I-AS/NZS 1163 iyindinganiso ethuthukiswe yi-Standards Australia kanye ne-Standards New Zealand.

Indinganiso icacisa izidingo zokwenziwa nokuhlinzekwa kwezingxenye zensimbi ezimbozwe ngokushisa, ezibizwa ngokuthi i-Electric Resistance Welding (ERW), ezakhiwe ngokubandayo ngenhloso yokwakha. Lezi zingxenye ezimbozwe ngogesi zivame ukusetshenziswa ekwakhiweni nasekubunjiniyeleni kwezakhiwo ezahlukahlukene njengezakhiwo, amabhuloho, kanye nengqalasizinda.

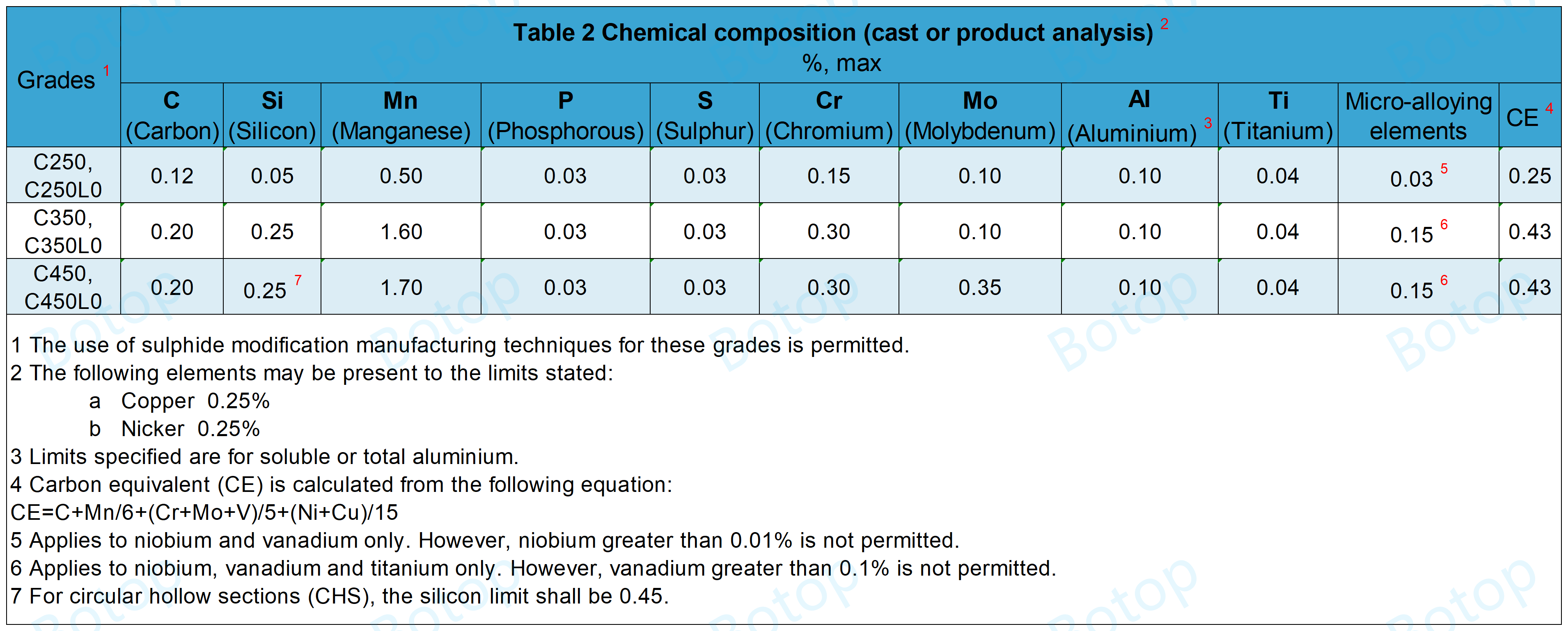

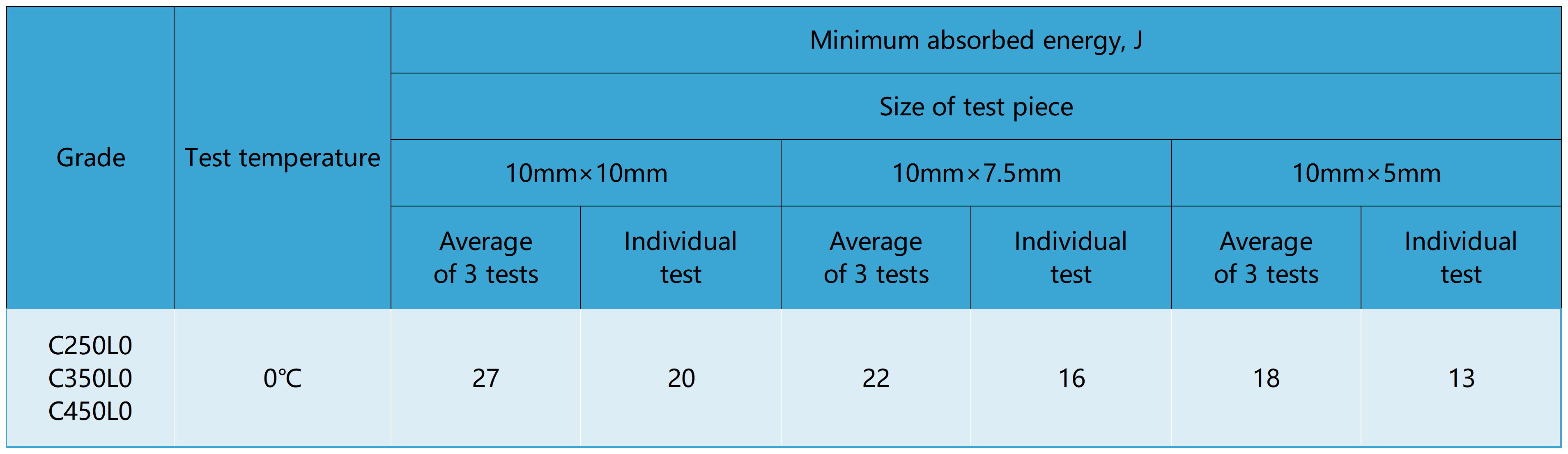

Amabanga amathathu ahlukaniswa ngokwezinga eliphansi lokukhiqiza kanye nokugcwaliseka kwemiphumela engu-0°C.

I-AS/NES 1163-C250/C250L0

I-AS/NES 1163-C350/C350L0

I-AS/NES 1163-C450/C450L0

ikhoyili egoqekile eshisayo noma ikhoyili egoqekile ebandayo.

Insimbi ecolekile ichazwa njengezinto zokusetshenziswa zamakhoyili ensimbi.

Izingxenye eziqediwe ezingenalutho zenziwa kusetshenziswa inqubo yokwakha okubandayo futhi imiphetho yomcu wensimbi ihlanganiswa kusetshenziswaukushisela ukumelana kagesi (ERW)ubuchwepheshe.

Futhi kufanele asuse ukushintshwa okungaphezulu kwangaphandle; ingaphakathi lingashiywa lingahlanzekile.

