I-ASTM A335 P91, obeye aziwe njengoI-ASME SA335 P91, iyipayipi lensimbi ye-ferritic alloy engenamthungo yesevisi yokushisa okuphezulu, i-UNS No. K91560.

Inenani eliphansiamandla okudonsa angu-585 MPa(85 ksi) kanye nokungenaniamandla okukhiqiza angu-415 MPa(60 ksi).

I-P91ikakhulukazi iqukethe izinto zokuhlanganisa ezifana ne-chromium ne-molybdenum, futhi kunezelwa ezinye izinto eziningi zokuhlanganisa, eziyingxenye ye-insimbi ene-alloy ephezulu, ngakho-ke inamandla amakhulu kanye nokumelana nokugqwala okuhle kakhulu.

Ngaphezu kwalokho, i-P91 itholakala ngezinhlobo ezimbili,Uhlobo 1futhiUhlobo 2, futhi ivame ukusetshenziswa ezitshalweni zikagesi, ezindaweni zokuhluza, ezindaweni zamakhemikhali imishini ebalulekile, kanye namapayipi ezindaweni ezinokushisa okuphezulu kanye nokucindezela okuphezulu.

Ipayipi lensimbi le-P91 lihlukaniswe ngezinhlobo ezimbili, Uhlobo 1 kanye noHlobo 2.

Zombili izinhlobo ziyafana ngokwezakhiwo zemishini kanye nezinye izidingo ezifana nokwelashwa kokushisa,ngomehluko omncane ekwakhiweni kwamakhemikhali kanye nokugxila kwesicelo esithile.

Ukwakheka kwamakhemikhaliUma kuqhathaniswa nohlobo 1, ukwakheka kwamakhemikhali kohlobo 2 kuqinile kakhulu futhi kuqukethe izinto eziningi zokuhlanganisa ukuze kuhlinzekwe ukumelana nokushisa nokugqwala okungcono.

Izicelo: Ngenxa yokwakheka kwamakhemikhali okwenziwe ngcono, Uhlobo 2 lufaneleka kakhulu emazingeni okushisa aphezulu kakhulu noma ezindaweni ezingcolisa kakhulu, noma ezisetshenziswayo lapho kudingeka khona amandla nokuqina okuphezulu.

Ipayipi lensimbi le-ASTM A335 kumele libengaphandle komthungo.

Inqubo yokukhiqiza engenamthungo ihlukaniswe ngezigabaisiphetho esishisayofuthikudonswe kubanda.

Ngezansi kunomdwebo wenqubo yokuqeda eshisayo.

Ikakhulukazi, i-P91, ipayipi lensimbi elinoketshezi oluningi, elivame ukusetshenziswa ezindaweni ezinzima ezingaphansi kwamazinga okushisa aphezulu kanye nokucindezeleka, ipayipi lensimbi elingenamthungo licindezelwe ngokulinganayo futhi lingenziwa libe nodonga olujiyile, ngaleyo ndlela kuqinisekiswe ukuphepha okuphezulu kanye nokusebenza kahle kwezindleko.

P91 Wonke amapayipi kumele aphathwe ngokushisa ukuze kuthuthukiswe isakhiwo sepayipi, kuthuthukiswe izakhiwo zalo zomshini, futhi kuthuthukiswe ukumelana nokushisa okuphezulu kanye nokucindezela.

| Ibanga | Uhlobo Lokwelapha Ukushisa | Ukulinganisa Izinga Lokushisa | Izinga Lokushisa Elilinganiselayo |

| Uhlobo lwe-P91 kanye nohlobo lwe-2 | ukwenza kube ngokwejwayelekile futhi kukhuthaze noma | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 ~ 1470 ℉ [730 - 800 ℃] |

| ukuthukuthela nokucindezeleka | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 - 1470 ℉ [730 - 800 ℃] |

