I-ASTM A178amashubhu ensimbi angamashubhu e-ERW aqinile okumelana nogesiinsimbi yekhabhoni nekhabhoni-manganeseisetshenziswa njengamapayipi e-boiler, amapayipi e-boiler, amapayipi e-superheater, kanye nezindawo zokuphepha.

Ifanele amashubhu ensimbi anobubanzi bangaphandle obungu-12.7-127mm kanye nobukhulu bodonga obuphakathi kuka-0.9-9.1mm.

Amashubhu e-ASTM A178 afaneleka kumashubhu ahlanganisiwe anokumelanaububanzi bangaphandle obuphakathi kuka-1/2 - 5 in [12.7 - 127 mm] kanye nobukhulu bodonga obuphakathi kuka-0.035 - 0.360 in [0.9 - 9.1 mm], yize amanye amasayizi etholakala njengoba kudingeka, uma nje la mashubhu ehlangabezana nazo zonke ezinye izidingo zale ncazelo.

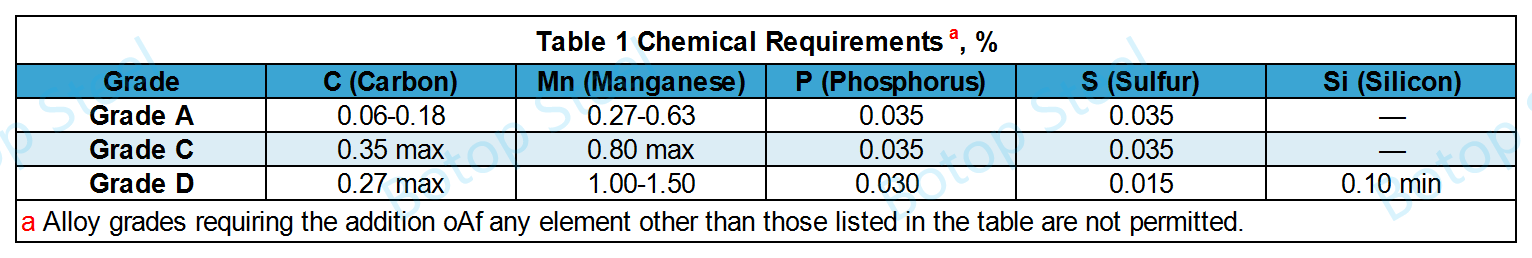

Kunezinhlobo ezintathu zokubhekana nezimo ezahlukene zokusetshenziswa.

Ibanga A, Ibanga C, kanye nebanga D.

| Ibanga | Uhlobo Lwensimbi Yekhabhoni |

| Ibanga A | Insimbi Enekhabhoni Ephansi |

| Ibanga C | Insimbi Ephakathi Nekhabhoni |

| Ibanga D | Insimbi ye-Carbon-Manganese |

Izinto ezinikezwe ngaphansi kwale ncazelo kufanele zihambisane nezidingo ezisebenzayo zohlelo lwamanje lwe-Specification A450/A450M. ngaphandle uma kunikezwe ngenye indlela lapha.

Ibanga AfuthiIbanga Cungasho insimbi ethile; khetha izinto zokusetshenziswa ezifanele njengoba kudingeka.

Insimbi yeIbanga Duzobulawa.

Insimbi ebulewe ikhiqizwa ngokufaka ama-deoxidizer (isb., i-silicon, i-aluminium, i-manganese, njll.) ensimbini encibilikisiwe ngesikhathi senqubo yokukhiqizwa kwensimbi, ngaleyo ndlela kunciphisa noma kuqede okuqukethwe yi-oxygen ensimbini.

Lokhu kwelashwa kuthuthukisa ukulingana kanye nokuqina kwensimbi, kuthuthukisa izakhiwo zayo zemishini, futhi kuthuthukisa ukumelana nokugqwala.

Ngakho-ke izinsimbi ezibulewe zisetshenziswa kabanzi ezisetshenziswa lapho kudingeka khona izinga eliphezulu lokufana kanye nezakhiwo ezinhle kakhulu zemishini, njengokwenziwa kwemikhumbi yokucindezela, ama-boiler, kanye nezingxenye ezinkulu zesakhiwo.

Amapayipi ensimbi akhiqizwa kusetshenziswaI-ERWinqubo yokukhiqiza.

