I-ASTM A106ipayipi lensimbi lingenamthungoipayipi lensimbi yekhabhoniifanele ukusetshenziswa ezindaweni ezinokushisa okuphezulu kanye nengcindezi ephezulu.Isetshenziswa kabanzi emikhakheni eminingi efana nemboni kawoyela negesi, izitshalo zikagesi kanye nezitshalo zamakhemikhali.

Ngokuqondene,I-ASTM A106 Ibanga BUkufakwa kwamapayipi kuthandwa kakhulu ezinhlotsheni eziningi zokusebenza ngenxa yekhono lalo lokuhlangabezana nezidingo zokusebenza kwemishini yemishini eminingi yokwakha kanye nokungabizi kwayo.

I-ASME SA106 = I-ASTM A106.

I-ASME SA106 kanye ne-ASTM A106 zilingana ngokwezinto zokwakha kanye nezakhiwo, futhi zinezidingo ezifanayo ezijwayelekile, kodwa zingaphansi kwezinhlangano ezahlukene zokushicilela amazinga futhi zisetshenziselwa ukwanelisa izinhlelo ezahlukene zokuqinisekisa.

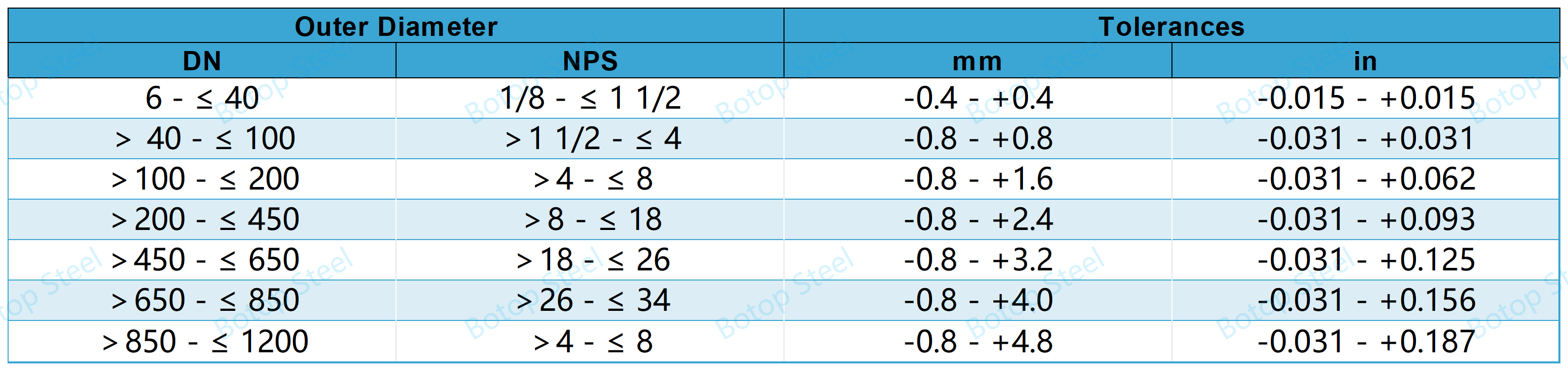

Ububanzi obujwayelekile: DN 6 - DN 1200 [NPS 1/8 - NPS 48];

Ububanzi Bangaphandle: 10.3 - 1219 mm [0.405 - 48 in.];

Ubukhulu bodonganjengoba kuboniswe ku-I-ASME B 36.10.

Amakilasi avamile okujiya kodonga yilawaIshejuli 40futhiIshejuli 80.

Amapayipi osayizi angewona ajwayelekile angasetshenziswa, uma nje ehlangabezana nazo zonke ezinye izidingo zale khodi.

