I-ASTM A335 P11ipayipi lensimbi liyipayipi lensimbi elihlanganisiwe le-ferritic elinomucu ophansi elihlanganisiwe elihlinzeka ngenkonzo yokushisa okuphezulu, igama le-UNS elithi K11597.

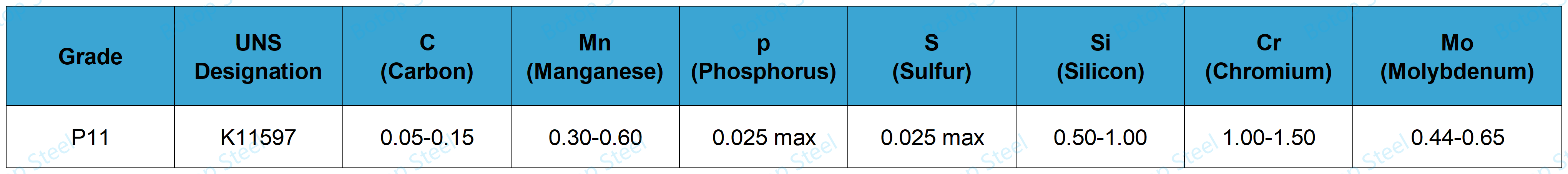

I-P11 iyi-alloy ye-chromium-molybdenum enokuqukethwe kwe-chromium okungu-1.00-1.50% kanye nokuqukethwe kwe-molybdenum okungu-0.44-0.65%.

Ivame ukusetshenziswa kuma-boiler, ama-superheater, kanye nama-heat exchanger eziteshini zikagesi nasezitshalweni zamakhemikhali.

Izidingo zobuchwepheshe zeI-ASME SA335futhiI-ASTM A335ziyafana, ngakho-ke ukuze kube lula ukwethula, sizosebenzisa i-"ASTM A335" ukubhekisela kulezi zindinganiso ezimbili.

Izintol: ipayipi lensimbi elingenamthungo le-ASTM A335 P11;

OD: 1/8"- 24";

WT: ngokuvumelana neI-ASME B36.10izidingo;

Ishejuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kanye ne-SCH160;

Ukuhlonza: STD, XS, XXS;

Ukwenza ngokwezifiso: Osayizi bamapayipi abangewona ajwayelekile nabo bayatholakala, osayizi abenziwe ngokwezifiso bayatholakala uma becelwa;

Ubude: Ubude obuqondile nobungahleliwe;

Isitifiketi se-IBR: Singaxhumana nenhlangano yokuhlola evela eceleni ukuze sithole isitifiketi se-IBR ngokwezidingo zakho, izinhlangano zethu zokuhlola ngokubambisana yi-BV, SGS, TUV, njll.;

Ukuphela: Isiphelo sepayipi esiyisicaba, esigobile, noma esihlanganisiwe;

Ubuso: Ipayipi elilula, upende, kanye nokunye ukuvikela kwesikhashana, ukususwa nokupholisha ukugqwala, ukugqunywa nge-galvanized kanye nepulasitiki, kanye nokunye ukuvikela kwesikhathi eside;

Ukupakisha: Ikesi lokhuni, ibhande lensimbi noma ukupakisha ucingo lwensimbi, isivikelo sokuphela kwepayipi lepulasitiki noma lensimbi, njll.

Ngaphandle kokuthi kuchazwe ngenye indlela ku-A335, izinto ezinikezwe ngaphansi kwalesi sichasiselo kufanele zihambisane nezidingo ezisebenzayo zohlelo lwamanje lweSichasiseloA999/A999M.

Ipayipi lensimbi le-ASTM A335 kumele libengaphandle komthungoAmashubhu ensimbi angenamthungo anikeza ukuthembeka okukhulu kanye nokufana okukhulu lapho ebhekene nezimo zokucindezela okuphezulu kanye nokushisa.

