I-ASTM A335 P9, ekwaziwa ngokuba yi-ASME SA335 P9, ngumbhobho wentsimbi ye-ferritic alloy engenamthungo osetyenziselwa inkonzo yobushushu obuphezulu kunyeInombolo ye-UNS K90941.

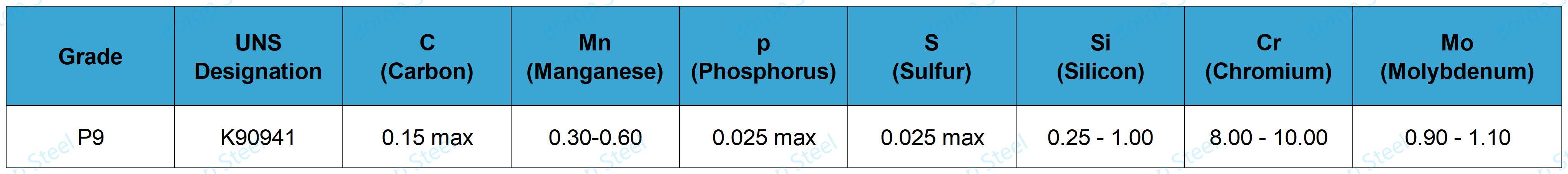

Izinto ezidibanisayo ngokuyintloko yi-chromium kunye ne-molybdenum. Umxholo we-chromium uphakathi kwe-8.00 - 10.00%, ngelixa umxholo we-molybdenum ukwi-0.90% - 1.10%.

P9inamandla agqwesileyo kwaye inokumelana nokugqwala okuhle kwiindawo ezinobushushu obuphezulu kwaye isetyenziswa kakhulu kwiibhoyila, izixhobo zepetrochemical, kunye nezikhululo zamandla apho kufuneka khona iindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu.

⇒ Izixhobo: Umbhobho wentsimbi ye-ASTM A335 P9 / ASME SA335 P9 engenamthungo.

⇒Ububanzi obungaphandle: 1/8"- 24".

⇒Ubukhulu bodongaIimfuneko ze-ASME B36.10.

⇒Ishedyuli: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 kunye neSCH160.

⇒Ukuchongwa: STD (eqhelekileyo), XS (eyomeleleyo kakhulu), okanye XXS (ephindwe kabini eyomeleleyo kakhulu).

⇒Ubude: Ubude obuthile okanye obungacwangciswanga.

⇒Ukwenziwa ngokwezifiso: Ububanzi obungaphandle obungengomgangatho, ubukhulu bodonga, ubude, njl. ngokweemfuno.

⇒Izixhobo: Singabonelela ngezinto ezifanayo zokugoba, ii-stamping flanges, kunye nezinye iimveliso ezixhasa imibhobho yentsimbi.

⇒Isatifikethi se-IBRIsatifikethi se-IBR singabonelelwa ukuba siyafuneka.

⇒Isiphelo: Isiphelo esingenanto, isiphelo esibhityiweyo, okanye isiphelo sombhobho odibeneyo.

⇒Ukupakisha: ityesi yomthi, ibhendi yentsimbi okanye ukupakisha ucingo lwentsimbi, iplastiki okanye umkhuseli wombhobho wentsimbi.

⇒Uthutho: ngolwandle okanye ngeenqwelo-moya.

Umbhobho wentsimbi we-ASTM A335 mawungabi namthungo.

Umbhobho wentsimbi ongenamthungo ngumbhobho wentsimbi ongenazo ii-welds kuyo yonke indawo.

Ekubeni umbhobho wentsimbi ongenamthungo ungenazo izithungo ezidityanisiweyo kwisakhiwo sawo, uphepha iingozi zokhuseleko ezinokubakho ezinokunxulunyaniswa nemiba yomgangatho we-weld. Olu phawu luvumela umbhobho ongenamthungo ukuba umelane noxinzelelo oluphezulu, kwaye ulwakhiwo lwangaphakathi olufanayo luqinisekisa ngakumbi ukuthembeka nokhuseleko lombhobho kwiindawo ezinoxinzelelo oluphezulu.

Ukongeza, ukuthembeka kweetyhubhu ze-ASTM A335 kuphuculwe ngokongezwa kwezinto ezithile zokudibanisa i-alloy kwiimeko zobushushu obuphezulu kunye noxinzelelo oluphezulu.