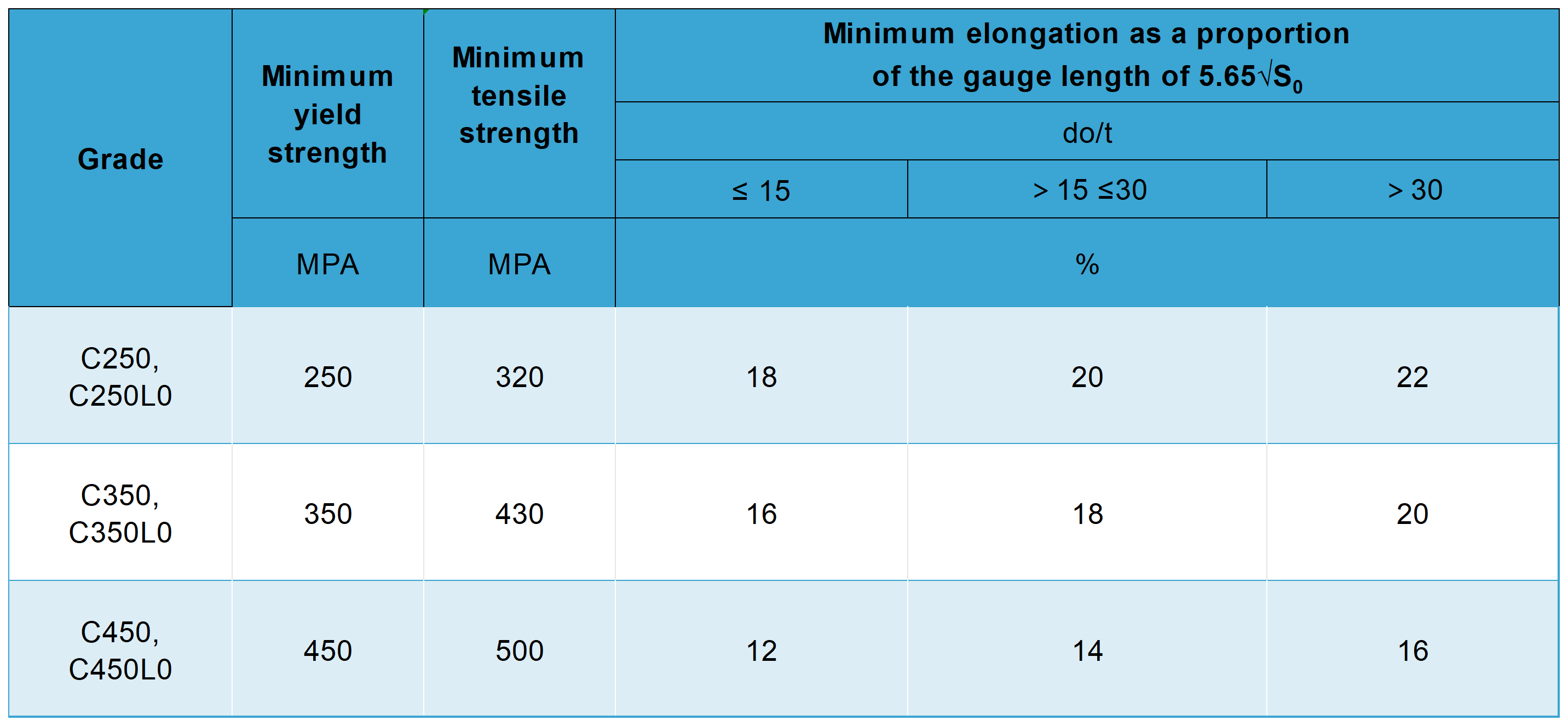

Ukuhlinzekwa kwezakhiwo zokudonsa kungenye yezingxenye ezibalulekile ze-AS/NZS 1163, ehlanganisa amandla okudonsa, amandla okukhiqiza, ukunwebeka, kanye nezinye izinhlaka ezibalulekile zensimbi, okuhlinzeka ngedatha eyisisekelo kanye nezindinganiso zokubhekisela zokuklama kobunjiniyela kanye nokuhlaziywa kwesakhiwo.

| Uhlobo | Ibanga | Ukubekezelelana |

| Isici | — | Izingxenye eziyindilinga ezingenalutho |

| Ubukhulu bangaphandle (do) | — | ±1%, okungenani okungu-±0.5 mm kanye nomkhawulo ophezulu ongu-±10 mm |

| Ubukhulu (t) | do≤406,4 mm | 土10% |

| yenza >406.4 mm | ±10% ngesilinganiso esiphezulu esingu-±2 mm | |

| Ukungaguquguquki (o) | Ububanzi bangaphandle(bo)/ubukhulu bodonga(t)≤100 | ±2% |

| Ukuqonda | ubude obuphelele | 0.20% |

| Isisindo (m) | isisindo esibekiwe | ≥96% |

| Uhlobo lobude | Ibanga m | Ukubekezelelana |

| Ubude obungahleliwe | 4m kuya ku-16m nge ububanzi obuyi-2m nge oda into | Izingxenye eziyi-10% ezinikeziwe zingaba ngaphansi kobuncane bobubanzi obu-odiwe kodwa kungabi ngaphansi kuka-75% wobuncane |

| ubude obungacacisiwe | KONKE | 0-+100mm |

| Ubude bokunemba | ≤ 6m | 0-+5mm |

| >6m ≤10m | 0-+15mm | |

| >10m | 0-+(5+1mm/m)mm |

Uhlu lwe-SSHS (Structural Steel Hollow Sections) luqukethe ithebula lezisindo zamapayipi kanye nezici zesigaba esiphambene, phakathi kwezinye izinto.

C250isetshenziselwa izakhiwo ezijwayelekile kanye namapayipi okudlulisa uketshezi olunomfutho ophansi.