Izingxenye Zamakhemikhali Zohlobo 1 lwe-P91

| Ibanga | Ukwakheka, % | ||||||

| Uhlobo 1 lwe-P91 | C | Mn | P | S | Si | Cr | Mo |

| 0.08 - 0.12 | 0.30 - 0.60 | Umkhawulo ongu-0.020 | Umkhawulo ongu-0.010 | 0.20 - 0.50 | 8.00 - 9.50 | 0.85 - 1.05 | |

| V | N | Ni | Al | Nb | Ti | Zr | |

| 0.18 - 0.25 | 0.030 - 0.070 | Ubuningi obungu-0.40 | Umkhawulo ongu-0.02 | 0.06 - 0.10 | Umkhawulo ongu-0.01 | Umkhawulo ongu-0.01 | |

Izingxenye Zamakhemikhali Zohlobo 2 ze-P91

| Ibanga | Ukwakheka, % | ||||||

| Izingxenye Zamakhemikhali Zomkhiqizo Wohlobo 2 lwe-P91 | C | Mn | P | S | Si | Cr | Mo |

| 0.07 - 0.13 | 0.30 - 0.50 | Umkhawulo ongu-0.020 | Umkhawulo ongu-0.005 | 0.20 - 0.40 | 8.00 - 9.50 | 0.80 - 1.05 | |

| V | Ni | Al | N | Isilinganiso se-N/Al | Nb | Ti | |

| 0.16 - 0.27 | Ubuningi obungu-0.20 | Umkhawulo ongu-0.02 | 0.035 - 0.070 | ≥ 4.0 | 0.05 - 0.11 | Umkhawulo ongu-0.01 | |

| Zr | Sn | Sb | As | B | W | Cu | |

| Umkhawulo ongu-0.01 | Umkhawulo ongu-0.01 | Umkhawulo ongu-0.003 | Umkhawulo ongu-0.01 | Umkhawulo ongu-0.001 | Umkhawulo ongu-0.05 | Ubuningi obungu-0.10 | |

Ngezithombe ezimbili ezingenhla, kulula ukubona umehluko phakathi kwezakhi zamakhemikhali zohlobo 1 nohlobo 2 kanye nemikhawulo.

1. Impahla Eqinile

Ukuhlolwa kokudonsa kuvame ukusetshenziselwa ukukalaamandla okukhiqiza, amandla okudonsa, futhiubuden yohlelo lokuhlola ipayipi lensimbi, futhi isetshenziswa kabanzi ezimpahleni zezinto zokuhlola.

| Uhlobo lwe-P91 kanye nohlobo lwe-2 | |||

| Amandla okudonsa | 85 ksi [585 MPa] min | ||

| Amandla okukhiqiza | 60 ksi [415 MPa] min | ||

| Ukwelulwa | Izidingo Zobude | I-Longitudinal | I-Transverse |

| Ukwelulwa okungu-2 in. noma 50 mm, (noma 4D), min, %; Ukwelulwa okuncane okuyisisekelo kodonga oluyi-6 in. [8 mm] nangaphezulu ngobukhulu, ukuhlolwa kwe-strip, kanye nabo bonke osayizi abancane abahlolwe esigabeni esigcwele | 20 | — | |

| Uma kusetshenziswa isampula ejwayelekile eyindilinga engu-2-intshi noma engu-50-mm ubude begeji noma usayizi omncane ngokulingana enobude begeji obulingana no-4D (ububanzi obuphindwe kane) | 20 | 13 | |

| Kuzivivinyo ze-strip, kufanele kukhishwe ukwehla ngakunye okungu-1/32 intshi. [0.8 mm] kobukhulu bodonga obungaphansi kuka-5/16 intshi. [8 mm] kusukela ekunwetshweni okuyisisekelo okuncane kwamaphuzu alandelayo amaphesenti. | 1 | — | |

2. Ubulukhuni

Izindlela ezahlukahlukene zokuhlola ubulukhuni zingasetshenziswa, okuhlanganisa iVickers, iBrinell, kanye neRockwell.

| Ibanga | UBrinell | AmaVickers | Rockwell |

| Uhlobo lwe-P91 kanye nohlobo lwe-2 | 190 - 250 HBW | 196 - 265 HV | 91 HRBW - 25HRC |

Ubukhulu bodonga <0.065 in. [1.7 mm]: Akukho ukuhlolwa kobulukhuni okudingekayo;

0.065 in. [1.7 mm] ≤ ubukhulu bodonga <0.200 in. [5.1 mm]: Kufanele kusetshenziswe isivivinyo sokuqina kweRockwell;

Ubukhulu bodonga ≥ 0.200 in. [5.1 mm]: ukusetshenziswa kokuhlolwa kobulukhuni beBrinell noma ukuhlolwa kobulukhuni beRockwell okungakhethwa.

