I-ASTM A252ipayipi lensimbi liyinqwaba yepayipi eliyindilinga elivamile elimboza izinhlobo ezihlanganisiwe nezingenamthungo zezinqwaba zamapayipi ensimbi lapho isilinda sensimbi sisetshenziswa njengelungu elihlala njalo lokuthwala umthwalo noma njengegobolondo ukwakha inqwaba yekhonkrithi efakwe endaweni.

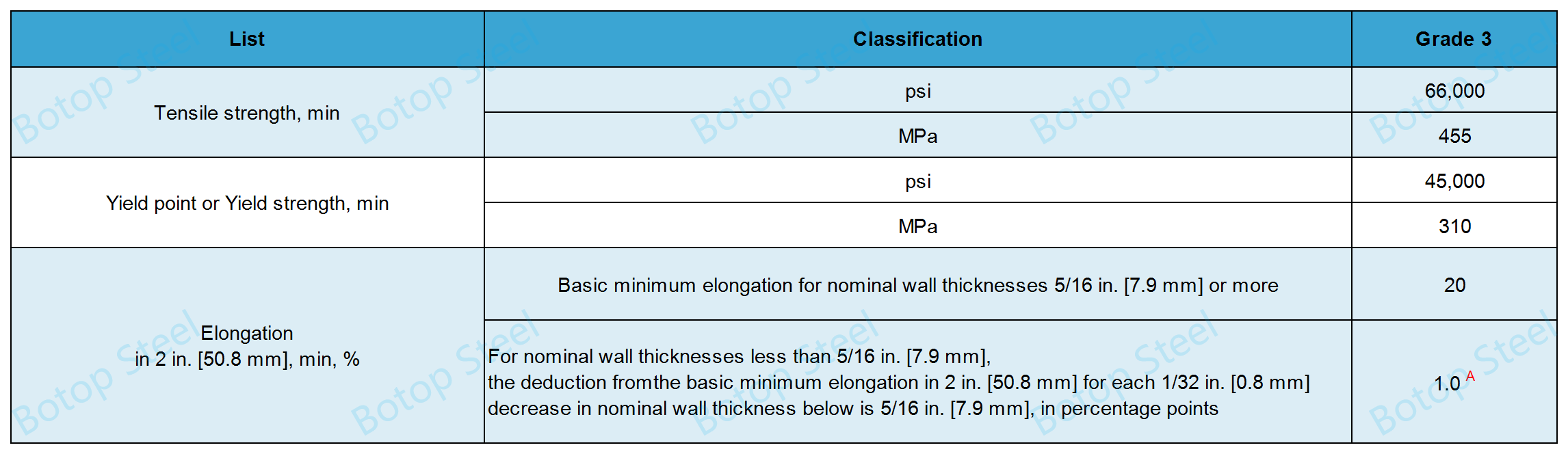

Ibanga lesi-3izinga lokusebenza eliphakeme kakhulu phakathi kwamabanga amathathu e-A252, okungenaniamandla okukhiqiza angu-310MPa [45,000 psi]kanye nokungenaniamandla okuthamba angu-455MPa [66,000 psi]Uma kuqhathaniswa namanye amabanga, iBanga lesi-3 lifaneleka kakhulu ezakhiweni ezithwala imithwalo esindayo noma ezindaweni ezidinga kakhulu, futhi livame ukusetshenziswa ekwakhiweni kwezisekelo zamabhuloho amakhulu, izakhiwo eziphakeme, noma amapulatifomu asogwini lolwandle.

I-A252 ihlukaniswe ngamagremu amathathu ukuze ibhekane nezimo ezahlukene zokusetshenziswa.

Ibanga 1,Ibanga lesi-2, futhiIbanga lesi-3.

Ukwanda kancane kancane kwezakhiwo zemishini.

Ibanga 1isetshenziswa kakhulu ezisetshenziswayo lapho ikhwalithi yenhlabathi ilungile futhi izidingo zokuthwala imithwalo zingekho phezulu kakhulu. Izibonelo zifaka phakathi izisekelo zesakhiwo ezilula zezakhiwo zokuhlala noma zezentengiselwano, noma amabhuloho amancane angadingi imithwalo emikhulu.

