Umbhobho wentsimbi we-JIS G 3461ngumbhobho wentsimbi yekhabhoni ongenamthungo (SMLS) okanye oxhathisa umbane (ERW), osetyenziswa kakhulu kwiibhoyila nakwii-heat exchangers kwizicelo ezifana nokwenza utshintsho lobushushu phakathi kwetyhubhu ngaphakathi nangaphandle kwayo.

STB340yipayipi yentsimbi yekhabhoni esemgangathweni weJIS G 3461. Inamandla okutsalwa aphantsi angama-340 MPa kwaye amandla okuvelisa aphantsi angama-175 MPa.

Yinto ekhethwayo kwiimveliso ezininzi ngenxa yamandla ayo aphezulu, uzinzo oluhle lobushushu, ukukwazi ukuguquguquka, ukumelana nokugqwala, ukusebenza kakuhle kweendleko, kunye nokuqhubekeka kakuhle kokusetyenziswa.

I-JIS G 3461ineeklasi ezintathu.STB340, STB410, STB510.

STB340Amandla okutsalwa aphantsi: 340 MPa; Amandla amancinci okuvelisa: 175 MPa.

STB410: Amandla okuThamba aphantsi: 410 MPa; Amandla okuKhula aphantsi: 255 MPa.

STB510:Amandla okuThamba aphantsi: 510 MPa; Amandla okuKhula aphantsi: 295 MPa.

Enyanisweni, akunzima ukufumanisa ukuba i-JIS G 3461 grade ihlelwe ngokwezinga eliphantsi lokutsalwa kwepayipi yentsimbi.

Njengoko umgangatho wezinto zokwakha usanda, amandla azo okuxinana kunye nokuvelisa ayanda ngokufanelekileyo, nto leyo evumela ukuba izinto zokwakha zikwazi ukumelana nemithwalo ephezulu kunye noxinzelelo kwiindawo zokusebenza ezinzima ngakumbi.

