I-ASTM A500 yityhubhu yesakhiwo sentsimbi yekhabhoni edityanisiweyo nengenamthungo eyenzelwe iibhulorho ezidityanisiweyo, ezinameva, okanye ezibolithiweyo kunye nezakhiwo kunye neenjongo zesakhiwo ngokubanzi.

Ibanga Byityhubhu yesakhiwo sentsimbi yekhabhoni edityanisiweyo okanye engenamthungo eguquguqukayo enamandla okuvelisa angaphantsi kwe-315 MPa [46,000 psi] kunye namandla okutsalwa angaphantsi kwe-400 MPa [58,000], esetyenziswa kwiintlobo ngeentlobo zeeprojekthi zesakhiwo sokwakha kunye nesoomatshini ngenxa yokuzinza kwayo okugqwesileyo kunye nokuqina kwayo.

I-ASTM A500 yahlula umbhobho wentsimbi ube ziiklasi ezintathu,ibakala B,ibakala Ckunye nebanga D.

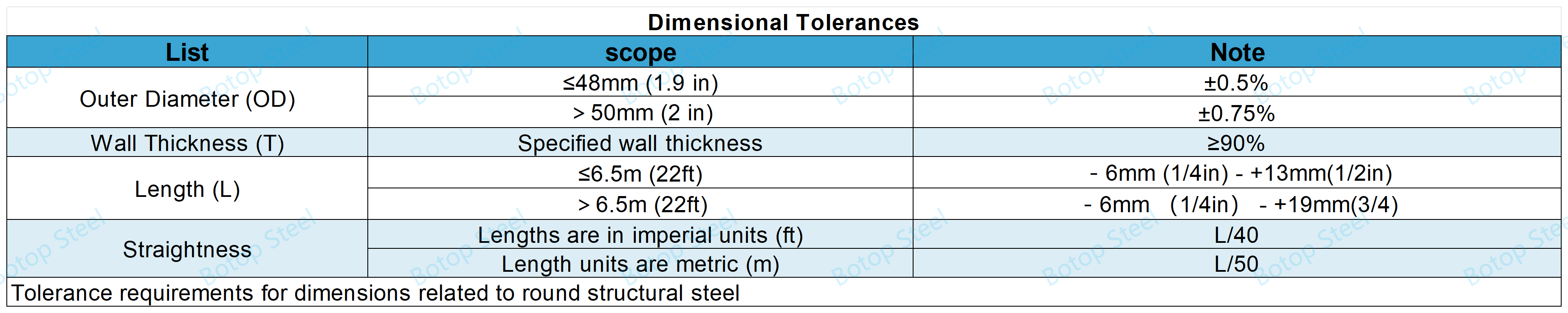

Kwiityhubhu ezineububanzi obungaphandle ≤ 2235mm [88in]kwayeubukhulu bodonga ≤ 25.4mm [1in].

Nangona kunjalo, ukuba kusetyenziswa inkqubo yokuwelda ye-ERW, kuphela imibhobho enobubanzi obuphezulu obuyi-660 mm kunye nobukhulu bodonga obuyi-20 mm bunokwenziwa.

Ukuba ufuna ukuthenga umbhobho onobukhulu bodonga obukhulu, ungakhetha ukusebenzisa inkqubo yokuwelda ye-SAW.

CHS: Amacandelo angqukuva ajikelezayo.

I-RHS: Iinxalenye ezingenanto okanye eziziingxande.

I-EHS: Iindawo ezingenanto ezigobileyo.

Intsimbi mayibe yenziwe ngenye okanye ngaphezulu kwezi nkqubo zilandelayo:ioksijini esisiseko okanye isithando sombane.

Inkqubo ye-Oxygen eSisiseko: Le yindlela yanamhlanje yokuvelisa intsimbi ngokukhawuleza, enciphisa umxholo wekhabhoni ngokuvuthela ioksijini kwisinyithi sehagu esinyibilikisiweyo ngelixa isusa ezinye izinto ezingafunekiyo ezifana nesalfure kunye ne-phosphorus. Ifanelekile kwimveliso ekhawulezayo yentsimbi eninzi.

Inkqubo yeSithando soMbane: Inkqubo yeSithando soMbane isebenzisa i-arc yombane eshushu kakhulu ukunyibilikisa iziqwenga kunye nokunciphisa ngokuthe ngqo isinyithi, kwaye iluncedo kakhulu ekuveliseni amanqanaba akhethekileyo kunye nokulawula ukuhlanganiswa kwe-alloy, kunye nemveliso encinci.

Iityhubhu mazizenziwe yiedityaniswe ngombane (ERW)inkqubo.

Umbhobho we-ERW yinkqubo yokwenza i-weld ngokufaka izinto zesinyithi kwisilinda kunye nokusebenzisa ukumelana kunye noxinzelelo kubude bayo.

Iityhubhu zeBakala B zinokutsalwa okanye zincitshiswe uxinezeleko.

