Umbhobho wentsimbi we-ASTM A556 usetyenziswa kakhulu njengombhobho wentsimbi yekhabhoni engenamthungo etsalwa ngokubandayo kwizifudumezi zamanzi ezithwala iityhubhu.

Ububanzi bokusetyenziswa kwayo yipayipi yentsimbi engenamthungo enobukhulu bobubanzi obungaphandle obuphakathi kwe-15.9-31.8mm kunye nobukhulu bodonga obungaphantsi kwe-1.1mm.

Eli nqaku ligxile kwimibhobho yentsimbi kwaye alibandakanyi ii-U-tubes ezikhankanyiweyo kumgangatho.

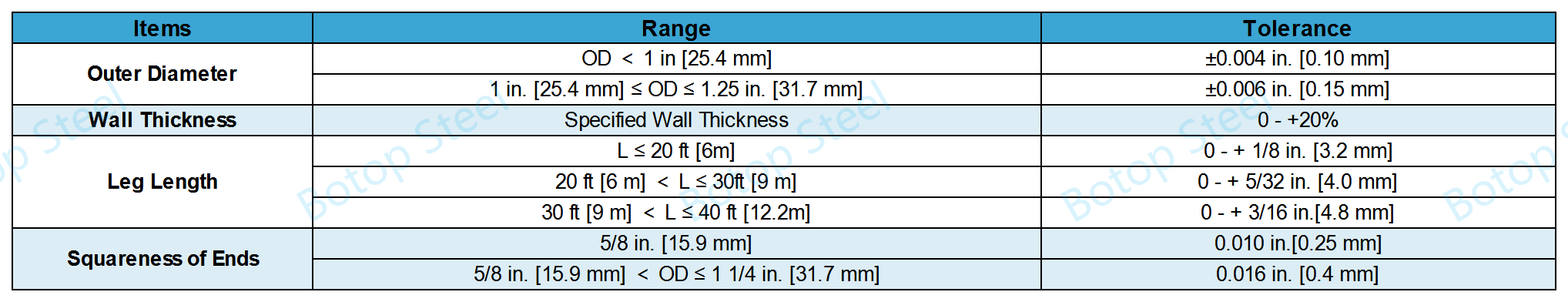

Ububanzi obungaphandle: 5/8 - 1 1/4 intshi. [15.9 -31.8 mm].

Ubukhulu bodonga: ≥ 0.045 in [1.1 mm].