Ukuhlolwa kobulukhuni be-Vickers kusebenza kuzo zonke izingqimba zodonga zamapayipi. Indlela yokuhlola yenziwa ngokuhambisana nezidingo ze-E92.

3. Ukuhlolwa Kokuthamba

Ukuhlolwa kufanele kwenziwe ngokuhambisana neSigaba 20 sendinganiso ye-ASTM A999.

4. Ukuhlolwa Kokugoba

Goba ngo-180° ekushiseni kwegumbi, akukho mifantu ezovela ngaphandle kwengxenye egobile.

Usayizi > NPS25 noma D/t ≥ 7.0: Ukuhlolwa kokugoba kufanele kwenziwe ngaphandle kokuhlolwa kokuthambekela.

5. Izinhlelo Zokuhlola Ongazikhethela ze-P91

Izinto ezilandelayo zokuhlola azidingeki, uma kudingeka zinganqunywa ngokuxoxisana.

S1: Ukuhlaziywa Komkhiqizo

S3: Ukuhlolwa Kokuthamba

S4: Ukuhlolwa Kwesakhiwo Sensimbi Nokuqopha

S5: Ama-Photomicrograph

S6: Ama-Photomicrograph Ezingxenye Ezizimele

S7: Ukwelashwa Kokushisa Okuhlukile-Ibanga le-P91 Uhlobo 1 kanye nohlobo 2

Ukuhlolwa kwe-P91 hydro kufanele kuhambisane nezidingo ezilandelayo.

Ububanzi bangaphandle >10in. [250mm] kanye nobukhulu bodonga ≤ 0.75in. [19mm]: lokhu kufanele kube ukuhlolwa kwe-hydrostatic.

Amanye amasayizi okuhlolwa kukagesi okungabhubhisi.

Ngensimbi ye-ferritic alloy kanye namashubhu ensimbi engagqwali, udonga lucindezelwa okungenani ngaphansi60% wamandla okukhiqiza okungenani acacisiwe.

Umfutho wokuhlolwa kwamanzi kufanele ugcinwe okungenani 5sngaphandle kokuvuza noma ezinye iziphambeko.

Ukucindezela kwe-hydraulicingabalwa kusetshenziswa ifomula:

P = 2St/D

P= ingcindezi yokuhlola ye-hydrostatic ku-psi [MPa];

S = ukucindezeleka kodonga lwepayipi ku-psi noma ku-[MPa];

t = ubukhulu bodonga obucacisiwe, ubukhulu bodonga obujwayelekile ngokwenombolo yeshejuli ye-ANSI ecacisiwe noma izikhathi ezingu-1.143 ubukhulu bodonga obucacisiwe, ngo. [mm];

D = ububanzi obungaphandle obucacisiwe, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elicacisiwe, noma ububanzi obungaphandle obubalwe ngokungeza u-2t (njengoba kuchaziwe ngenhla) kububanzi obungaphakathi obucacisiwe, ngo. [mm].

Ipayipi le-P91 lihlolwa ngendlela yokuhlola ye-E213. Izinga le-E213 liphathelene kakhulu nokuhlolwa kwe-ultrasonic (UT).

Uma kuchazwe ngokuqondile ku-oda, kungabuye kuhlolwe ngokwendlela yokuhlola ye-E309 noma ye-E570.

Izinga le-E309 livame ukubhekana nokuhlolwa kwe-electromagnetic (eddy current), kanti i-E570 iyindlela yokuhlola ehilela ama-array wamanje e-eddy.

Izinguquko Ezivumelekile Ngobubanzi

Ukuze ipayipi li-odweububanzi bangaphakathi, ububanzi bangaphakathi akufanele buhluke ngaphezu kuka-±1% kunobubanzi bangaphakathi obucacisiwe.