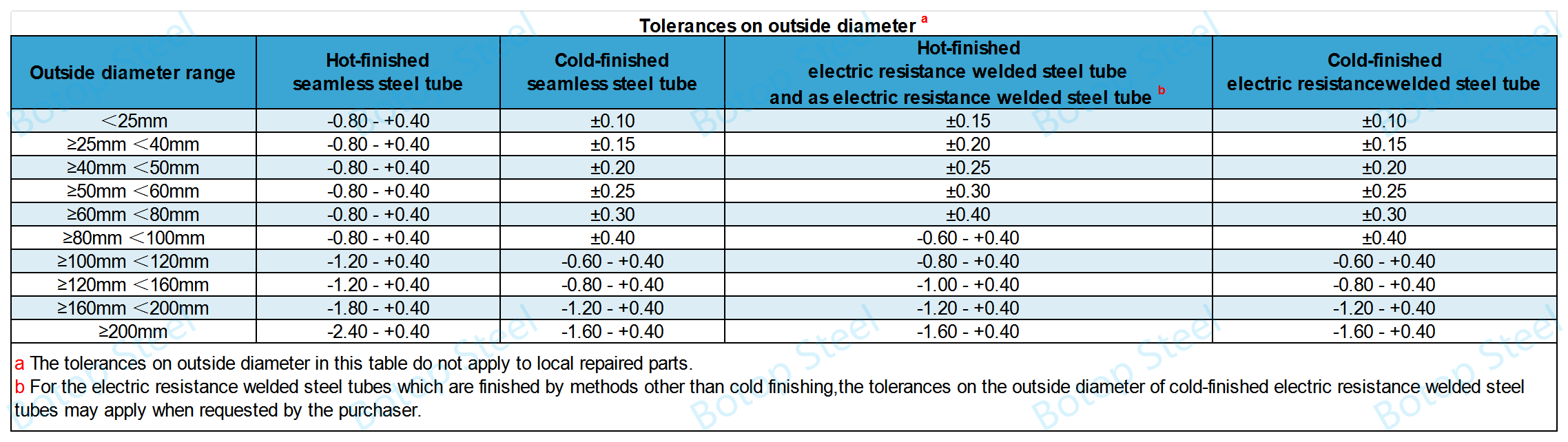

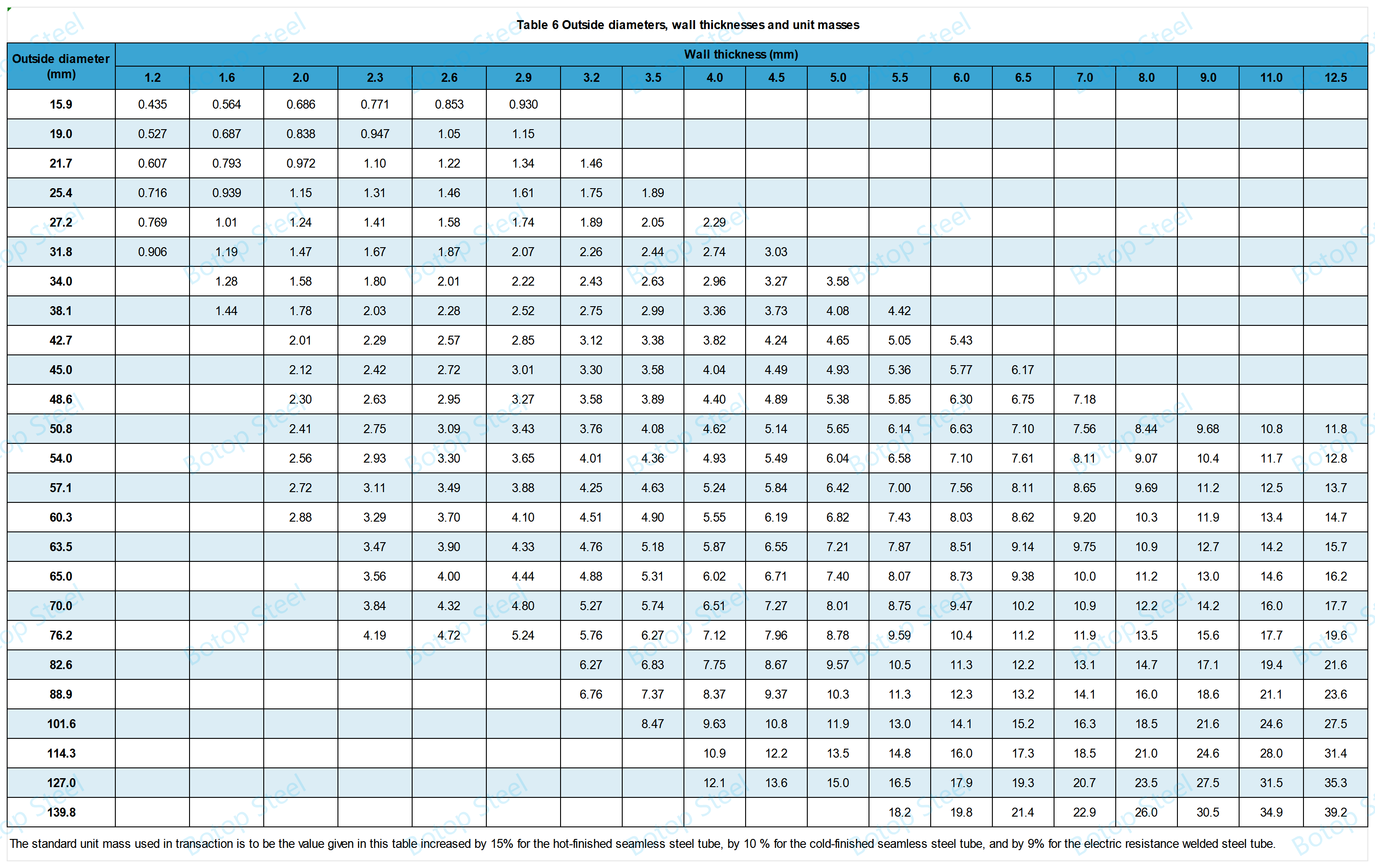

Ububanzi obungaphandle buyi-15.9-139.8mm.

