I-JIS G 3455yi-Japanese Industrial Standard (JIS) yenkonzo yoxinzelelo oluphezulu kumaqondo obushushu angama-350 °C okanye ngaphantsi, ikakhulu kwiindawo zoomatshini.

Umbhobho wentsimbi we-STS370ngumbhobho wentsimbi onamandla okutsalwa angaphantsi kwe-370 MPa kunye namandla okuvelisa angaphantsi kwe-215 MPa, onomxholo wekhabhoni ongadluli kwi-0.25% kunye nomxholo we-silicon ophakathi kwe-0.10% kunye ne-0.35%, kwaye usetyenziswa kakhulu kwizicelo ezifuna amandla aphezulu kunye nokudityaniswa kakuhle, njengezakhiwo zokwakha, iibhulorho, iinqanawa zoxinzelelo, kunye nezixhobo zenqanawa.

I-JIS G 3455 inamanqanaba amathathu.I-STS370, STS410, STA480.

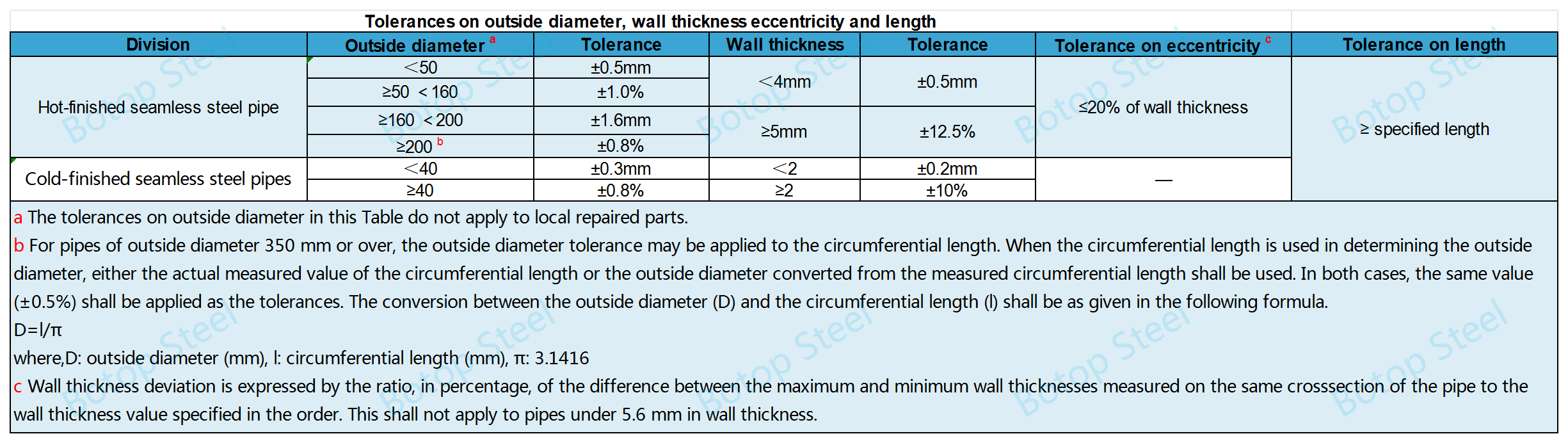

Ububanzi obungaphandle be-10.5-660.4mm (6-650A) (1/8-26B).

Iityhubhu kufuneka zenziwe ngeintsimbi ebuleweyo.

Intsimbi ebuleweyo yintsimbi esuswe ngokupheleleyo ioksijini ngaphambi kokuba ifakwe kwii-ingots okanye kwezinye iindlela. Le nkqubo ibandakanya ukongeza i-deoxidizing agent efana ne-silicon, i-aluminium, okanye i-manganese kwintsimbi ngaphambi kokuba iqine. Igama elithi "ebuleweyo" libonisa ukuba akukho mpendulo yeoksijini eyenzekayo kwintsimbi ngexesha lenkqubo yokuqina.

