I-ASTM A334Ibanga lesi-6iyipayipi lensimbi yekhabhoni elinamandla aphezulu, elinokushisa okuphansi elinokuqukethwe okuphezulu kwekhabhoni okungu-0.30%, okuqukethwe kwe-manganese okungu-0.29-1.06%, amandla okudonsa okungenani angu-415Mpa (60ksi), kanye namandla okukhiqiza angu-240Mp (35ksi).

Isetshenziswa kakhulu emkhakheni wezindawo zegesi yemvelo encibilikisiwe, ubunjiniyela be-polar, kanye nobuchwepheshe bokuqandisa, ukuzivumelanisa nezimo ezishisa kakhulu.

I-ASTM A334kuyincazelo ejwayelekile yamapayipi e-carbon kanye nensimbi ye-alloy angenamthungo futhi ahlanganisiwe ukuze kusetshenziswe i-cryogenic.

Kunezinhlobo eziningana zamazinga okuhlangabezana nezidingo ezahlukene.

Ibanga 1, Ibanga 3, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9, kanye neBanga 11.

Ibanga 1kanye neBanga lesi-6 zombili ziyipayipi lensimbi yekhabhoni.

Ipayipi lensimbi le-ASTM A334 lebanga lesi-6 lingakhiqizwa ngezinqubo ezingenamthungo noma ezihlanganisiwe.

Izinqubo zokushisela zifaka izindlela ezahlukene ezifanaukushisela ukumelana kagesi (ERW)futhiukushisela i-arc engaphansi komhlaba (i-SAW).

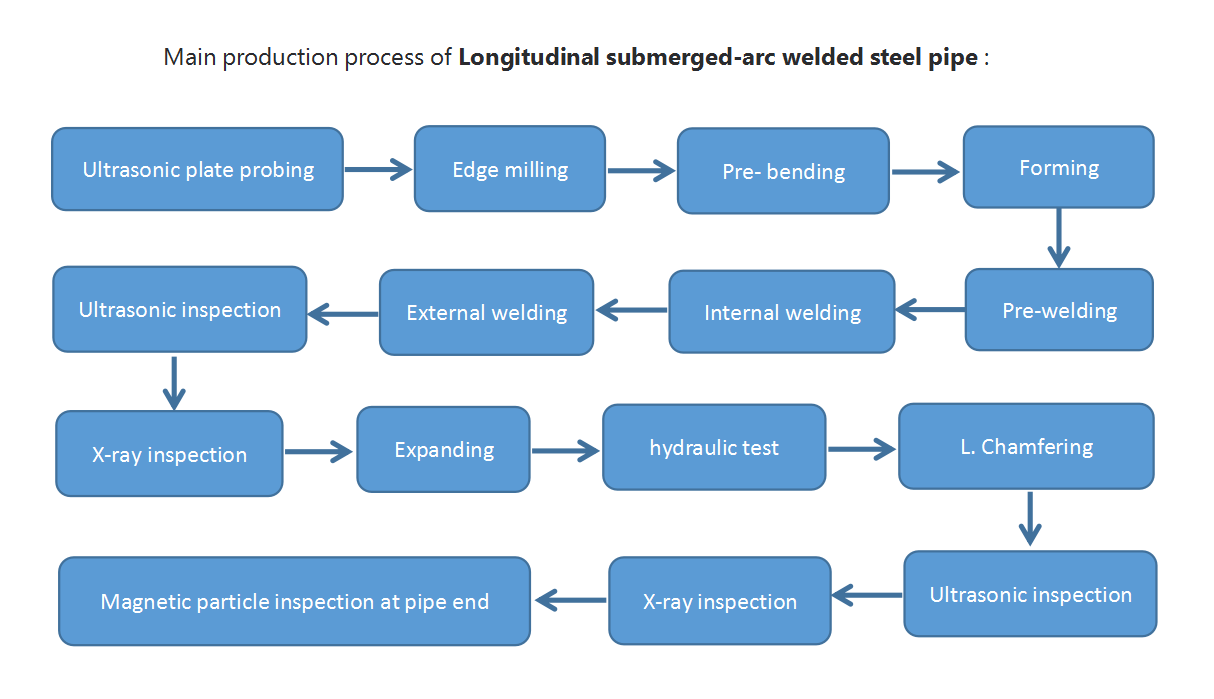

Ngezansi, inqubo yokukhiqiza yeUkushisela i-Arc Engaphansi Komphetho Ohlala Isikhathi Eside (LSAW).