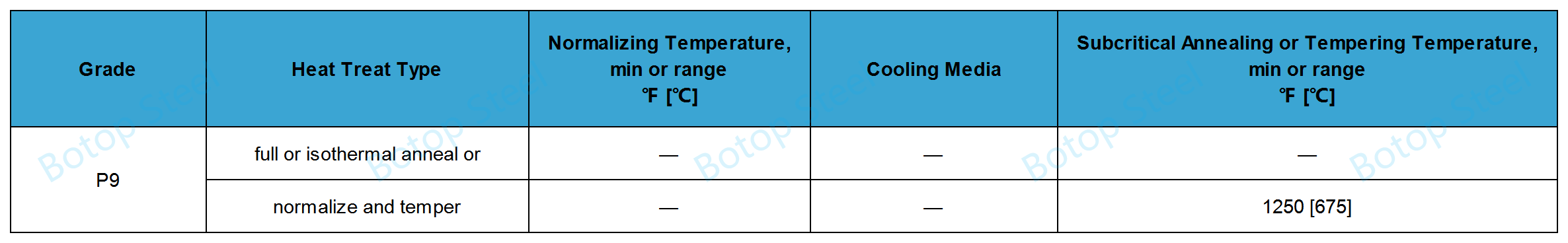

Iintlobo zonyango lobushushu ezikhoyo kwizinto ze-P9 ziquka ukutsalwa kwe-full okanye i-isothermal annealing, kunye nokulungelelanisa kunye nokulungisa. Inkqubo yokulungelelanisa kunye nokulungisa ineqondo lobushushu eliyi-1250°F [675°C].

Izinto eziphambili zokudibanisa ze-P9 zeziCrkwayeMo, eziyi-chromium-molybdenum alloys.

I-Cr (iChromium): Njengento ephambili ye-alloy, i-Cr inika amandla aphezulu obushushu kunye nokumelana ne-oxidation. Yenza ifilimu ye-chromium oxide exineneyo kumphezulu wentsimbi, inyusa uzinzo kunye nokumelana nokugqwala kombhobho kubushushu obuphezulu.

IMo (iMolybdenum): Ukongezwa kweMo kuphucula kakhulu amandla kunye nokuqina kwee-alloys, ingakumbi kwiindawo ezinobushushu obuphezulu. IMo ikwanceda ukuphucula amandla okuhamba kwezinto, oko kukuthi, amandla okumelana nokuguquka xa zichaphazeleka bubushushu ixesha elide.

