I-ASTM A335 P11Umbhobho wentsimbi ngumbhobho wentsimbi ye-ferritic low alloy engenamthungo yenkonzo yobushushu obuphezulu, igama le-UNS K11597.

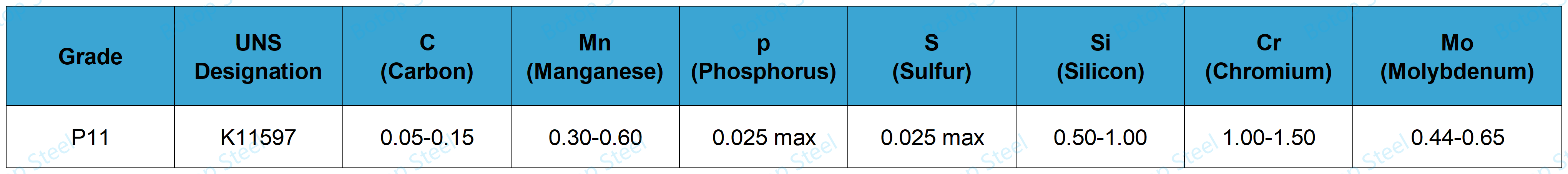

I-P11 yi-alloy ye-chromium-molybdenum enomxholo we-chromium oyi-1.00-1.50% kunye nomxholo we-molybdenum oyi-0.44-0.65%.

Isetyenziswa kakhulu kwiibhoyila, ii-superheater, kunye nee-heat exchangers kwizikhululo zamandla kunye nezityalo zeekhemikhali.

Iimfuno zobugcisa zeI-ASME SA335kwayeI-ASTM A335ziyafana, ngoko ke ukuze kube lula ukubonakalisa, siza kusebenzisa i-"ASTM A335" ukubhekisa kwezi migangatho mibini.

Izintol: Umbhobho wentsimbi engenamthungo we-ASTM A335 P11;

OD: 1/8"- 24";

WT: ngokwenxa yeI-ASME B36.10iimfuno;

Ishedyuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kunye neSCH160;

Ukuchongwa: STD, XS, XXS;

Ukwenziwa ngokwezifiso: Kukho nobukhulu beepayipi obungengomgangatho, ubungakanani obulungiselelwe wena bufumaneka xa buceliwe;

Ubude: Ubude obuthile nobungacwangciswanga;

Isiqinisekiso se-IBR: Singaqhagamshelana nombutho wokuhlola wesithathu ukuze sifumane isiqinisekiso se-IBR ngokweemfuno zakho, imibutho yethu yokuhlola intsebenziswano yi-BV, i-SGS, i-TUV, njl.njl.;

Isiphelo: Isiphelo esithe tyaba, esibhityiweyo, okanye esidityanisiweyo sombhobho;

Umphezulu: Umbhobho olula, ipeyinti, kunye nolunye ukhuselo lwexeshana, ukususwa nokupholishwa komhlwa, ukugqunywa nge-galvanized kunye neplastiki, kunye nolunye ukhuselo lwexesha elide;

Ukupakisha: Ibhokisi yomthi, ibhande lentsimbi okanye ucingo lwentsimbi, iplastiki okanye umkhuseli wombhobho wentsimbi, njl.njl.

Ngaphandle kokuba kuchazwe ngenye indlela kwi-A335, izixhobo ezinikezelwe phantsi kwale nkcazelo ziya kuhambelana neemfuno ezifanelekileyo zohlelo lwangoku lweNgcacisoA999/A999M.

Umbhobho wentsimbi we-ASTM A335 kufuneka ubeingenamthungoIityhubhu zentsimbi ezingenamthungo zinika ukuthembeka okukhulu kunye nokufana xa ziphantsi koxinzelelo oluphezulu kunye nobushushu obuphezulu.