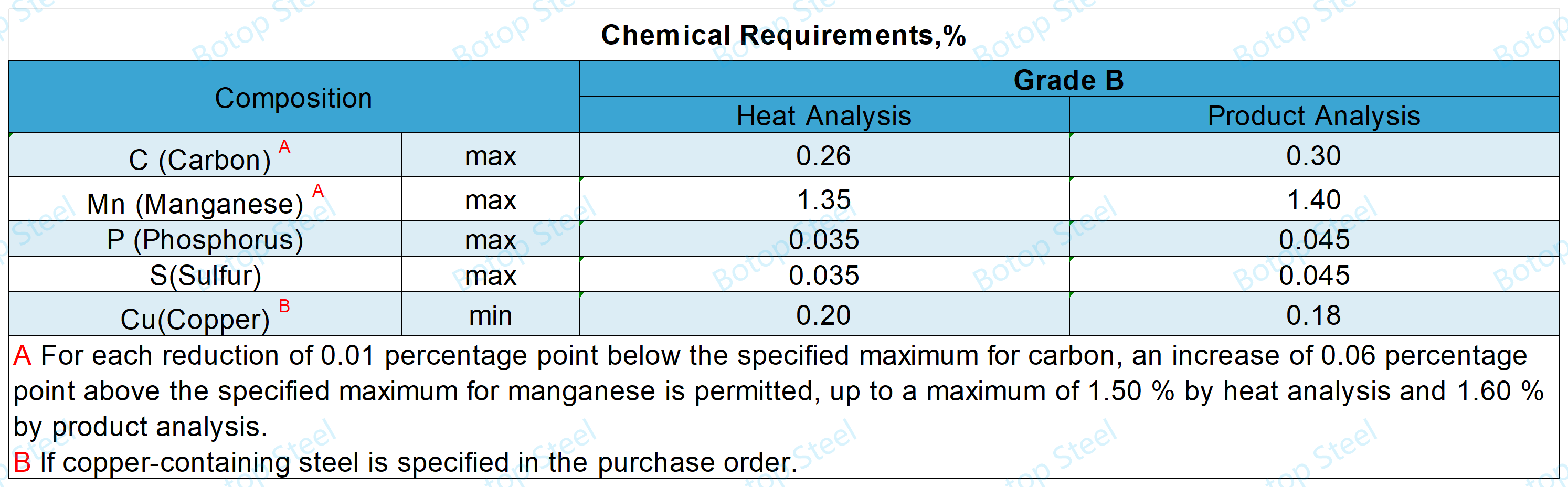

Ulwakhiwo lweekhemikhali lwentsimbi ye-ASTM A500 Grade B luquka ubungakanani obuphakathi bekhabhoni kunye ne-manganese ukuqinisekisa iipropati ezilungileyo zoomatshini kunye nokudityaniswa. Kwangaxeshanye, amanqanaba e-phosphorus kunye ne-sulfur alawulwa ngokuqinileyo ukuze kuthintelwe ukuqhekeka, kwaye ukongezwa okuphakathi kobhedu kuphucula ukumelana nokugqwala.

Ezi mpawu zifanelekile kakhulu kwizicelo zesakhiwo, ingakumbi kwiindawo apho kufuneka ukudityaniswa kakuhle kunye nokuqina.

Imizekelo iya kuhlangabezana neemfuno ezifanelekileyo ze-ASTM A370, Isihlomelo A2.

| Uluhlu | Ibanga B | |

| Amandla okutyhafa, umzuzu | i-psi | 58,000 |

| I-MPa | 400 | |

| Amandla okuvelisa, umzuzu | i-psi | 46,000 |

| I-MPa | 315 | |

| Ukwandiswa kwi-2 intshi. (50 mm), min,C | % | 23A |

| AIsebenza kubukhulu bodonga obuchaziweyo (t) obulingana okanye obungaphezulu kwe-0.180 in. [4.57 mm]. Kubukhulu bodonga obuchaziweyo obukhaphukhaphu, amaxabiso amancinci okwandiswa aza kubalwa ngefomula: ipesenti yokwandiswa kwi-2 in. [50 mm] = 61t+ 12, ejikelezwe kwipesenti ekufutshane. Kwi-A500M sebenzisa le fomyula ilandelayo: 2.4t+ 12, ejikelezwe kwipesenti ekufutshane. CAmaxabiso amancinci okwandiswa achazwe apha asebenza kuphela kuvavanyo olwenziwe ngaphambi kokuthunyelwa kwetyhubhu. | ||

UkuweldadubuchuletEst: Sebenzisa isampuli enobude obuzii-intshi ezi-4 (100 mm), lungisa isampuli nge-weld kwi-90° ukuya kwicala lokulayisha ude umgama phakathi kweepleyiti ube ngaphantsi kwe-2/3 yobubanzi bangaphandle bombhobho. Isampuli ayizukuqhekeka okanye yaphuke kwindawo engaphakathi okanye engaphandle ngeli xesha lenkqubo.