Ngokususa ioksijini, intsimbi ebuleweyo ithintela ukwakheka kwamaqamza omoya kwintsimbi enyibilikisiweyo, ngaloo ndlela ithintela ukuvuleka kunye namaqamza omoya kwimveliso yokugqibela. Oku kubangela intsimbi efanayo nexineneyo eneempawu zoomatshini eziphezulu kunye nokuqina kwesakhiwo.

Intsimbi ebuleweyo ifanelekile ngokukodwa kwizicelo ezifuna umgangatho ophezulu kunye nokuqina, njengeenqanawa zoxinzelelo, izakhiwo ezinkulu, kunye nemibhobho eneemfuno zomgangatho ophezulu.

Ngokusebenzisa intsimbi ebuleweyo ukuvelisa iityhubhu, unokuqiniseka ngokusebenza ngcono kunye nobomi benkonzo obude, ingakumbi kwiindawo ezithwaxwa yimithwalo enzima kunye noxinzelelo.

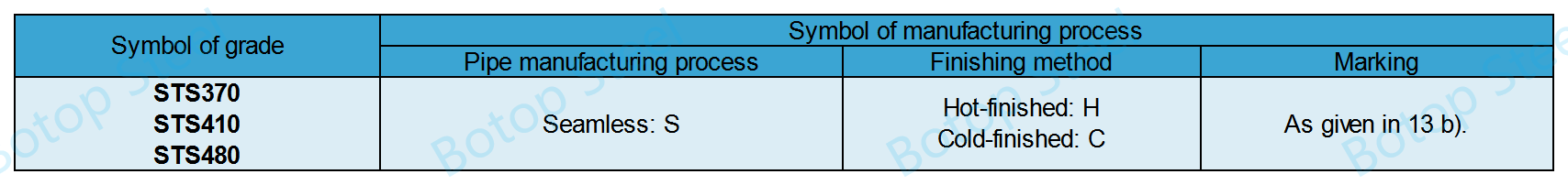

Yenziwe kusetyenziswa inkqubo yokuvelisa engenamthungo kunye nendlela yokugqiba.

Umbhobho wesinyithi ongenamthungo ogqityiweyo ngobushushu: SH;

Umbhobho wentsimbi engenamthungo ogqityiweyo ebandayo: SC.

Kwinkqubo yokwenziwa engenamthungo, ingahlulwahlulwa ibe yimibhobho yentsimbi engenamthungo enobubanzi bangaphandle obungaphezulu kwe-30mm kusetyenziswa imveliso yokugqiba eshushu, kunye ne-30mm kusetyenziswa imveliso yokugqiba ebandayo.

Nantsi indlela yokuvelisa i-Hot-finished seamless.

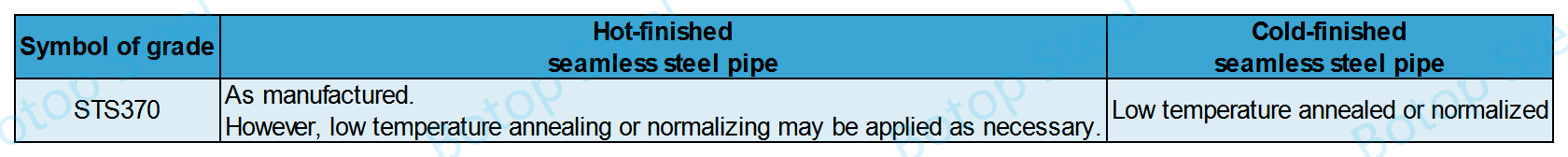

Ukufakelwa kobushushu obuphantsi kusetyenziswa kakhulu ukuphucula ukusebenza kakuhle kwezinto, ukunciphisa ubulukhuni, nokuphucula ubulukhuni, kwaye kufanelekile kwintsimbi ebanda.

Ukulungisa izinto kusetyenziselwa ukuphucula amandla nokuqina kwezinto, ukuze intsimbi ifaneleke ngakumbi ukumelana noxinzelelo loomatshini kunye nokudinwa, okuhlala kusetyenziselwa ukuphucula ukusebenza kwentsimbi ebandayo.