C350isetshenziselwa ukwakha izakhiwo namabhuloho.

C450isetshenziselwa amabhuloho amakhulu kanye namapayipi anomfutho ophezulu.

C350L0futhiC250L0yizinsimbi zokuqina ezisezingeni eliphansi ezisetshenziselwa izakhiwo namapayipi ezindaweni ezibandayo.

C450L0ifanele izimo zemvelo ezimbi kakhulu njengezinkundla zasogwini kanye nokwakhiwa kwezindawo ezibandayo.

Ukuhlolwa kosayizi wokubukeka kwepayipi lensimbi kuhlanganisa kakhulu izinto ezilandelayo:

Ububanzi kanye nobukhulu bodonga, ubude, ukuqondile, ukujiya, kanye nekhwalithi yobuso.

I-angle ye-bevel yepayipi lensimbi

Ubukhulu bodonga lwepayipi

Ububanzi bangaphandle bepayipi lensimbi

Ngokwezidingo zamakhasimende, ukwelashwa kokulwa nokugqwala kwezindawo zamapayipi ensimbi kungenziwa ngezindlela eziningi ezahlukene ukuze kuthuthukiswe ukumelana nokugqwala kwayo futhi kwandise isikhathi sayo sokusebenza.

Kubandakanya i-varnish, upende, i-galvanization, i-3PE, i-FBE, nezinye izindlela.

Singomunye wabakhiqizi nabahlinzeki bepayipi lensimbi yekhabhoni elihlanganisiwe abahamba phambili kanye namapayipi ensimbi angenamthungo abavela eShayina, sinezinhlobonhlobo zamapayipi ensimbi asezingeni eliphezulu esitokweni, sizibophezele ekukunikezeni uhla oluphelele lwezixazululo zamapayipi ensimbi.

Ukuze uthole imininingwane eyengeziwe yomkhiqizo, sicela ukhululeke ukuxhumana nathi, silangazelela ukukusiza ukuthola izinketho ezinhle kakhulu zamapayipi ensimbi ezifanela izidingo zakho!