I-EN 10219 S275J0H kunye ne-S275J2Hziinxalenye ezingenanto ezibunjiweyo ezakhiwe ngokubandayo ezenziwe ngentsimbi engaxutywanga ngokwe-EN 10219.

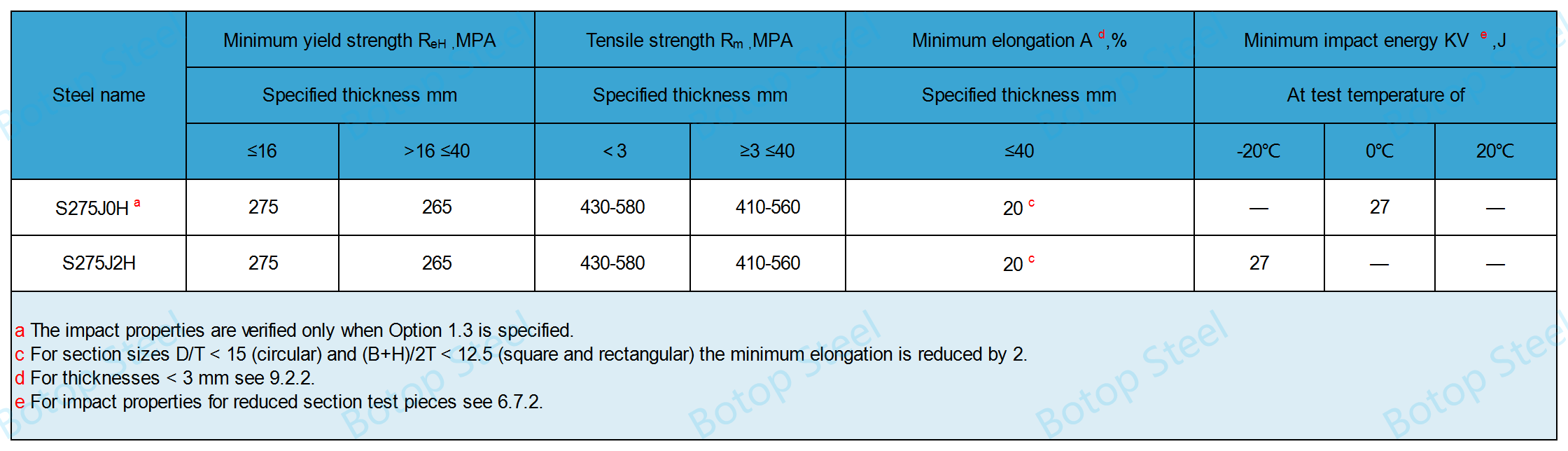

Zombini zinamandla okuvelisa ubuncinane be-275MPa (ubukhulu bodonga ≤16mm). Umahluko ophambili ukwiimpawu zempembelelo: I-S275J0H inamandla okuvelisa ubuncinane be-27 J kwi-0°C, ngelixa i-S275J2H inamandla okuvelisa ubuncinane be-27 J kwi--20°C.

Ifanelekile ukusetyenziswa kwizakhiwo nakwizakhiwo zobunjineli ezithwala imithwalo elula.

I-BS EN 10219 yi-European Standard EN 10219 eyamkelwe yi-UK.

Ubukhulu bodonga ≤40mm, Ububanzi bangaphandle ≤2500mm.

I-CFCHS sisifinyezo seCandelo eliyi-Cold-Formed Circular Hollow Section.

Umgangatho we-EN 10219 ugubungela uluhlu olubanzi lweemilo zentsimbi ezingenanto, kubandakanya umjikelo, isikwere, uxande, kunye no-oval, ukuze kuhambelane neemfuno ezahlukeneyo zokusetyenziswa.

Intsimbi yeBotopIngcali ekuboneleleni ngeetyhubhu zentsimbi ezingqukuva ezineenxalenye ezahlukeneyo ngobukhulu kunye neenkqubo ukuze zilungele uluhlu olubanzi lwezicelo zoshishino, iqinisekisa ukuba iimfuno ezithile zabathengi bethu zinokufezekiswa.

Ukususela oko yasekwa ngo-2014,Intsimbi yeBotopiye yaba ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Le nkampani inikezela ngeendidi ngeendidi zeepayipi zentsimbi yekhabhoni kunye neemveliso ezinxulumene noko, kuqukaii-SMLS, I-ERW, I-LSAWkunyeI-SSAWumbhobho wentsimbi, kunye noluhlu olupheleleyo lwezinto zokufakelwa kwemibhobho kunye neeflanges. Iimveliso zayo ezikhethekileyo ziquka ii-alloys ezikumgangatho ophezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.