Okungenamthungo kungahlukaniswa ngokukhethekile njengokudonswa okubandayo kanye nokuqediwe okushisayo, kuye ngokusetshenziswa kanye nosayizi othile.

Ukudweba okubandayo kuvame ukusetshenziselwa ububanzi obuncane noma amashubhu adinga ukunemba okuphezulu kanye nekhwalithi enhle yobuso. Ukuqeda okushisayo kuvame ukusetshenziselwa ukukhiqiza amapayipi amakhulu ensimbi aqondile futhi anodonga olujiyile.

Ngezansi ishadi lokugeleza kwenqubo yokukhiqiza ipayipi lensimbi elingenamthungo eliqediwe ngokushisa.

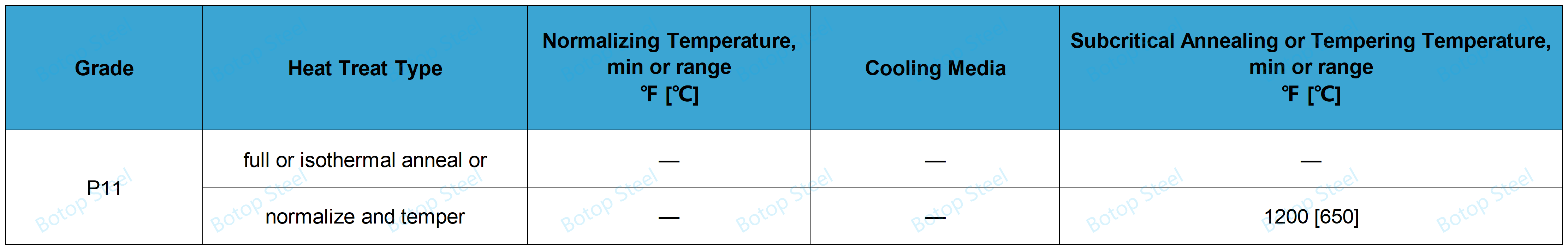

Ukwelashwa ngokushisa kwezinto ze-P11 kungaba ukugcwala noma ukufudumala okufana nokushisa noma ukufudumala ngemva kokufudumala, futhi lapho kulungiswa futhi kulungiswa, izinga lokushisa lokufudumala kufanele okungenani libe ngu-1200°F (650°C).

Kusukela ekwakhiweni kwamakhemikhali, singabona kalula ukuthiI-P11 iyi-alloy ye-chromium-molybdenum.

Ama-alloy e-Chromium-molybdenum ayisigaba sezinsimbi ezine-chromium (Cr) kanye ne-molybdenum (Mo) njengezinto eziyinhloko zokuhlanganisa. Ukwengezwa kwalezi zinto kwandisa kakhulu amandla, ubulukhuni, ukumelana nokuguguleka, kanye nokumelana nokugqwala kwensimbi. Emazingeni okushisa aphezulu, ama-alloy e-Cr-Mo ayakwazi ukugcina izakhiwo ezinhle zemishini kanye nesakhiwo esizinzile.

Cr: kuthuthukisa ukumelana nokugqwala kwe-alloy kanye nokumelana nokugqwala, kusiza ekwakheni ifilimu ye-oxide enamandla, futhi kuvikela izinto ezingcolisayo.

Mo: Kuthuthukisa amandla e-alloy, ikakhulukazi emazingeni okushisa aphezulu, kuthuthukisa ukumelana nokuqhekeka, futhi kuthuthukisa amandla okushisa aphezulu ezinto.

