Ipayipi lensimbi le-AS 1579iyipayipi lensimbi elihlanganisiwe elinomshini wokuwelda we-butt weld elisetshenziswa kakhulu ekuthuthweni kwamanzi namanzi angcolile anobubanzi bangaphandle obungu-≥ 114 mm kanye namapayipi anengcindezi elinganiselwe engadluli ku-6.8 MPa.

Izinqwaba zamapayipi zingamalungu ajikelezayo afakwa enhlabathini futhi azisetshenziselwa ukulawula ingcindezi yangaphakathi.

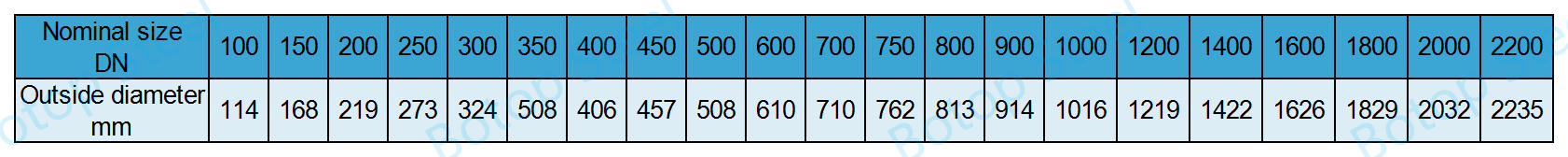

Ububanzi obuncane bangaphandle bungu-114mm, yize kungekho mkhawulo oqondile ngobukhulu bepayipi kodwa osayizi abakhethwayo banikezwa.

Kufanele kukhiqizwe ngamamaki ahlaziyiwe noma esakhiwo sensimbi egoqwe ngokushisa ehambisana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Kuye ngokusetshenziswa kokugcina, kusahlukaniswa kanje:

Amapayipi ahlolwe ngamanzikumele kukhiqizwe ngokuhlaziywa noma izinga lesakhiwo sensimbi egoqwe ngokushisa ehambisana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Amapayipi kanye nepayipi elingahlolwanga ngamanzikumele kukhiqizwe ngensimbi yezinga lesakhiwo ehambisana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Ngaphandle kwalokho,izinqwabakungenziwa ngebanga lokuhlaziya elihambisana ne-AS/NZS 1594., lapho insimbi kufanele ihlolwe ngomshini ngokuhambisana ne-AS 1391 ukuze kuboniswe ukuthi ihlangabezana nezidingo zokubopha ezichazwe ngumthengi.