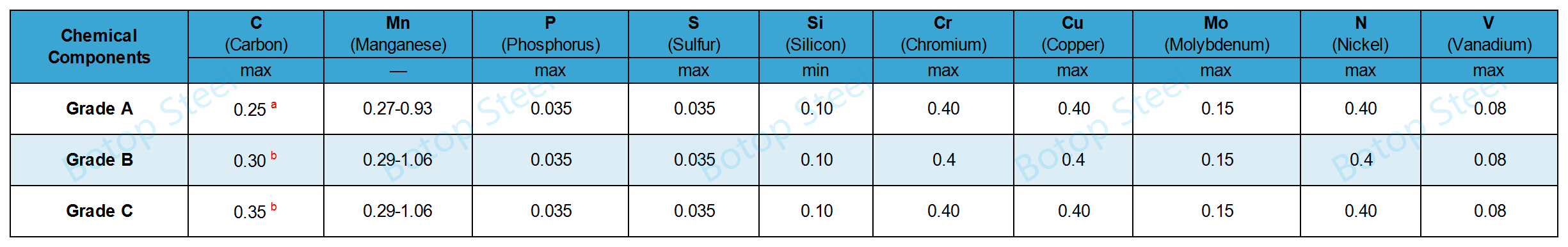

II-ASTM A106standard inezigaba ezintathu ezahlukene,Ibanga A, Ibanga B, kanye nebanga C.

Amandla okukhiqiza kanye namandla okudonsa ayanda ngokwezinga, elisetshenziselwa ukubhekana nezimo ezahlukene zokusetshenziswa.

Insimbi kufanele ibulawe ngensimbi.

Ipayipi lensimbi le-ASTM A106 kufanele likhiqizwe kusetshenziswainqubo yokukhiqiza engenamthungo.

Kuye ngobukhulu bepayipi kanye nokusetshenziswa okuthile, zingahlukaniswa kabanzi zibekuqediwe ngokushisafuthiokudonswa kubandaizinhlobo.

I-DN ≤ 40 [NPS ≤ 1 1/2], ingenza ukudweba okuqediwe okushisayo noma okubandayo, ikakhulukazi okubandayo.

I-DN ≥ 50 [NPS ≥ 2] kufanele iqedwe ngokushisa. Amashubhu ensimbi adonswa ngokubandayo angenamthungo nawo ayatholakala uma ecelwa.

Ngezansi kunomdwebo ochaza inqubo yokukhiqiza ipayipi lensimbi elingenamthungo eliqediwe ngokushisa.

Imidwebo yeshadi lokugeleza kokukhiqiza edwetshwe ngokubandayo ingabukwa ngokuchofoza ku-Amashubhu Ensimbi Yekhabhoni Engenamthungo E-ASTM A556 Adonswe Ngobandayo.

Amashubhu ensimbi angenamthungo aqediwe ngokushisa nabandayo anezakhiwo zomshini, ikhwalithi yobuso, kanye nokunemba kobukhulu ngaphezu komehluko wobukhulu.

Amashubhu aqediwe ashisayo akhiqizwa emazingeni okushisa aphezulu futhi anokuqina okungcono kodwa izindawo eziqinile kanye nokunemba okuphansi; kanti amashubhu adonswayo abandayo akhiqizwa ngokuguqulwa kwepulasitiki emazingeni okushisa egumbi futhi anamandla aphezulu, izindawo ezibushelelezi, kanye nokulawula okunembe kakhudlwana, okwenza afaneleke ezinhlelweni zokusebenza ezidinga ukunemba nokusebenza okuphezulu.

Kudonswa kubandaamapayipi kufanele aphathwe ngokushisa1200°F [650°C]noma ngaphezulu ngemva kokudonsa kokugcina okubandayo.

Kuqediwe ngokushisaamashubhu ensimbi ngokuvamile awadingi ukwelashwa kokushisa okwengeziwe.

Uma kudingeka ukwelashwa kokushisa kwepayipi lensimbi eliqediwe elishisayo, izinga lokushisa lokwelashwa kokushisa kufanele libe ngaphezulu1500°F [650°C].