1. Impahla Eqinile

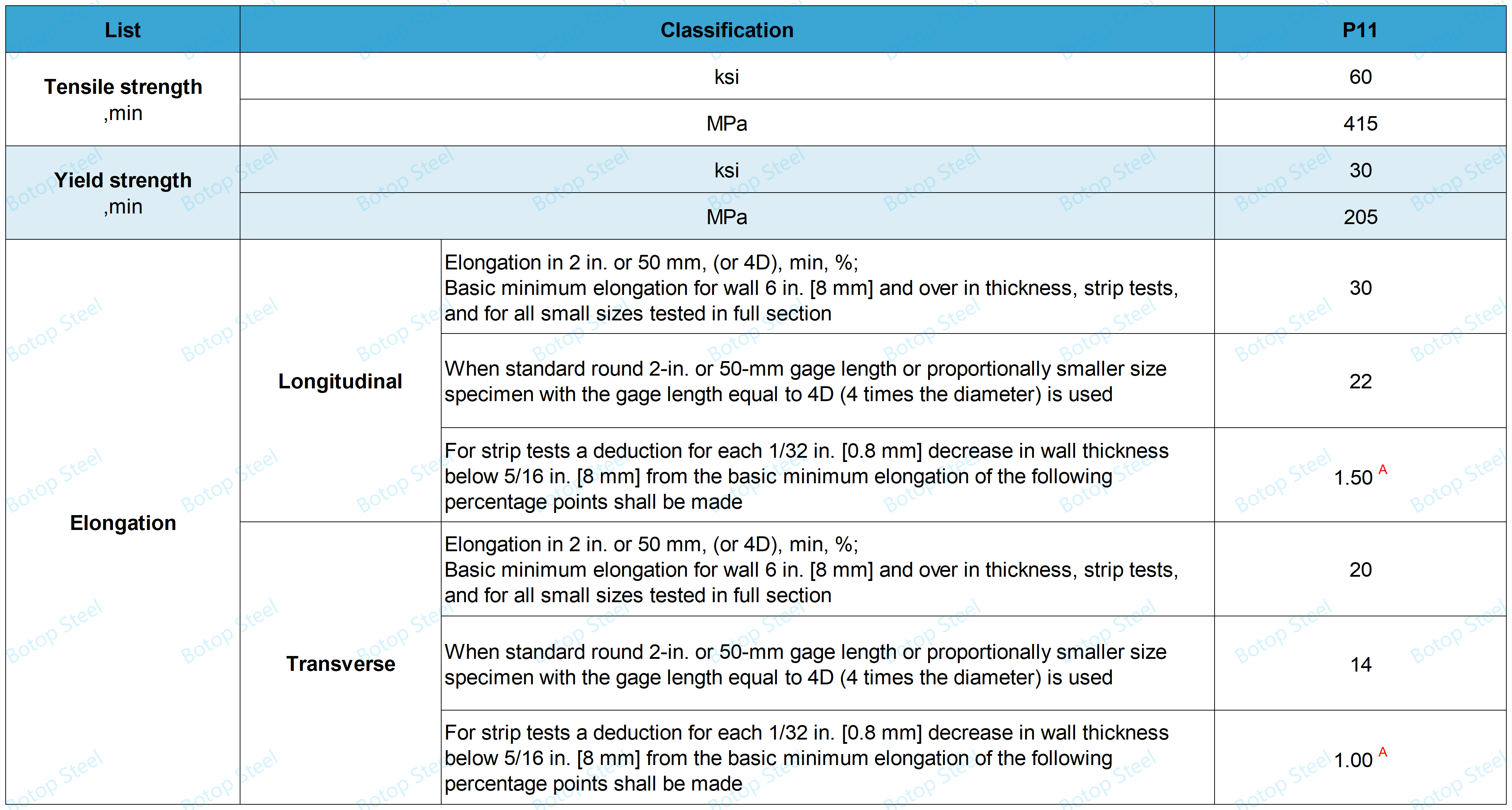

Ukuhlolwa kokudonsa kuvame ukusetshenziselwa ukukalaamandla okukhiqiza, amandla okudonsa, futhiubuden yohlelo lokuhlola ipayipi lensimbi, futhi isetshenziswa kabanzi ezimpahleni zezinto zokuhlola.

