I-ASTM A519Iityhubhu kufuneka zenziwe ngenkqubo engenamthungo kwaye mazigqitywe ngobushushu okanye ngokubandayo njengoko kuchaziwe.

Kwiityhubhu ezingqukuva ezinobubanzi obungaphandle obungadluli kwi-325 mm (12 3/4 in).

Iityhubhu zentsimbi zinokwenziwa zibe ziimilo ezisikwere, ezizinxantathu, okanye ezinye izinto njengoko kufuneka.

I-ASTM A519 inokwahlulwa ngokwezinto ezenziwe ngentsimbi:Intsimbi yeCarbonkunye neNsimbi yeAlloy.

Intsimbi yekhabhoniyahlulwe yabaI-MT yeKhabhoni ephantsi(Umatshini wokuhambisa ityhubhu),Intsimbi yeCarbon ephezulukwayeInyibilikisiwe okanye iphinda ifakelwe i-phosphor, okanye zombiniIntsimbi yeCarbon, ukuze ihambelane neemfuno ezahlukeneyo zoshishino kunye neemeko zokusetyenziswa.

Xa kungekho nqanaba lichaziweyo, abavelisi banokukhetha ukubonelelaI-MT1015 okanye i-MTX1020amabakala.

Ububanzi bangaphandle: 13.7 - 325 mm;

Ubukhulu bodonga: 2-100mm.

Intsimbi ingenziwa nangayiphi na indlela.

Intsimbi inokwenziwa ngee-ingots okanye yenziwe ngentambo.

Iityhubhu mazibe zenziwe nguinkqubo engenamthungokwaye kufuneka igqitywe ngokushisa okanye ngokubandayo, njengoko kuchaziwe.

Iityhubhu zentsimbi ezingenamthungo ziityhubhu ezingenazo ii-seams ezidityanisiweyo kuyo yonke indawo.

Iityhubhu ezigqityiweyo ezibandayoziyacetyiswa ngenxa yemfuno ephezulu yokuchaneka kobukhulu kunye nomgangatho womphezulu.

Eyona nto iphambili kukusebenza kakuhle kweendleko kunye nokuqina kwezinto,umbhobho wentsimbi ogqityiweyo oshushuisenokuba lolona khetho lufanelekileyo.

Okulandelayo yinkqubo yokuvelisa umbhobho wentsimbi ongenamthungo ojijekileyo oshushu.

Umenzi wentsimbi kufuneka ahlalutye ubushushu bentsimbi nganye ukuze abone ipesenti yezinto ezichaziweyo.

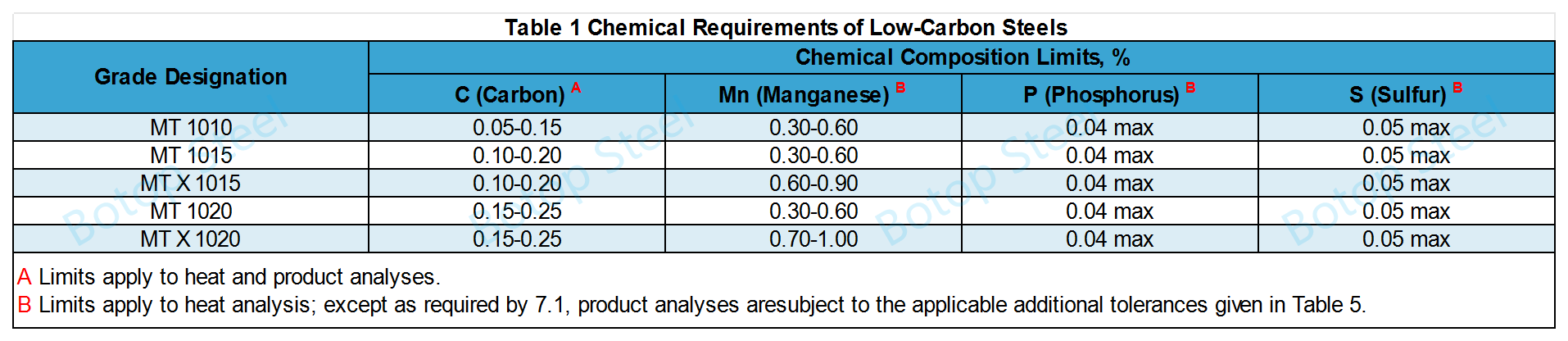

Itheyibhile 1 Iimfuno zeKhemikhali zeentsimbi ezineKhabhoni ephantsi

Intsimbi ethambileyo yintsimbi enomxholo wekhabhoni odla ngokungadluli kwi-0.25%. Ngenxa yokuba umxholo wayo wekhabhoni uphantsi, le ntsimbi inamandla okuguquguquka nokuguquguquka ngcono kwaye ayiqinanga kangako xa ithelekiswa nentsimbi enekhabhoni ephezulu.