Ukusetyenziswa kwiibhoyila nakwii-heat exchangers akudli ngokufuna ububanzi beetyhubhu ezinkulu kakhulu. Ububanzi beetyhubhu ezincinci zonyusa ukusebenza kakuhle kobushushu kuba umlinganiselo womphezulu ukuya kumthamo wokudluliselwa kobushushu uphezulu. Oku kunceda ukudlulisa amandla obushushu ngokukhawuleza nangokufanelekileyo.

Iityhubhu kufuneka zenziwe ngeintsimbi ebuleweyo.

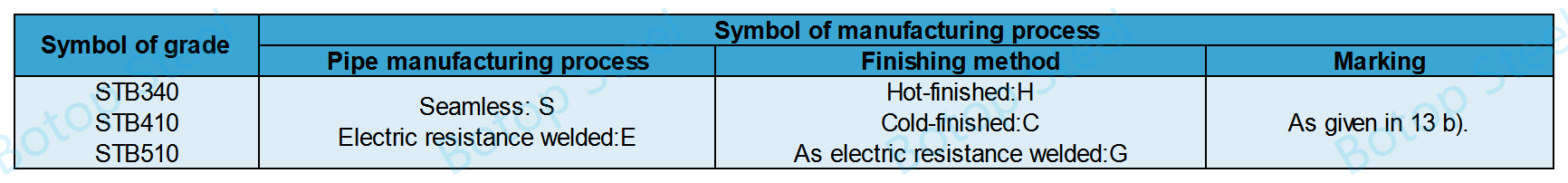

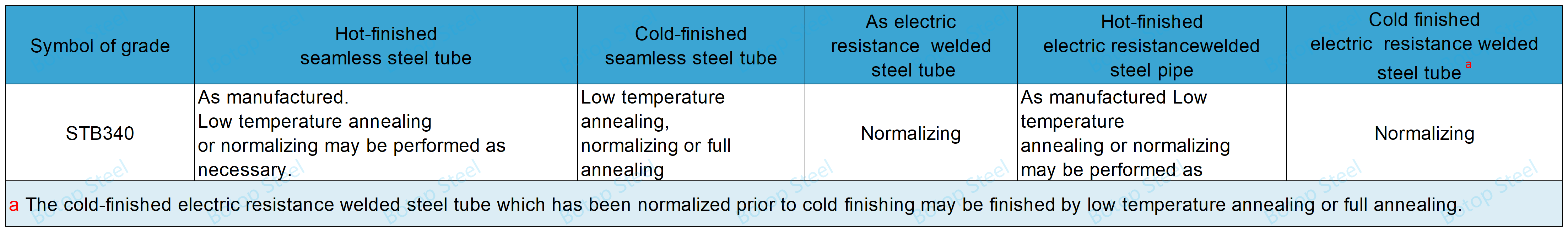

Ukudibanisa iindlela zokwenza iipayipi kunye neendlela zokugqiba.

Ngokweenkcukacha, zinokuhlulwahlulwa ngolu hlobo lulandelayo:

Ityhubhu yentsimbi engenamthungo egqityiweyo eshushu: SH

Ityhubhu yentsimbi engenamthungo egqityiweyo ebandayo: SC

Njengoko ityhubhu yentsimbi edibeneyo yokumelana nombane: EG

Ityhubhu yentsimbi edityanisiweyo eshushu enokuxhathisa umbane: EH

Ityhubhu yentsimbi edityanisiweyo yokumelana nombane egqityiweyo kubanda: EC

Nantsi indlela yokuvelisa i-Hot-finished seamless.

Kwinkqubo yokwenziwa engenamthungo, ingahlulwahlulwa ibe yimibhobho yentsimbi engenamthungo enobubanzi bangaphandle obungaphezulu kwe-30mm kusetyenziswa imveliso yokugqiba eshushu, kunye ne-30mm kusetyenziswa imveliso yokugqiba ebandayo.

Iindlela zohlalutyo lobushushu kufuneka zihambelane nemigangatho ekwi-JIS G 0320.

Izinto ezidibanisayo ngaphandle kwezo zingongezwa ukuze kufunyanwe iimpawu ezithile.