Sijonge phambili ekusekeni ubudlelwane bentsebenziswano nani kunye nokudala ikamva eliya kuba yimpumelelo kubo bonke kunye.

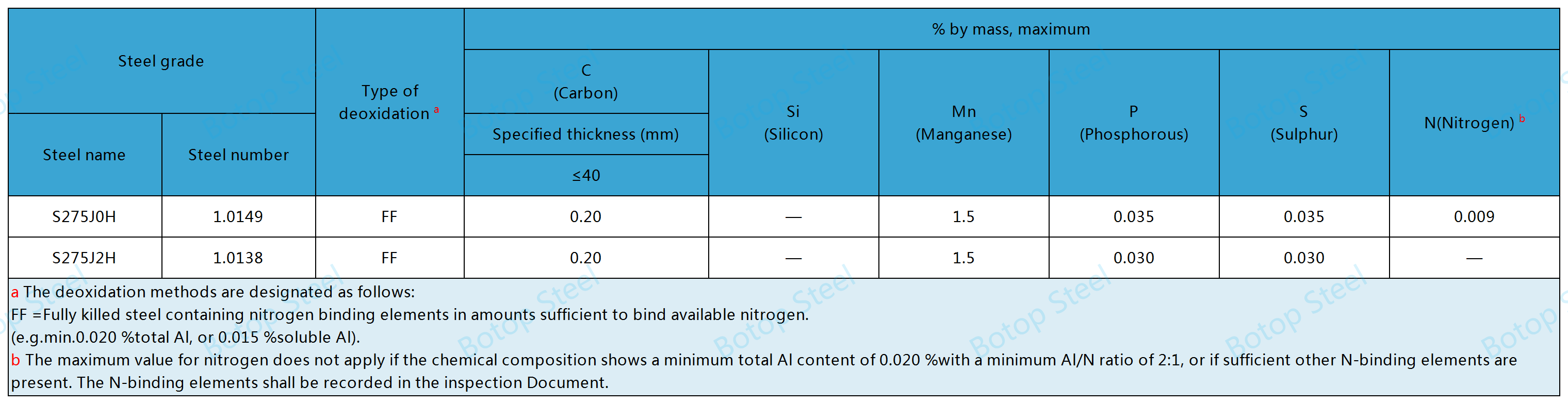

Intsimbi eluhlaza yokwenziwa kweendawo ezingenanto ezibandayo iyasuswa ioksijini kwaye kufuneka ihlangabezane neemeko ezithile zokuhanjiswa.

Iimfuneko ezifanelekileyo ze-S275J0H kunye ne-S275J2H zeziFF(Intsimbi ebulewe ngokupheleleyo equlethe izinto ezibopha initrogen ngobuninzi obaneleyo ukubopha initrogen ekhoyo (umz. ubuncinci be-0,020% iyonke ye-Al okanye i-0,015% ye-Al enyibilikayo)).

Imeko yokuhanjiswa: Iiroli eziqengqelweyo okanye ezilungelelanisiweyo/ezilungelelanisiweyo (N) zeentsimbi ze-JR, J0, J2, kunye ne-K2.

Imibhobho yentsimbi eya kwi-EN 10219 ingaveliswa zizo zombiniI-ERW(ukuwelda kokumelana nombane) kunyeI-SAWIinkqubo zokuvelisa (ukuwelda kwe-arc engaphantsi komhlaba).

Imveliso yeIityhubhu ze-ERWInenzuzo yokuba ikhawuleza kwaye ifikeleleka lula kwaye idla ngokukhethwa kwiiprojekthi ezifuna imveliso enkulu kunye neendleko eziphezulu.

I-ERWiityhubhu zihlala zisetyenziselwa ukuvelisa ububanzi obuncinci kunye nobukhulu bodonga obuncinci, ngelixaI-SAWIityhubhu zilungele ngakumbi ububanzi obukhulu kunye neendonga ezityebileyo. Nceda ukhethe uhlobo olufanelekileyo lombhobho wentsimbi kwiprojekthi yakho.

Imibhobho ye-ERW eyenziwe ngokwe-EN 10219 ayisoloko ifuna ukuchetywa kwe-weld yangaphakathi.