Ibanga lesi-2ifanele ukusetshenziswa kwezimo zenhlabathi ezimbi noma izidingo eziphezulu zokuthwala imithwalo. Isibonelo, amabhuloho alayishwe ngokulinganisela, izakhiwo ezinkulu zezentengiselwano, noma ingqalasizinda yezindawo zomphakathi. Ingasetshenziswa nasezindaweni ezinamanzi amaningi, njengemifula namachibi, lapho kudingeka khona ukumelana okunamandla kokuguquguquka.

Ibanga lesi-3isetshenziselwa izidingo zomsebenzi osindayo ezimweni ezimbi kakhulu, njengamabhuloho amakhulu, izisekelo zemishini esindayo, noma umsebenzi wesisekelo ojulile wezakhiwo eziphakeme. Ngaphezu kwalokho, ezimweni ezikhethekile ze-geological, njengenhlabathi ethambile kakhulu noma engazinzile, iBanga lesi-3 linikeza amandla aphezulu okuthwala umthwalo kanye nokuqina.

Yasungulwa ngo-2014,Insimbi yeBotopingumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngokukhiqiza amapayipi ensimbi ashiselwe futhi angenamthungo asezingeni eliphezulu.

Yonke imikhiqizo yethu ihlangabezana nezindinganiso eziqinile ze-ASTM A252, okuqinisekisa ukusebenza kahle ngaphansi kwezimo ezimbi kakhulu.

Siphinde sinikeze uhla oluphelele lwezihlanganisi nama-flange ukuhlangabezana nezidingo zemiklamo eyahlukahlukene yamapayipi.

Uma ukhetha i-Botop Steel, ukhetha ubuhle nokuthembeka.

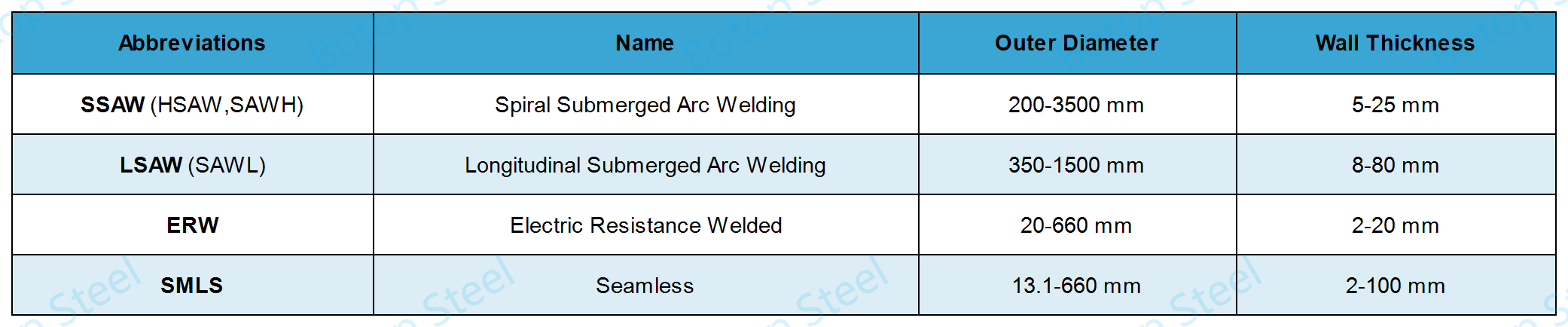

Amapayipi e-ASTM A252 Pipe Pipe angahlukaniswa ngezigaba ezimbili eziyinhloko zokukhiqiza:ingenamthungo futhi ihlanganisiwe.

Enqubweni yokushisela, ingahlukaniswa kabanzi ibeI-ERW, I-EFW, futhiI-SAW.

I-SAW ingahlukaniswa ngezigabaI-LSAW(SAWL) kanyeI-SSAW(HSAW) kuye ngokuthi iphi i-weld iqondiswa kuphi.

Ngenxa yokuthi ama-SAW avame ukushintshwa kusetshenziswa indlela yokushiswa kwe-arc engaphansi kwezinhlangothi ezimbili, avame ukubizwa ngokuthiI-DSAW.

Lezi zindlela ezahlukene zokukhiqiza zivumela ipayipi lenqwaba ye-ASTM A252 ukuthi lihlangabezane nezidingo eziningi zobunjiniyela.