Xa imveliso ihlalutywa, amaxabiso okuphambuka kokwakheka kweekhemikhali zombhobho aya kuhlangabezana neemfuno zeTheyibhile 3 ye-JIS G 0321 yeepayipi zentsimbi ezingenamthungo kunye neTheyibhile 2 ye-JIS G 0321 yeepayipi zentsimbi ezidityaniswe nokumelana.

| Uphawu lwebanga | C (iKhabhoni) | I-Si (iSilicon) | I-Mn (iManganese) | I-P (iPhosphorus) | S (Isalfure) |

| ubuninzi | ubuninzi | ubuninzi | ubuninzi | ||

| STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Umthengi angachaza isixa se-Si esiphakathi kwe-0.10% ukuya kwi-0.35%. | |||||

Ulwakhiwo lweekhemikhali ze-STB340 luyilelwe ukuqinisekisa iipropati ezifanelekileyo zoomatshini kunye nokusebenza kakuhle koomatshini ngelixa lusenza ukuba izinto zilungele ukuwelda kunye nokusetyenziswa kwiindawo ezinobushushu obuphezulu.

| Uphawu lwebanga | Amandla okutsalwa a | Ingongoma yokukhupha okanye uxinzelelo lobungqina | Ubungakanani obuncinci, % | ||

| Ububanzi obungaphandle | |||||

| <10mm | ≥10mm <20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Isiqwenga sovavanyo | |||

| Inombolo 11 | Inombolo 11 | Inombolo 11/Inombolo 12 | |||

| umzuzu | umzuzu | Isikhokelo sovavanyo lokuxinana | |||

| Ihambelana ne-axis yetyhubhu | Ihambelana ne-axis yetyhubhu | Ihambelana ne-axis yetyhubhu | |||

| STB340 | 340 | 175 | 27 | 30 | 35 |

Qaphela: ngokukodwa kwiityhubhu zokutshintsha ubushushu, umthengi angachaza, apho kuyimfuneko, ixabiso eliphezulu lamandla okutsalwa. Kule meko, ixabiso eliphezulu lamandla okutsalwa liya kuba lixabiso elifunyenwe ngokongeza i-120 N/mm² kwixabiso elikule theyibhile.

Xa uvavanyo lokutsalwa luqhutywa kwiCandelo loVavanyo No. 12 letyhubhu engaphantsi kwe-8 mm ubukhulu bodonga.

| Uphawu lwebanga | Isixhobo sovavanyo esisetyenzisiweyo | Ukwandiswa umzuzu, % | ||||||

| Ubukhulu bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| STB340 | Inombolo 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Amaxabiso okunwebeka kule theyibhile abalwa ngokuthabatha i-1.5% kwixabiso lokunwebeka elinikiweyo kwiTheyibhile 4 yokuncipha ngakunye kwe-1 mm kubukhulu bodonga lwetyhubhu ukusuka kwi-8 mm, nangokujikelezisa isiphumo sibe yinani elipheleleyo ngokweMithetho A yeJIS Z 8401.