I-seamless inokwahlulwa ngokweendidi ezitsalwa ngokubandayo kunye ne-hot finished, kuxhomekeke kwisicelo kunye nobukhulu obuthile.

Umzobo obandayo udla ngokusetyenziselwa iidayamitha ezincinci okanye iityhubhu ezifuna ukuchaneka okuphezulu kunye nomgangatho olungileyo womphezulu. Ukugqitywa okushushu kudla ngokusetyenziselwa ukuvelisa iipayipi ezinkulu zentsimbi ezithe nkqo nezinodonga oluqinileyo.

Apha ngezantsi kukho itshathi yenkqubo yokwenziwa kombhobho wentsimbi ongenamthungo ogqityiweyo ngobushushu.

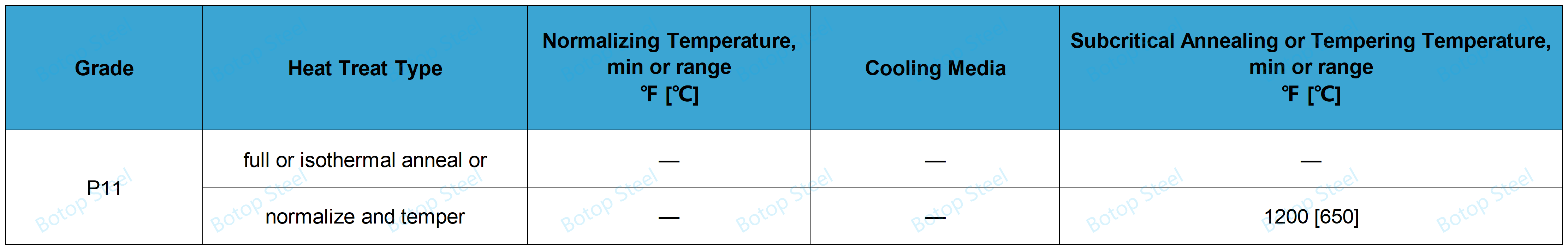

Unyango lobushushu lwezinto ze-P11 lunokuba kukufakelwa ngokupheleleyo okanye kufakwe i-isothermal okanye kufakwe i-temperature emva kokulungiswa, kwaye xa kulungiswa kwaye kusenziwa i-temperature, ubushushu bokufakwa kwe-temperature kufuneka bube yi-1200°F (650°C).

Ukusuka kwimilo yeekhemikhali, sinokubona lula ukubaI-P11 yi-alloy ye-chromium-molybdenum.

Ii-alloy zeChromium-molybdenum ziluhlobo lweentsimbi ezine-chromium (Cr) kunye ne-molybdenum (Mo) njengezona zinto ziphambili zokuxutywa. Ukongezwa kwezi zinto kwandisa kakhulu amandla, ubulukhuni, ukumelana nokuguguleka, kunye nokumelana nokugqwala kwentsimbi. Kumaqondo obushushu aphezulu, ii-alloy zeCr-Mo ziyakwazi ukugcina iipropati ezilungileyo zoomatshini kunye nesakhiwo esizinzileyo.

Cr: iphucula ukumelana ne-oxidation kunye nokumelana nokugqwala kwe-alloy, inceda ekwenzeni ifilimu ye-oxide enamandla, kwaye ikhusela izinto kwi-media egqwalisayo.

Mo: Yonyusa amandla e-alloy, ingakumbi kumaqondo obushushu aphezulu, iphucula ukumelana nokuqhekeka, kwaye yonyusa amandla obushushu aphezulu ezinto.

