Intsimbi ye-ASTM A501yityhubhu yesakhiwo sentsimbi yekhabhoni edityanisiweyo emnyama neshushu edityanisiweyo eyenziwe ngobushushu edityanisiweyo kwaye engenamthungo yeebhulorho, izakhiwo, kunye nezinye iinjongo zesakhiwo ngokubanzi.

Amaqhosha okuHamba

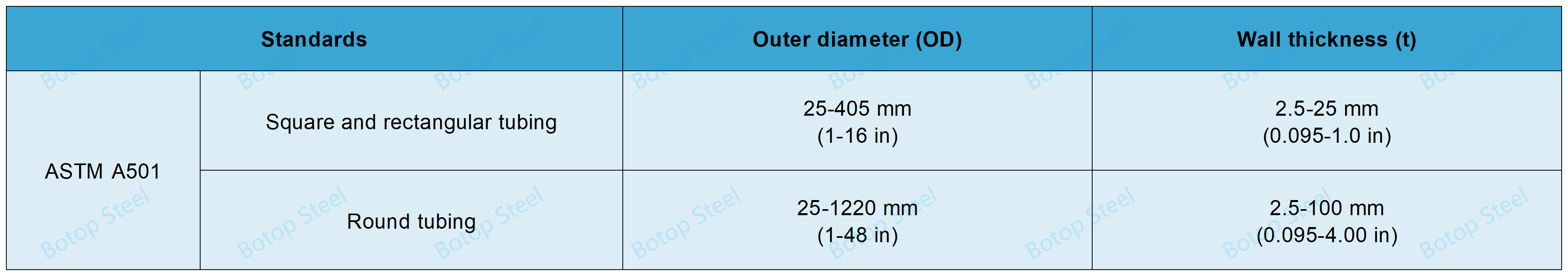

Uluhlu lobungakanani be-ASTM A501

Ukwahlulwahlulwa kwamaBanga

IiMilo zeCandelo elingenanto

Iimpahla ezingekasilwa

Iinkqubo zoMveliso

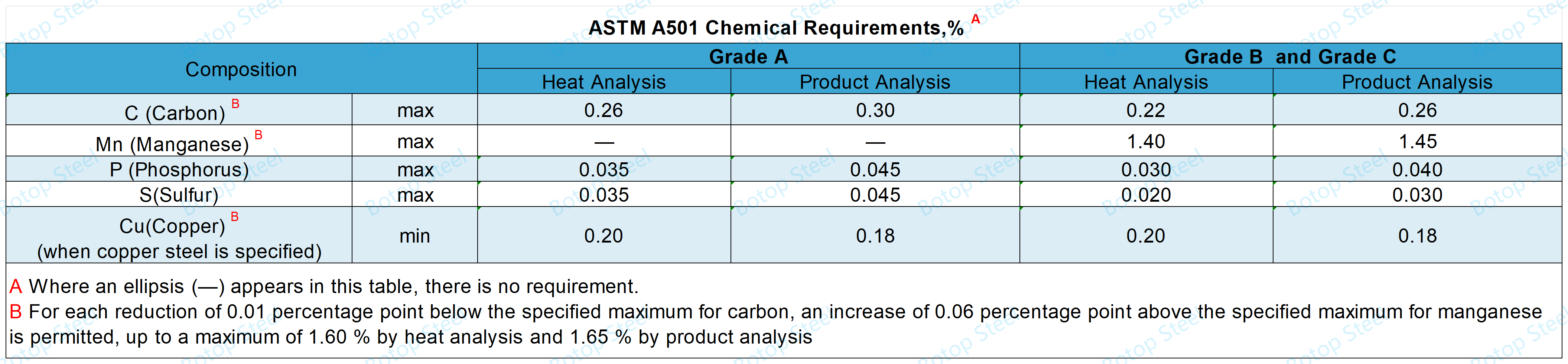