Oku kungenxa yokuba iityhubhu ze-EN 10219 zisetyenziswa kakhulu kwizicelo zesakhiwo, njengokwakha kunye nobunjineli boomatshini, apho iimfuno zembonakalo ye-weld zihlala zincinci kunezo zemikhumbi yoxinzelelo okanye iipayipi ezinoxinzelelo oluphezulu. Ke ngoko, lo gama nje amandla kunye nokuthembeka kwe-weld kuhambelana neemfuno zomgangatho, ii-weld zangaphakathi zingasetyenziswa ngaphandle kokunciphisa okongeziweyo.

Akukho nyango lobushushu oluza kwenziwa emva koko, ngaphandle kokuba i-weld isenokuba kwimeko edibeneyo okanye ephethwe ngobushushu.

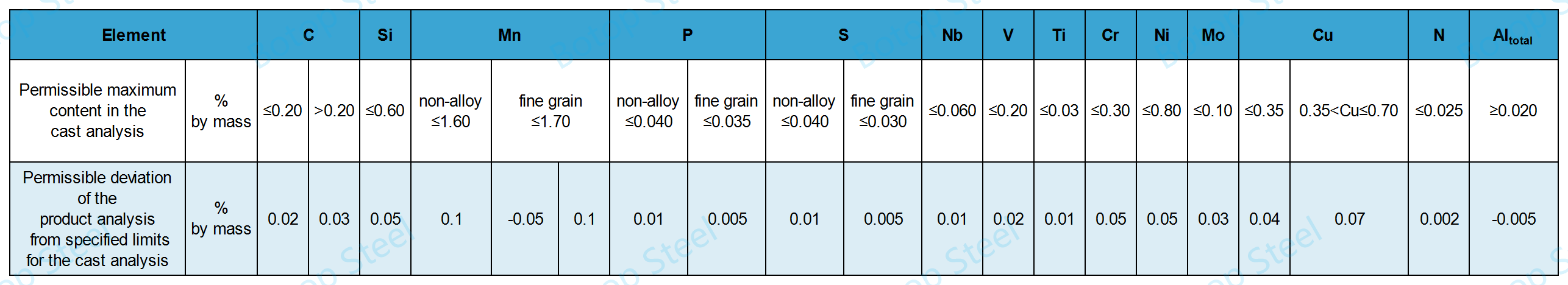

Uhlalutyo lweCast (Ukwakhiwa kweekhemikhali zezinto eziluhlaza)

Zombini i-S275J0H kunye ne-S275J2H zinexabiso elilinganayo lekhabhoni (i-CEV) eliyi-0.40%.

I-S725J0H kunye ne-S275J2H ezine-CEV ephezulu ye-0.4% zibonisa ukudityaniswa okungcono kunye nomngcipheko omncinci wokuqina nokuqhekeka ngexesha lokudityaniswa.

Ingabalwa kusetyenziswa le fomyula ilandelayo:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

Uhlalutyo lweMveliso (Ukwakhiwa kweeKhemikhali zeeMveliso eziGqityiweyo)

Ngexesha lokuveliswa kwentsimbi, ukwakheka kweekhemikhali kunokutshintsha ngenxa yezizathu ezahlukeneyo, kwaye olu tshintsho lunokuchaphazela iimpawu kunye nomgangatho wentsimbi.

Ulwakhiwo lwekhemikhali lombhobho wentsimbi olugqityiweyo lokugqibela kufuneka luhambelane nolwakhiwo lwekhemikhali lwe-casting kunye nokuphambuka kwayo okuvumelekileyo.

Iiparamitha zeempawu zoomatshini ziquka amandla okuvelisa, amandla okutsalwa, ukunwebeka, kunye namandla okuchaphazela.

Ukuncitshiswa koxinzelelo ngaphezu kwama-580 ℃ okanye ngaphezulu kweyure enye kunokukhokelela ekuwohlokeni kweempawu zoomatshini.

Amanqaku:

Uvavanyo lwempembelelo alufuneki xa ubukhulu obuchaziweyo bungaphantsi kwe-6mm.

Iimpawu zempembelelo zeetyhubhu zomgangatho we-JR kunye ne-J0 aziqinisekiswanga ngaphandle kokuba kuchaziwe.

I-EN 10219 Ii-welds kwimibhobho yentsimbi ye-ERW zingavavanywa ngokukhetha enye yezi zilandelayo.

I-EN 10246-3 ukuya kwinqanaba lokwamkelwa i-E4, ngaphandle kokuba indlela ye-rotary tube/pancake coil ayivumelekanga;

EN 10246-5 ukuya kwinqanaba lokwamkelwa F5;

EN 10246-8 ukuya kwinqanaba lokwamkelwa U5.