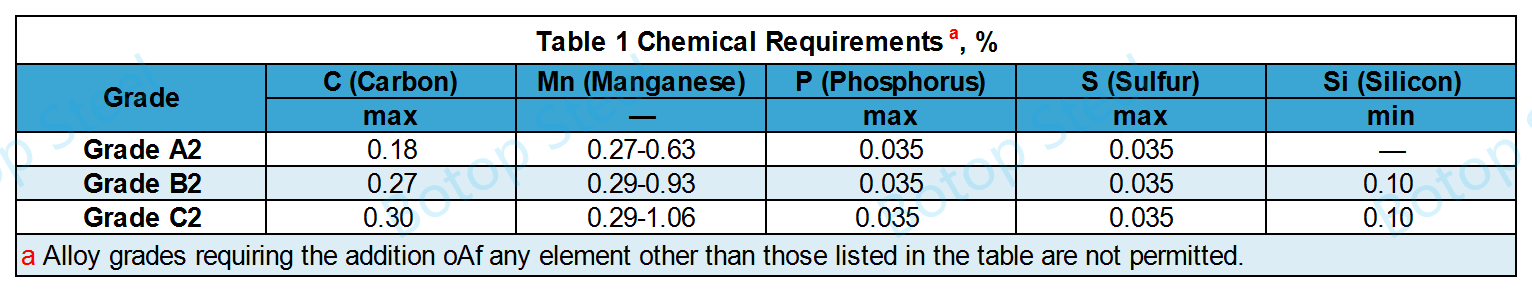

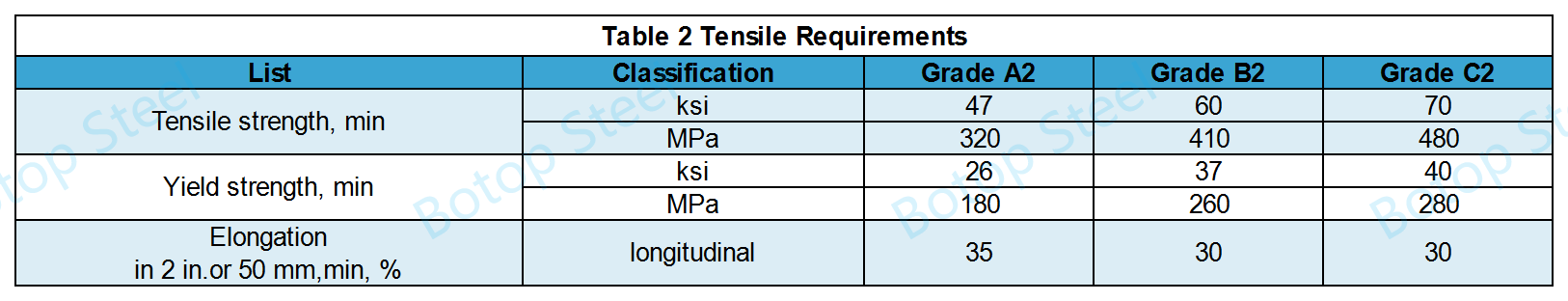

I-ASTM A556 ihlela amanqanaba amathathu,Ibanga A2, Ibanga B2kunyeIbanga C2.

Iityhubhu zentsimbi maziveliswe yi-ingenamthungoiqhubekeke kwaye iya kutsalwa kubanda.

Iityhubhu zentsimbi ezingenamthungo ezitsalwa ngokubandayo zibonelela ngokuchaneka okuphezulu kunye nokugqitywa kakuhle komphezulu ngelixa zicoca isakhiwo esincinci kwaye ziphucula iimpawu zaso zoomatshini ezifana namandla kunye nobunzima. Isakhiwo esingenamthungo senza iityhubhu ziqine kwaye zikhuseleke ngakumbi xa ziphantsi koxinzelelo oluphezulu kunye namaqondo obushushu, nto leyo eyenza zifaneleke ukusetyenziswa kwemizi-mveliso ezifuna ukuchaneka okuphezulu kunye nokusebenza.

Nangona kunjalo, iityhubhu zentsimbi ezingenamthungo ezitsalwa ngokubandayo zibiza kakhulu ukuzivelisa kuba inkqubo yazo yokuvelisa iyinkimbinkimbi kwaye ifuna imisebenzi kunye nezixhobo ezintsonkothileyo. Ukongeza, ukusebenza kwazo okuphantsi kwemveliso, ingakumbi kwimveliso ephezulu, akubizi kakhulu njengenkqubo yokuqengqeleka okushushu, kwaye kwezinye iimeko kunokubakho ukulahleka kwezinto ezininzi, okunciphisa ukusetyenziswa kwazo kwezinye iinkqubo.

Iityhubhu ezitsalwa ngokubandayo mazinyangwe ngobushushu emva kokuba ukutsalwa kokugqibela okubandayo kudlule kubushushu obuyi-1200°F [640°C] okanye ngaphezulu ukuqinisekisa ukuba ziyakwazi ukugungqa kakuhle kwiityhubhu kwaye zihlangabezane neempawu zoomatshini njengoko kuchaziwe.

Ukuba uhlalutyo lwemveliso lwenziwe, jonga i-ASTM A751 ukuze ufumane iindlela zovavanyo.

1. Ipropati yokuThatha

Indlela yovavanyo: ASTM A450 Icandelo 7.