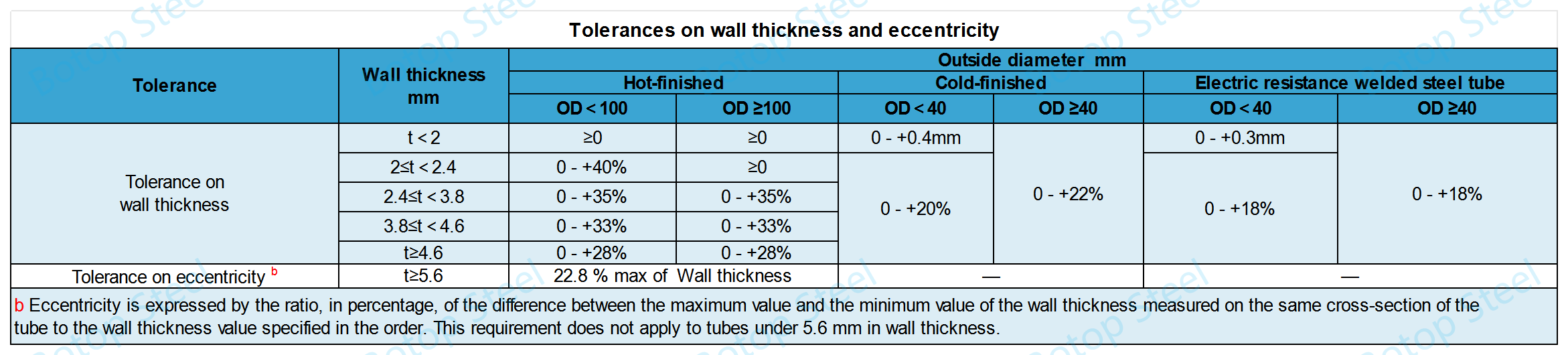

Indlela yovavanyo mayihambelane ne-JIS Z 2245. Ubunzima besiqwenga sovavanyo buya kulinganiswa kwicandelo laso elinqamlezileyo okanye umphezulu wangaphakathi kwiindawo ezintathu kwisiqwenga sovavanyo ngasinye.

| Uphawu lwebanga | Ubulukhuni beRockwell (ixabiso eliphakathi leendawo ezintathu) I-HRBW |

| STB340 | 77 ubuninzi. |

| STB410 | Ubuninzi obuyi-79. |

| STB510 | 92 ubuninzi. |

Olu vavanyo aluyi kwenziwa kwiityhubhu ezinobukhulu bodonga obuyi-2 mm okanye ngaphantsi. Kwiityhubhu zentsimbi ezidityanisiweyo ezixhathisa umbane, uvavanyo lufanele lwenziwe kwicandelo elingaphandle kwe-weld okanye kwiindawo ezichaphazelekileyo bubushushu.

Ayisebenzi kwiityhubhu zentsimbi ezingenamthungo.

Indlela Yovavanyo Beka isampuli kumatshini uze uyicaba ude umgama ophakathi kwamaqonga amabini ufikelele kwixabiso elichaziweyo u-H. Emva koko jonga isampuli ukuba ayinazimfanta.

Xa kuvavanywa umbhobho odibeneyo ochasene nobunzima obubalulekileyo, umgca ophakathi kwe-weld kunye nombindi wombhobho umi nkqo kwicala lokucinezelwa.

H=(1+e)t/(e+t/D)

H: umgama phakathi kweeplatens (mm)

t: ubukhulu bodonga lwetyhubhu (mm)

D: ububanzi obungaphandle betyhubhu (mm)

e:i-constant echazwe kwinqanaba ngalinye letyhubhu. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Ayisebenzi kwiityhubhu zentsimbi ezingenamthungo.

Isiphelo esinye sesampuli sivutha kubushushu begumbi (5°C ukuya kuma-35°C) ngesixhobo esijijekileyo kwi-engile yama-60° de ububanzi bangaphandle bukhuliswe nge-1.2 kwaye kuhlolwe ukuba akukho mifantu.

Le mfuneko ikwasebenza nakwiityhubhu ezinobubanzi obungaphandle obungaphezulu kwe-101.6 mm.

Uvavanyo lokuthamba olubuyela umva lunokungafakwa xa kusenziwa uvavanyo lokuthamba.

Sika isiqwenga sovavanyo esinobude obuyi-100 mm ukusuka kwelinye icala lombhobho uze usike isiqwenga sovavanyo sibe sisiqingatha se-90° ukusuka kumgca we-weld kumacala omabini omjikelezo, uthabathe isiqingatha esiqulethe i-weld njengesiqwenga sovavanyo.

Kubushushu begumbi (5°C ukuya kuma-35°C) lungisa isampuli ibe yipleyiti ene-weld phezulu uze uhlole isampuli ukuba ayinazimfanta kwi-weld.

Yonke imibhobho yentsimbi kufuneka ivavanywe ngamanzi okanye ingatshabalalisiukuqinisekisa umgangatho nokhuseleko lombhobho kunye nokuhlangabezana nemigangatho yokusetyenziswa.

Uvavanyo lweHydraulic

Bamba ingaphakathi lombhobho kuxinzelelo oluphantsi okanye oluphezulu lwe-P (P max 10 MPa) ubuncinane imizuzwana emi-5, uze ujonge ukuba umbhobho ungamelana noxinzelelo ngaphandle kokuvuza.