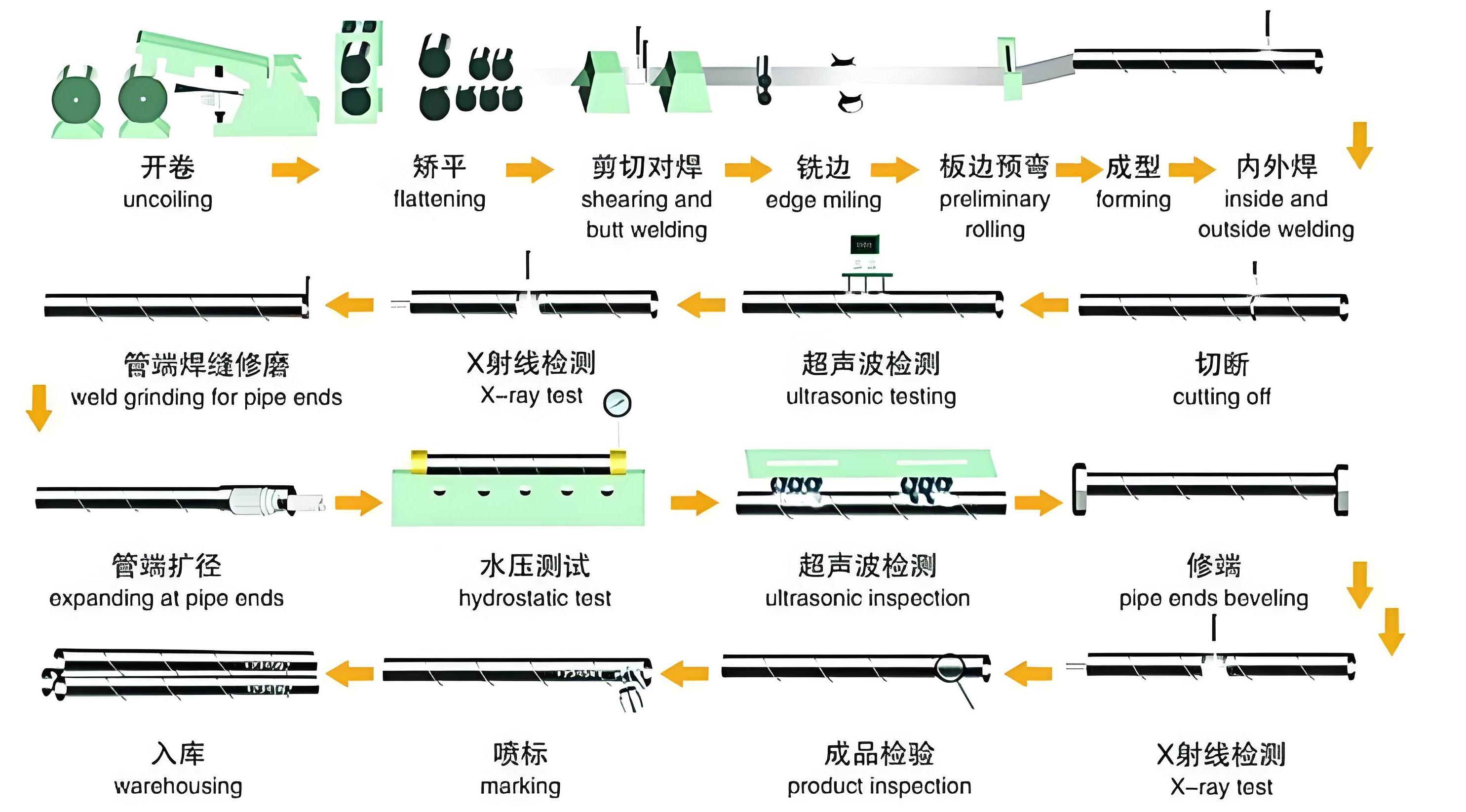

Ipayipi lensimbi le-AS 1579 lenziwa kusetshenziswaukushisela i-arc.

Zonke izindwangu zokushisela kumele zibe yizindwangu zokushisela ezifakwe ngokuphelele.

Ukushisela i-arc kusebenzisa ukushisa kwe-arc kagesi ukuncibilikisa izinto zensimbi bese kwakha i-welded joint phakathi kwezinsimbi ukudala isakhiwo sepayipi lensimbi esiqhubekayo.

Inqubo yokukhiqiza i-arc welding evame ukusetshenziswa yi-SAW (Suberged Arc Welding), eyaziwa nangokuthiI-DSAW, ezingahlukaniswa ngezigabaI-LSAW(SAWL) kanye ne-SSAW (I-HSAW) ngokuya ngesiqondiso se-butt weld.

Ngaphezu kwe-SAW, kunezinye izinhlobo zokushisela i-arc njenge-GMAW, i-GTAW, i-FCAW, kanye ne-SMAW. Amasu ahlukahlukene okushisela i-arc anezici zawo kanye nezimo zokusetshenziswa, futhi ukukhethwa kwendlela efanele yokushisela kuncike ezinhlotsheni zepayipi lensimbi elizokhiqizwa, isabelomali, kanye nezidingo zekhwalithi.

Izindinganiso ngokwazo azichazi ngokuqondile ukwakheka kwamakhemikhali athile kanye nezakhiwo zemishini, njengoba lokhu kuvame ukuncika ezindinganisweni ezithile zensimbi ezifana ne-AS/NZS 1594 noma i-AS/NZS 3678, ezichaza izidingo zezakhiwo zamakhemikhali kanye nezemishini zensimbi esetshenziswa ukwenza la mashubhu.