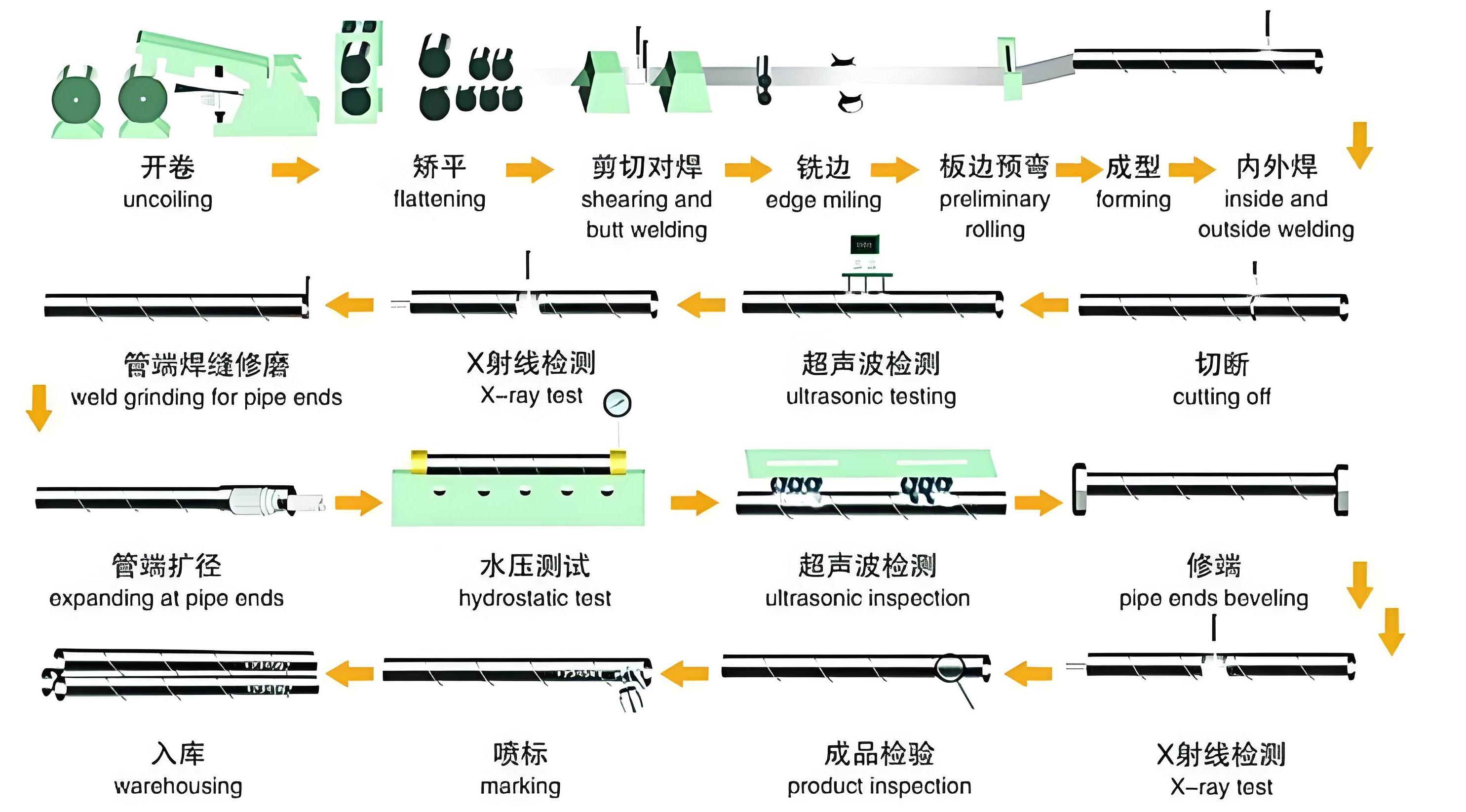

Okulandelayo ishadi lokugeleza kokukhiqiza kwepayipi lensimbi elijikelezayo (i-SSAW):

Ipayipi lensimbi le-SSAWilungele ukwenziwa kwepayipi lensimbi elinobubanzi obukhulu futhi ingakhiqizwa ngobubanzi obufika ku-3,500mm. Ayikwazi nje kuphela ukukhiqizwa ngobude obude kakhulu, ilungele izakhiwo ezinkulu, kodwa ipayipi lensimbi le-SSAW nalo lishibhile uma liqhathaniswa nepayipi lensimbi le-LSAW ne-SMLS.