Ngezi nkqubo zonyango lobushushu, ulwakhiwo lwangaphakathi lwentsimbi luyaphuculwa kwaye iimpawu zayo ziyaphuculwa, nto leyo eyenza ukuba ifaneleke ngakumbi ukusetyenziswa kwiindawo ezifuna ukusetyenziswa kwemizi-mveliso.

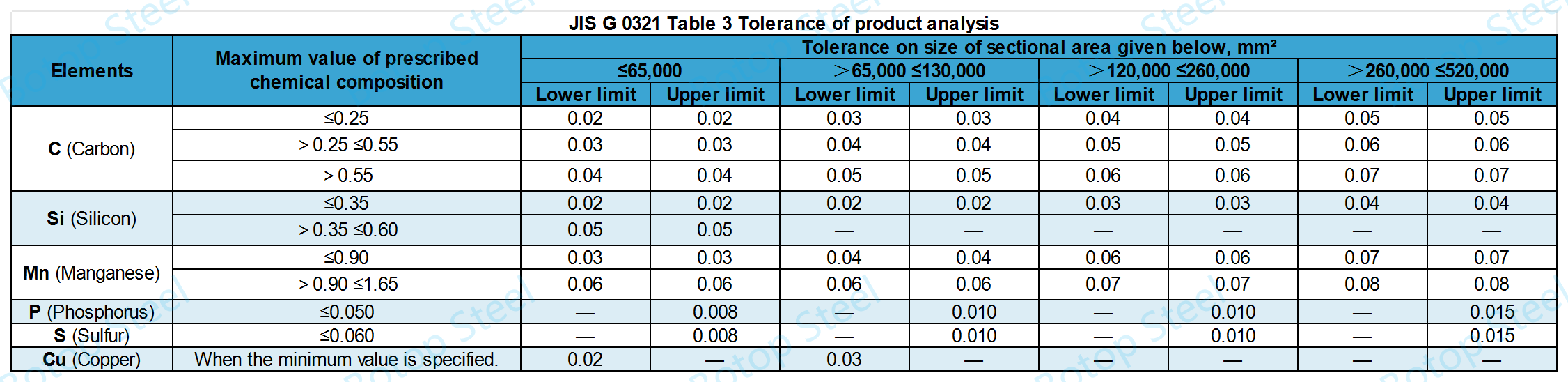

Uhlalutyo lobushushu kufuneka luhambelane ne-JIS G 0320. Uhlalutyo lwemveliso kufuneka luhambelane ne-JIS G 0321.

| ibakala | C (Ikhabhoni) | I-Si (iSilicon) | I-Mn (iManganese) | I-P (iPhosphorus) | S (Isalfure) |

| I-STS370 | Ubuninzi be-0.25% | 0.10-0.35% | 0.30-1.10% | Ubuninzi be-0.35% | Ubuninzi be-0.35% |

Uhlalutyo lobushushuijolise kakhulu ekuvavanyeni ukwakheka kweekhemikhali zezinto ezikrwada.

Ngokuhlalutya ukwakheka kweekhemikhali zezinto ezikrwada, kunokwenzeka ukuqikelela nokulungisa amanyathelo okucubungula kunye neemeko ezinokuthi zifuneke kwinkqubo yemveliso, ezifana neeparameter zonyango lobushushu kunye nokongezwa kwezinto ezixutyiweyo.

Uhlalutyo lwemvelisoihlalutya ukwakheka kweekhemikhali zeemveliso ezigqityiweyo ukuqinisekisa ukuthotyelwa kunye nomgangatho wemveliso yokugqibela.

Uhlalutyo lwemveliso luqinisekisa ukuba zonke iinguqu, izongezo okanye naluphi na ukungcola okunokwenzeka kwimveliso ngexesha lenkqubo yokuvelisa kuyalawulwa kwaye imveliso yokugqibela iyahlangabezana neemfuno zobugcisa kunye neemfuno zokusetyenziswa.