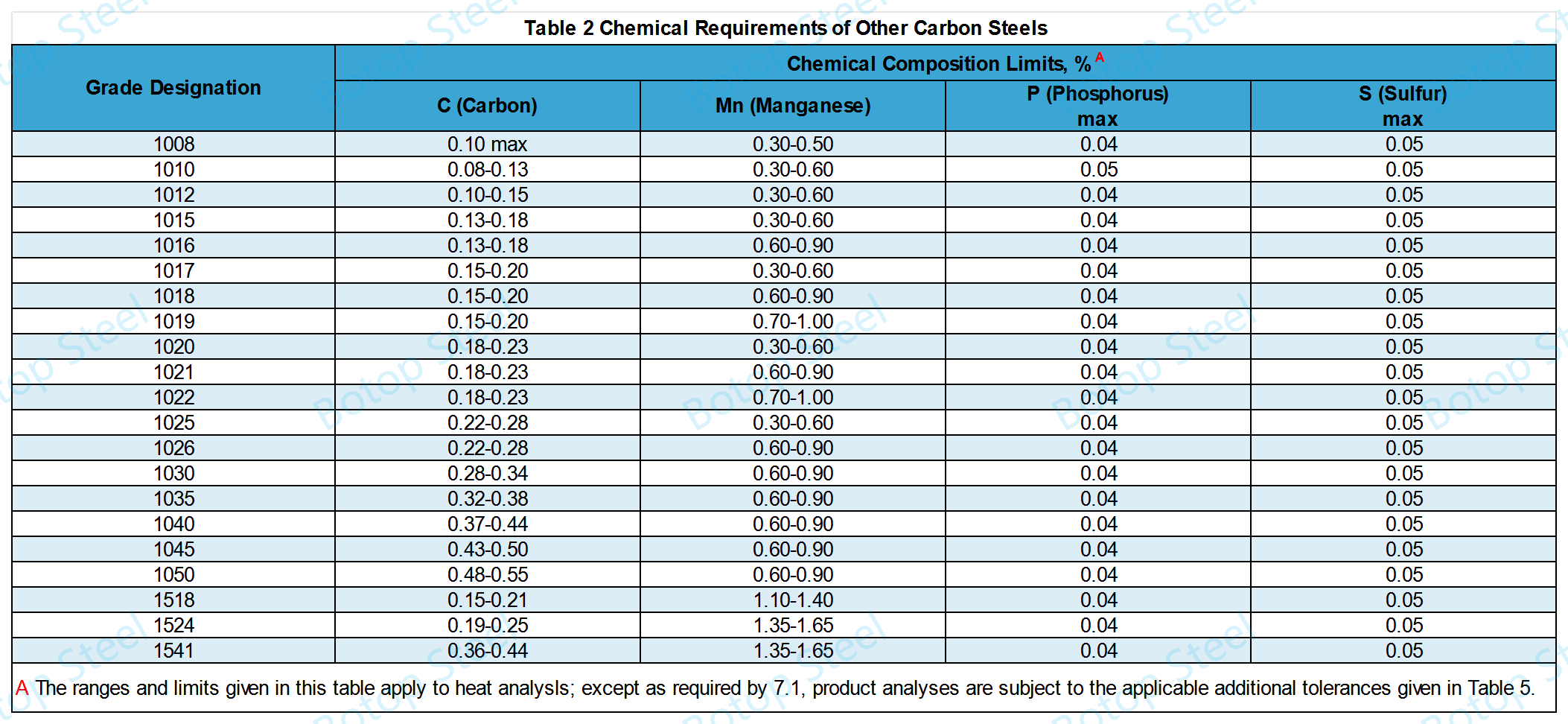

Itheyibhile 2 Iimfuno zeekhemikhali zezinye iintsimbi zekhabhoni

Iintsimbi zekhabhoni eziphakathi: Ziqulathe ikhabhoni ephakathi kwe-0.25% kunye ne-0.60%, zinika ubulukhuni namandla aphezulu kwaye zifuna unyango lobushushu ukuphucula iimpawu.