I-ERW (Ukumelana Nogesi Okuhlanganisiwe)inqubo efaneleka kakhulu ekukhiqizeni ipayipi lensimbi yekhabhoni.

Ngenxa yezinzuzo zamandla aphezulu okushisela, izindawo zangaphakathi nezangaphandle ezibushelelezi, isivinini sokukhiqiza esisheshayo, kanye nentengo ephansi, isetshenziswa kabanzi emikhakheni eminingi yezimboni nezokwakha.

I-ASTM A178ipayipi lensimbikumele iphathwe ngokushisangesikhathi senqubo yokukhiqiza. Isetshenziselwa ukuthuthukisa izakhiwo zemishini kanye nokuqina kwesakhiwo sepayipi, kanye nokuqeda ukucindezeleka okungenzeka ukuthi kwethulwe ngesikhathi senqubo yokushisela.

Ngemva kokushisela, wonke amapayipi kufanele aphathwe ngokushisa ekushiseni okungu-1650°F [900°C] noma ngaphezulu bese kulandelwa ukupholisa emoyeni noma ekamelweni lokupholisa lesithando somoya esilawulwayo.

Amapayipi adonswa ngokubandayokufanele iphathwe ngokushisa ngemva kokudlula kokugcina kokubanda ekushiseni okungu-1200°F [650°C] noma ngaphezulu.

Uma kwenziwa ukuhlaziywa komkhiqizo, imvamisa yokuhlolwa inqunywa kanje.

| Ukuhlukaniswa | Imvamisa Yokuhlola |

| Ububanzi bangaphandle ≤ 3in [76.2mm] | 250 ama-pcs/isikhathi |

| Ububanzi bangaphandle > 3in [76.2mm] | 100 ama-pcs/isikhathi |

| Hlukanisa ngenombolo yokushisa kwepayipi | Inombolo ngayinye yokushisa |

Izidingo zesakhiwo semishini azisebenzi kumapayipi amancane kuno-1/8 intshi [3.2 mm] ububanzi bangaphakathi noma ubukhulu obungu-0.015 intshi [0.4 mm].

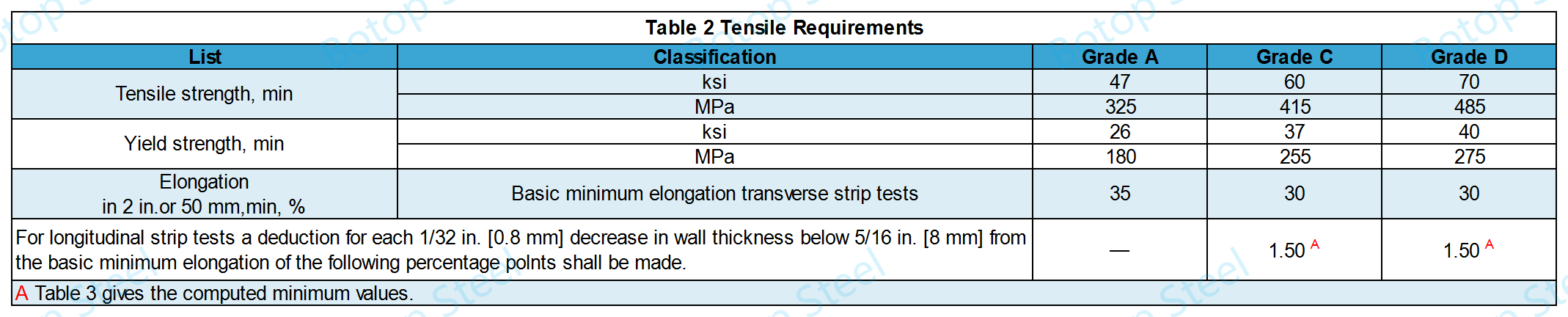

1. Impahla Eqinile

KumaKlasi C no-D, ukuhlolwa kokudonswa kufanele kwenziwe kumashubhu amabili ku-lot ngayinye.

Kumapayipi eBanga A, ukuhlolwa kokuthamba akudingeki ngokuvamile. Lokhu kungenxa yokuthi amapayipi eBanga A asetshenziswa kakhulu ekusetshenzisweni komfutho ophansi kanye nokushisa okuphansi.