Ukwelashwa ngokushisa kuthuthukisa isakhiwo se-microstructure ye-tube, kuthuthukisa izakhiwo zemishini, kuthuthukisa ukumelana nokugqwala, kuthuthukisa ukusebenza kahle kwe-machina, kuqinisekisa ukuzinza kobukhulu, kanye nokuhlangabezana nezidingo zezindinganiso ezithile, ngaleyo ndlela kuthuthukisa kakhulu ukusebenza kanye nokufaneleka kwe-tube iyonke.

a Ngokunciphisa ngakunye okungu-0.01% ngaphansi komkhawulo wekhabhoni ochaziwe, ukwanda okungu-0.06% we-manganese ngaphezu komkhawulo ochaziwe kuzovunyelwa kufikela kumkhawulo ophezulu ongu-1.35%.

b Ngaphandle kokuthi kuchazwe ngenye indlela ngumthengi, ngokwehliswa ngakunye okungu-0.01% ngaphansi komkhawulo wekhabhoni ocacisiwe, ukwenyuka okungu-0.06% we-manganese ngaphezu komkhawulo ocacisiwe kuzovunyelwa kufikela kumkhawulo ophezulu ongu-1.65%.

cI-Cr, i-Cu, i-Mo, i-Ni, kanye ne-V akumele idlule i-1% yokuqukethwe okuphelele kwalezi zinto ezinhlanu.

Amabanga A, B kanye no-Cziyahlukahluka ekwakhekeni kwamakhemikhali azo, ikakhulukazi ngokwezinga lekhabhoni kanye ne-manganese.

Lo mehluko uthinta izakhiwo zemishini kanye nezimo zokusetshenziswa kwamapayipi. Uma okuqukethwe kwekhabhoni kuphakeme, ipayipi lizoqina kakhulu, kodwa ukuqina kungancishiswa. Ukwanda kokuqukethwe kwe-manganese kunegalelo emandleni nasebulukhunini bensimbi.

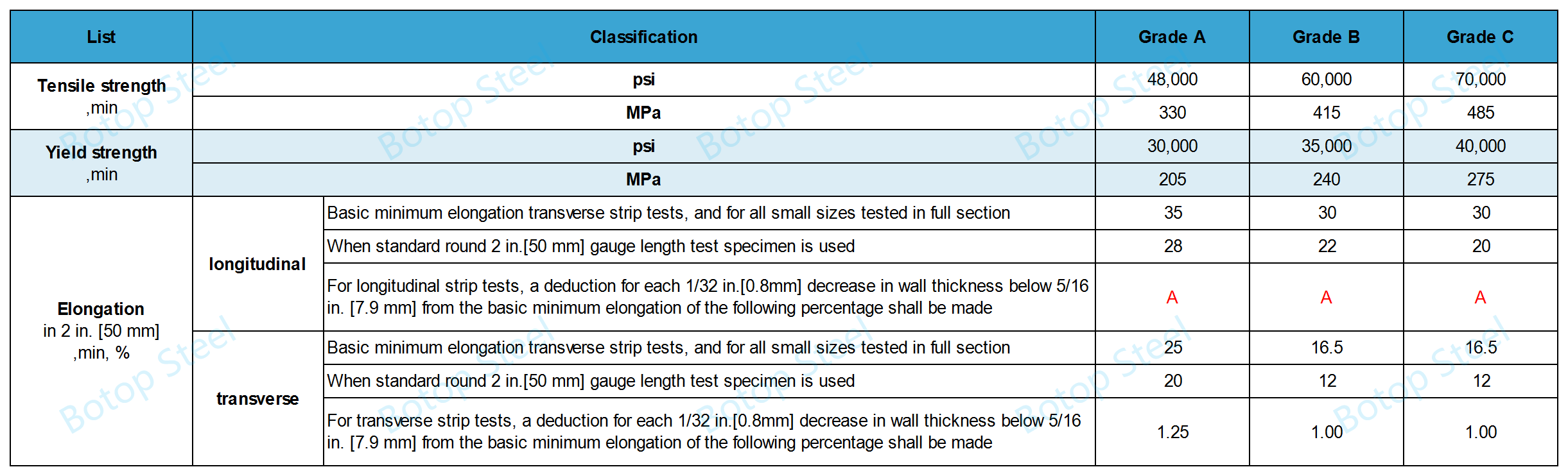

Impahla Eqinile

A: Ukwelulwa okuncane kakhulu ngamasentimitha angu-2 [50 mm] kuzonqunywa yi-equation elandelayo:

amayunithi angama-intshi-pound:e = 625,000A0.2/UO.9

Amayunithi e-Sl:e = 1940A0.2/U0.9

e: ukunwebeka okuncane ngamasentimitha angu-2 [50 mm], %, kufinyelelwe ku-0.5% eseduze,

A: indawo enqamula ingxenye yesampula yokuhlolwa kokucindezeleka, ku.2[mm2], ngokusekelwe kububanzi obucacisiwe bangaphandle noma ububanzi besampula obujwayelekile kanye nobukhulu bodonga obucacisiwe, okuzungezwe ku-0.01 inches eseduze2[1 mm2].