Njengomkhiqizi wamashubhu ensimbi ahlanganisiwe, siyakwazi ukuhlangabezana nezidingo ezithile zamakhasimende ethu ahlukahlukene, sinikeza izinketho ezahlukene zomkhiqizo ukuqinisekisa ukusebenza okuhle kakhulu kanye nekhwalithi yazo zonke izinhlelo zokusebenza.

Ukushintshwa kwepayipi elilodwa le-LSAW kuthuthukisa kakhulu amandla alo lonke ipayipi, okuvumela ukuthi imelane nokucindezeleka okuphezulu.

Ngaphezu kwalokho, ifaneleka kahle ekukhiqizweni kwepayipi lensimbi elinobubanzi obukhulu nelinodonga oluqinile elihlangabezana nezidingo ze-ASTM A334 Grade 6 ezinhlelweni ezinkulu zokulethwa kwezimboni namandla, njengokwakhiwa kwezikhungo ezinkulu zegesi yemvelo encibilikisiwe (LNG).

Ngesikhathi esifanayo, ukulawulwa okunembile kobukhulu kuqinisekisa ububanzi bamapayipi obuhambisanayo kanye nobukhulu bodonga ukuze kuthuthukiswe ukuthembeka kokuxhumeka kanye nokuvimbela ukuvuza ezinhlelweni zamapayipi.

Yenza kube ngokwejwayelekile ngokushisa kufike ezingeni lokushisa elifanayo okungenani elingaphansi kuka-1550 °F [845 °C] bese uphola emoyeni noma ekamelweni lokupholisa lesithando esilawulwa umoya.

Uma kudingeka ukuhlungwa, kuzodingeka kuxoxiswane ngakho.

Ukwakheka kwamakhemikhali kwepayipi lensimbi le-ASTM A334 Grade 6 kuklanyelwe ukuqinisekisa izakhiwo ezinhle zemishini emazingeni okushisa aphansi kanye nokuqina okwanele kwenkonzo ethembekile ngaphansi kwezimo ezimbi kakhulu.

| Ibanga | C (Ikhabhoni) | Mn (I-Manganese) | P (I-phosphorus) | S (Isibabule) | Si (I-Silicon) |

| Ibanga lesi-6 | ubuningi obungu-0.30 | 0.29-1.06 | ubuningi obungu-0.025 | ubuningi obungu-0.025 | ubuncane 0.10 |

| Ngokunciphisa ngakunye kwe-carbon engu-0.01% ngaphansi kuka-0.30%, ukwanda kwe-manganese engu-0.05% ngaphezu kuka-1.06% kuzovunyelwa kufike ku-1.35% manganese. | |||||

Kwezinsimbi zeBanga loku-1 noma leBanga lesi-6, akuvunyelwe ukunikeza amazinga okuhlanganisa noma yiziphi izakhi ngaphandle kwalezo ezidingekayo ngokusobala. Kodwa-ke, kuvunyelwe ukwengeza izakhi ezidingekayo ukuze kususwe i-oxidation yensimbi.