Ukubalwa kobunzima bethiyori beetyhubhu ze-EN 10219 kunokusekelwe kubuninzi beetyhubhu ze-7.85 kg/dm³.

M=(DT)×T×0.02466

U-M bubunzima ngeyunithi nganye ubude;

U-D bububanzi obungaphandle obuchaziweyo, iiyunithi kwi-mm;

U-T bubukhulu bodonga obuchaziweyo, iiyunithi nge-mm.

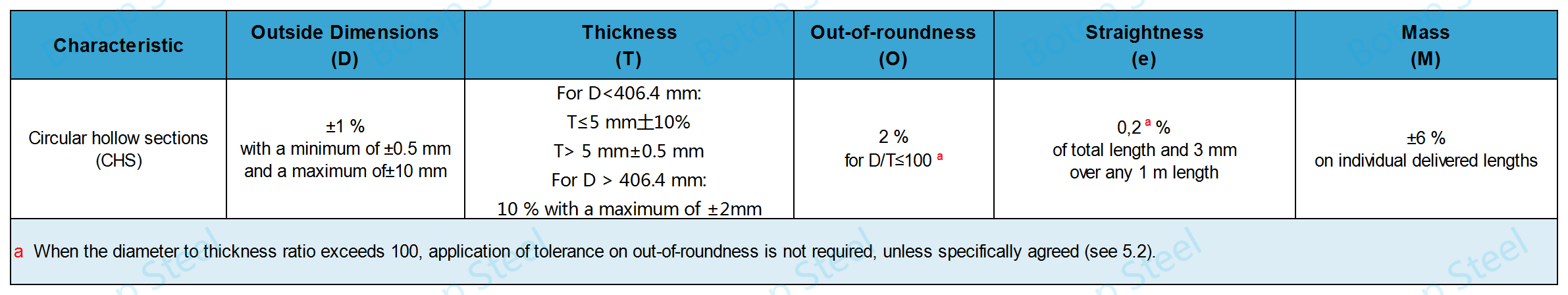

Ukunyamezelana kwiMilo, Ukuthe tye kunye noBunzima

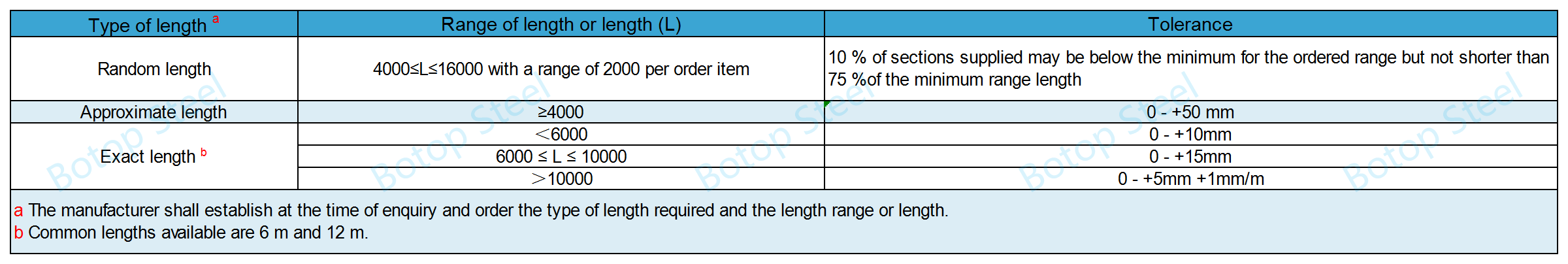

Ubude bokunyamezela

Iityhubhu zecandelo elingenanto ezenziwe ngokwe-EN 10219 ziyaxhunyelelwa.

Xa kudityaniswa, ukuqhekeka okubandayo kwindawo yokudityaniswa kwempahla yeyona mngcipheko uphambili njengoko ubukhulu, amandla, kunye ne-CEV yemveliso isanda. Ukuqhekeka okubandayo kubangelwa kukudibana kwezinto ezininzi:

amanqanaba aphezulu e-hydrogen esasazekayo kwisinyithi esitshixiweyo;

isakhiwo esibuthathaka kwindawo echaphazelekileyo bubushushu;

uxinzelelo olubalulekileyo loxinzelelo lokuxinana kwijoyinti edibeneyo.

Umphezulu wombhobho wentsimbi kufuneka ube mpuluswa kwaye ungabi naziphene ezichaphazela ukusebenza kwemveliso, ezinje ngokuqhekeka, imingxunya, imikrwelo, okanye ukugqwala.