I-Botop Steel inganikeza izinhlobo ezilandelayo zosayizi wamashubhu ensimbi:

Okuqukethwe kwe-phosphorus akufanele kudlule u-0.050%.

Izidingo zokwakheka kwamakhemikhali ze-ASTM A252 zilula kakhulu uma kuqhathaniswa nezinye izindinganiso zamapayipi kwezinye izinhlelo zokusebenza ngoba lapho ipayipi lisetshenziswa njengenqwaba yamapayipi, ngokuyinhloko liyisakhiwo. Kwanele ukuthi ipayipi lensimbi likwazi ukumelana nemithwalo edingekayo kanye nezimo zemvelo. Le khemistri elula isiza ukuthuthukisa izindleko kanye nokukhiqiza ngenkathi ihlangabezana nezidingo eziyisisekelo zokuphepha kwesakhiwo kanye nokuqina.

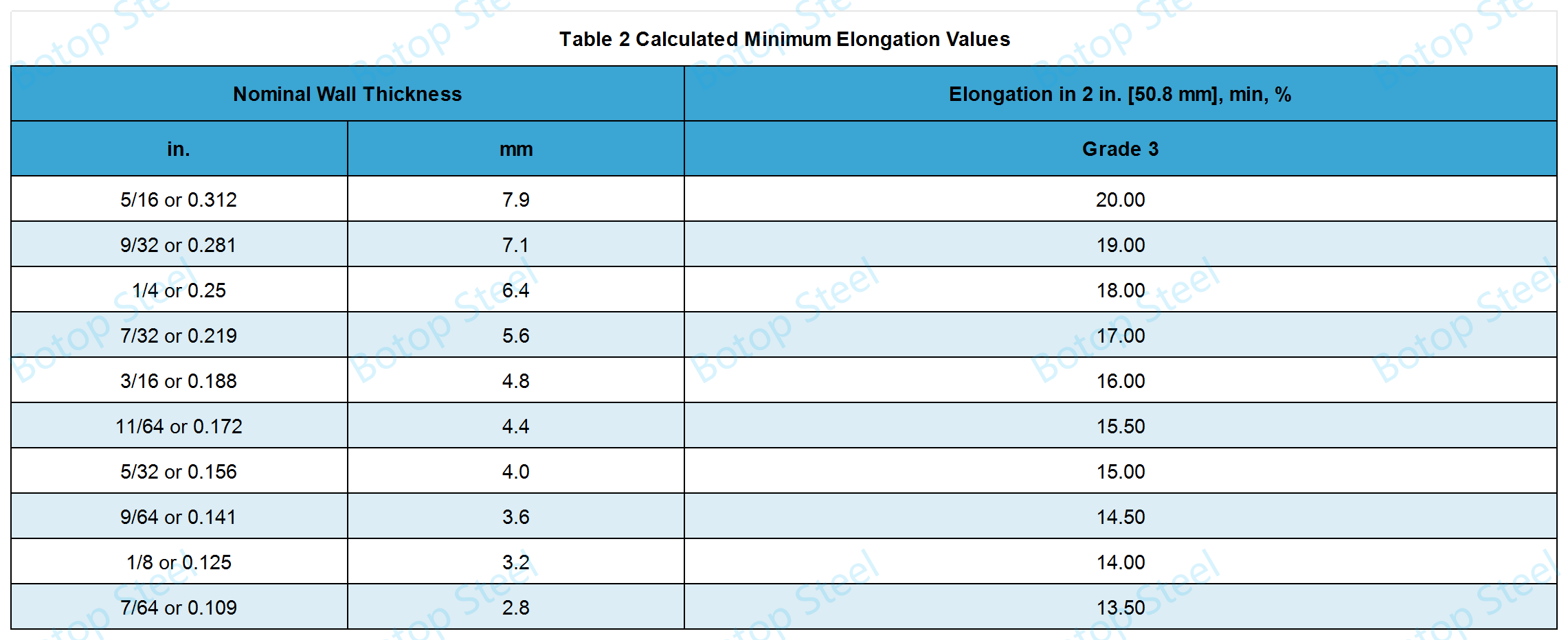

AIthebula 2 linikeza amanani aphansi abaliwe:

Lapho ubukhulu bodonga obucacisiwe buphakathi kwalabo ababoniswe ngenhla, inani elincane lokwelulwa lizonqunywa kanje:

Ibanga lesi-3: E = 32t + 10.00 [E = 1.25t + 10.00]

E: ukunwebeka ngamasentimitha angu-2. [50.8 mm], %;

t: ubukhulu bodonga obuqokiwe, ngo. [mm].