I-JIS G 3455 ixabiso lohlalutyo lwemveliso aliyi kuhambelana kuphela neemfuno zezinto ezikwitheyibhile engentla, kodwa noluhlu lokunyamezelana luya kuhambelana neemfuno ze-JIS G 3021 Itheyibhile 3.

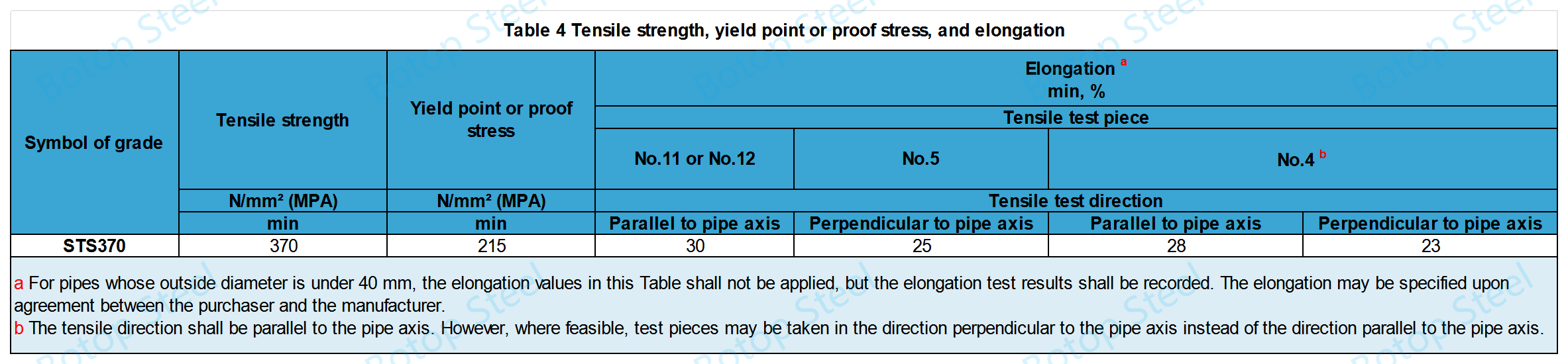

Amaxabiso obude becandelo lovavanyo No. 12 (elihambelana ne-axis yombhobho) kunye necandelo lovavanyo No. 5 (elithe nkqo kwi-axis yombhobho) elithathwe kwiipayipi ezingaphantsi kwe-8 mm ubukhulu bodonga.

| Uphawu lwebanga | Isixhobo sovavanyo esisetyenzisiweyo | Ukwandiswa umzuzu, % | ||||||

| Ubukhulu bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| I-STS370 | Inombolo 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Inombolo 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Amaxabiso okunwebeka kule theyibhile afunyanwa ngokuthabatha i-1.5% kwixabiso lokunwebeka elinikiweyo kwiTheyibhile 4 yokuncipha ngakunye kwe-1 mm kubukhulu bodonga ukusuka kwi-8 mm, nangokujikelezisa isiphumo sibe yinani elipheleleyo ngokweMithetho A ye-JIS Z 8401. | ||||||||

Uvavanyo lokuthamba lunokungafakwa ngaphandle kokuba kuchazwe ngenye indlela ngumthengi.

Beka isampuli kumatshini uze uyicaba de umgama ophakathi kwamaqonga amabini ufikelele kwixabiso elichaziweyo u-H. Emva koko jonga isampuli ukuba ayinazimfanta na.

Xa kuvavanywa umbhobho odibeneyo ochasene nobunzima obubalulekileyo, umgca ophakathi kwe-weld kunye nombindi wombhobho umi nkqo kwicala lokucinezelwa.

H=(1+e)t/(e+t/D)

H: umgama phakathi kweeplatens (mm)

t: ubukhulu bodonga lwetyhubhu (mm)

D: ububanzi obungaphandle betyhubhu (mm)

e:ichazwe rhoqo kwinqanaba ngalinye letyhubhu.0.08 kwi-STS370: 0.07 kwi-STS410 kunye ne-STS480.

Ifanelekile kwiipayipi ezinobubanzi obungaphandle obuyi-≤ 50 mm.