Iingqumba, imijelo, okanye imijelo emide enganzulu eyenziwe yinkqubo yokuvelisa iyamkeleka lo gama nje ubukhulu bodonga obuseleyo bukwimeko yokunyamezelana, isiphene singasuswa ngokusila, kwaye ubukhulu bodonga obulungisiweyo buhlangabezana neemfuno zobukhulu obuncinci.

Intsimbi yeBotopAyiboneleli nje kuphela ngeetyhubhu zentsimbi ezikumgangatho ophezulu ngokuhambelana ne-EN 10219, ikwabonelela ngeendlela ezahlukeneyo zokugquma umphezulu weetyhubhu zentsimbi ukuze zilungele iimfuno ezithile zabathengi bayo kwiiprojekthi ezahlukeneyo zobunjineli. Ezi gqubuthelo zenzelwe ukuphucula ukumelana nokugqwala kweetyhubhu kwaye zongeze ukhuseleko olongezelelweyo, ngaloo ndlela zandisa ubomi bazo benkonzo.

Ukuntywila okushushu

Ukwaleka kwe-3LPE (HDPE)

Ukwaleka kweFBE

Ukwaleka kweVarnish

Ukwaleka kwepeyinti

Ukwaleka kobunzima besamente

Izinto zebhulorho: izakhiwo ezingezizo eziphambili ezithwala imithwalo ezisetyenziswa kwiibhulorho, ezifana neerelingi kunye neeparapet.

Iintsika zokwakha: iikholamu zokuxhasa kunye neebhanti ezisetyenziswa kwizakhiwo nakubunjineli bokwakha.

Iinkqubo zombhobho: imibhobho yokuthutha ulwelo kunye neegesi, ingakumbi kwizicelo ezifuna inqanaba elithile lokuguquguquka kunye nokumelana nokugqwala.

Izakhiwo zexeshana: izixhaso zexeshana kunye neefreyimu ezifanelekileyo kwiindawo zokwakha nezobunjineli.

Ezi zicelo zisebenzisa iipropati ezintle zoomatshini kunye nokudityaniswa kwe-S275J0H kunye ne-S275J2H ukuhlangabezana neemfuno zezakhiwo ezikhaphukhaphu kodwa ezizinzileyo.

I-ASTM A500:Ingcaciso Esemgangathweni yeetyhubhu zeCarbon Steel ezidityanisiweyo nezingenamthungo ezenziwe ngentsimbi ebandayo.

I-ASTM A501: Inkcazelo Esemgangathweni Yeetyhubhu Zesinyithi Zekhabhoni Ezifakwe Ngobushushu Nezingenamthungo.

EN 10210: Amacandelo angaphakathi ashushu agqityiweyo enziwe ngeentsimbi ezingenanto yokwenza i-alloy kunye neentsimbi ezincinci.

EN 10219: Amacandelo angaphakathi adityanisiweyo aqinileyo enziwe ngentsimbi engenanto yokuxuba kunye neentsimbi ezincinci.

I-JIS G 3466: Iityhubhu zesinyithi sekhabhoni ezisikwere kunye nezixande zesakhiwo ngokubanzi.

AS/NZS 1163: Iinxalenye ezingenanto zentsimbi ezakhiwe ngesakhiwo esibandayo.

Le migangatho isetyenziswa kakhulu kwihlabathi liphela, kwaye inceda ekuqinisekiseni ukuba iityhubhu zentsimbi ezakhiweyo ziyahlangabezana nemigangatho yokusebenza elindelekileyo kwizicelo ezahlukeneyo zobunjineli. Xa ukhetha umgangatho wepayipi yentsimbi, kubalulekile ukuqwalasela iimfuno zayo ezithile zokusetyenziswa, imigaqo yengingqi, kunye neemfuno zokusebenza.

Umbhobho wentsimbi yekhabhoni we-ASTM A252 GR.3 LSAW(JCOE) wesakhiwo

Ipayipi yentsimbi ye-BS EN10210 S275J0H LSAW(JCOE)

Umbhobho wentsimbi we-ASTM A671/A671M LSAW

Umbhobho wentsimbi yekhabhoni we-ASTM A672 B60/B70/C60/C65/C70 LSAW LSAW

I-API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / I-API 5L Grade X70 LSAW Steel Pipe

Umbhobho wentsimbi we-EN10219 S355J0H wesakhiwo se-LSAW(JCOE)