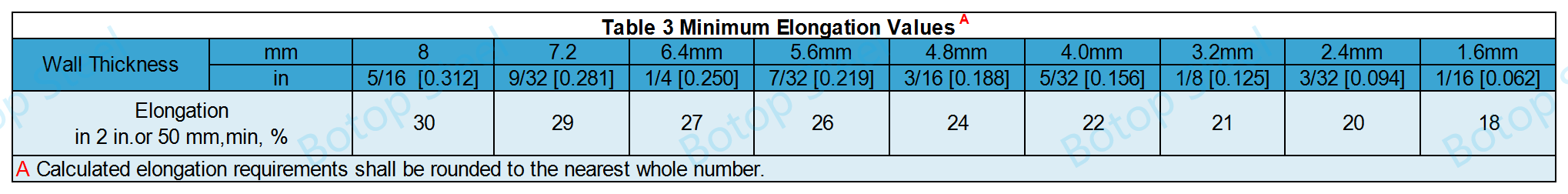

Ithebula 3 linikeza amanani okunwebeka okungenani okubaliwe kokwehla ngakunye okungu-1/32 intshi. [0.8 mm] kobukhulu bodonga.

Uma ubukhulu bodonga lwepayipi lensimbi bungebona obunye balobu bukhulu bodonga, bungabalwa futhi ngefomula.

Amayunithi E-intshi: E = 48t + 15.00nomaAmayunithi e-ISI: E = 1.87t + 15.00

E = ukunwebeka ngamasentimitha angu-2 noma angu-50 mm, %,

t= ubukhulu bangempela besampula, ngo. [mm].

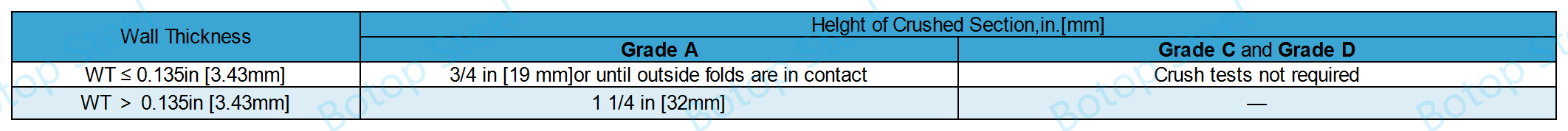

2. Ukuhlolwa Kokuchoboza

Ukuhlolwa kokukhipha kwenziwa ezingxenyeni zamapayipi ezingama-intshi angu-63 ubude okumele zimelane nokukhipha okude ngaphandle kokuqhekeka, ukuqhekeka, noma ukuqhekeka kuma-weld.

Ngokufaka ipayipi elingaphansi kwe-1 intshi [25.4 mm] ububanzi bangaphandle, ubude besampula kufanele bube izikhathi eziphindwe kabili kune-diameter yangaphandle yepayipi. Ukuhlolwa okuncane kobuso ngeke kube yimbangela yokwenqatshwa.

3. Ukuhlolwa Kokuthamba

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450 Isigaba 19.

4. Ukuhlolwa kweFlange

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450 Isigaba 22.

5. Ukuhlolwa Kokugoba Okubuyela Emuva

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450, Isigaba 20.

Ukuhlolwa kukagesi okubangelwa amanzi noma okungabhubhisi kwenziwa epayipini ngalinye lensimbi.

Izimfuneko zihambisana ne-ASTM A450, Isigaba 24 noma 26.

Idatha elandelayo ithathwe ku-ASTM A450 futhi ihlangabezana nezidingo ezifanele zamapayipi ensimbi ahlanganisiwe kuphela.

Ukuphambuka Kwesisindo

0 - +10%.

Ukuphambuka Kokujiya Kodonga

0 - +18%.

Ukuphambuka Kobubanzi Bangaphandle

| Ububanzi Bangaphandle | Izinguquko Ezivumelekile | ||

| in | mm | in | mm |

| I-OD ≤1 | I-OD≤ 25.4 | ±0.004 | ±0.1 |

| 1 OD ≤1½ | 25.4<OD ≤38.4 | ±0.006 | ±0.15 |

| 1½ OD 2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD<2½ | 50.8≤ OD <63.5 | ±0.010 | ±0.25 |

| 2½≤ OD<3 | 63.5≤ OD <76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Ngemva kokufakwa kubhoyila, ithubhu kufanele ikwazi ukumelana nokunwebeka nokugoba ngaphandle kokuphazamiseka noma ukuqhekeka kuma-weld.

Amapayipi e-superheater azokwazi ukumelana nayo yonke imisebenzi yokubopha, ukushisela, kanye nokugoba edingekayo ngaphandle kweziphambeko.