Kwiibhetshi zeetyhubhu ezifikelela kuma-50, kufuneka kukhethwe ityhubhu enye ukuze kuvavanywe.

Kwiibhetshi zeetyhubhu ezingaphezu kwama-50, kuya kukhethwa iityhubhu ezi-2 ukuze kuvavanywe.

2. Ukuqina

Indlela yovavanyo: ASTM A450 Icandelo 23.

Iisampuli ezivela kwiityhubhu ezimbini zovavanyo ezivela kwilothi nganye kufuneka zivavanyelwe ubulukhuni bukaBrinell okanye bukaRockwell.

Ubunzima bombhobho weRockwell abuyi kudlula obo buboniswe kwitheyibhile.

| Ibanga | Ukuqina |

| Ibanga A2 | 72 HRBW |

| Ibanga B2 | 79 HRBW |

| Ibanga C2 | 89 HRBW |

3. Uvavanyo lokuThabatha

Indlela yovavanyo: ASTM A450 Icandelo 19.

Uvavanyo lokuthamba kufuneka lwenziwe kwisampuli enye ukusuka kwisiphelo ngasinye setyhubhu yentsimbi egqityiweyo ukusuka kwiityhubhu ezikhethiweyo ezingadluli kwi-125 ukusuka kwilothi nganye.

4. Uvavanyo lokuvutha

Indlela yovavanyo: ASTM A450 Icandelo 21.

Uvavanyo lokutshaya kufuneka lwenziwe kwisampuli enye ukusuka kwisiphelo ngasinye setyhubhu egqityiweyo, kungabikho ngaphezulu kwe-125 yeetyhubhu ezikhethiweyo kwibhetshi nganye.

Akukho vavanyo lwe-hydrostatic oluyimfuneko kwiipayipi zentsimbi.

Nangona kunjalo, yonke i-U-pipe kufuneka ivavanywe ngamanzi anganyakaziyo ngolwelo olungaboliyo.

Ityhubhu nganye mayivavanywe ngesixhobo sokuvavanya esingonakalisiyo esikwaziyo ukubona iziphene kulo lonke icala letyhubhu emva konyango lobushushu bomphezulu emva kokutsalwa kokugqibela kokubanda.

Iindlela zovavanyo ezingonakalisiyo zeSpecificationE213, InkcazoE309(kwizinto ze-ferromagnetic), InkcazeloE426(kwizinto ezingezizo zemagnethi), okanye InkcazeloE570inokukhethwa kuvavanyo.

Ezi meko zilandelayo azisebenzi kwinxalenye egobileyo ye-U-tube.

Umbhobho ogqityiweyo kufuneka ungabi nasikali kodwa unokuba nefilimu ye-oxide yomphezulu phezu komphezulu.

Iityhubhu ezigqityiweyo mazithe tye ngokufanelekileyo kwaye zibe neziphelo ezigudileyo ezingenamaqhuqhuva. Iityhubhu mazibe nomgangatho ofana nowenziwe ngumntu kwaye mazingabi naziphene ezingaphezulu ezingenakususwa ngaphakathi komgangatho ovumelekileyo wodonga.

Ukususwa kweziphene zomphezulu ezifana neempawu zokuphatha, iimpawu zokulungisa, iimpawu ze-mandrel ezikhanyayo kunye neempawu ze-die, imingxuma enganzulu, kunye neepateni zesikali akuyi kufuneka ukuba zingaphakathi kwemilinganiselo yokumelana nodonga evumelekileyo.

Ububanzi bangaphakathi nobangaphandle bombhobho ogqityiweyo kufuneka bugqunywe ukuze kuthintelwe ukugqwala ngexesha lokuthuthwa.

Iingubo eziqhelekileyo zeziiioyile zokuthintela umhlwa, iivarnishokanyeiipeyinti.

Ukukhethwa kwezinto zokugquma kudla ngokuxhomekeka kwiimfuno ezithile zokusetyenziswa kombhobho wentsimbi, indawo ekucetywayo ukusetyenziswa kuyo, kunye nobude bexesha lokukhusela.