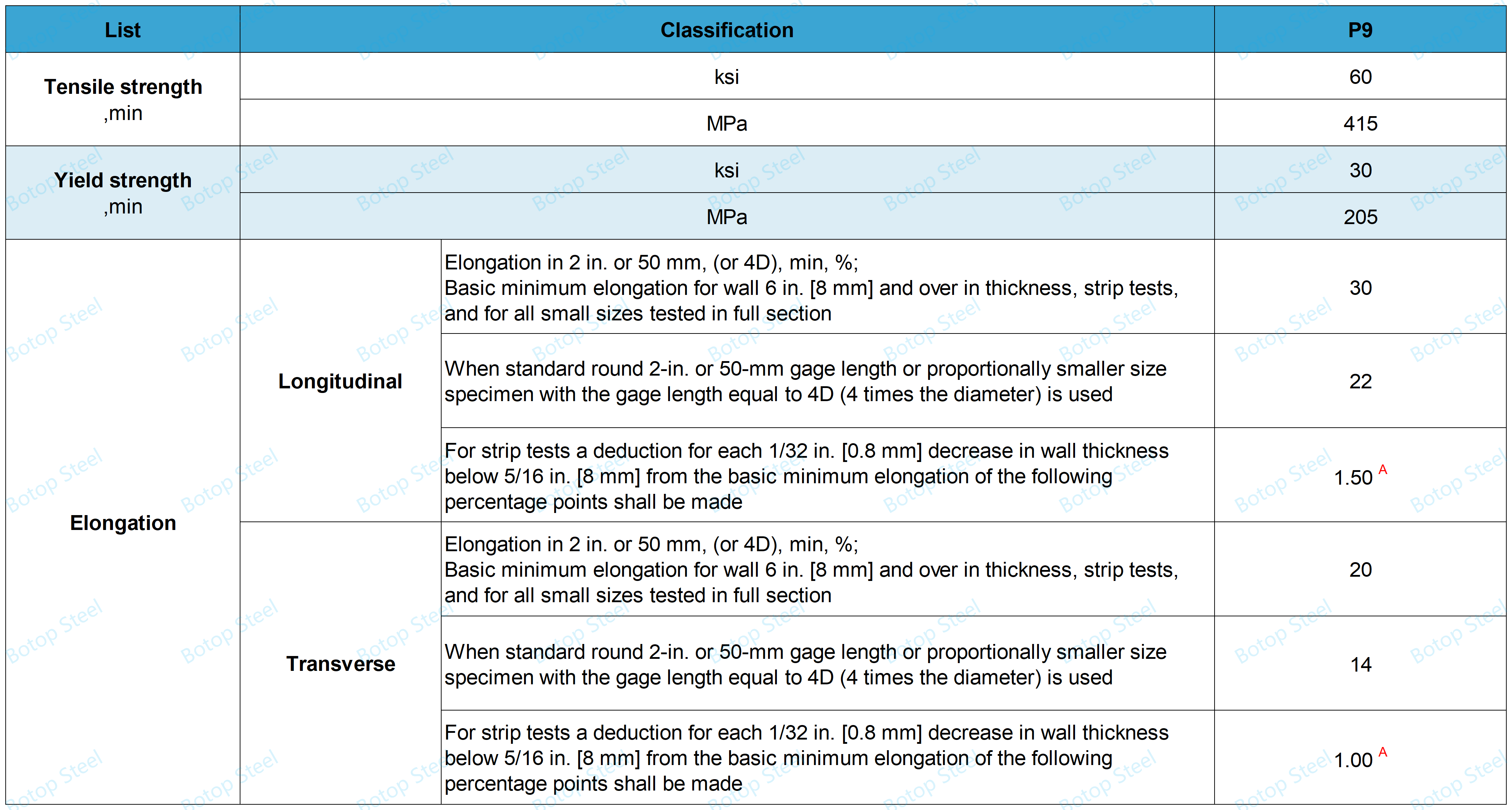

Iipropati zokuThatha

P5, P5b, P5c, P9,P11, P15, P21, kunye neP22Amandla okutsalwa kunye nokuguquguquka kwemveliso ayafana.