Isampuli mayingabi nazimfa xa igobile kwi-90° kunye nobubanzi bangaphakathi obuphindwe kathandathu kunobubanzi bangaphandle bombhobho.

I-engile yokugoba mayilinganiswe ekuqaleni kokugoba.

Yonke imibhobho yentsimbi kufuneka ivavanywe ngamanzi okanye ingatshabalalisiukuqinisekisa umgangatho nokhuseleko lombhobho kunye nokuhlangabezana nemigangatho yokusetyenziswa.

Uvavanyo lweHydraulic

Ukuba akukho xinzelelo lovavanyo luchaziweyo, uxinzelelo oluphantsi lovavanyo lwe-hydro luya kugqitywa ngokuhambelana neShedyuli yeMibhobho.

| Ubukhulu bodonga oluqhelekileyo | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Uxinzelelo oluphantsi lovavanyo lwe-hydraulic, i-Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Xa ubukhulu bodonga lobubanzi bangaphandle bombhobho wentsimbi bungengoxabiso eliqhelekileyo kwitheyibhile yobunzima bombhobho wentsimbi, kuyimfuneko ukusebenzisa le fomula ukubala ixabiso loxinzelelo.

P=2st/D

Puxinzelelo lovavanyo (MPa)

t: ubukhulu bodonga lombhobho (mm)

D: ububanzi bangaphandle bombhobho (mm)

s: 60% yexabiso elincinci le-yield point okanye uxinzelelo lobungqina olunikiweyo.

Xa uxinzelelo oluncinci lovavanyo lwe-hydrostatic lwenombolo yesicwangciso esikhethiweyo ludlula uxinzelelo lovavanyo u-P olufunyenwe yifomula, uxinzelelo u-P luya kusetyenziswa njengoxinzelelo oluncinci lovavanyo lwe-hydrostatic endaweni yokukhetha uxinzelelo oluncinci lovavanyo lwe-hydrostatic kwitheyibhile engentla.

Uvavanyo olungatshabalalisiyo

Uvavanyo olungonakalisiyo lweetyhubhu zentsimbi kufuneka lwenziwe nguuvavanyo lwe-ultrasonic okanye lwe-eddy current.

Ngokubai-ultrasoundiimpawu zokuhlola, uphawu oluvela kwisampulu yesalathiso equlethe umgangatho wesalathiso weklasi ye-UD njengoko kuchaziwe kwiI-JIS G 0582kufuneka ithathwe njengenqanaba le-alamu kwaye kufuneka ibe nesignali esisiseko elingana okanye engaphezulu kwenqanaba le-alamu.

Uvakalelo oluqhelekileyo lokuchongwa kweumsinga we-eddyUvavanyo luza kuba ludidi lwe-EU, i-EV, i-EW, okanye i-EX oluchazwe kwiI-JIS G 0583, kwaye akuyi kubakho zimpawu zilingana okanye zinkulu kunezibonakaliso ezivela kwisampulu yesalathiso equlethe umgangatho wesalathiso wolu didi lukhankanyiweyo.

Ukuze ufumane okungakumbiIitshati zoBunzima beePipe kunye neeShedyuli zeePipengaphakathi komgangatho, ungacofa.