Izifudumezi zamanzi ezithwala amanzi: Le yenye yezona zinto zixhaphakileyo ezisetyenziswa kwiityhubhu zentsimbi ze-ASTM A556.

Kwishishini lombane, izifudumezi zamanzi okuhambisa amanzi zisetyenziselwa ukufudumeza amanzi okuhambisa amanzi kwibhoyila, ngokuqhelekileyo ngokutsala umphunga. Ukusetyenziswa kolu hlobo lwemibhobho yentsimbi kuvumela ukudluliselwa kwamandla obushushu ngokufanelekileyo, kuphucula ukusebenza kakuhle kwamandla kunye nokusebenza kwenkqubo.

Izitshintshi zobushushu kunye nezikhuseliNgenxa yeempawu zayo ezibalaseleyo zokudlulisa ubushushu kunye nokumelana nokugqwala, iityhubhu zentsimbi ze-ASTM A556 zikwafanelekile ukusetyenziswa kwezinye iintlobo ze-heat exchangers kunye ne-condenser, ezisetyenziswa kwiinkqubo ezahlukeneyo zeekhemikhali, ze-petrochemical, kunye nezinye iinkqubo zoshishino.

Iinkqubo zomphunga ezinoxinzelelo oluphezulu: Ukumelana nobushushu obuphezulu kunye noxinzelelo oluphezulu kwe-ASTM A556 tubes kwenza ukuba ifaneleke ukusetyenziswa kwiinkqubo zomphunga oxinzelelo oluphezulu kunye nezinye izicelo ezifuna ukumelana noxinzelelo oluphezulu kakhulu kunye nobushushu.

I-ASTM A179/A179M- Lo ngumgangatho wezinto zokutshintsha ubushushu zentsimbi yekhabhoni ezitsalwa ngokubandayo kunye neetyhubhu ze-condenser zenkonzo ye-cryogenic.

I-ASTM A192/A192M- Icacisa iimfuno zobugcisa zeetyhubhu zebhoyila zentsimbi yekhabhoni ezingenamthungo kwiibhoyila ezisetyenziswa kwinkonzo yoxinzelelo oluphezulu.

I-ASTM A210/A210M- Umgangatho weetyhubhu zebhoyila zentsimbi yekhabhoni ephakathi engenamthungo kunye nekhabhoni-manganese yeebhoyila kunye nee-superheater.

I-ASTM A213/A213M- Ibonelela ngemigangatho yebhoyila yentsimbi ye-ferritic ne-austenitic alloy, i-superheater, kunye neetyhubhu ze-heat exchanger.

I-ASTM A249/A249M- Imigangatho esebenzayo kwi-welded austenitic steel boiler, i-superheater, i-heat exchanger, kunye nee-condenser tubes.

I-ASTM A334/A334M- Umgangatho weetyhubhu zekhabhoni kunye nentsimbi ye-alloy ezingenamthungo nezihlanganisiweyo zenkonzo ye-cryogenic.

Ngamnye kule migangatho ugubungela iityhubhu zentsimbi ezisetyenziswa kwi-heat exchangers, ii-boilers okanye ezinye izinto ezifanayo. Ukuba yeyiphi imigangatho ekhethiweyo ixhomekeke kwiimfuno ezithile zesicelo, ezifana nobushushu bokusebenza, umlinganiselo woxinzelelo, kunye nokumelana nokugqwala okulindelekileyo.

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Le nkampani inikezela ngeendidi ngeendidi zeepayipi zentsimbi yekhabhoni kunye neemveliso ezinxulumene nazo, kuquka ipayipi yentsimbi engenamthungo, i-ERW, i-LSAW, kunye ne-SSAW, kunye noluhlu olupheleleyo lwee-fittings zepayipi kunye nee-flanges. Iimveliso zayo ezikhethekileyo ziquka ii-alloys ezikumgangatho ophezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.