(Uma indawo ebalwe ngaleyo ndlela ilingana noma ingaphezu kuka-0.75 inches2[500 mm]2], bese kuba inani elingu-0.75 ku-2[500 mm]2] kuzosetshenziswa.)

U: amandla okudonsa acacisiwe, i-psi [MPa].

Ukuhlolwa Kokugoba

Kumapayipi e-DN 50 [NPS 2] nangaphansi, kufanele kube nobude obanele bepayipi ukuvumela ukugoba okubandayo kwepayipi kudlule ku-90° ngaphandle kokuqhekeka kuzungeze i-mandrel esilinda enobubanzi obuphindwe izikhathi ezingu-12 kunobubanzi bangaphandle bepayipi.

Ku-OD > 25in. [635mm], uma i-OD/T ≤ 7, kudingeka ukuhlolwa kokugoba ukuze kugobe ngo-180° ngaphandle kokuqhekeka ekushiseni kwegumbi. Ububanzi bangaphakathi bengxenye egobile buyi-1in.

Ukuhlolwa Kokuthamba

Ipayipi lensimbi elingenamthungo le-ASTM A106 alidingi ukuhlolwa okuyisicaba, kodwa ukusebenza kwepayipi kumele kuhlangabezane nezidingo ezifanele.

Ngaphandle uma kudingeka ngokuqondile, wonke amapayipi kumele ahlolwe ngamanzi noma angabhubhisi ngogesi, futhi ngezinye izikhathi kokubili.

Uma kungekho ukuhlolwa kwe-hydrostatic noma okungabhubhisi okwenziwe, ipayipi kufanele limakwe ngo-“NH".

Ukuhlolwa Kwamanzi

Inani lomfutho wamanzi akufanele libe ngaphansi kuka-60% wamandla amancane okukhiqiza ashiwo.

Kungabalwa ngale ndlela elandelayo:

P = 2St/D

P = ingcindezi yokuhlola ye-hydrostatic ku-psi noma i-MPa,

S = ukucindezeleka kodonga lwamapayipi ku-psi noma i-MPa,

t = ubukhulu bodonga obuqokiwe obuqondile, ubukhulu bodonga obuqondile obuhambisana nenombolo yeshejuli ye-ANSI ecacisiwe, noma izikhathi ezingu-1.143 ubukhulu bodonga obuncane obucacisiwe, ngo. [mm],

D = ububanzi obungaphandle obucacisiwe, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elicacisiwe, noma ububanzi obungaphandle obubalwe ngokungeza u-2t (njengoba kuchaziwe ngenhla) kububanzi obungaphakathi obucacisiwe, ngo. [mm].

Uma kwenziwa ukuhlolwa komfutho wamanzi, ipayipi lensimbi kufanele limakwe ngophawuingcindezi yokuhlola.

Ukuhlolwa Kukagesi Okungabhubhisi

Kungasetshenziswa njengendlela ehlukile yokuhlolwa kwe-hydrostatic.

Umzimba wonke wepayipi ngalinye kufanele uhlolwe ngogesi ngendlela engonakalisi ngokuhambisana ne-E213, I-E309nomaE570imininingwane.

Uma kwenziwe ukuhlolwa okungabhubhisi, “I-NDE"Kumelwe kukhonjiswe ebusweni bepayipi."

Isisindo

Isisindo sangempela sepayipi kufanele sibe sebangeni97.5% - 110%yesisindo esichaziwe.

Ububanzi Bangaphandle

Ubukhulu

Ubukhulu bodonga obuncane = 87.5% wobukhulu bodonga obucacisiwe.