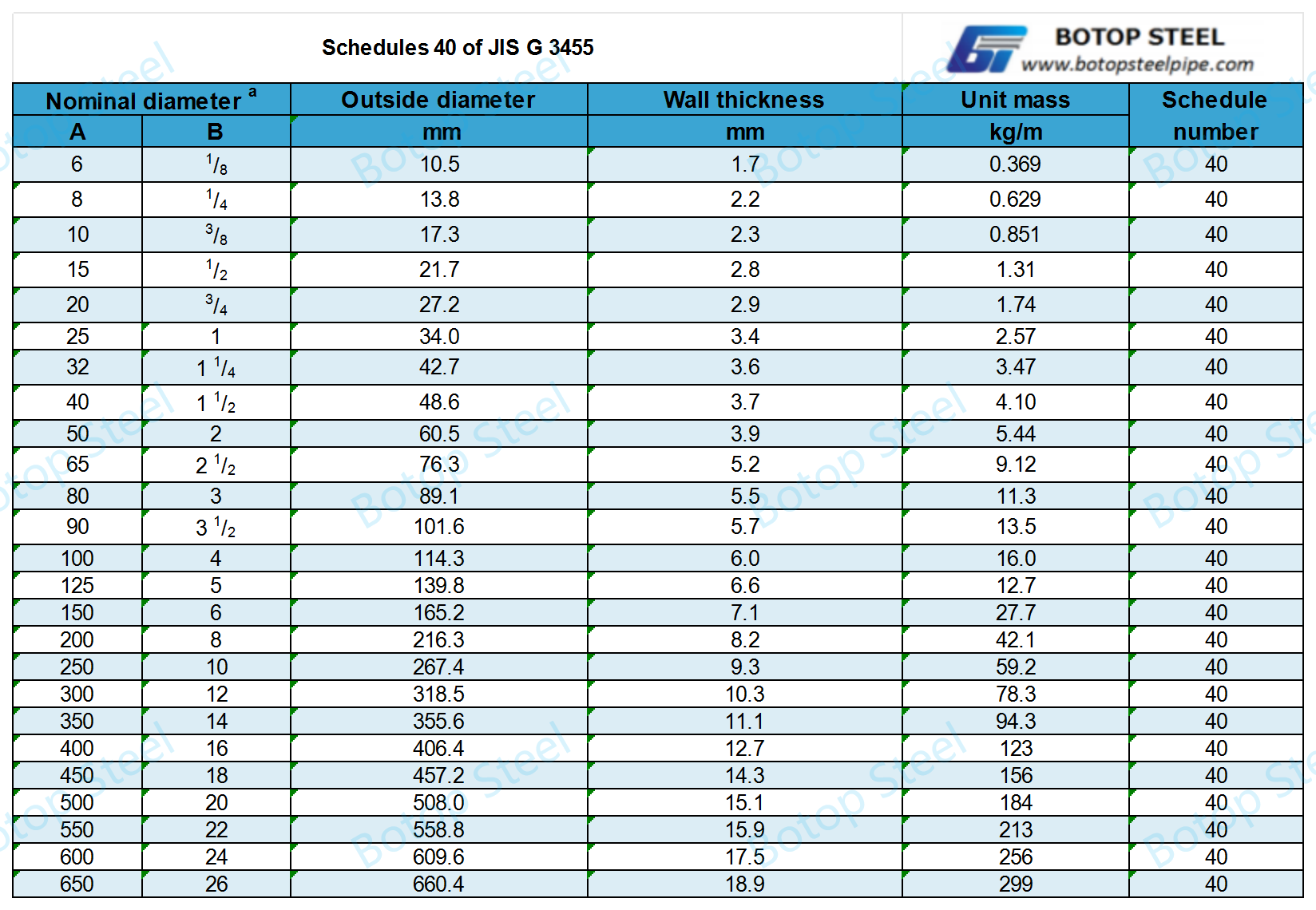

Umbhobho weShedyuli 40 ufanelekile kakhulu kwiindlela zokusetyenziswa koxinzelelo oluphantsi ukuya koluphakathi kuba unika ubukhulu bodonga obuphakathi obuthintela ubunzima obugqithisileyo kunye neendleko ngelixa uqinisekisa amandla aneleyo.