I-AS 1579 ichaza kuphela okulingana nekhabhoni.

Isilinganiso sekhabhoni (CE) sensimbi akumele sidlule u-0.40.

CE=Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

I-CE iyipharamitha ebalulekile esetshenziswa ukuhlola ukushibilika kwensimbi. Iyasiza ukubikezela ukuqina okungenzeka ensimbini ngemva kokushibilika futhi ngaleyo ndlela ihlole ukushibilika kwayo.

Ukuhlolwa kwengcindezi ye-hydrostatic kuyadingeka kuwo wonke amapayipi ensimbi amanzi noma amanzi angcolile asetshenziselwa ukuthutha.

Amapayipi ngokuvamile awadingeki ukuthi ahlolwe ngamanzi ngoba asetshenziswa kakhulu ukuthwala imithwalo yesakhiwo kunokucindezela kwangaphakathi.

Izimiso Zokuhlola

Ipayipi livaliwe ekugcineni ngakunye futhi licindezelwa ngamanzi.

Kuhlolwa amandla engcindezini emele ingcindezi yomklamo wepayipi. Kuhlolwa ukuqina kokuvuza engcindezini elinganisiwe yepayipi.

Izingcindezi Zokuhlola

Ingcindezi ephezulu kakhulu yepayipi lensimbi ingu-6.8 MPa. Lokhu okuphezulu kunqunywa umkhawulo wemishini yokuhlola ingcindezi engu-8.5 MPa.

Pr= 0.72×(2×SMYS×t)/OD noma Pr= 0.72×(2×NMYS×t)/OD

Pr: Ingcindezi elinganisiwe, ku-MPa;

I-SMYS: Amandla amancane okukhiqiza acacisiwe, ku-MPa;

I-NMYS: Amandla amancane okukhiqiza, ku-MPa;

t: Ubukhulu bodonga, ngo-mm;

OD: Ububanzi bangaphandle, ngo-mm.

Ezimweni eziphuthumayo, ukucindezela kwesikhashana kungaholela ekwandeni kokucindezeleka kwamapayipi. Ngaphansi kwalezi zimo, ukucindezeleka okuphezulu okuvunyelwe okuhlanganisiwe kuzonqunywa ngumklami, kodwa akufanele kudlule u-0.90 x SMYS.

Pt= 1.25Pr

Ngemva kokuhlolwa kwamandla, akumele kube nokuqhekeka noma ukuvuza epayipini lokuhlola.

90% wamandla amancane okukhiqiza (SMYS) noma amandla amancane okukhiqiza (NMYS) noma 8.5 MPa, noma yikuphi okuncane.

Pl= Pr

Ukuhlolwa kokuvuza kufanele kwenziwe epayipini.

Lapho kuhlolwa ukuvuza, akufanele kube khona ukuvuza okubonakalayo ebusweni bepayipi.

Wonke amapayipi okuhlola angewona ama-hydrostatic kufanele abe nobukhulu bodonga obungaphansi kuka-8.0 mm.

Ipayipikufanele ihlolwe ngo-100% ama-weld ayo ngendlela engabhubhisi ngezindlela ze-ultrasonic noma ze-radiographic ngokuhambisana ne-AS 1554.1 Category SP futhi ivumelane nezindinganiso zokwamukelwa ezichaziwe.

Ukuhlolwa okungonakalisi kokushintshwa kwenqwaba okungaphelelengezinqwaba zamapayipiImiphumela yokuhlolwa kufanele ihambisane nezimfuneko ze-AS/NZS 1554.1 Class SP. Uma ukuhlolwa kwembula ukungalandeli ilebula, yonke i-weld kuleyo nqwaba yamapayipi kufanele ihlolwe.

