushisa Okubandayo, I-SR-Edambisiwe Ukucindezeleka, I-A-Eyenziwe Kabi futhi Ejwayelekile.

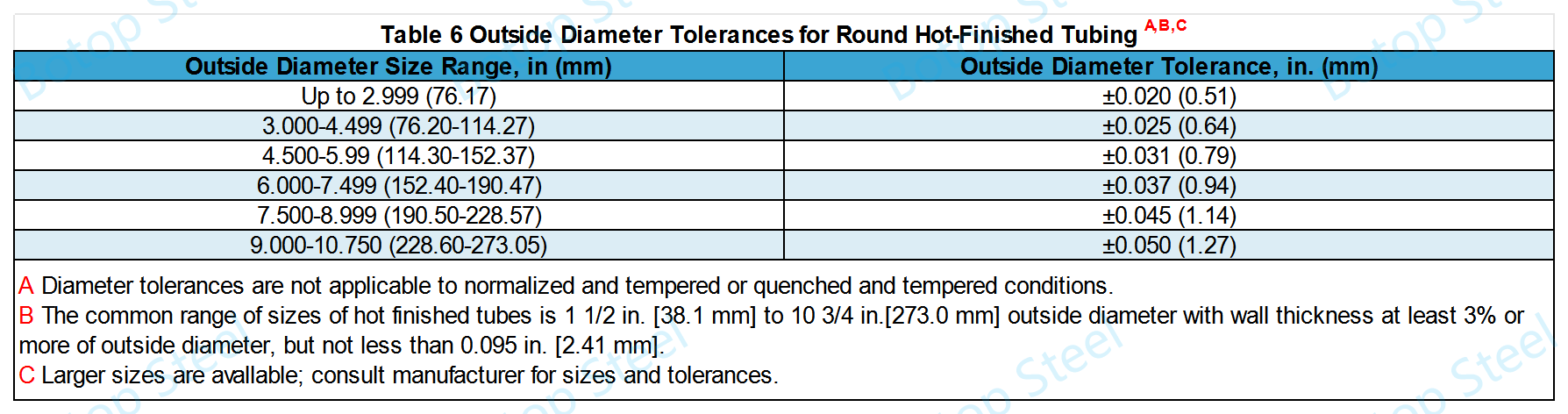

Ukubekezelelana Kwangaphandle Kobubanzi

Ithebula 6 Ukubekezelelana Kwangaphandle Kobubanziyepayipi eliyindilinga eliqediwe elishisayo

Ithebula 12 Ukubekezelelana Kwangaphandle Kobubanzi be-Ipayipi Elingenamthungo Elingaphansi

| Usayizi Ububanzi Ngaphandle, ku.[mm] | Ukubekezelelana Kwangaphandle Kobubanzi Bosayizi Nobude Okunikeziwe, ngo. [mm] | |||

| Kuphelile | Ngaphansi | Kuphelile | Ngaphansi | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] lapho i-L≤16ft[4.9m] | 0.000 | 0.004 [0.10] lapho i-L >16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] lapho i-L≤16ft[4.9m] | 0.000 | 0.006 [0.15] lapho i-L >16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] lapho i-L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lapho i-L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] lapho i-L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lapho i-L≤16ft[4.9m] | 0.000 |

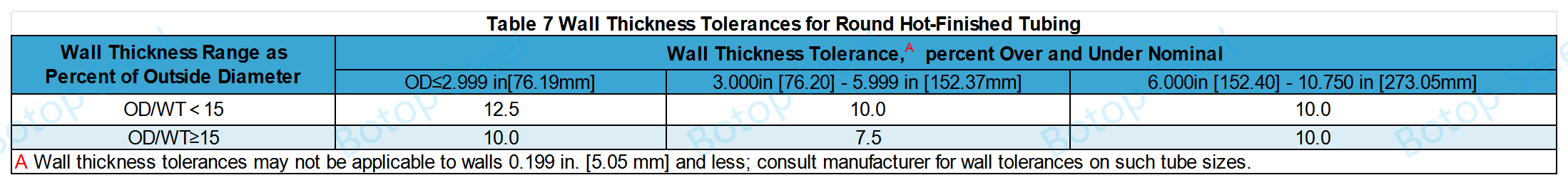

Ukubekezelela Ubukhulu Bodonga

Ithebula 7 Ukubekezelelana Kokujiya Kodongayepayipi eliyindilinga eliqediwe elishisayo