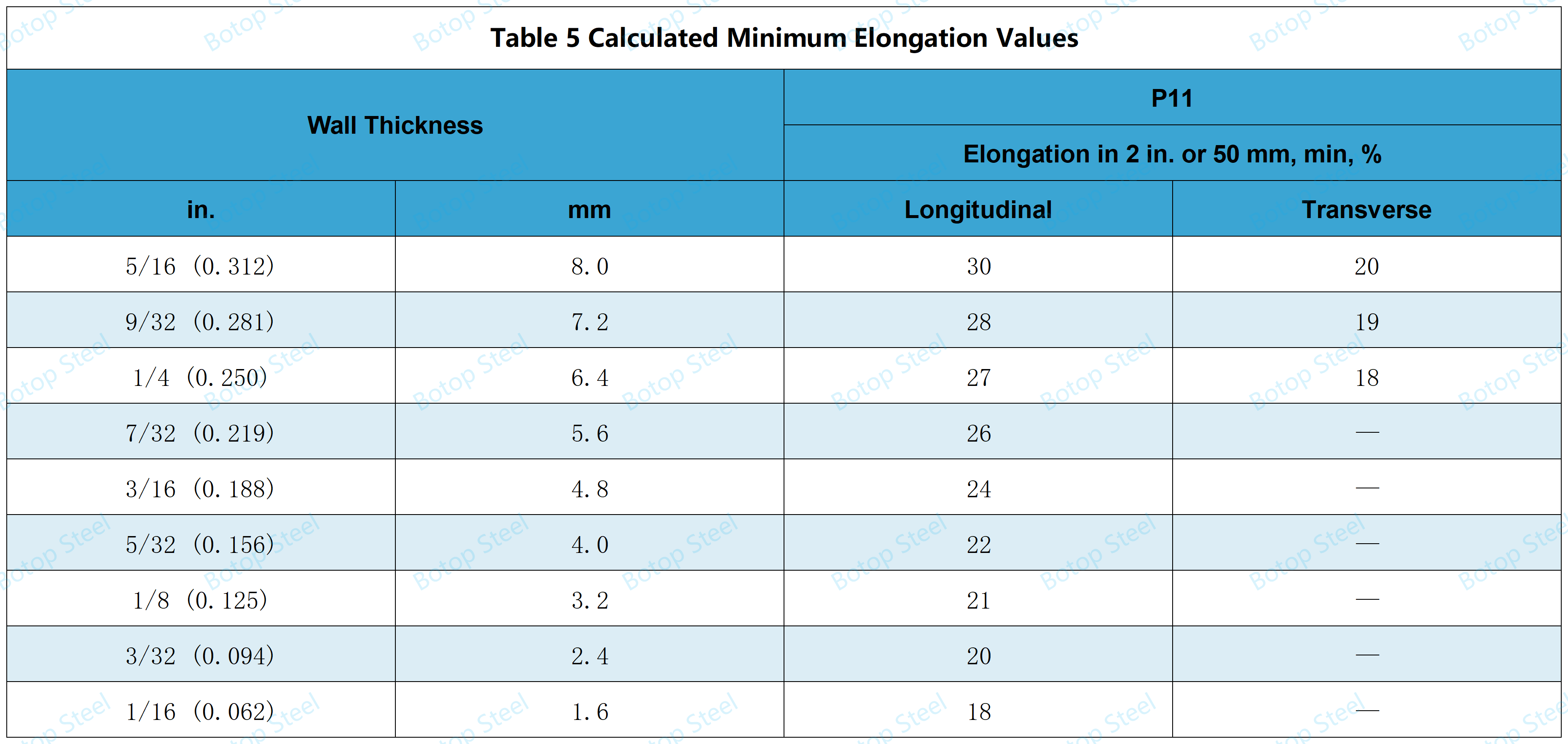

AIthebula 5 linikeza amanani aphansi abaliwe.