Ubude

Kungahlukaniswa ngezigabaubude obucacisiwe, ubude obungahleliwe obubodwa, futhiubude obuphindwe kabili obungahleliwe.

Ubude obucacisiwe: njengoba kudingeka yi-oda.

Ubude obungahleliwe obubodwa: 4.8-6.7 m [16-22ft].

Ubude obungu-5% buvunyelwe ukuba ngaphansi kwamamitha angu-4.8 [16 ft], kodwa kungabi bufushane kunamamitha angu-3.7 [12 ft].

Ubude obuphindwe kabili obungahleliwe: Ubude obujwayelekile obuncane buyi-10.7 m [35 ft] kanti ubude obuncane buyi-6.7 m [22 ft].

Amaphesenti amahlanu obude avunyelwe ukuba ngaphansi kwamamitha angu-6.7 [22 ft], kodwa kungabi mfushane kunamamitha angu-4.8 [16 ft].

Ipayipi lensimbi le-ASTM A106 lisetshenziswa kabanzi ezinhlotsheni eziningi zezimboni ngenxa yokumelana kwalo okuphezulu namazinga okushisa aphezulu kanye nokucindezela.

1. Imboni yamafutha negesi: Ipayipi lensimbi le-ASTM A106 lisetshenziswa kabanzi emapayipini kawoyela negesi aqhelelene, imishini yokubhoboza, kanye nezindawo zokuhluza, lapho ukumelana kwalo nokushisa okuphezulu kanye nokucindezela okuphezulu kuqinisekisa ukuphepha nokuthembeka ezindaweni ezinzima.

2. Izitshalo zikagesi: Isetshenziswa kumapayipi ebhoyila anokushisa okuphezulu, anomfutho ophezulu, ama-heat exchanger, kanye nezinhlelo zokulethwa komusi ophakeme ukuze kuhlinzekwe ukusebenza okuzinzile kanye nokuphila kwenkonzo ngaphansi kwezimo ezimbi kakhulu.

3. Izitshalo zamakhemikhali: Amapayipi ensimbi e-ASTM A106 asetshenziswa ezitshalweni zamakhemikhali zezinhlelo zamapayipi ezinto zokusabela ezinomfutho ophezulu, imikhumbi yokucindezela, imibhoshongo yokuhluza, kanye nama-condenser, lapho ingamelana khona nokushisa okuphezulu kanye namakhemikhali agqwalisayo ukuqinisekisa ukuphepha nokusebenza kahle kwenqubo.

4. Izakhiwo kanye nengqalasizinda: Isetshenziswa ezinhlelweni zokushisa, zokungenisa umoya, kanye nezokupholisa umoya (i-HVAC) kanye nezinhlelo zokuvikela umlilo ezinomfutho ophezulu ukuqinisekisa ukusebenza kahle nokuphepha kwezinhlelo ezakhiweni.

I-ASTM A53 Ibanga BfuthiI-API 5L Ibanga B yizona ezinye izindlela ezivamile esikhundleni se-ASTM A106 Grade B.

Ekuphawulweni kwepayipi lensimbi elingenamthungo, sivame ukubona ipayipi lensimbi elihlangabezana nalezi zindinganiso ezintathu ngesikhathi esisodwa, okubonisa ukuthi linezinga eliphezulu lokuvumelana ngokwezakhi zamakhemikhali, izakhiwo zemishini, njalo njalo.

Ngaphezu kwezinto ezijwayelekile okukhulunywe ngazo ngenhla, kunezinye izindinganiso eziningana ezifana ne-ASTM A106 ngokwesakhiwo samakhemikhali kanye nezakhiwo zemishini.

I-GB/T 5310: Faka epayipini lensimbi elingenamthungo kubhoyila enomfutho ophezulu.

I-JIS G3454: Yepayipi lensimbi yekhabhoni lokufaka amapayipi okucindezela.

I-JIS G3455: Ifanelekela ipayipi lensimbi yekhabhoni kumapayipi anomfutho ophezulu.

I-JIS G3456: Amapayipi ensimbi yekhabhoni amapayipi okushisa okuphezulu.