Ukwakheka kweekhemikhali ze-ASTM A501

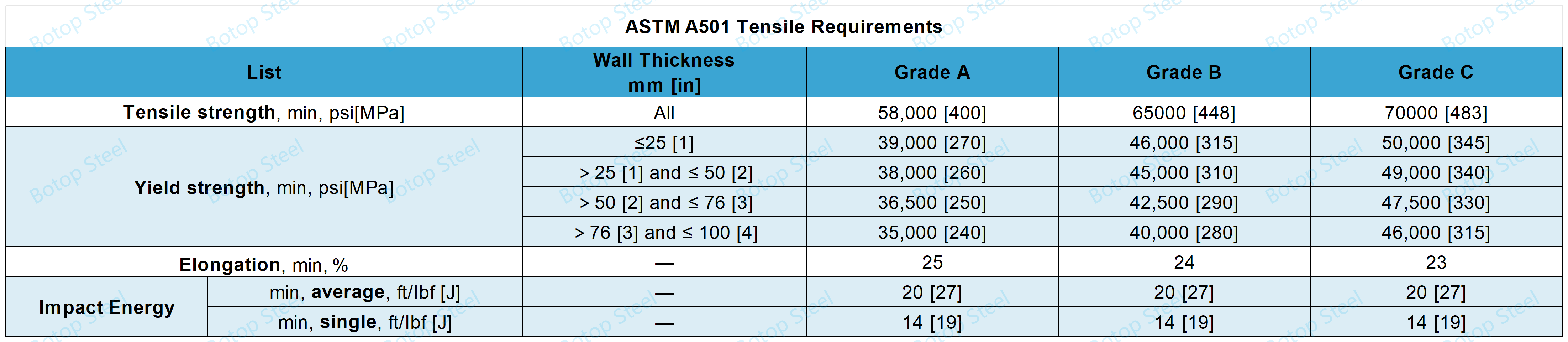

Iipropati zoomatshini ze-ASTM A501

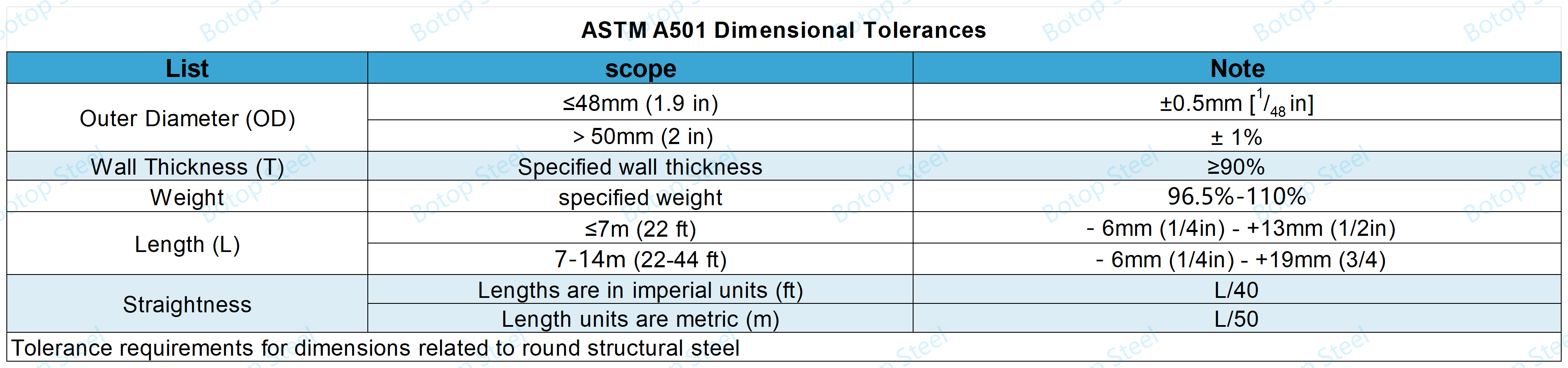

Ukunyamezelana kwe-ASTM A501 ngokwemilinganiselo

Ukugaya nge-galvanizing

Inkangeleko

Ukumakisha

Imigangatho Efanelekileyo

Izicelo

Iingenelo Zethu

Uluhlu lobungakanani be-ASTM A501

Ukwahlulwahlulwa kwamaBanga

I-ASTM A501 yahlulwe yangamanqanaba amathathu, iBanga A, iBanga B, kunye neBanga C.