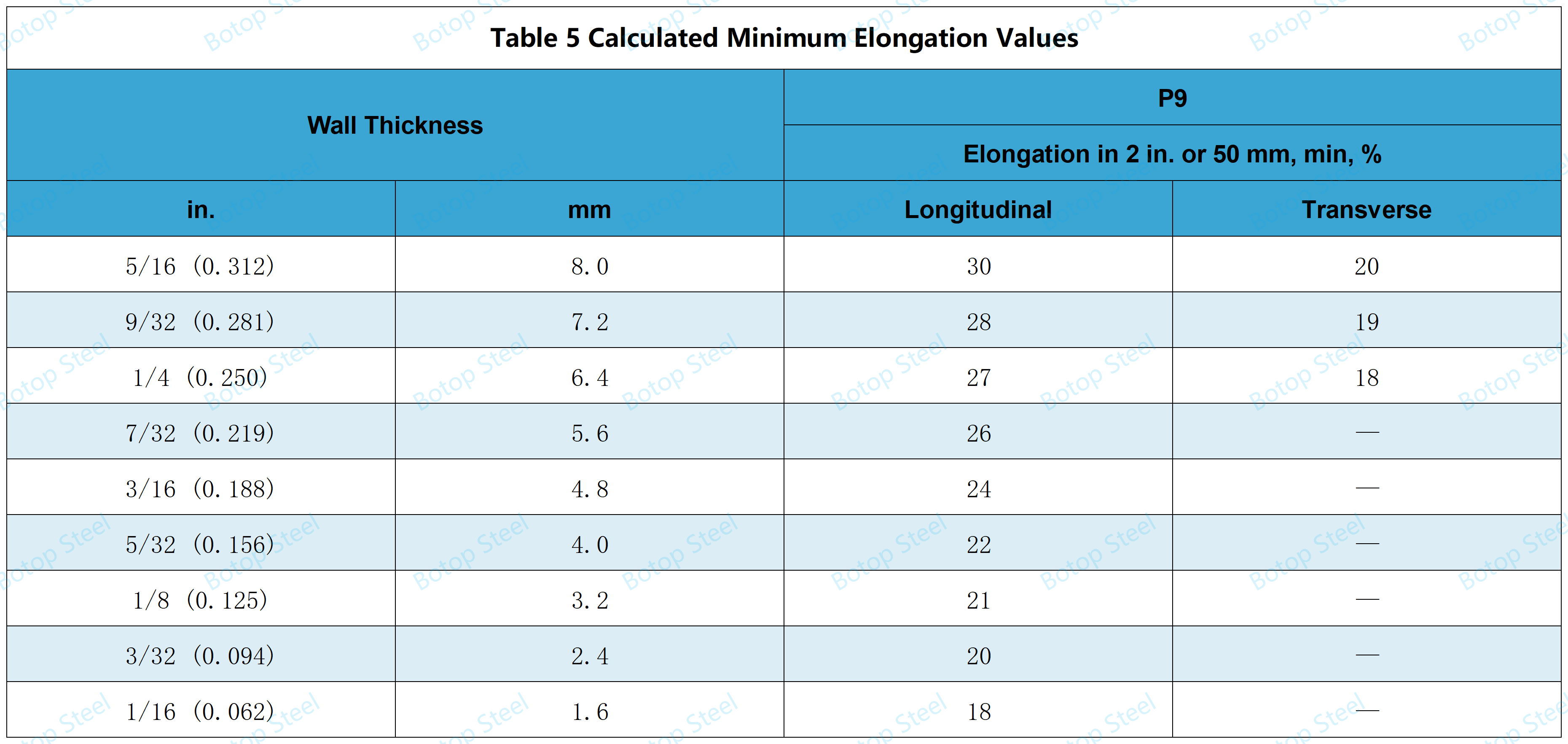

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, kunye ne-P22: Ukwandiswa okufanayo.

AItheyibhile 5 inika amaxabiso aphantsi abaliweyo.

Apho ubukhulu bodonga buphakathi kwamaxabiso amabini angentla, ixabiso elincinci lokwandiswa limiselwa yile fomyula ilandelayo:

I-Longitudinal, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

apho:

E = ubude obuziisentimitha ezi-2 okanye ezingama-50 mm, %,

t = ubukhulu bokwenyani beesampuli, kwi. [mm].

Ukuqina

I-P9 ayifuni uvavanyo lobunzima.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, kunye neP921Akukho mfuneko yovavanyo lobunzima.

Xa ububanzi bangaphandle bungaphezulu kwe-10 intshi. [250 mm] kunye nobukhulu bodonga obuyi-≤ 0.75 intshi. [19 mm], zonke kufuneka zivavanywe ngamanzi.

Uxinzelelo lovavanyo lunokubalwa kusetyenziswa esi sibalo silandelayo.

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S= uxinzelelo lodonga lwepayipi kwi-psi okanye kwi-[MPa];

t= ubukhulu bodonga obuchaziweyo, ubukhulu bodonga obuqhelekileyo ngokwenombolo yeshedyuli ye-ANSI echaziweyo okanye amaxesha ayi-1.143 ubukhulu bodonga obuchaziweyo, kwi. [mm];

D= ububanzi obuchaziweyo bangaphandle, ububanzi obungaphandle obuhambelana nobungakanani bombhobho we-ANSI obuchaziweyo, okanye ububanzi obungaphandle obubalwe ngokongeza i-2t (njengoko kuchaziwe ngasentla) kububanzi obuchaziweyo bangaphakathi, kwi. [mm].

Ixesha lovavanyo: gcina ubuncinane ii-5s, akukho kuvuza.