Intsimbi yekhabhoni ephezulu: Iqulethe phakathi kwe-0.60% kunye ne-1.0% okanye ngaphezulu kwekhabhoni, kwaye inika ubulukhuni kunye namandla aphezulu kakhulu, kodwa ubulukhuni obuphantsi.

Itheyibhile 3 Iimfuneko zeekhemikhali zeentsimbi ze-alloy

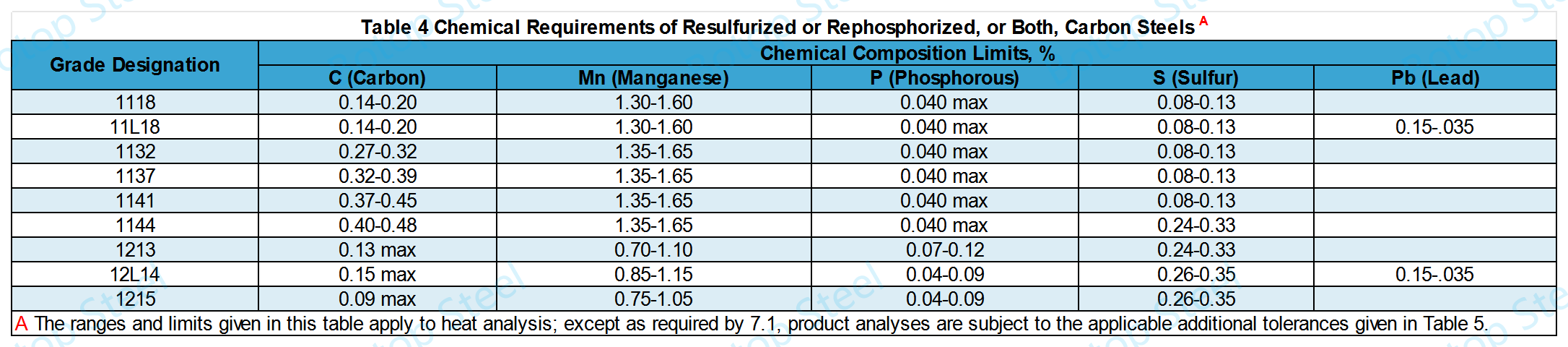

Itheyibhile 4 Iimfuno zeekhemikhali ze-Resulfurized okanye Rephosphorized, okanye zombini, iintsimbi ze-Carbon