IiMilo zeCandelo elingenanto

Iimilo ezisikwere, ezingqukuva, ezizinxantathu, okanye ezikhethekileyo.

Iimpahla ezingekasilwa

Intsimbi mayibe yenziwe ngenkqubo yokwenza intsimbi esebenzisa ioksijini esisiseko okanye i-electric-arc-furnace.

Intsimbi inokwenziwa ngee-ingots okanye yenziwe ngentambo.

Iinkqubo zoMveliso

Ityhubhu kufuneka yenziwe ngenye yezi nkqubo zilandelayo:ingenamthungoukuwelda ngesitovu-isiqu (ukuwelda okuqhubekayo);ukuwelda kokumelana nombane (ERW)okanye ukuwelda kwe-arc engaphantsi komhlaba (i-SAW) kulandele ukufudumeza kwakhona kulo lonke icandelo elinqamlezileyo kunye nokwenza ubushushu ngenkqubo yokunciphisa okanye yokubumba, okanye zombini.

Ukwakheka kokugqibela kwesimo kufuneka kwenziwe ngenkqubo yokwakheka eshushu.

Kuya kuvunyelwa ukongeza unyango lobushushu oluqhelekileyo kwiityhubhu ezinobukhulu bodonga obungaphezulu kwe-13mm [1/2 intshi].

Ukwakheka kweekhemikhali ze-ASTM A501

Indlela yoVavanyo: ASTM A751.

Kwimigangatho ye-ASTM A501, kukho iindlela ezimbini zokuhlalutya ukwakheka kweekhemikhali zentsimbi: uhlalutyo lobushushu kunye nohlalutyo lwemveliso.

Uhlalutyo lobushushu lwenziwa ngexesha lenkqubo yokunyibilikisa intsimbi. Injongo yalo kukuqinisekisa ukuba ukwakheka kweekhemikhali zentsimbi kuyahlangabezana neemfuno zomgangatho othile.

Uhlalutyo lwemveliso, kwelinye icala, lwenziwa emva kokuba intsimbi sele yenziwe imveliso. Le ndlela yohlalutyo isetyenziselwa ukuqinisekisa ukuba ulwakhiwo lweekhemikhali lwemveliso yokugqibela luyahlangabezana neemfuno ezichaziweyo.

Iipropati zoomatshini ze-ASTM A501

Iindlela zovavanyo kunye neenkcazo ziyahambelana neemfuno ezifanelekileyo ze-ASTM A370.

Ubukhulu bodonga obuyi-≤ 6.3mm [0.25in] abufuni vavanyo lokuchaphazela.

Ukunyamezelana kwe-ASTM A501 ngokwemilinganiselo

Ukugaya nge-galvanizing

Ukuze iityhubhu zesakhiwo zibe zi-hot-dip galvanized, olu phawu kufuneka luhlangabezane neemfuno zeSpecial A53/A53M.

Linganisa ixabiso lengubo engaphandle kombhobho ukuze ubone ubunzima/ubukhulu bengubo.

Inkangeleko

Iityhubhu zesakhiwo mazingabi naziphene kwaye zibe nomphezulu ogudileyo ngexesha lokwenziwa kwe-hot rolling.

Iziphene zomphezulu ziya kuhlelwa ngolu hlobo xa ubunzulu beziphene zomphezulu budlula i-10% yobukhulu bodonga obuqhelekileyo.

Iziphene ezifuna ukulungiswa mazisuswe ngokupheleleyo ngokusika okanye ngokusila ngaphambi kokuba zifakwe kwi-welding.