Lapho ubukhulu bodonga buphakathi kwamanani amabili angenhla, inani elincane lokwelulwa linqunywa yifomula elandelayo:

I-Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

I-Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

kuphi:

E = ukunwebeka ngamasentimitha angu-2 noma angu-50 mm, %,

t = ukujiya kwangempela kwamasampula, ngo. [mm].

2. Ubulukhuni

Ipayipi le-Grade P11 alidingi ukuhlolwa kobulukhuni.

Inani lokuqina elibhekiselwe linikezwe ngezansi.

Isimo esihlanganisiwe:

Ubulukhuni buvame ukuba phakathi kuka-150 no-200 HB.

Isimo esijwayelekile nesithambile:

Ukuqina kuhluka kusuka cishe ku-170 kuya ku-220 HB.

Isimo esiqinile nesithambile:

Ukuqina kungafinyelela ku-250 kuya ku-300 HB noma ngaphezulu, kuye ngokuthi izinga lokushisa linjani kanye nesikhathi.

3. Izinhlelo Zokuhlola Ongazikhethela

Izinto ezilandelayo zokuhlola azidingeki, uma kudingeka zinganqunywa ngokuxoxisana.

Ukuhlaziywa Komkhiqizo

Ukuhlolwa Kokuthamba

Ukuhlolwa Kokugoba

Ukuhlolwa Kwesakhiwo Sensimbi Nokuqopha

Ama-Photomicrograph

Ama-Photomicrographs Ezingcezu Ezithile

I-P11 hydrotest kufanele ihambisane nezimfuneko ezilandelayo.

Ububanzi bangaphandle >10in. [250mm] kanye nobukhulu bodonga ≤ 0.75in. [19mm]: lokhu kufanele kube ukuhlolwa kwe-hydrostatic.

Amanye amasayizi okuhlolwa kukagesi okungabhubhisi.

Izidingo ezilandelayo zokuhlolwa kwe-hydrostatic zihlanganiswe kusukela ezidingweni ze-ASTM A999:

Ngensimbi ye-ferritic alloy kanye namashubhu ensimbi engagqwali, udonga lucindezelwa okungenani ngaphansi60% wamandla okukhiqiza okungenani acacisiwe.

Umfutho wokuhlolwa kwamanzi kufanele ugcinwe okungenani 5sngaphandle kokuvuza noma ezinye iziphambeko.

Ukucindezela kwe-hydraulicingabalwa kusetshenziswa ifomula:

P = 2St/D

P= ingcindezi yokuhlola ye-hydrostatic ku-psi [MPa];

S = ukucindezeleka kodonga lwepayipi ku-psi noma ku-[MPa];

t = ubukhulu bodonga obucacisiwe, ubukhulu bodonga obujwayelekile ngokwenombolo yeshejuli ye-ANSI ecacisiwe noma izikhathi ezingu-1.143 ubukhulu bodonga obucacisiwe, ngo. [mm];

D = ububanzi obungaphandle obucacisiwe, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elicacisiwe, noma ububanzi obungaphandle obubalwe ngokungeza u-2t (njengoba kuchaziwe ngenhla) kububanzi obungaphakathi obucacisiwe, ngo. [mm].

Ipayipi ngalinye kufanele lihlolwe ngendlela yokuhlola engonakalisi ngokuhambisana nomkhubaE213, UkuzijwayezaI-E309, noma UkuzijwayezaE570.

Izinguquko Ezivumelekile Ngobubanzi

Ukuze ipayipi li-odweububanzi bangaphakathi, ububanzi bangaphakathi akufanele buhluke ngaphezu kuka-±1% kunobubanzi bangaphakathi obucacisiwe.