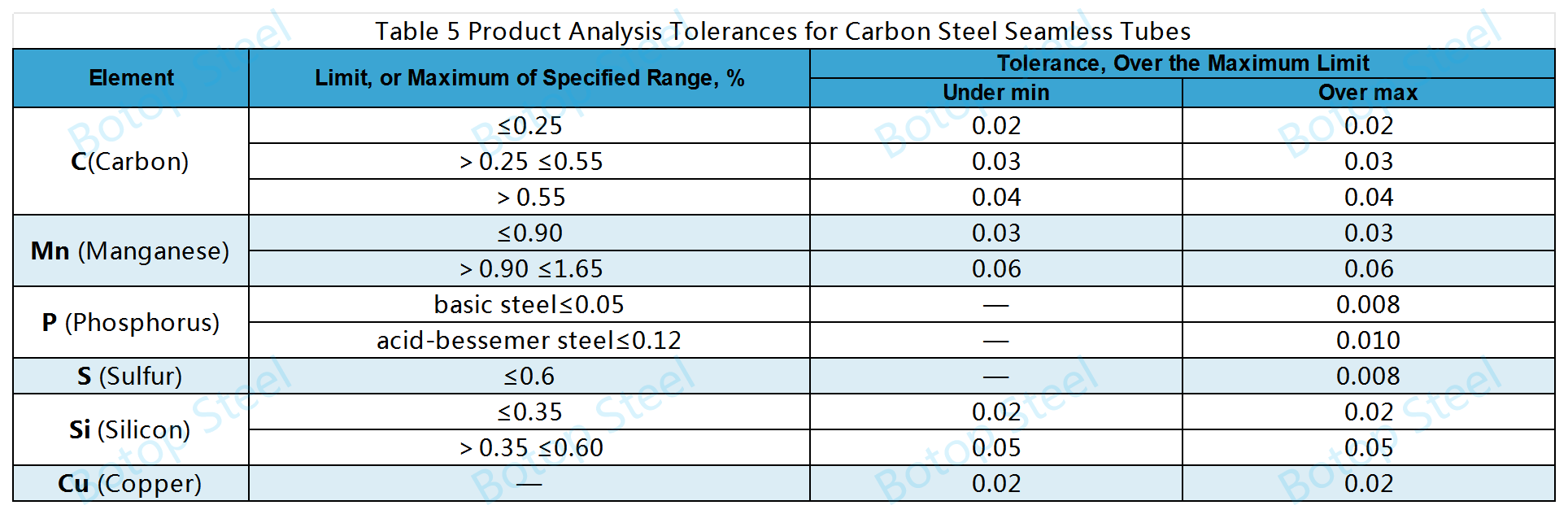

ITHEYIBHILE 5 Uhlalutyo lweMveliso Ukunyamezelana koMda okanye umda ochaziweyo ngaphezulu okanye ngaphantsi

Umenzi kufuneka acelwe kuphela ukuba ahlalutye imveliso ukuba ifunwa yi-odolo.

I-ASTM A519 igubungela ezi zinto zilandelayo zovavanyo:

Uvavanyo loBulukhuni; Uvavanyo loxinzelelo; Uvavanyo olungatshabalalisiyo; Uvavanyo lokuvutha; Ukucoceka kunye nokuQiniswa kweNsimbi.

| Ukubekwa kweBanga | Uhlobo lwePipe | Imeko | Amandla afanelekileyo | Unikeze Amandla | Ukwandiswa kwi-2in.[50mm],% | uRockwell, Isikali soBunzima B | ||

| ksi | I-Mpa | ksi | I-Mpa | |||||

| 1020 | Intsimbi yeCarbon | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Intsimbi yeCarbon | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Intsimbi yeCarbon | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Intsimbi yeCarbon | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Intsimbi yeCarbon | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Iphinde yatshiswa okanye i-Rephosphorized, okanye Zombini, Iintsimbi zeCarbon | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Iphinde yatshiswa okanye i-Rephosphorized, okanye Zombini, Iintsimbi zeCarbon | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Iintsimbi ze-alloy | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Iintsimbi ze-alloy | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

I-HR-Ishushu Iqengqeleka, Isebenza Ngobushushu, I-SR-Ithomalalisiwe, I-A-Ihlaziyiwe kwaye Iqhelekile.

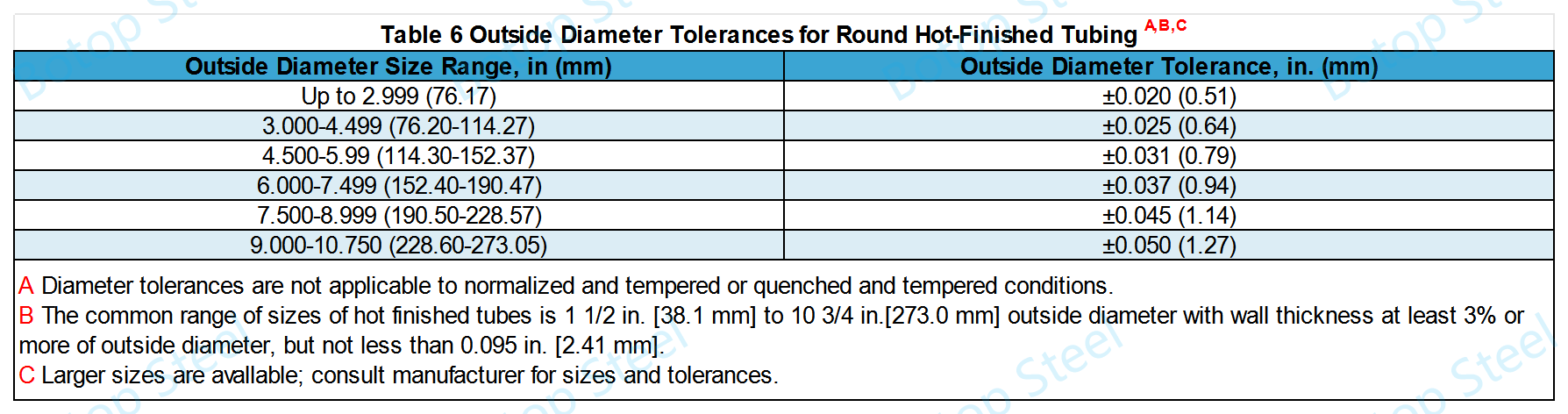

Ukunyamezelana kobubanzi bangaphandle

Itheyibhile 6 Ukunyamezelana kobubanzi bangaphandlekwi-Round Hot-Finished Tubing

Itheyibhile 12 Ukunyamezelana kobubanzi bangaphandleImibhobho Engenamthungo Esemhlabeni