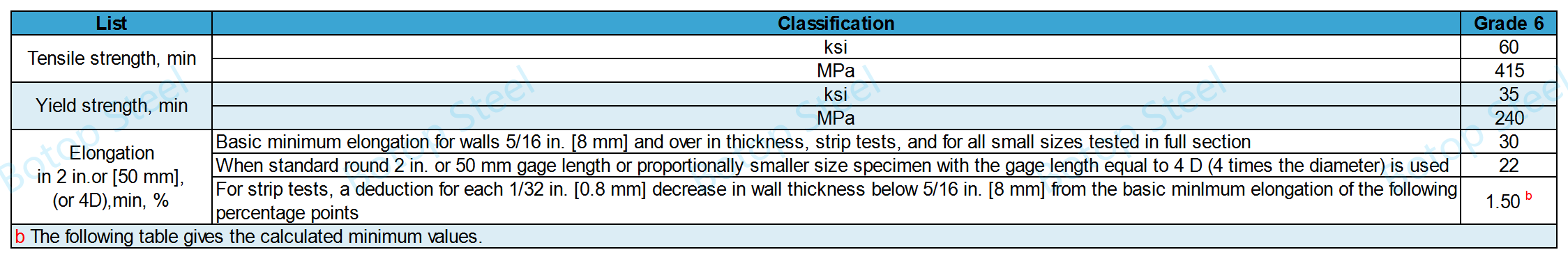

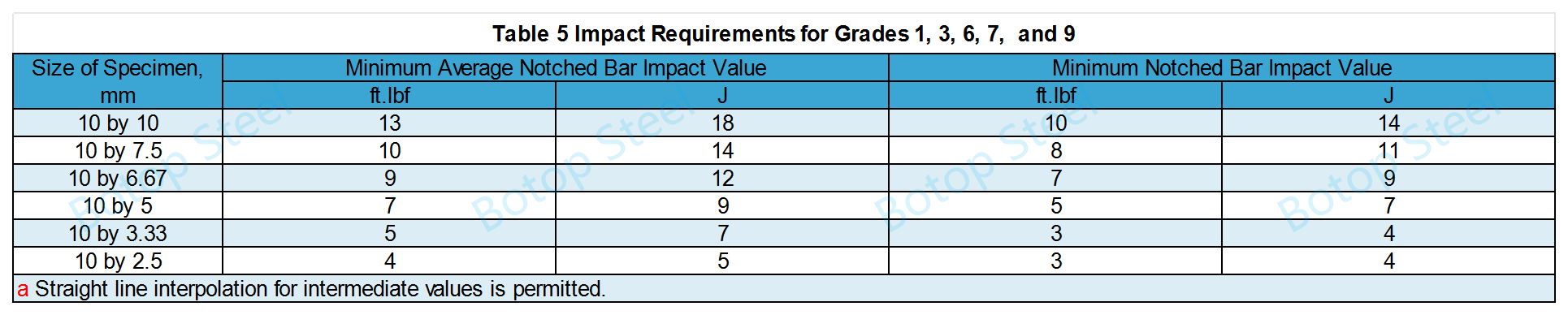

Ukuhlolwa komthelela epayipini lensimbi leBanga lesi-6 kwenziwa ku--45°C [-50°F] njengendlela yokuqinisekisa ukuqina kanye nokumelana komthelela kwezinto ezindaweni ezishisa kakhulu.

Ukuhlolwa kwenziwe ngokukhetha amandla okushaya afanele ngokusekelwe ekujikeni kodonga lwepayipi lensimbi.

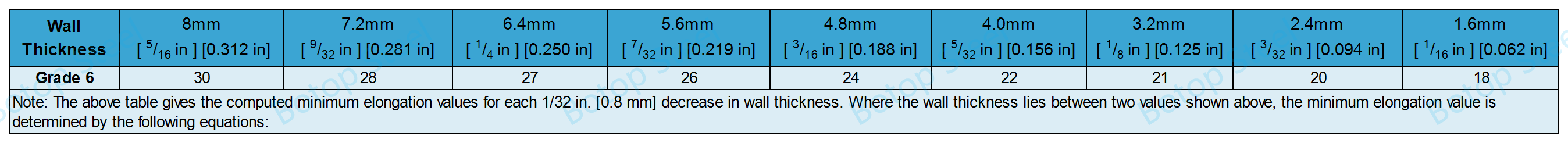

Amanani okuphakama okuncane okubaliwe kokwehla ngakunye okungu-1/32 in.[0.80 mm] kobukhulu bodonga.

| Ibanga | Rockwell | UBrinell |

| I-ASTM A334 Ibanga 6 | B 90 | 190 |

Ipayipi ngalinye kufanele lihlolwe ngaphandle kokubhujiswa ngogesi noma ngamanzi ngokuhambisana ne-Special A1016/A1016M.

Ngaphandle kokuthi kuchazwe ngenye indlela ku-oda lokuthenga, uhlobo lokuhlolwa oluzosetshenziswa luzokhethwa ngumenzi.

Ukuhlolwa Kokuthamba

Ukuhlolwa Kokuvutha (Amashubhu Angenamthungo)

Ukuhlolwa kweFlange (Amashubhu Ahlanganisiwe)

Ukuhlolwa Kokugoba Okuphambene

1. Izindawo zegesi yemvelo encibilikisiwe (LNG)Ngenxa yezakhiwo zayo ezinhle kakhulu zokushisa okuphansi, ipayipi lensimbi leBanga lesi-6 lisetshenziswa kabanzi ezindaweni zokukhiqiza, zokugcina kanye nezokuthutha i-LNG. Lezi zindawo zidinga izinto ezigcina amandla aphezulu kanye nokuqina okuhle emazingeni okushisa aphansi kakhulu.