Ithebula 10 Ukubekezelelana Kokujiya KodongaAmapayipi Asebenza Ngobandayo Ajikelezayo

| Ububanzi Bokujiya Kodonga njenge Amaphesenti Obubanzi Bangaphandle | Ukubekezelela Ubukhulu Bodonga Okujwayelekile, % | |

| OD≤1.499in[38.07mm] | OD≥1.500 ku-[38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| I-OD/WT >25 | 12.5 | 10.0 |

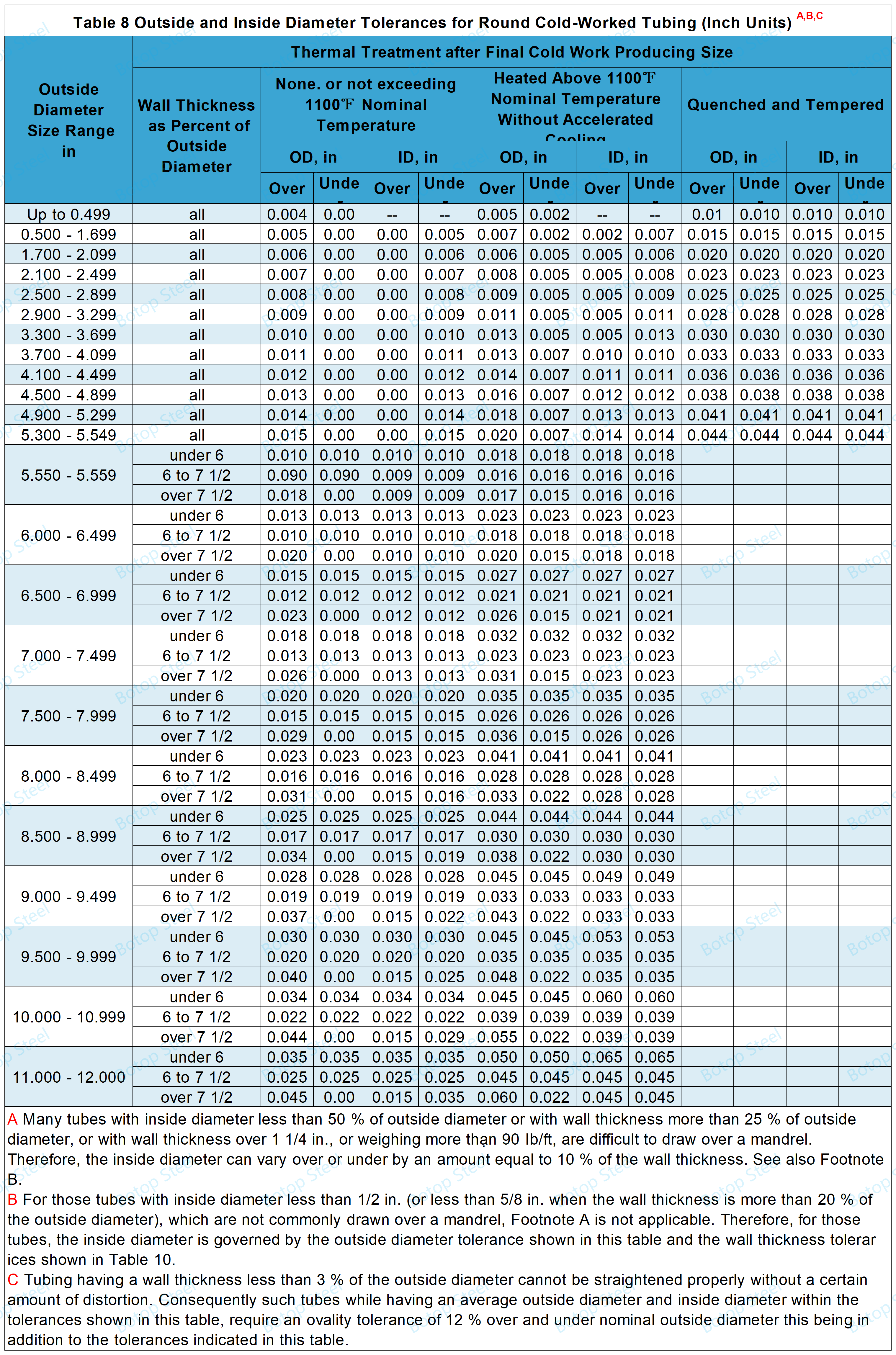

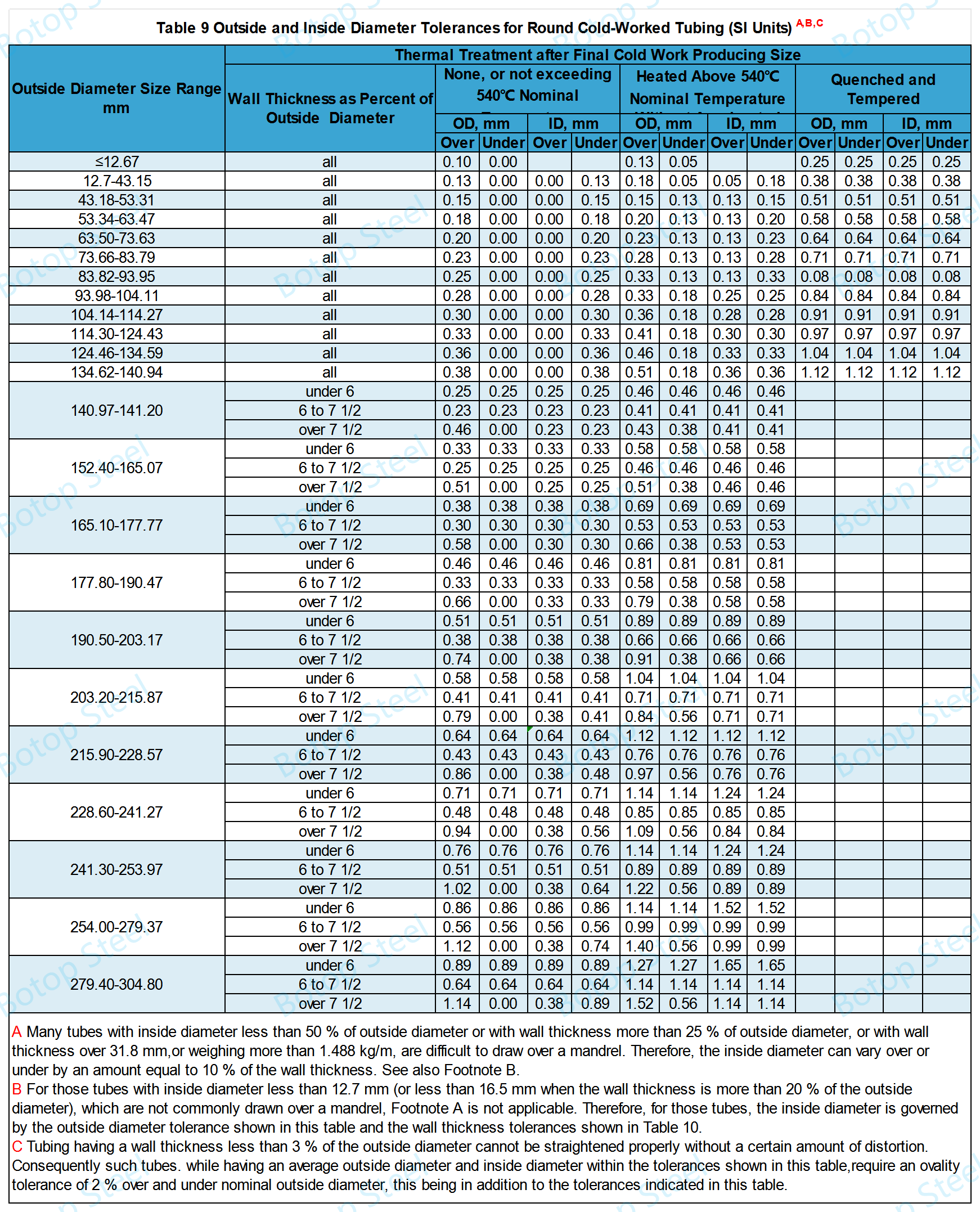