| Ubungakanani Ububanzi Ngaphandle, ngaphakathi.[mm] | Ukunyamezelana kobubanzi bangaphandle kobungakanani kunye nobude obunikiweyo, ngaphakathi [mm] | |||

| Phezu | Ngaphantsi | Phezu | Ngaphantsi | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] xa i-L≤16ft[4.9m] | 0.000 | 0.004 [0.10] xa i-L >16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] xa i-L≤16ft[4.9m] | 0.000 | 0.006 [0.15] xa i-L >16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] xa i-L≤12ft[3.7m] | 0.000 | 0.006 [0.15] xa i-L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] xa i-L≤12ft[3.7m] | 0.000 | 0.006 [0.15] xa i-L≤16ft[4.9m] | 0.000 |

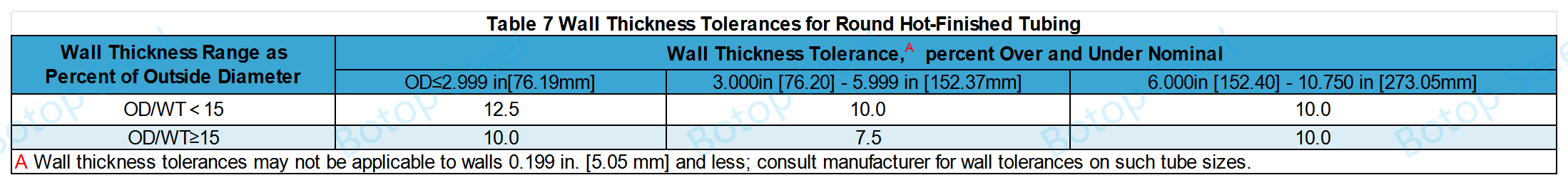

Ukunyamezelana koBungqingqwa bodonga

Itheyibhile 7 Ukunyamezelana koBungqingqwa boDongakwi-Round Hot-Finished Tubing

Itheyibhile 10 Ukunyamezelana koBungqingqwa boDongakwiMibhobho Ejikelezayo Esebenza Ngobandayo

| Ububanzi boBungqingqwa boDonga njenge Ipesenti yobubanzi bangaphandle | Ukunyamezelana koBungqingqwa boDonga Ngaphantsi nangaphaya kwegama eliqhelekileyo, % | |

| OD≤1.499in[38.07mm] | OD≥1.500 kwi [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

