I-ASTM A500 iyipayipi lesakhiwo sensimbi yekhabhoni elihlanganisiwe nelingenamthungo lamabhuloho ahlanganisiwe, aboshwe, noma aboshwe kanye nezakhiwo zokwakha kanye nezinjongo ezijwayelekile zesakhiwo.

Ibanga Biyithubhu yesakhiwo sensimbi yekhabhoni eyakhiwe ngendlela eguquguqukayo eyakhiwe ngokubandayo ehlanganisiwe noma engenamthungo enamandla okukhiqiza angaphansi kwama-315 MPa [46,000 psi] kanye namandla okudonsa angaphansi kwama-400 MPa [58,000], esetshenziswa ezinhlobonhlobo zemiklamo yesakhiwo sokwakha kanye nesomshini ngenxa yokuqina kwayo okuhle kakhulu kwesakhiwo kanye nokuqina.

I-ASTM A500 ihlukanisa ipayipi lensimbi libe amazinga amathathu,ibanga B,ibanga C, kanye nebanga D.

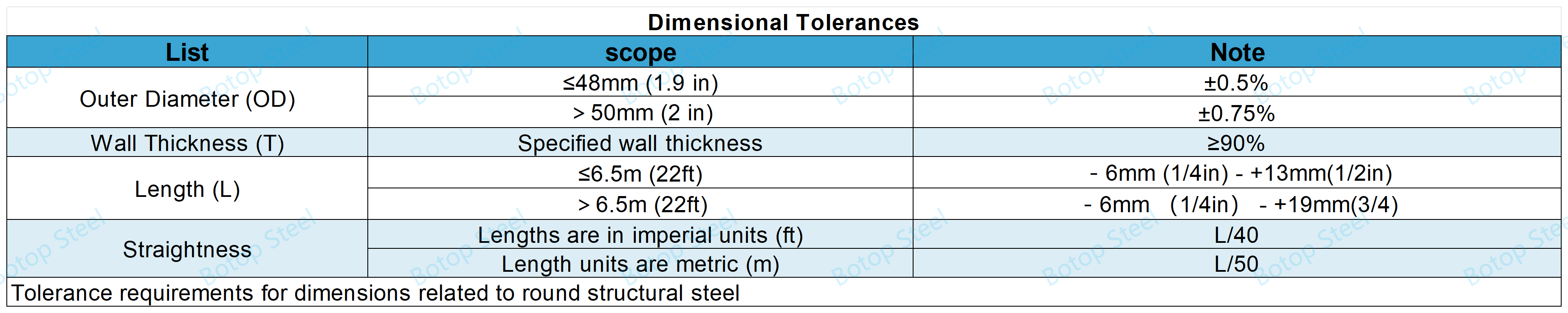

Kwamapayipi aneububanzi bangaphandle ≤ 2235mm [88in]futhiubukhulu bodonga ≤ 25.4mm [1in].

Kodwa-ke, uma kusetshenziswa inqubo yokushisela ye-ERW, kungenziwa amapayipi anobubanzi obukhulu obungu-660 mm kanye nobukhulu bodonga obungu-20 mm kuphela.

Uma ufuna ukuthenga ipayipi elinobukhulu bodonga obukhulu, ungakhetha ukusebenzisa inqubo yokushisela ye-SAW.

I-CHS: Izingxenye eziyindilinga ezingenalutho.

I-RHS: Izingxenye ezinezimbobo eziyisikwele noma eziyisikwele.

I-EHS: Izingxenye ezingenalutho ezi-elliptical.

Insimbi kumele yenziwe ngenqubo eyodwa noma ngaphezulu kwalezi ezilandelayo:i-oxygen eyisisekelo noma isithando sikagesi.

Inqubo Eyisisekelo Yomoya-mpilo: Lena indlela yesimanje esheshayo yokukhiqiza insimbi, enciphisa okuqukethwe yikhabhoni ngokufutha umoya-mpilo ensimbini yengulube encibilikisiwe ngenkathi isusa ezinye izinto ezingafuneki njengesulfure ne-phosphorus. Ifanele ukukhiqizwa okusheshayo kwensimbi eningi.

Inqubo Yesithando Sikagesi: Inqubo Yesithando Sikagesi isebenzisa i-arc kagesi eshisa kakhulu ukuncibilikisa izingcezu nokunciphisa insimbi ngqo, futhi iwusizo kakhulu ekukhiqizeni amamaki akhethekile nokulawula ukwakheka kwe-alloy, kanye nokukhiqizwa kweqembu elincane.

Amapayipi kufanele enziwe yi-okushiselwe ngokumelana nogesi (ERW)inqubo.

Ipayipi le-ERW inqubo yokwakha i-weld ngokuhlanganisa izinto zensimbi zibe yi-cylinder bese usebenzisa ukumelana nokucindezela ubude bayo.

Amapayipi e-Grade B angasuswa noma ancishiswe ukucindezeleka.