Ngosayizi wenqwaba yamapayipi ongabhalwanga eshadini lesisindo samapayipi, isisindo ngobude beyunithi ngayinye kufanele sibalwe kanje:

W = 10.69(D - t)t [W = 0.0246615(D - t)t ]

W = isisindo ngobude beyunithi ngayinye, lb/ft [kg/m].

D = ububanzi obungaphandle obucacisiwe, ngo. [mm],

t = ubukhulu bodonga obuqokiwe, ngo. [mm].

Inkampani yethu inikeza izinhlobo eziningi zokumboza okuhlanganisa upende, i-varnish, i-galvanized, i-epoxy ecebile nge-zinc, i-3LPE, i-epoxy ye-coal tar, njll. ukuze kuhlangatshezwane nezidingo zamaphrojekthi ahlukahlukene nokuqinisekisa ukuqina kwesikhathi eside.

Uma uthenga i-A252 Pipe Pile Tubing, ulwazi olulandelayo kufanele lunikezwe ukuze kube lula ikhono lomhlinzeki lokuhlangabezana nezidingo zakho ezithile ngokunembile nokunciphisa izinguquko ezilandelayo kanye nokubambezeleka okungenzeka.

1 Inani (izinyawo noma inani lobude),

2 Igama lezinto (izinqwaba zamapayipi ensimbi),

Izindlela ezi-3 zokukhiqiza (ezingenamthungo noma ezihlanganisiwe),

Ibanga lesi-4 (1, 2, noma 3),

Usayizi 5 (ububanzi obungaphandle kanye nobukhulu bodonga obujwayelekile),

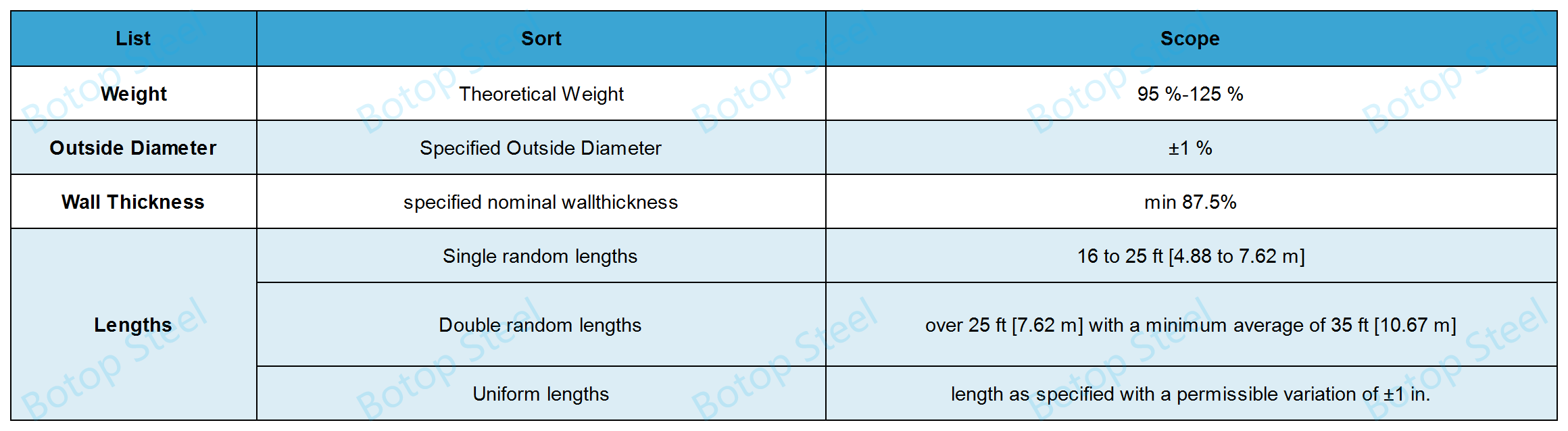

Ubude obuyi-6 (okungahleliwe okukodwa, okungahleliwe okuphindwe kabili, noma okulinganayo),

7 Ukuqeda kokuphela,

8 Ukuqokwa kwemininingwane ye-ASTM kanye nonyaka wokukhishwa.