Ukubekezelelana Kwangaphandle Nangaphakathi Kobubanzi

Ithebula 8 Ukubekezelelana Kwangaphandle Nangaphakathi Kobubanzi be-Ipayipi Eliyindilinga Elisebenza Ngobandayo (Amayunithi E-intshi)

Ithebula 9 Ukubekezelelana Kwangaphandle Nangaphakathi KobubanziAmapayipi Asebenza Ngobandayo Ajikelezayo (ama-SI Units)

Ububanzi Bangaphandle Nokubekezelela Ubukhulu Bodonga

Ithebula 11 Ububanzi Bangaphandle Nokubekezelelana KodongaAmapayipi Ensimbi Angenamthungo Ajike Kabi

| Usayizi Ocacisiwe Ububanzi Bangaphandle, ngaphakathi. [mm] | Ububanzi Bangaphandle, ngaphakathi. [mm] | Ubukhulu Bodonga, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Ukubekezelela Ubude

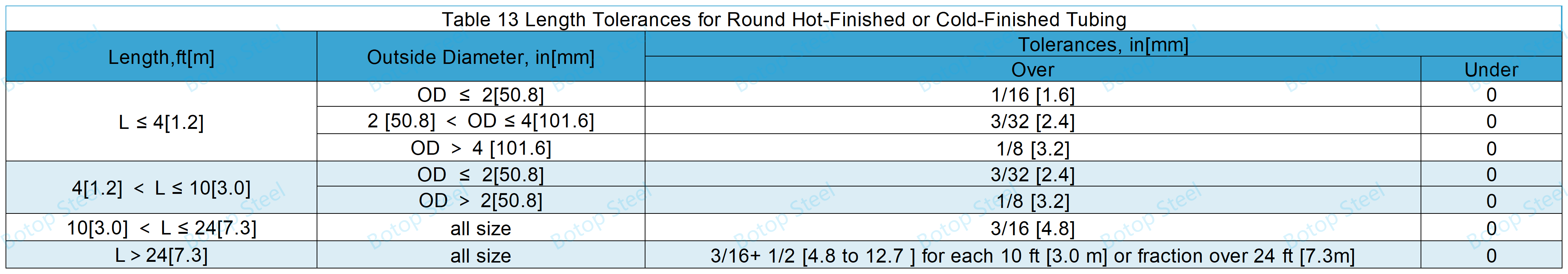

Ithebula 13 Ukubekezelela Ubudengepayipi eliyindilinga eliqediwe ngokushisa noma elibandayo