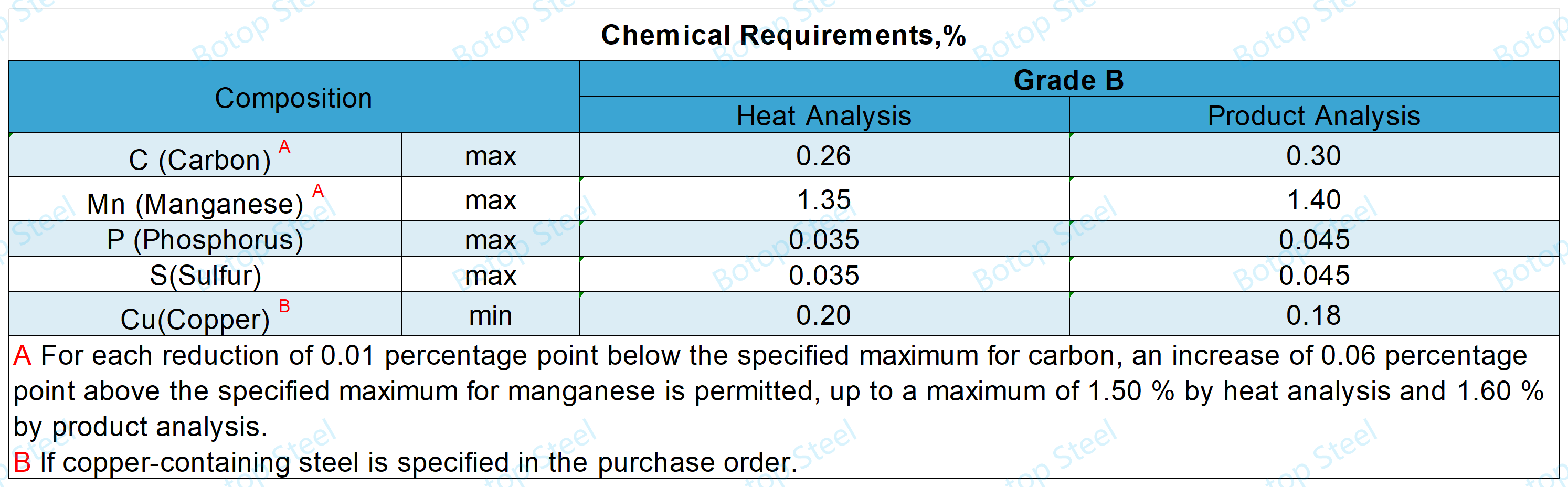

Ukwakheka kwamakhemikhali kwensimbi ye-ASTM A500 Grade B kufaka phakathi inani elilinganiselwe lekhabhoni kanye ne-manganese ukuqinisekisa izakhiwo ezinhle zemishini kanye nokushibilika. Ngesikhathi esifanayo, amazinga e-phosphorus kanye ne-sulfur alawulwa ngokuqinile ukuze kugwenywe ukuqhekeka, futhi ukwengezwa okulinganiselwe kwethusi kuthuthukisa ukumelana nokugqwala.

Lezi zakhiwo zilungele ukusetshenziswa kwesakhiwo, ikakhulukazi ezindaweni lapho kudingeka khona ukushintshwa okuhle nokuqina.

Ama-specimens kufanele ahlangabezane nezimfuneko ezifanele ze-ASTM A370, Isithasiselo A2.

| Uhlu | Ibanga B | |

| Amandla okudonsa, ubuncane | i-psi | 58,000 |

| I-MPa | 400 | |

| Amandla okukhiqiza, ubuncane | i-psi | 46,000 |

| I-MPa | 315 | |

| Ukwelulwa ngamasentimitha angu-2 (50 mm), min,C | % | 23A |

| AKusebenza kubukhulu bodonga obucacisiwe (t) obulingana noma obukhulu kuno-0.180 in. [4.57 mm]. Kubukhulu bodonga obucacisiwe obulula, amanani obude obuncane azobalwa ngefomula: ubude bephesenti ku-2 in. [50 mm] = 61t+ 12, obuzungezwe kuphesenti eliseduze. Ku-A500M sebenzisa ifomula elandelayo: 2.4t+ 12, obuzungezwe kuphesenti eliseduze. CAmanani amancane okwandiswa acacisiwe asebenza kuphela ekuhlolweni okwenziwe ngaphambi kokuthunyelwa kwepayipi. | ||

Ukushiseladikhonoti-est: Usebenzisa isampula okungenani amasentimitha angu-100 (100 mm) ubude, cindezela isampula nge-weld ku-90° ukuya endaweni yokulayisha kuze kube yilapho ibanga eliphakathi kwamapuleti lingaphansi kuka-2/3 wobubanzi bangaphandle bepayipi. isampula akufanele iqhekeke noma iphuke ezindaweni zangaphakathi noma zangaphandle phakathi nale nqubo.