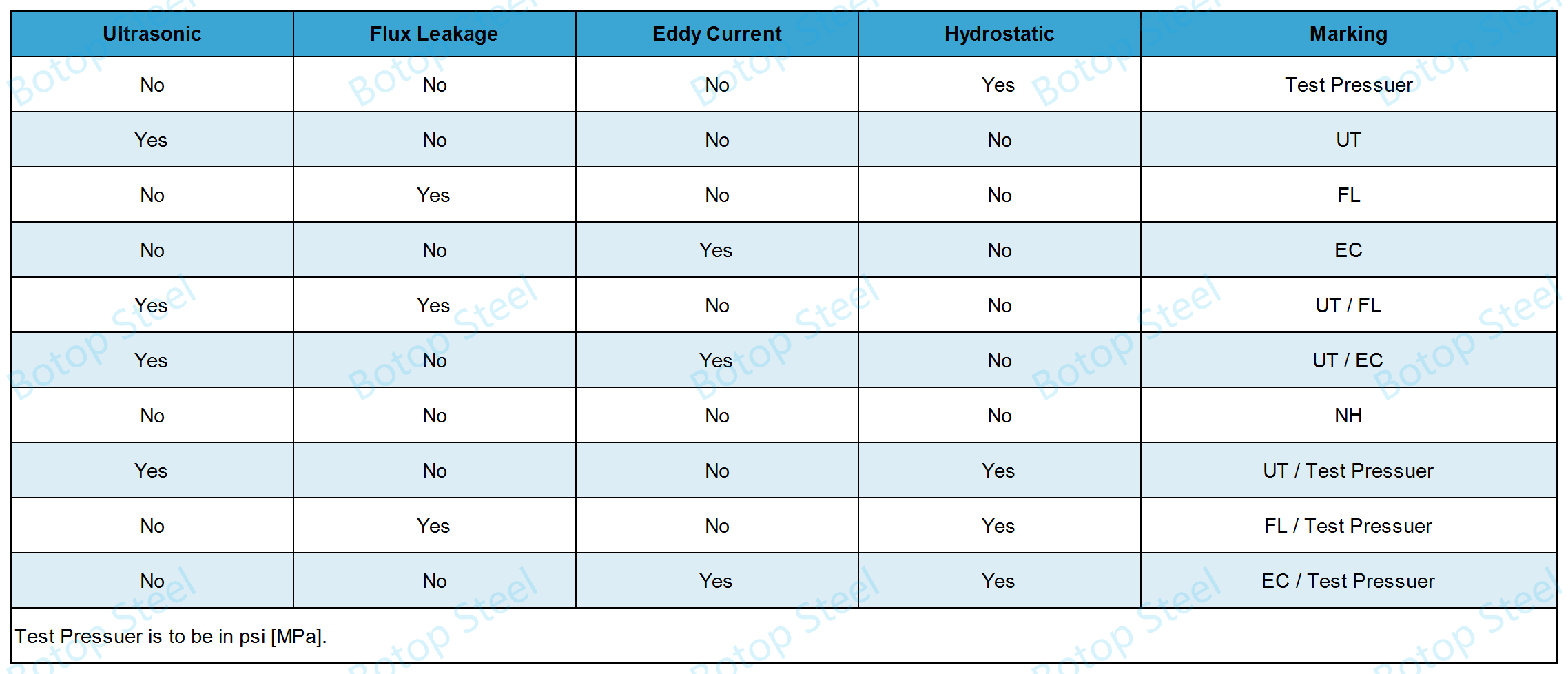

Xa umbhobho ungavavanywa ngamanzi, kufuneka kwenziwe uvavanyo olungonakalisiyo kumbhobho ngamnye ukuze kufunyanwe iziphene.

Uvavanyo olungonakalisiyo lwezinto ze-P9 kufuneka lwenziwe ngenye yeendlelaE213, E309 or E570.

E213: Ukuziqhelanisa noVavanyo lwe-Ultrasonic lweMibhobho yesinyithi kunye neetyhubhu;

E309: Ukuziqhelanisa novavanyo lwangoku lwe-Eddy lweeMveliso zeTubular zeNtsimbi ezisebenzisa iMagnetic Saturation;

E570: Uqheliso loVavanyo lokuVula ukuVula kweFlux lweeMveliso zeFerromagnetic Steel Tubular;

Utshintsho oluvumelekileyo kwiDayamitha

Ukuphambuka kobubanzi kunokwahlulwa ngokwe-1. ngokusekwe kububanzi bangaphakathi okanye 2. ngokusekwe kububanzi obuqhelekileyo okanye bangaphandle.