Amapayipi kanye nezinto zokufaka ezisetshenziselwa ukuthutha amanzi kanye nendle kumele zivikelwe ekugqwaleni ngokukhetha ingubo efanele. Ingubo kufanele isetshenziswe ngokuhambisana ne-AS 1281 kanye ne-AS 4321.

Uma kuziwa emanzini aphuzwayo, kufanele ahambisane ne-AS/NZS 4020. Inhloso ukuqinisekisa ukuthi le mikhiqizo, uma ithinta uhlelo lokuhlinzeka ngamanzi, ayithinti kabi ikhwalithi yamanzi, njengokungcoliswa kwamakhemikhali, ukungcoliswa kwezinto eziphilayo, noma ukushintsha ukunambitheka nokubukeka kwamanzi.

Ubuso bangaphandle bepayipi, obungadluli ku-150 mm ukusuka ekugcineni, kufanele buphawulwe ngokucacile nangokuhlala njalo ngolwazi olulandelayo:

a) Inombolo ye-serial ehlukile, okungukuthi inombolo yeshubhu;

b) Indawo yokukhiqiza;

c) Ububanzi bangaphandle kanye nobukhulu bodonga;

d) Inombolo ejwayelekile, okungukuthi AS 1579;

e) Igama noma uphawu lokuhweba lomkhiqizi;

f) Isilinganiso sokucindezela kwepayipi lokuhlola i-hydrostatic (kuphela ipayipi lensimbi elihlolwe i-hydrostatic);

g) Ukumaka kokuhlola okungabhubhisi (NDT) (kuphela kwepayipi lensimbi eliye lahlolwa ngokungabhubhisi).

Umenzi kufanele anikeze uMthengi isitifiketi esisayiniwe esisho ukuthi ipayipi lenziwe ngokuhambisana nezidingo zoMthengi kanye naleli Zinga.

I-ASTM A252: Yakhelwe izinqwaba zamapayipi ensimbi futhi iqukethe izakhiwo zemishini ezinemininingwane kanye nezincazelo zokwakheka kwamakhemikhali zezigaba ezintathu zokusebenza.

I-EN 10219: ihlobene namapayipi ensimbi ahlanganisiwe abandayo okusetshenziswa kwesakhiwo okuhlanganisa nezinqwaba zamapayipi.

I-ISO 3183: Ipayipi lensimbi lemboni kawoyela negesi, elinezidingo zekhwalithi namandla ezenza lifanelekele ukuthwala izinqwaba zamapayipi.

I-API 5L: Isetshenziswa kakhulu kumapayipi okuthutha embonini kawoyela negesi, amazinga ekhwalithi ephezulu ayenza ifaneleke nokwenza izinqwaba ezithwala imithwalo ephezulu.

I-CSA Z245.1: Icacisa amapayipi ensimbi kanye nezinto zokufakelwa zokuthutha uwoyela negesi, ezifanelekile futhi ezinqwabeni zamapayipi.

I-ASTM A690: Yakhelwe izinqwaba zamapayipi ensimbi asetshenziswa ezindaweni zasolwandle nakwezinye izindawo ezifanayo, okugcizelela ukumelana nokugqwala.

I-JIS A 5525: Ipayipi lensimbi elimboza izinga laseJapan lamapayipi, okuhlanganisa izinto zokwakha, ukwenziwa, ubukhulu kanye nezidingo zokusebenza.

I-GOST 10704-91: Ipayipi lensimbi eliqondile elihlanganisiwe ngogesi elisetshenziswa ezakhiweni zokwakha nezobunjiniyela, kufaka phakathi izinqwaba zamapayipi.

I-GOST 20295-85Imininingwane yamapayipi ensimbi ashiselwe ngogesi okuthutha uwoyela negesi, okubonisa ukusebenza kwawo ngaphansi komfutho ophezulu nasezindaweni ezinzima, okusebenza kumapayipi anqwabelene.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza izinhlobo ezahlukene zamapayipi ensimbi yekhabhoni kanye nemikhiqizo ehlobene nawo, okuhlanganisa ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.