Isetshenziswa kakhulu kumapayipi e-boiler, amapayipi e-boiler, amapayipi e-superheater, kanye nama-safe end.

I-ASTM A178 Ibanga AUkuqukethwe kwe-tubing okuphansi kwekhabhoni kuyinika ukushibilika okuhle kanye nokuqina okuphezulu kwezicelo ezingacindezelwa kakhulu.

Isetshenziswa kakhulu ekusetshenzisweni okunomfutho ophansi kanye nokushisa okuphakathi njengama-boiler aphansi (isb., ama-boiler asekhaya, isakhiwo samahhovisi amancane, noma ama-boiler asefektri) kanye nezinye izinto zokushintshanisa ukushisa ezindaweni ezinokushisa okuphansi.

I-ASTM A178 Ibanga Cinokuqukethwe okuphezulu kwekhabhoni kanye ne-manganese okunikeza leli payipi amandla angcono kanye nokumelana nokushisa ezimweni zokusebenza ezidinga kakhulu.

Ifanele ukusetshenziswa komfutho ophakathi kanye nokushisa okuphakathi njengama-boiler ezimboni kanye namanzi ashisayo, ngokuvamile adinga ukucindezeleka okuphezulu kanye namazinga okushisa kunama-boiler asekhaya.

I-ASTM A178 Ibanga DAmashubhu anokuqukethwe okuphezulu kwe-manganese kanye nokuqukethwe kwe-silicon okufanele ukunikeza amandla amahle kakhulu kanye nokumelana nokushisa, okwenza aqine ezindaweni ezinokushisa okuphezulu kanye nokucindezela okuphezulu futhi afanelekele ukumelana nezimo zokusebenza ezimbi kakhulu.

Ngokuvamile kusetshenziswa ezindaweni ezinomfutho ophezulu kanye nezinokushisa okuphezulu, njengama-boiler eziteshi zamandla kanye nama-superheater ezimboni.

1. I-ASTM A179 / ASME SA179: I-heat exchanger yensimbi ethambile engenamthungo kanye namashubhu e-condenser ukuze kuhlinzekwe nge-cryogenic. Isetshenziswa kakhulu ezindaweni eziphansi kwengcindezi, ifana ngezakhiwo zamakhemikhali nezemishini ne-ASTM A178.

2. I-ASTM A192 / ASME SA192: Amashubhu ebhoyila ensimbi yekhabhoni angenamthungo asebenza ngokucindezela okuphezulu. Asetshenziswa kakhulu ekwenziweni kwezindonga zamanzi, izinto ezigcina umswakama kanye nezinye izingxenye zokucindezela zamabhoyila anomfutho ophezulu kakhulu.

3. I-ASTM A210 / ASME SA210: Imboza ibhoyila yensimbi ye-carbon ephakathi nendawo kanye ne-alloy kanye namashubhu e-superheater ukuze kube nezinhlelo zebhoyila ezinokushisa okuphezulu kanye nokucindezela okuphakathi.

4. I-DIN 17175: Amapayipi ensimbi angenamthungo kanye namapayipi okusetshenziswa ezindaweni ezicindezelayo kakhulu kanye nezishisa kakhulu. Asetshenziswa kakhulu ekwakhiweni kwamapayipi anomusi wama-boilers kanye nemikhumbi yokucindezela.

5. I-EN 10216-2: Ibeka izimo zobuchwepheshe zamashubhu namapayipi angenamthungo ezinsimbi ezingezona i-alloy kanye ne-alloy ezinezakhiwo ezicacisiwe zokushisa okuphezulu zokusetshenziswa ngaphansi kwengcindezi.

6. I-JIS G3461: Imboza amashubhu ensimbi yekhabhoni ama-boiler kanye nama-heat exchanger. Ifaneleka ezimweni ezijwayelekile zokushintshana kokushisa okuphansi nokuphakathi.

Singumkhiqizi kanye nomhlinzeki wamapayipi ensimbi yekhabhoni ashiselwe ngekhwalithi ephezulu avela eShayina, futhi siphinde sibe ngumthengisi wamapayipi ensimbi angenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Uma unemibuzo noma ufuna ukwazi kabanzi ngezinsizakalo zethu, ungangabazi ukuxhumana nathi. Izixazululo zakho ezinhle zamapayipi ensimbi zitholakala nje!