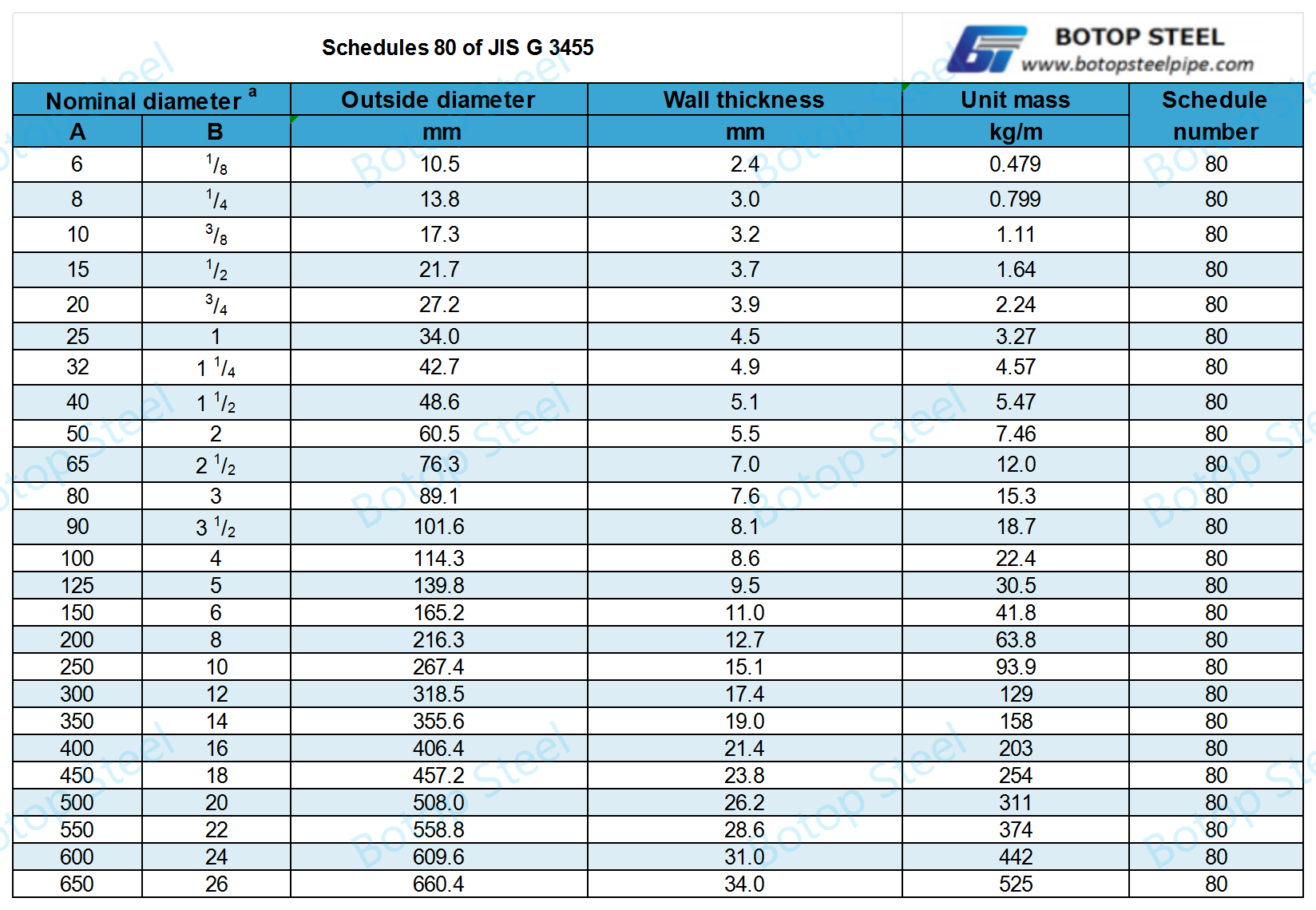

I-Schedule 80 piping isetyenziswa kakhulu kwiindawo zoshishino ezifuna ukuphathwa ngoxinzelelo oluphezulu, njengeenkqubo zokucubungula iikhemikhali kunye nemibhobho yokudlulisa ioyile negesi, ngenxa yokukwazi kwayo ukumelana noxinzelelo oluphezulu kunye neempembelelo ezinamandla zoomatshini ngenxa yobukhulu bayo bodonga, okubonelela ngokhuseleko olongezelelweyo, ukhuseleko, kunye nokuqina.

Ityhubhu nganye mayibhalwe ngolu lwazi lulandelayo.

a)Uphawu lwebanga;

b)Uphawu lwendlela yokuvelisa;

c)UbukhuluUmzekelo 50AxSch80 okanye 60.5x5.5;

d)Igama lomenzi okanye uphawu oluchazayo.