Izinguquko Ezivumelekile Ekujiyeni Kodonga

Ukulinganiswa kobukhulu bodonga kufanele kwenziwe kusetshenziswa ama-caliper omshini noma amadivayisi okuhlola angabhubhisi alinganiswe kahle anemba efanele. Uma kuba nempikiswano, ukulinganiswa okunqunywe kusetshenziswa ama-caliper omshini kuzosebenza.

Ubukhulu bodonga obuncane kanye nobubanzi bangaphandle bokuhlolwa ukuze kutholakale ukuthi kuyahambisana yini nale mfuneko yepayipi eli-odwe yi-NPS [DN] kanye nenombolo yeshejuli kuboniswe ku-I-ASME B36.10M.

Amaphutha

Ukungapheleli kobuso kubhekwa njengokukhubazeka uma kudlula u-12.5% wobukhulu bodonga obujwayelekile noma kudlula ubukhulu bodonga obuncane.

Ukungapheleli

Amamaki emishini, imihuzuko, kanye nemigodi, noma yikuphi ukungapheleli kwakho kujule ngaphezu kuka-1/16 in. [1.6 mm].

Amamaki kanye nokuhuzuka kuchazwa njengezimpawu zekhebula, ama-dinge, amamaki okuqondisa, amamaki okugoqa, imihuzuko yebhola, amamaki, amamaki okufa, nokunye okunjalo.

Ukulungisa

Amaphutha angasuswa ngokugaya, uma nje ubukhulu bodonga obusele bungaphansi kobukhulu bodonga obuncane.

Ukulungiswa kungenziwa nangokushisela kodwa kumele kuhambisane nezidingo ezifanele ze-A999.

Zonke izindwangu zokushisela zokulungisa ku-P91 kumele zenziwe ngenye yezinqubo zokushisela ezilandelayo kanye nezinto ezisetshenziswayo: i-SMAW, i-A5.5/A5.5M E90XX-B9:SAW, i-A5.23/A5.23M EB9 + i-neutral flux; i-GTAW, i-A5.28/A5.28M ER90S-B9; kanye ne-FCAW A5.29/A5.29M E91TI-B9. Ngaphezu kwalokho, inani lokuqukethwe kwe-Ni+Mn kwazo zonke izinto ezisetshenziswayo zokushisela ezisetshenziselwa ukulungisa i-P91 Type 1 kanye ne-Type 2 akumele lidlule u-1.0%.

Ipayipi le-P91 kufanele liphathwe ngokushisa ku-1350-1470 °F [730-800°C] ngemva kokulungiswa kokushiswa.

Ubuso bangaphandle bepayipi lensimbi elihloliwe kufanele buqukathe izinto ezilandelayo:

Igama lomenzi noma uphawu lokuhweba; inombolo ejwayelekile; ibanga; ubude kanye nophawu olwengeziwe "S".