Uvavanyo lokuguguleka kombhobho: qhubeka ucoca isampuli ude umgama phakathi kweepleyiti ube ngaphantsi kwe-1/2 yobubanzi bangaphandle bombhobho. ngeli xesha, umbhobho akufuneki ube nemingxunya okanye amaqhekeza kwiindawo zangaphakathi nezangaphandle.

IngqibelelotEst: Qhubeka ulungisa isampuli de kubekho ukwaphuka okanye de kuhlangatyezwane neemfuno zobukhulu bodonga. Ukuba ubungqina bokuxobuka kweply, izinto ezingazinzanga, okanye ukuwelda okungaphelelanga kufunyenwe ngexesha lovavanyo lokuthamba, isampuli iya kugwetywa njengenganelisiyo.

Uvavanyo lokuvutha luyafumaneka kwiityhubhu ezingqukuva ezinobubanzi obuyi-≤ 254 mm (10 in) ububanzi, kodwa alunyanzelekanga.

Zonke iityhubhu mazingabi naziphene kwaye zibe nomgangatho ofana nowenziwe ngumntu.

Iziphene zomphezulu ziya kuhlelwa njengeziphene xa ubunzulu bazo bunciphisa ubukhulu bodonga obuseleyo bube ngaphantsi kwama-90% obubanzi bodonga obuchaziweyo.

Iziphene ezifikelela kwi-33% yobunzulu bodonga obuchaziweyo zingasuswa ngokupheleleyo ngokusika okanye ngokusila ukuze zibe yintsimbi epheleleyo.

Ukuba kusetyenziswa i-filler welding, kuya kusetyenziswa inkqubo ye-welding emanzi kwaye isinyithi se-weld esiphumayo siya kususwa ukuze kugcinwe umphezulu uthambile.

Iziphene zomphezulu, ezinje ngeempawu zokuphatha, iimpawu zokungunda okanye zokuqengqeleka, okanye imingxunya enganzulu, azithathwa njengeziphene ukuba zinokususwa ngaphakathi kobukhulu bodonga obuchaziweyo.

Olu lwazi lulandelayo kufuneka lufakwe:

Igama lomenzi: Eli lingaba ligama elipheleleyo lomenzi okanye isifinyezo.

Uphawu okanye uphawu lwentengiso: Igama lophawu okanye uphawu lorhwebo olusetyenziswa ngumvelisi ukwahlula iimveliso zakhe.

Umyili weenkcukacha: ASTM A500, okunganyanzelekanga ukuba ibandakanye unyaka wokupapashwa.

Ileta yeBanga: Ibanga B, C okanye D.

Kwiityhubhu zesakhiwo ezi-≤ 100mm (4in) ububanzi, iilebheli zingasetyenziselwa ukuphawula ulwazi lokuchonga ngokucacileyo.

Ngokuyintloko isetyenziselwa iinjongo zokwakha, inika amandla oomatshini afunekayo kunye nokukwazi ukudityaniswa ukuze kuxhaswe uyilo kunye nokwakhiwa kwezakhiwo zokwakha nezobunjineli.

Le pipe yentsimbi isetyenziswa kakhulu ekwakheni izakhelo, iibhulorho, izakhiwo zoshishino, kunye nezinye izinto ezahlukeneyo zesakhiwo ezifuna amandla nokuqina.

I-ASTM A370: Iindlela zoVavanyo kunye neeNkcazelo zoVavanyo lweeMveliso zeNsimbi ngoomatshini.

I-ASTM A700: Isikhokelo sokuPakisha, ukuMakisha, kunye neendlela zokulayisha iimveliso zentsimbi zokuthunyelwa.

I-ASTM A751: Iindlela zoVavanyo kunye neMisebenzi yoHlalutyo lweeKhemikhali lweeMveliso zeNsimbi.

Amagama e-ASTM A941 aphathelele kwiNsimbi, iNsimbi engagqwaliyo, ii-Alloys ezinxulumene nayo, kunye nee-Ferroalloys.

Ngokweemfuno zabathengi, unyango lokulwa nokugqwala kwemiphezulu yemibhobho yentsimbi lunokwenziwa ngeendlela ezininzi ezahlukeneyo ukuphucula ukumelana nokugqwala kwayo nokwandisa ubomi bayo benkonzo.

Kubandakanya i-varnish, ipeyinti, i-galvanization, i-3PE, i-FBE, kunye nezinye iindlela.

Singumvelisi kunye nomthengisi wemibhobho yentsimbi yekhabhoni edityanisiweyo ekumgangatho ophezulu evela eTshayina, kwaye sikwangumthengisi wemibhobho yentsimbi engenamthungo, sikunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Ukuba ufuna ukwazi ulwazi oluthe kratya malunga neemveliso zemibhobho yentsimbi, ungaqhagamshelana nathi!