Ukuhlolwa kokuguquguquka kwamapayipi: qhubeka ugobe isampula kuze kube yilapho ibanga eliphakathi kwamapuleti lingaphansi kwengxenye eyodwa kwengxenye yobubanzi bangaphandle bepayipi. ngalesi sikhathi, ipayipi akufanele libe nemifantu noma ama-fractures ezindaweni zangaphakathi nezangaphandle.

Ubuqothoti-estQhubeka uthambekisela isampula kuze kube yilapho kuvela ukuphuka noma kuze kube yilapho izidingo zobukhulu bodonga zihlangatshezwa. Uma kutholakala ubufakazi bokuqhekeka kwe-ply, izinto ezingazinzile, noma ukushintshwa okungaphelele ngesikhathi sokuhlolwa kokuthambekisa, isampula izokwahlulelwa njengenganelisi.

Ukuhlolwa kokuvutha kuyatholakala kumashubhu ayindilinga angu-≤ 254 mm (10 in) ububanzi, kodwa akuyona impoqo.

Zonke izimbobo zokufaka amapayipi kufanele zingabi namaphutha futhi kufanele zibe nomphumela ofana nowenziwe ngumuntu.

Ukungapheleli kobuso kufanele kubhekwe njengokukhubazeka lapho ukujula kwabo kunciphisa ukujiya kodonga okusele kube ngaphansi kuka-90% wobukhulu bodonga obubekiwe.

Amaphutha afinyelela ku-33% wobukhulu bodonga obucacisiwe ngokujula angasuswa ngokuphelele ngokusika noma ukugaya ukuze kube yinsimbi ephelele.

Uma kusetshenziswa ukushisela kokugcwalisa, inqubo yokushisela okumanzi kufanele isetshenziswe futhi insimbi yokushisela ephumayo kufanele isuswe ukuze kugcinwe indawo ebushelelezi.

Amaphutha angaphezulu, njengezimpawu zokuphatha, amamaki amancane okubumba noma okugoqa, noma imigodi engajulile, awabhekwa njengamaphutha uma nje engasuswa ngaphakathi kobukhulu bodonga obubekiwe.

Ulwazi olulandelayo kufanele lufakwe:

Igama lomkhiqizi: Lokhu kungaba igama eliphelele lomenzi noma isifinyezo.

Umkhiqizo noma Uphawu Lokuhweba: Igama lomkhiqizo noma uphawu lokuhweba olusetshenziswa umenzi ukuhlukanisa imikhiqizo yalo.

Umklami Wezincazelo: ASTM A500, okungadingeki ukuthi kufakwe unyaka wokushicilelwa.

Incwadi Yebanga: Ibanga B, C noma D.

Kumapayipi esakhiwo angu-≤ 100mm (4in) ububanzi, amalebula angasetshenziswa ukumaka ulwazi lokuhlonza ngokucacile.

Isetshenziswa ngokuyinhloko ngezinjongo zokwakha, inikeza amandla okusebenza kanye nokukwazi ukushibilika ukuze kusekelwe ukuklama nokwakhiwa kwezakhiwo zokwakha nezobunjiniyela.

Leli payipi lensimbi lisetshenziswa kabanzi ekwakheni ozimele, amabhuloho, izikhungo zezimboni, kanye nezinye izakhi zesakhiwo ezahlukahlukene ezidinga amandla nokuqina.

I-ASTM A370: Izindlela Zokuhlola Nezincazelo Zokuhlolwa Kwemishini Kwemikhiqizo Yensimbi.

I-ASTM A700: Umhlahlandlela Wokupakisha, Ukumaka, kanye Nezindlela Zokulayisha Zemikhiqizo Yensimbi Yokuthunyelwa.

I-ASTM A751: Izindlela Zokuhlola Nemikhuba Yokuhlaziya Amakhemikhali Emikhiqizo Yensimbi.

Amagama e-ASTM A941 aphathelene nensimbi, insimbi engagqwali, ama-alloy ahlobene, kanye nama-ferroalloy.

Ngokwezidingo zamakhasimende, ukwelashwa kokulwa nokugqwala kwezindawo zamapayipi ensimbi kungenziwa ngezindlela eziningi ezahlukene ukuze kuthuthukiswe ukumelana nokugqwala kwayo futhi kwandise isikhathi sayo sokusebenza.

Kubandakanya i-varnish, upende, i-galvanization, i-3PE, i-FBE, nezinye izindlela.

Singumkhiqizi kanye nomhlinzeki wamapayipi ensimbi yekhabhoni ashiselwe ngekhwalithi ephezulu avela eShayina, futhi siphinde sibe ngumthengisi wamapayipi ensimbi angenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Uma ufuna ukwazi ulwazi olwengeziwe mayelana nemikhiqizo yamapayipi ensimbi, ungaxhumana nathi!