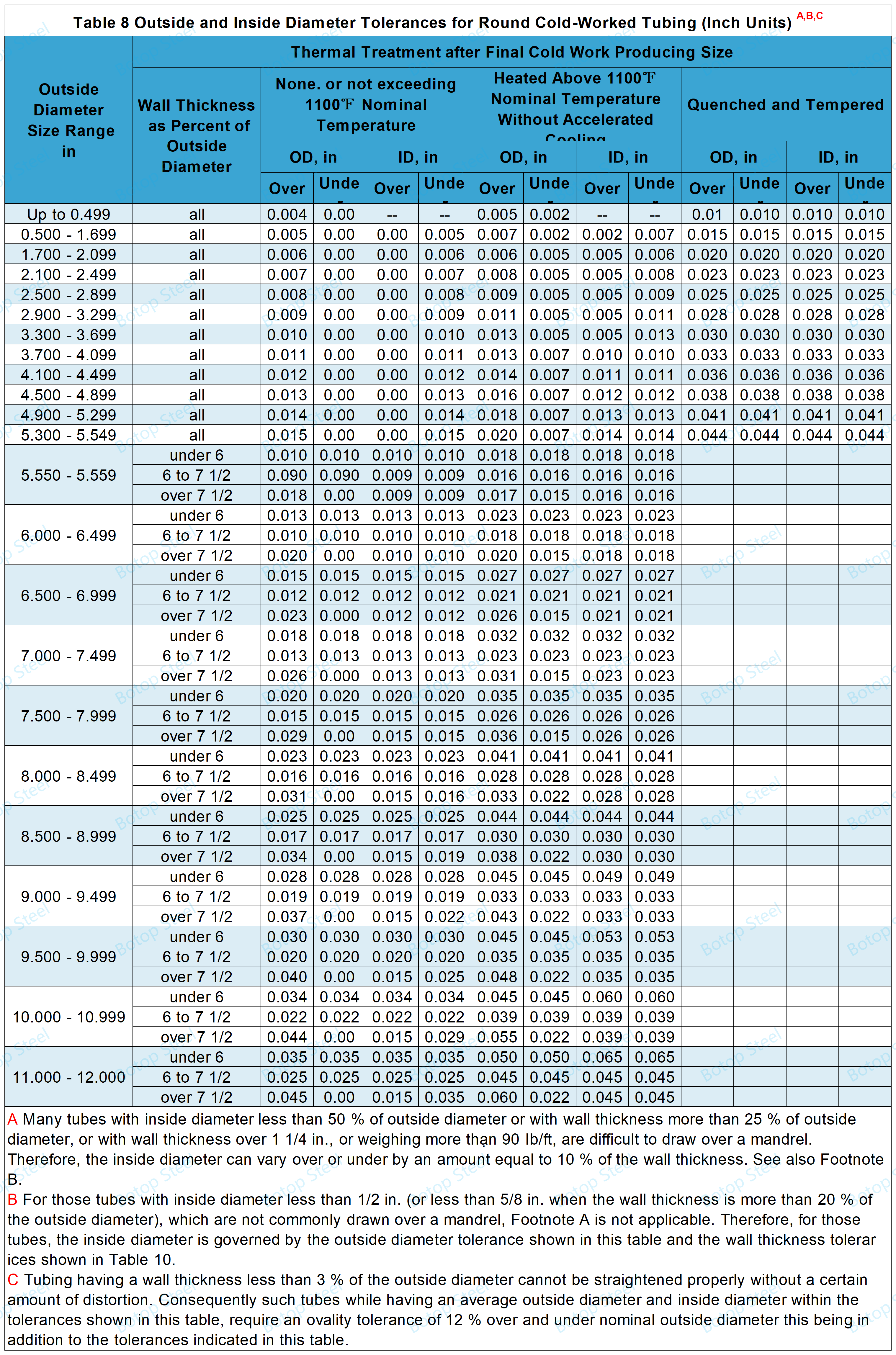

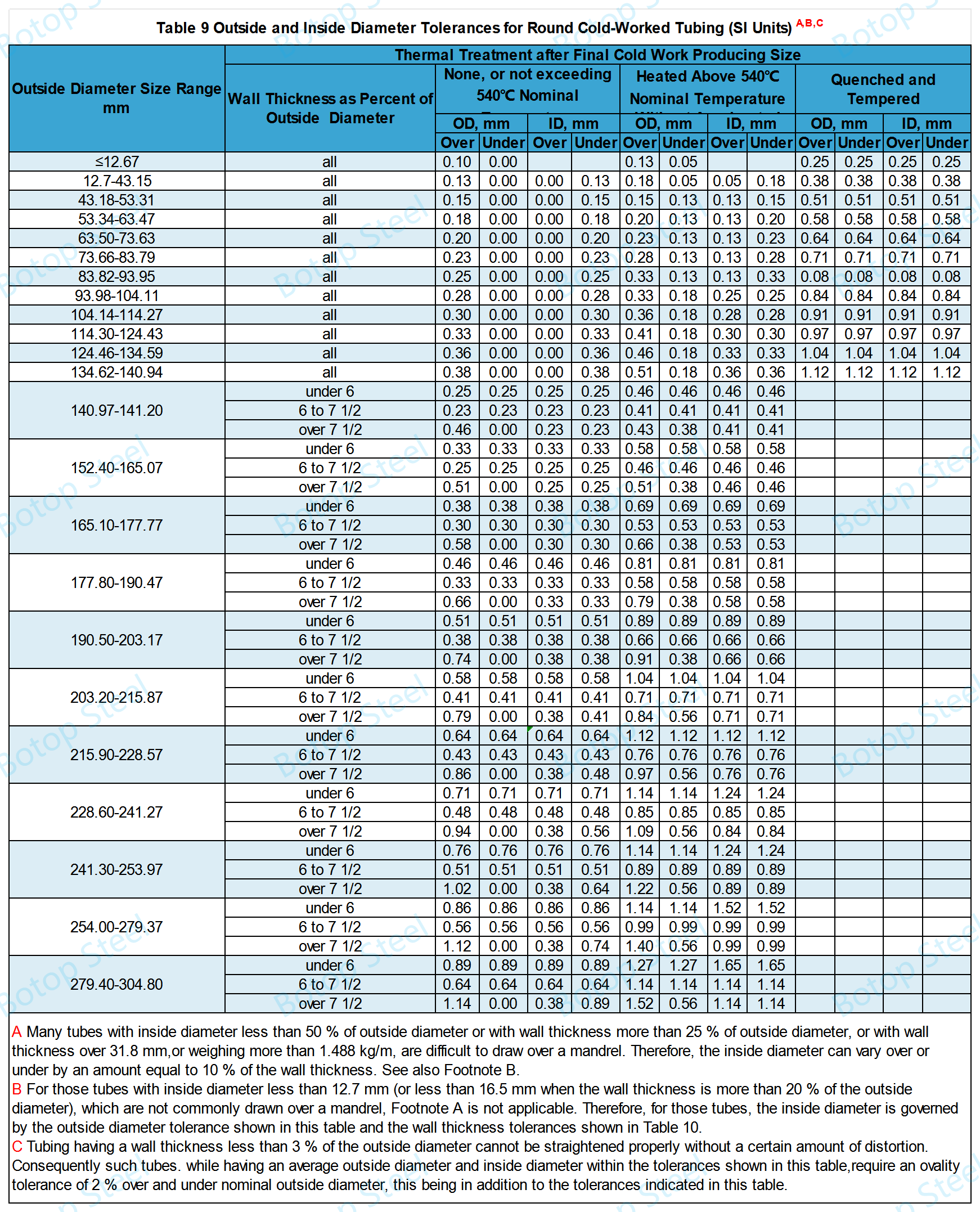

Ukunyamezelana kobubanzi bangaphandle nangaphakathi

Itheyibhile 8 Ukunyamezelana kobubanzi bangaphandle nangaphakathiIityhubhu Ezijikelezayo Ezisebenza Ngobandayo (Iiyunithi ze-intshi)

Itheyibhile 9 Ukunyamezelana kobubanzi bangaphandle nangaphakathikwiMibhobho Ejikelezayo Esebenza Ngobandayo (iiYunithi ze-SI)

Ububanzi bangaphandle kunye nokunyamezelana kobukhulu bodonga

Itheyibhile 11 Ububanzi bangaphandle kunye nokunyamezelana kodongakwiMibhobho yentsimbi engenamthungo ejijekileyo

| Ubungakanani obuchaziweyo ngaphandle kobubanzi, ngaphakathi. [mm] | Ububanzi obungaphandle, ngaphakathi. [mm] | Ubukhulu bodonga, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Ukunyamezela Ubude