Xa ububanzi bangaphandle betyhubhu nganye buncinci kwaye kunzima ukuphawula ityhubhu nganye, okanye xa umthengi efuna ukuba ityhubhu nganye iphawulwe, ityhubhu nganye inokuphawulwa ngendlela efanelekileyo.

I-STS370 ifanelekile kwiinkqubo zokudlulisa ulwelo ezinoxinzelelo oluphantsi kodwa ezinobushushu obuphezulu.

Iinkqubo zokufudumeza: Kwiinkqubo zokufudumeza isixeko okanye kwizakhiwo ezinkulu, i-STS370 ingasetyenziselwa ukuthutha amanzi ashushu okanye umphunga kuba inokumelana noxinzelelo kunye notshintsho lobushushu kwinkqubo.

Izityalo zombane: Kwimveliso yombane, kufuneka inani elikhulu leepayipi zomphunga ezinoxinzelelo oluphezulu, kwaye i-STS370 yeyona nto ifanelekileyo yokwenza ezi payipi kuba inokumelana nexesha elide lobushushu obuphezulu kunye neendawo zokusebenza ezinoxinzelelo oluphezulu.

Iinkqubo zomoya ezicinezelweyo: Kwimizila yokuvelisa neyemveliso ezenzekelayo, umoya ocinezelweyo ngumthombo obalulekileyo wamandla, kwaye umbhobho wentsimbi we-STS370 usetyenziselwa ukwakha imibhobho yezi nkqubo ukuqinisekisa ukuhanjiswa komoya okukhuselekileyo nokufanelekileyo.

Ukusetyenziswa kwesakhiwo kunye noomatshini ngokubanziNgenxa yeempawu zayo ezilungileyo zoomatshini, i-STS370 ingasetyenziswa nakwimveliso yezinto ezahlukeneyo zokwakha nezoomatshini, ingakumbi kwizicelo apho kufuneka amandla athile okucinezela.

I-JIS G 3455 STS370 sisixhobo sentsimbi yekhabhoni esisetyenziswa kwinkonzo yoxinzelelo oluphezulu. Ezi zinto zilandelayo zinokuthathwa njengezilinganayo okanye eziphantse zilingane:

1. I-ASTM A53 Ibanga B: Ifanelekile ukusetyenziswa ngokubanzi kwesakhiwo kunye noomatshini kunye nokuthuthwa kolwelo.

2. I-API 5L Ibanga B: Kwimibhobho yokuthutha ioyile negesi enoxinzelelo oluphezulu.

3. I-DIN 1629 St37.0: Yobunjineli boomatshini ngokubanzi kunye nokwakhiwa kweenqanawa.

4. I-EN 10216-1 P235TR1: Umbhobho wentsimbi ongenamthungo olungele ubushushu obuphezulu kunye noxinzelelo oluphezulu.

5. I-ASTM A106 Ibanga B: Umbhobho wentsimbi yekhabhoni ongenamthungo wenkonzo yobushushu obuphezulu.

6.I-ASTM A179: Iityhubhu zentsimbi ethambileyo ezitsalwa ngokubandayo ezingenamthungo kunye neepayipi zenkonzo yobushushu obuphantsi.

7. I-DIN 17175 St35.8: Izinto zetyhubhu ezingenamthungo zeebhoyila kunye neenqanawa zoxinzelelo.

8. I-EN 10216-2 P235GH: Iityhubhu kunye neepayipi ezingenamthungo ezenziwe ngentsimbi engaxutywanga neye-alloy zeendawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu.

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi. Le nkampani inikezela ngeentlobo ngeentlobo zemibhobho yentsimbi yekhabhoni kunye neemveliso ezinxulumene nayo, kubandakanya i-seamless, i-ERW, i-LSAW, kunye nombhobho wentsimbi we-SSAW, kunye noluhlu olupheleleyo lwezixhobo zemibhobho kunye neeflanges.

Iimveliso zayo ezikhethekileyo ziquka ii-alloys zodidi oluphezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.