Izinguquko Ezivumelekile Ekujiyeni Kodonga

Ukulinganiswa kobukhulu bodonga kufanele kwenziwe kusetshenziswa ama-caliper omshini noma amadivayisi okuhlola angabhubhisi alinganiswe kahle anemba efanele. Uma kuba nempikiswano, ukulinganiswa okunqunywe kusetshenziswa ama-caliper omshini kuzosebenza.

Ubukhulu bodonga obuncane kanye nobubanzi bangaphandle bokuhlolwa ukuze kutholakale ukuthi kuyahambisana yini nale mfuneko yepayipi eli-odwe yi-NPS [DN] kanye nenombolo yeshejuli kuboniswe ku-I-ASME B36.10M.

Ngokuvamile kusetshenziswa kuma-boiler, ama-superheater, kanye nama-heat exchanger eziteshini zamandla kanye nezitshalo zamakhemikhali.

Amabhoyila: I-P11 isetshenziswa kabanzi ekwakhiweni kwama-boiler ngenxa yokumelana kwayo namazinga okushisa aphezulu kanye nokucindezela, ikakhulukazi ezingxenyeni ezibhekene namazinga okushisa aphezulu kanye nokucindezela.

I-Superheater: Isetshenziselwa ukwandisa izinga lokushisa lomusi ukuze kuthuthukiswe ukusebenza kahle kokushisa. I-p11 iqinisekisa ukuthi amandla nokuqina kwezinto kugcinwa ngisho noma amazinga okushisa aphezulu.

Izishintshi zokushisa: I-P11 ithuthukisa ukugqwala kanye nokumelana nokushisa okuphezulu kwama-heat exchanger, ngaleyo ndlela ithuthukisa ukuthembeka nokuphepha kwemishini.

Izinhlelo zokufaka amapayipi: Izinhlelo zamapayipi ezitshalweni zamakhemikhali zivame ukudinga ukuthutha uketshezi olushisa kakhulu noma umusi. Amandla okushisa aphezulu kanye nezakhiwo ezinhle zemishini ze-P11 kwenza kube kuhle kulezi zinhlelo zokusebenza.

a) I-ASTM A335 P11 ilingana nani?

GI-B/T 5310: 12CrMo;

I-DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

I-BS 3604: 10CrMo9-10;

I-JIS G3462: STPA23;

I-GOST 550-75: 12Kh1MF.

b)Ingabe i-P11 iyinsimbi engena-alloy ephansi?

Yebo, i-P11 iyinsimbi ethambile nethambile.

Insimbi e-alloy ephansi iyi-alloy yensimbi-ikhabhoni lapho kufakwe khona into eyodwa noma eziningi ezihlanganisayo (isb., i-chromium, i-molybdenum, i-nickel, njll.), kanye nokuqukethwe okuphelele kwento ehlanganisayo ngokuvamile kusuka ku-1 kuya ku-5%.

c)Iyini amandla okuthamba e-ASTM A335 P11?

Amandla amancane okuthambekela angu-415 MPa [60 ksi].

d)Iyini amandla okukhiqiza e-ASTM A335 P11?

Amandla amancane okuthambekela angu-205 MPa [30 ksi].

e) Uyini umkhawulo wokushisa we-ASTM A335 P11?

Ezindaweni ezifaka i-oxidation: Amazinga okushisa aphezulu kakhulu ngokuvamile angaba ngu-593°C (1100°F).

Ezindaweni ezingena-oxidizing: amazinga okushisa aphezulu kakhulu angaba ngu-650°C (1200°F) angafinyelelwa.

f)Ingabe i-A335 P11 inamandla kazibuthe?

Inamandla kazibuthe ekamelweni lokushisa. Lesi sici singaba usizo kwezinye izinhlelo zokusebenza, njengalapho kudingeka khona ukuthi izinto zihambisane nemishini yokuthola amandla kazibuthe.

g)Intengo ye-ASTM A335 P11 ingakanani?

Amanani ayahlukahluka kuye ngemakethe, xhumana nathi ukuze uthole isilinganiso esinembile.