I-EN 10216-2: Amashubhu ensimbi angenamthungo okusetshenziswa kwezinga lokushisa eliphezulu.

I-EN 10217-2: Amapayipi ensimbi ashiselwe okusetshenziswa ezindaweni zokushisa okuphezulu.

I-GOST 8732: Amashubhu ensimbi angenamthungo ashiswayo asetshenziswa ngomfutho ophezulu kanye nokushisa okuphezulu.

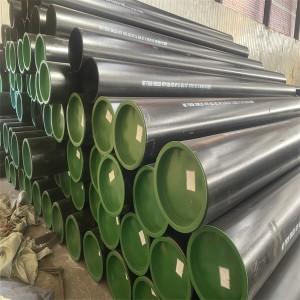

Iqoqo ngalinye lamapayipi ensimbi angenamthungo e-ASTM A106 lizihlole ngokucophelela noma lihlolwe ngochwepheshe ngaphambi kokushiya ifektri, okuwukugcizelela kwethu ikhwalithi kanye nokuzibophezela kwethu okungaguquki kumakhasimende.

Ukuhlolwa Kobubanzi Bangaphandle

Ukuhlolwa Kokujiya Kodonga

Ukuhlolwa Kokuqondile

Ukuhlolwa kwe-UT

Ukuhlolwa Kokugcina

Ukuhlolwa Kokubukeka

Ngenkathi siqinisekisa ikhwalithi yemikhiqizo yethu, siphinde sinikeze izinketho ezahlukene zokupakisha ukuze kuhlangatshezwane nezidingo ezahlukene zokuhamba nokugcina. Kusukela ekuboshweni kwendabuko kuya ekupakisheni okuvikelayo okwenziwe ngokwezifiso, sizibophezele ekuhlinzekeni ngesivikelo esingcono kakhulu sokuthunyelwa ngakunye kwamashubhu ensimbi ukuqinisekisa ukuthi afika kuwe ngokuphephile nangaphandle komonakalo.