2. Izinhlelo zokuthutha uwoyela negesi: esetshenziselwa ukuthutha ama-hydrocarbon aketshezi noma agesi, njengegesi kaphethiloli encibilikisiwe (i-LPG) kanye nolunye uketshezi oluphansi lokushisa endaweni enokushisa okuphansi.

3. Ubuchwepheshe befriji kanye nezindawo zokugcina izinto ezibandayoLokhu kusebenza nakwezinye izindawo zobuchwepheshe bokuqandisa, njengezinhlelo zokugcina ukudla nokubanda ekucubunguleni ukudla kanye nezinye izinqubo zamakhemikhali ezidinga ukusebenza ngezinga lokushisa eliphansi.

4. Ubunjiniyela be-polar: Emaphrojekthini obunjiniyela ezindaweni ezibandayo, njengeziteshi zocwaningo lwesayensi e-Arctic noma e-Antarctica, asetshenziselwa ukwakha izinhlelo zokuhambisa ezizinzile nezithembekile kanye nezakhiwo okumele zikwazi ukumelana namazinga okushisa abandayo kakhulu kanye nezimo zemvelo ezinzima.

5. Izinhlelo zokupholisa umoya kanye nezishintshi zokushisa: Isetshenziswa kakhulu ezinhlelweni ezinkulu zokupholisa umoya kanye nezishintshi zokushisa, okudingeka zisebenze kahle emazingeni okushisa aphansi ukuqinisekisa ukusebenza kahle nokuphepha kohlelo.

6. Ubunjiniyela bamandla kanye neziteshi zamandla: Kumaphrojekthi obunjiniyela bamandla akhethekile, njengezinhlobo ezithile zeziteshi zamandla, amashubhu ensimbi ebanga lesi-6 angasetshenziswa ukuphatha uketshezi noma amagesi emazingeni okushisa aphansi ukuqinisekisa ukusebenza okuphephile nokuphumelelayo kohlelo.

I-EN 10216-4:P265NL: Isetshenziswa kakhulu emithanjeni yokucindezela kwe-cryogenic kanye nezinhlelo zamapayipi e-cryogenic, inokuqina okuhle kanye namandla futhi ifanele ukusetshenziswa ezindaweni ze-cryogenic.

I-DIN 17173:TTSt41N: Yakhelwe ukusetshenziswa kwezinga lokushisa eliphansi, inikeza ukusebenza okuhle kakhulu kwezinga lokushisa eliphansi futhi ivame ukusetshenziswa emishinini nasemapayipini adinga izindawo zokusebenza ezinokushisa okuphansi kakhulu.

I-JIS G3460:STPL46: Isetshenziselwa izinhlelo zokuthutha amapayipi ezindaweni ezinokushisa okuphansi, ezikwazi ukumelana nemiphumela ethile yokushisa okuphansi kanye nezingcindezi.

GB/T 18984:09Mn2V: Le nto ikhethekile ekukhiqizweni kwamashubhu ensimbi angenamthungo ukuze asetshenziswe ezindaweni ezinokushisa okuphansi, anokuqina okuhle kokushisa okuphansi kanye nokumelana nokuqhekeka.

Uma ukhetha lezi zinto ezilinganayo, kubalulekile ukuqinisekisa ukuthi ukwakheka kwamakhemikhali azo kanye nezakhiwo zemishini kuhlangabezana nezindinganiso zokusetshenziswa ezidingekayo kanye nezidingo zokusebenza.

Lezi zinhlaka kufanele ziqhathaniswe ngokuningiliziwe futhi kungadingeka izinqubo ezengeziwe zokuhlola kanye neziqinisekiso ukuqinisekisa ukufaneleka nokusebenza kwezinto.

Selokhu yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili we-ipayipi lensimbi yekhabhonieNyakatho yeShayina, eyaziwa ngesevisi enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele. Le nkampani inikeza izinhlobo ezahlukene zamapayipi ensimbi yekhabhoni kanye nemikhiqizo ehlobene nayo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.