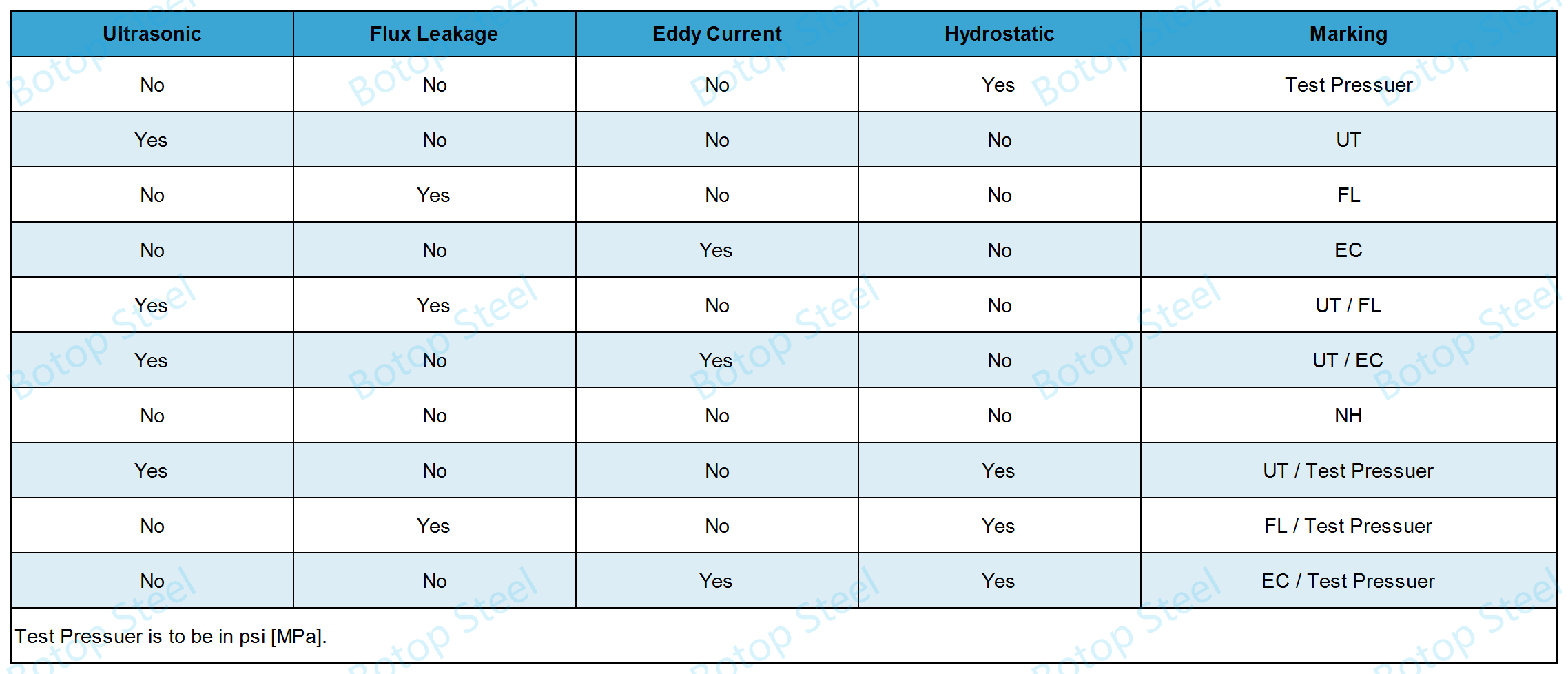

Izimpawu zokucindezela kwe-hydrostatic kanye nokuhlolwa okungabhubhisi kuthebula elingezansi nazo kufanele zifakwe.

Uma ipayipi lilungiswa ngokushisela, kufanele liphawulwe ngokuthi "WR".

k91 Uhlobo (Uhlobo 1 noma Uhlobo 2) kufanele luboniswe.

| I-ASME | I-ASTM | EN | GB |

| I-ASME SA335 P91 | I-ASTM A213 T91 | I-EN 10216-2 X10CrMoVNb9-1 | I-GB/T 5310 10Cr9Mo1VNbN |

Izintol: ipayipi lensimbi elingenamthungo le-ASTM A335 P91;

OD: 1/8"- 24";

WT: ngokuvumelana neI-ASME B36.10izidingo;

Ishejuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kanye ne-SCH160;

Ukuhlonza:I-STD (ejwayelekile), i-XS (eqinile kakhulu), noma i-XXS (eqinile kakhulu kabili);

Ukwenza ngokwezifiso: Osayizi bamapayipi abangewona ajwayelekile nabo bayatholakala, osayizi abenziwe ngokwezifiso bayatholakala uma becelwa;

Ubude: Ubude obuqondile nobungahleliwe;

Isitifiketi se-IBR: Singaxhumana nenhlangano yokuhlola evela eceleni ukuze sithole isitifiketi se-IBR ngokwezidingo zakho, izinhlangano zethu zokuhlola ngokubambisana yi-BV, SGS, TUV, njll.;

Ukuphela: Isiphelo sepayipi esiyisicaba, esigobile, noma esihlanganisiwe;

Ubuso: Ipayipi elilula, upende, kanye nokunye ukuvikela kwesikhashana, ukususwa nokupholisha ukugqwala, ukugqunywa nge-galvanized kanye nepulasitiki, kanye nokunye ukuvikela kwesikhathi eside;

Ukupakisha: Ikesi lokhuni, ibhande lensimbi noma ukupakisha ucingo lwensimbi, isivikelo sokuphela kwepayipi lepulasitiki noma lensimbi, njll.