1. Ububanzi bangaphakathi: ±1%.

2. I-NPS [DN] okanye ububanzi obungaphandle: Oku kuhambelana nokuphambuka okuvumelekileyo kwitheyibhile engezantsi.

Utshintsho oluvumelekileyo kuBungqingqwa bodonga

Ubukhulu bodonga lombhobho nakweyiphi na indawo abuyi kudlula ukunyamezelana okuchaziweyo.

Ubuncinane bobukhulu bodonga kunye nobubanzi bangaphandle bokuhlolwa ukuze kujongwe ukuthotyelwa kwalo mfuneko yombhobho o-odolwe yi-NPS [DN] kunye nenombolo yeshedyuli iboniswe kwiI-ASME B36.10M.

Okuqulethwe kukumakisha: Igama lomenzi okanye uphawu lorhwebo; inombolo eqhelekileyo; ibakala; ubude kunye nophawu olongezelelweyo "S".

Iimpawu zoxinzelelo lwe-hydrostatic kunye novavanyo olungonakalisiyo kwitheyibhile engezantsi nazo mazifakwe.

Indawo yokumakisha: Ukumakisha kufanele kuqale malunga nee-intshi ezili-12 (300 mm) ukusuka esiphelweni sombhobho.

Kwimibhobho efikelela kwi-NPS 2 okanye ngaphantsi kwe-3 ft (1 m) ubude, uphawu lolwazi lunokuncamathiselwa kwithegi.

Umbhobho wentsimbi we-ASTM A335 P9 usetyenziswa kakhulu kwiibhoyila, kwizikhululo zamandla zezixhobo ze-petrochemical, njl.njl., ezifuna ukumelana nobushushu obuphezulu kunye noxinzelelo oluphezulu ngenxa yobushushu obuphezulu kunye nokumelana noxinzelelo oluphezulu.

Iibhoyila: Ingakumbi kwimibhobho ephambili yomphunga kunye nemibhobho yokuphinda ifudumale yeebhoyila ezibaluleke kakhulu nezibaluleke kakhulu kumaqondo obushushu aphezulu kakhulu kunye noxinzelelo.

Izixhobo zePetrochemical: Ezifana neepayipi ze-cracker kunye neepayipi zobushushu obuphezulu, eziphatha umphunga kunye neekhemikhali zobushushu obuphezulu, zifuna izixhobo ezinobushushu obuhle kunye nokumelana nokugqwala.

Izikhululo zamandla: Kwimibhobho ephambili yomphunga kunye nezifudumezi zoxinzelelo oluphezulu, kunye nemibhobho yangaphakathi yeturbine ukuze ikwazi ukumelana nexesha elide lobushushu obuphezulu kunye noxinzelelo.

Izixhobo ze-P9 zinemigangatho yazo esemgangathweni kwiinkqubo ezahlukeneyo zemigangatho yesizwe.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

I-JIS G3462: STBA 26;

I-ISO 9329: 12CrMo195;

I-GOST 550: 12ChM;

Ngaphambi kokukhetha naziphi na izinto ezifanayo, kucetyiswa ukuba kwenziwe uthelekiso oluneenkcukacha zokusebenza kunye novavanyo ukuqinisekisa ukuba ezinye izinto ziya kuhlangabezana neemfuno zoyilo lokuqala.

Ukususela oko yasekwa ngo-2014,Intsimbi yeBotopiye yaba ngumthengisi ophambili wemibhobho yentsimbi yekhabhoni eMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Le nkampani inikezela ngeendidi ngeendidi zeepayipi zentsimbi yekhabhoni kunye neemveliso ezinxulumene nazo, kuquka ipayipi yentsimbi engenamthungo, i-ERW, i-LSAW, kunye ne-SSAW, kunye noluhlu olupheleleyo lwee-fittings zepayipi kunye nee-flanges. Iimveliso zayo ezikhethekileyo ziquka ii-alloys ezikumgangatho ophezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

Nceda uzive ukhululekile ukuqhagamshelana nathi ukuba unayo nayiphi na imfuno okanye imibuzo malunga neetyhubhu zentsimbi. Silangazelela ukufumana ulwazi lwakho kwaye silangazelela ukukunceda.