Ukumakisha

Uphawu lwe-ASTM A501 kufuneka lube nolwazi olulandelayo ubuncinane:

Igama lomenzi

Uphawu okanye uphawu lwentengiso

Ubungakanani

Igama lomgangatho (unyaka wokupapashwa awufuneki)

Ibanga

Ubude ngabunye bombhobho wolwakhiwo kufuneka buphawulwe ngendlela efanelekileyo, efana nokuqengqeleka, ukunyathela, ukunyathela, okanye ukupeyinta.

Kwiityhubhu zesakhiwo ezingaphantsi kwama-50 mm [2 in] OD, kuvumelekile ukuphawula ulwazi lwentsimbi kwileyibhile eqhotyoshelwe kwiphakheji nganye.

Imigangatho Efanelekileyo

I-ASTM A53/A53M: Iinkcukacha zePipe, iSteel, emnyama neshushu, eneZinc-Coated, eWelded, kunye nengenamthungo.

I-ASTM A370: Iindlela zoVavanyo kunye neeNkcazelo zoVavanyo lweeMveliso zeNsimbi ngoomatshini.

I-ASTM A700: Isikhokelo sokuPakisha, ukuMakisha, kunye neendlela zokulayisha iimveliso zentsimbi zokuthunyelwa.

I-ASTM A751: Iindlela zoVavanyo kunye neMisebenzi yoHlalutyo lweeKhemikhali lweeMveliso zeNsimbi.

I-ASTM A941: Amagama athetha ngentsimbi, intsimbi engatyiwayo, ii-alloys ezinxulumene nayo, kunye nee-Ferroalloys.

Izicelo

Isetyenziswa kakhulu kulwakhiwo kunye nobunjineli bokwakha.

Ukwakhiwa kwebhulorho: ngenxa yeempawu zayo ezintle zoomatshini kunye namandla, ifanelekile kwiindawo ezibalulekileyo zezakhiwo zebhulorho, kubandakanya ii-girders ezithwala imithwalo, iidekhi zebhulorho, kunye nezakhiwo ezixhasayo.

Ukwakhiwa kwezakhiwo: ingasetyenziswa kwisakhiwo sezakhiwo, kuquka iintsika, imiqadi, iinkqubo zokubiyela, kunye neenkxaso zophahla kunye nomgangatho.

Izicelo zoLwakhiwo ngokubanziUkongeza kwiibhulorho nezakhiwo, ikwafanelekile nakwezinye iiprojekthi ezifuna inkxaso yesakhiwo, njengokwakhiwa kwamabala emidlalo, iindawo zokupaka iimoto, izikolo, kunye nezinye izibonelelo ezinkulu zikawonke-wonke.

Izicelo zoshishino: Kwezinye izakhiwo zoshishino, ezinje ngeefektri kunye neendawo zokugcina impahla, le ntsimbi ingasetyenziselwa ukwakha izakhiwo ezixhasayo, izakhelo zophahla, kunye nezinye izakhiwo ezithwala umthwalo.

Iziseko zophuhliso: Le ntsimbi ingasetyenziswa nakwiziseko zophuhliso ezifana neempawu zendlela, izibane, kunye neenqaba zonxibelelwano, umzekelo.

Iingenelo Zethu

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi. Uluhlu olubanzi lwemveliso yenkampani luquka imibhobho yentsimbi engenamthungo, i-ERW, i-LSAW, kunye ne-SSAW, kunye nokufakelwa kwemibhobho, iiflanges, kunye neentsimbi ezikhethekileyo.

Ngokuzibophelela okukhulu kumgangatho, iBotop Steel isebenzisa ulawulo oluqinileyo kunye novavanyo ukuqinisekisa ukuthembeka kweemveliso zayo. Iqela layo elinamava libonelela ngezisombululo ezenzelwe wena kunye nenkxaso yeengcali, igxile ekwanelisekeni kwabathengi.

Iithegi: ASTM a501, ibakala a, ibakala b, ibakala c, ityhubhu yentsimbi, iityhubhu zentsimbi ezakhiweyo.

Ixesha leposi: Meyi-06-2024