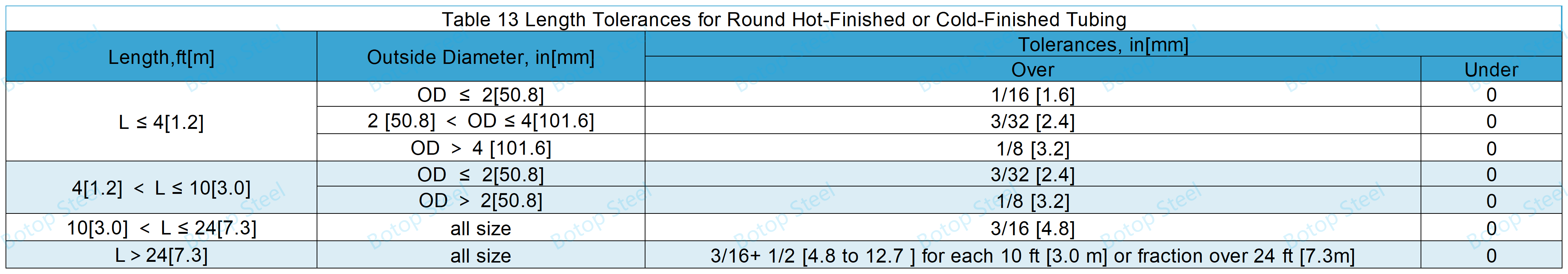

Itheyibhile 13 Ukunyamezela UbudekwiTubing eQokelelweyo eshushu okanye ebandayo

Ukunyamezelana Kokuthe Tye

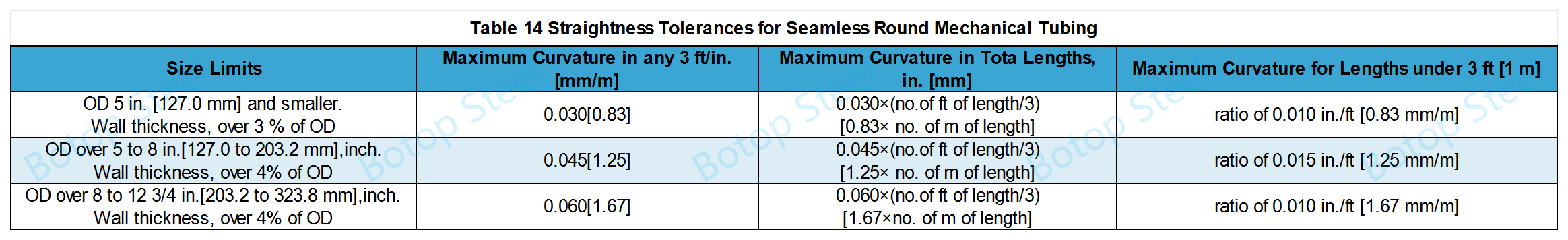

Itheyibhile 14 Ukunyamezelana Kokuthe Tyekwi-Seamless Round Mechanical Tubing

Umbhobho kufuneka ugqunywe ngefilimu yeoyile ngaphambi kokuba ugqunywe ukuze ungagqwali.

Ioyile yokuthintela umhlwa ingafakwa nakwindawo zangaphakathi nangaphandle zombhobho.

Inqwelomoya kunye neenqwelo-moya: ukuveliswa kwezinto ezibalulekileyo ezifana neenjini zeenqwelo-moya kunye neenkqubo zokuxhasa iinqanawa.

Ishishini lamandla: izixhobo zokubhola kunye nokuveliswa kwemibhobho yebhoyila enoxinzelelo oluphezulu.

Ukwenziwa koomatshini nezixhobo: Izinto eziphambili ezenza uluhlu olubanzi lwezixhobo zoshishino.

Izixhobo zemidlalo: Ukwenziwa kweefreyimu zeebhayisekile ezisebenza kakuhle kunye nezinye izakhiwo zemidlalo.

Ukwakha kunye nokwakha: izinto ezixhasa ulwakhiwo lwezakhiwo kunye nokusetyenziswa kwiindawo ezinoxinzelelo oluphezulu.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, njl. Ezi zinto zinokuthathwa njengezilingana nezinye iintsimbi zekhabhoni kunye ne-alloy kwi-ASTM A519.

2. DIN 1629: St52, St37.4, njl. Ngokuqhelekileyo zisetyenziselwa iinjongo zoomatshini kunye nolwakhiwo, ezi zifana neeklasi zentsimbi ethambileyo kwi-ASTM A519.

3. I-JIS G3445: STKM13A, STKM13B, njl. Ezi ziityhubhu zentsimbi yekhabhoni ezisetyenziselwa iinjongo zoomatshini kunye nolwakhiwo.

4. BS 6323:CFS 3, CFS 4, CFS 8, njl. Ezi ziityhubhu zentsimbi ezingenamthungo nezidibeneyo zeenjongo zobunjineli bezithuthi, oomatshini, kunye nobunjineli ngokubanzi.

5. GB/T 8162:20#, 45#, 40Cr, 20CrMo, njl. Iityhubhu zentsimbi ezingenamthungo kunye neepayipi zesakhiwo ngokubanzi kunye nesakhiwo soomatshini.

6. I-ISO 683-17:100Cr6, njl., esetyenziswa kakhulu ekwenzeni iibheringi, inokufumana ukusetyenziswa kubunjineli bemishini kwaye inezicelo ezifanayo neentsimbi ezithile ze-alloy ze-ASTM A519.

Xa ukhetha into elinganayo, kubalulekile ukubhekisa kwiinkcukacha zekhemikhali kunye neenkcukacha zeempawu zoomatshini ukuqinisekisa ukuba into ekhethiweyo iya kuhlangabezana neemfuno zokusebenza kwesicelo esithile.

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi. Le nkampani inikezela ngeentlobo ngeentlobo zemibhobho yentsimbi yekhabhoni kunye neemveliso ezinxulumene nayo, kubandakanya i-seamless, i-ERW, i-LSAW, kunye nombhobho wentsimbi we-SSAW, kunye noluhlu olupheleleyo lwezixhobo zemibhobho kunye neeflanges.

Iimveliso zayo ezikhethekileyo ziquka ii-alloys zodidi oluphezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.