P=2st/D

Puxinzelelo lovavanyo (MPa)

t: ubukhulu bodonga lwetyhubhu (mm)

D: ububanzi obungaphandle kwetyhubhu (mm)

s: 60% yexabiso eliphantsi elichaziweyo le-yield point okanye uxinzelelo lobungqina.

Uvavanyo olungatshabalalisiyo

Uvavanyo olungonakalisiyo lweetyhubhu zentsimbi kufuneka lwenziwe nguuvavanyo lwe-ultrasonic okanye lwe-eddy current.

Ngokubai-ultrasoundiimpawu zokuhlola, uphawu oluvela kwisampulu yesalathiso equlethe umgangatho wesalathiso weklasi ye-UD njengoko kuchaziwe kwiI-JIS G 0582kufuneka ithathwe njengenqanaba le-alamu kwaye kufuneka ibe nesignali esisiseko elingana okanye engaphezulu kwenqanaba le-alamu.

Uvakalelo oluqhelekileyo lokuchongwa kweumsinga we-eddyUvavanyo luza kuba ludidi lwe-EU, i-EV, i-EW, okanye i-EX oluchazwe kwiI-JIS G 0583, kwaye akuyi kubakho zimpawu zilingana okanye zinkulu kunezibonakaliso ezivela kwisampulu yesalathiso equlethe umgangatho wesalathiso wolu didi lukhankanyiweyo.

Ukuze ufumane okungakumbiIitshati zoBunzima beePipe kunye neeShedyuli zeePipengaphakathi komgangatho, ungacofa.

Sebenzisa indlela efanelekileyo yokubhala iilebheli kolu lwazi lulandelayo.

a) Uphawu lomgangatho;

b) Uphawu lwendlela yokuvelisa;

c) Ubukhulu: ububanzi bangaphandle kunye nobukhulu bodonga;

d) Igama lomenzi okanye uphawu olumchazayo.

Xa uphawu kwityhubhu nganye lunzima ngenxa yobubanzi bayo obuncinci bangaphandle okanye xa umthengi ecelile njalo, uphawu lunokunikwa kwiphakheji nganye yeetyhubhu ngendlela efanelekileyo.

I-STB340 isetyenziswa kakhulu ekwenzeni imibhobho yamanzi kunye nemibhobho yeflue kwiibhoyila ezahlukeneyo zoshishino, ingakumbi kwiindawo apho kufuneka ukumelana namaqondo obushushu aphezulu kunye noxinzelelo.

Ngenxa yeempawu zayo ezilungileyo zokuhambisa ubushushu, ikwafanelekile ekwenzeni imibhobho yezixhobo zokutshintshiselana ubushushu, inceda ekudluliseni ubushushu ngokufanelekileyo phakathi kweendawo ezahlukeneyo zokusasaza ubushushu.

Ingasetyenziselwa ukuthutha ulwelo olushushu kakhulu okanye olunoxinzelelo oluphezulu, olufana nomphunga okanye amanzi ashushu, kwaye isetyenziswa kakhulu kumashishini okuvelisa iikhemikhali, amandla ombane, kunye noomatshini.

I-ASTM A106 Ibanga A

I-DIN 17175 St35.8

I-DIN 1629 St37.0

I-BS 3059-1 Ibanga 320

I-EN 10216-1 P235GH

GB 3087 20#

I-GB 5310 20G

Nangona ezi zinto zinokufana ngokwemilo yeekhemikhali kunye neempawu ezisisiseko, iinkqubo ezithile zonyango lobushushu kunye nomatshini wokwenza izinto zinokuchaphazela iimpawu zemveliso yokugqibela.

Ngoko ke, uthelekiso oluneenkcukacha kunye novavanyo olufanelekileyo kufuneka lwenziwe xa kukhethwa izixhobo ezifanayo kwizicelo ezisebenzayo.

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi. Le nkampani inikezela ngeentlobo ngeentlobo zemibhobho yentsimbi yekhabhoni kunye neemveliso ezinxulumene nayo, kubandakanya i-seamless, i-ERW, i-LSAW, kunye nombhobho wentsimbi we-SSAW, kunye noluhlu olupheleleyo lwezixhobo zemibhobho kunye neeflanges.

Iimveliso zayo ezikhethekileyo ziquka ii-alloys zodidi oluphezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.