Umdwebo Omnyama

Amakepisi epulasitiki

3LPE

Isimbozo

I-Galvanised

Ukubopha kanye ne-Sling

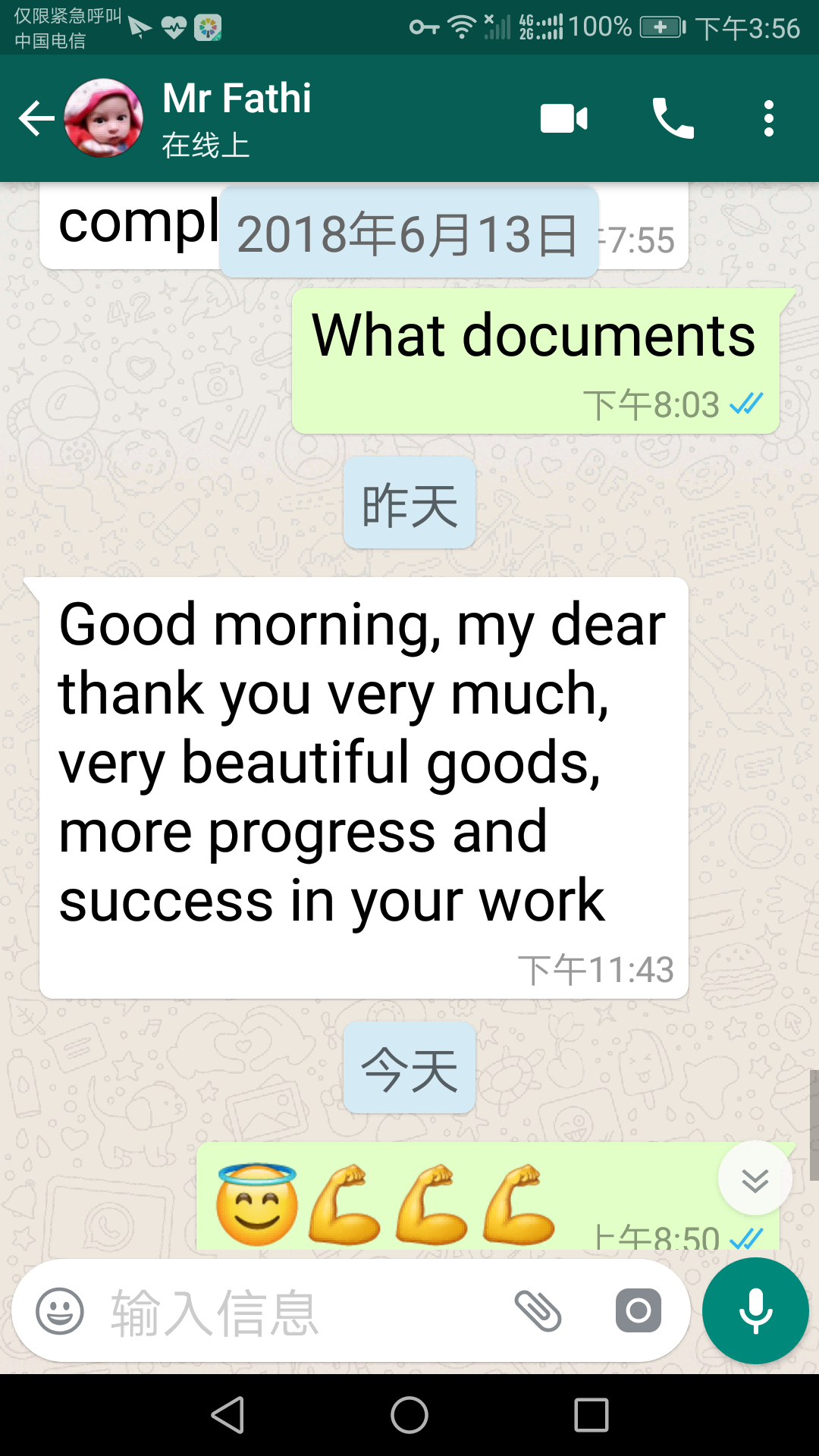

Lokhu kubuyekezwa akugcini nje ngokuqaphela ikhwalithi yemikhiqizo yethu kodwa futhi nokuzibophezela kwethu enkonzweni. Silangazelela ukubambisana nawe ukuhlinzeka ngezixazululo zepayipi lensimbi ze-ASTM A106 GR.B ezifanele kakhulu kumaphrojekthi akho ngesevisi yobungcweti nephumelelayo.

Selokhu yasungulwa ngo-2014,Insimbi yeBotopisibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza amapayipi ahlukahlukene ensimbi yekhabhoni kanye nemikhiqizo ehlobene nayo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange. Imikhiqizo yayo ekhethekile ifaka phakathi ama-alloy ebanga eliphezulu kanye nezinsimbi ezingagqwali ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene amapayipi.

Ipayipi Lensimbi Engenamthungo Yekhabhoni ye-ASTM A53 Gr.A & Gr. B Yepayipi Lamafutha Negesi

Amapayipi e-ASTM A556 e-Seamless Carbon Steel Feedwater Heater adonswe ngokubandayo

Ipayipi Lensimbi Engenamthungo Yekhabhoni ye-ASTM A334 Ibanga 1

Ipayipi Lomshini Wensimbi Engenamthungo ye-ASTM A519 Carbon And Alloy

Ipayipi Lensimbi Elingenamthungo le-JIS G3455 STS370 Lensizakalo Yokucindezela Okuphezulu

Amashubhu Ensimbi Yekhabhoni Ye-ASTM A192 Yengcindezi Ephezulu

Ipayipi Lebhoyila Lensimbi Yekhabhoni Engenamthungo ye-JIS G 3461 STB340

Amashubhu Ensimbi Angenamthungo e-AS 1074 Esevisi Ejwayelekile

Ipayipi Lensimbi Elingenamthungo le-API 5L GR.B Eliqinile Lokujiya Kodonga Lokucubungula Okwenziwa Ngomshini

Ipayipi Lensimbi Engenamthungo Yekhabhoni ye-ASTM A53 Gr.A & Gr. B Yepayipi Lamafutha Negesi