Ukubekezelelana Kokuqondile

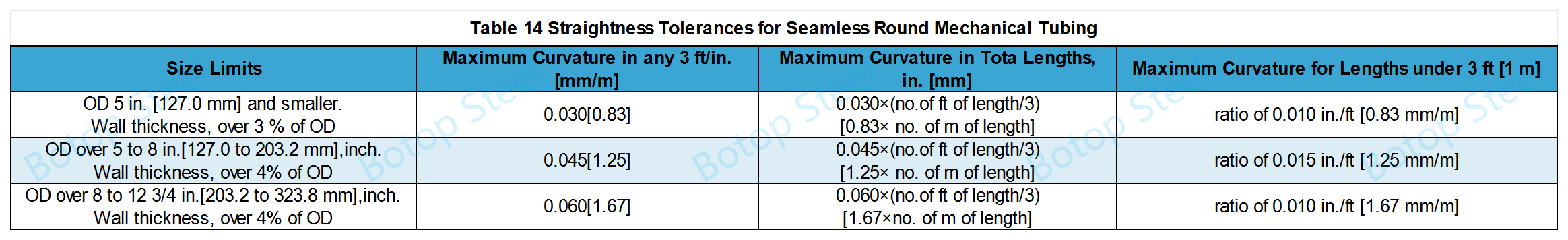

Ithebula 14 Ukubekezelelana KokuqondileAmapayipi Omshini Angenamthungo Ayindilinga

Ipayipi kufanele limbozwe ngefilimu yamafutha ngaphambi kokubumba ukuze kuvinjelwe ukugqwala.

Uwoyela wokuvimbela ukugqwala ungasetshenziswa nasezindaweni zangaphakathi nezangaphandle zepayipi.

Izindiza kanye nezindiza: ukukhiqizwa kwezingxenye ezibalulekile njengezinjini zezindiza kanye nezinhlelo zokusekela izindiza-mkhathi.

Imboni yamandla: imishini yokubhoboza kanye nokukhiqizwa kwamapayipi ebhoyila anomfutho ophezulu.

Ukukhiqizwa kwemishini nemishini: Izingxenye eziyinhloko ezakha uhla olubanzi lwemishini yezimboni kanye nemishini.

Imishini yezemidlalo: Ukwenziwa kwamafreyimu amabhayisikili asebenza kahle kanye nezinye izikhungo zemidlalo.

Ukwakha nokwakha: izakhi zokusekela isakhiwo zezakhiwo kanye nezinhlelo zokusebenza ezindaweni ezinomfutho ophezulu.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, njll. Lezi zinto zingabhekwa njengezilingana nezinye izinsimbi zekhabhoni ne-alloy ku-ASTM A519.

2. I-DIN 1629: St52, St37.4, njll. Ngokuvamile isetshenziselwa izinjongo zemishini nezakhiwo, lezi zifana nezinhlobo zensimbi ezithambile ku-ASTM A519.

3. I-JIS G3445: STKM13A, STKM13B, njll. Lawa amashubhu ensimbi yekhabhoni asetshenziselwa izinjongo zemishini nezakhiwo.

4. BS 6323: CFS 3, CFS 4, CFS 8, njll. Lawa amashubhu ensimbi angenamthungo futhi ahlanganisiwe ngezinjongo zobunjiniyela bezimoto, obunjiniyela bemishini, kanye nobunjiniyela obujwayelekile.

5. GB/T 8162:20#, 45#, 40Cr, 20CrMo, njll. Amapayipi ensimbi angenamthungo kanye namapayipi esakhiwo esijwayelekile kanye nesakhiwo semishini.

6. I-ISO 683-17:100Cr6, njll., evame ukusetshenziswa ekukhiqizeni amabhere, ingathola nokusetshenziswa kobunjiniyela bemishini futhi inezinhlelo zokusebenza ezifanayo nezinsimbi ezithile ze-alloy ze-ASTM A519.

Uma ukhetha into efanayo, kubalulekile ukubhekisela ekwakhiweni kwamakhemikhali okuningiliziwe kanye nemininingwane yempahla yemishini ukuqinisekisa ukuthi into ekhethiwe izohlangabezana nezidingo zokusebenza kwesicelo esithile.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele. Le nkampani inikeza amapayipi ensimbi yekhabhoni ahlukahlukene kanye nemikhiqizo ehlobene nawo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.