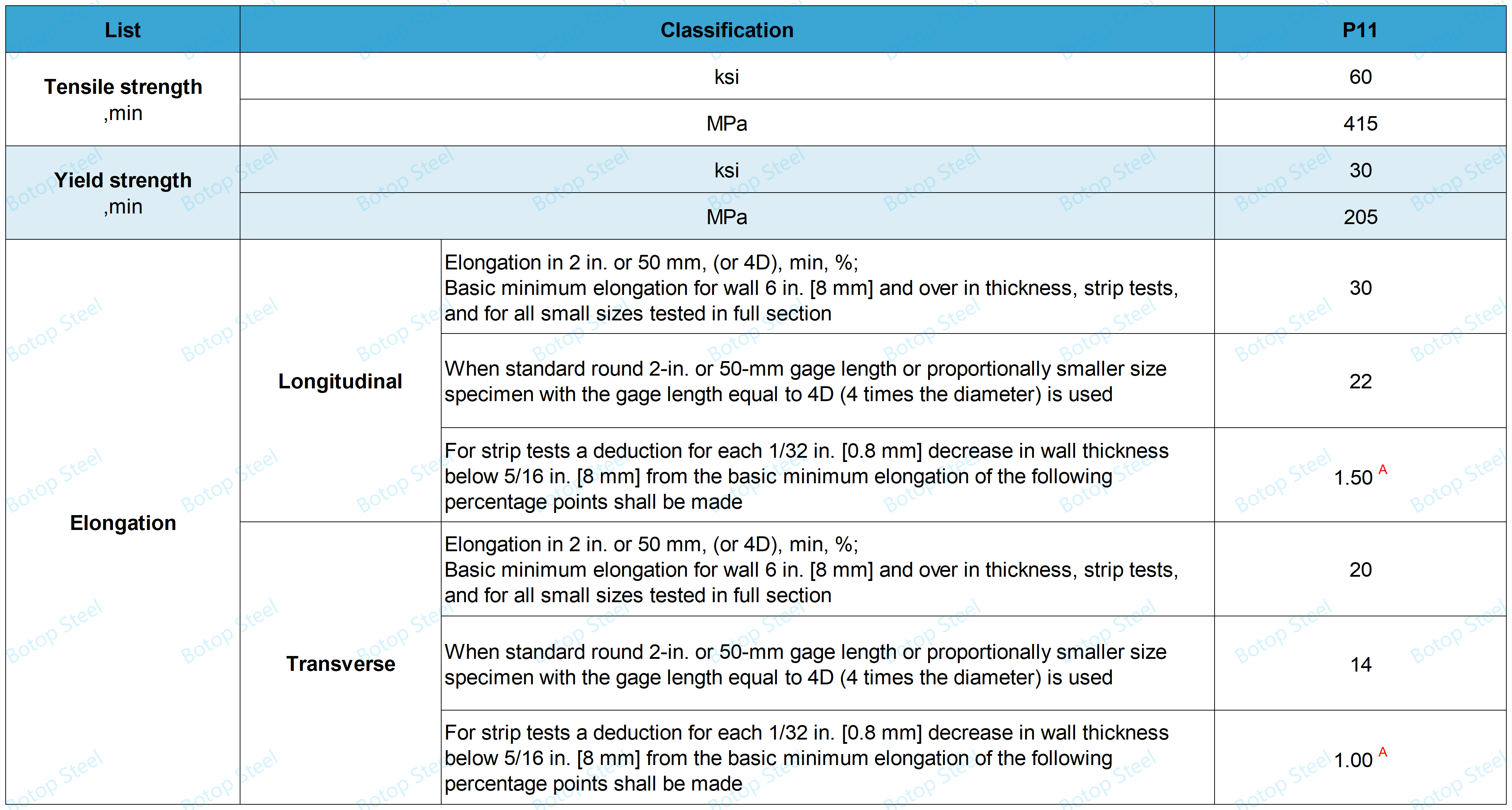

1. Ipropati yokuThatha

Uvavanyo lokuxinana lusetyenziswa rhoqo ukulinganisaunikeze Amandla, tensile strengthkunyeubuden yenkqubo yovavanyo lombhobho wentsimbi, kwaye isetyenziswa kakhulu kwiimpawu zezinto zovavanyo.

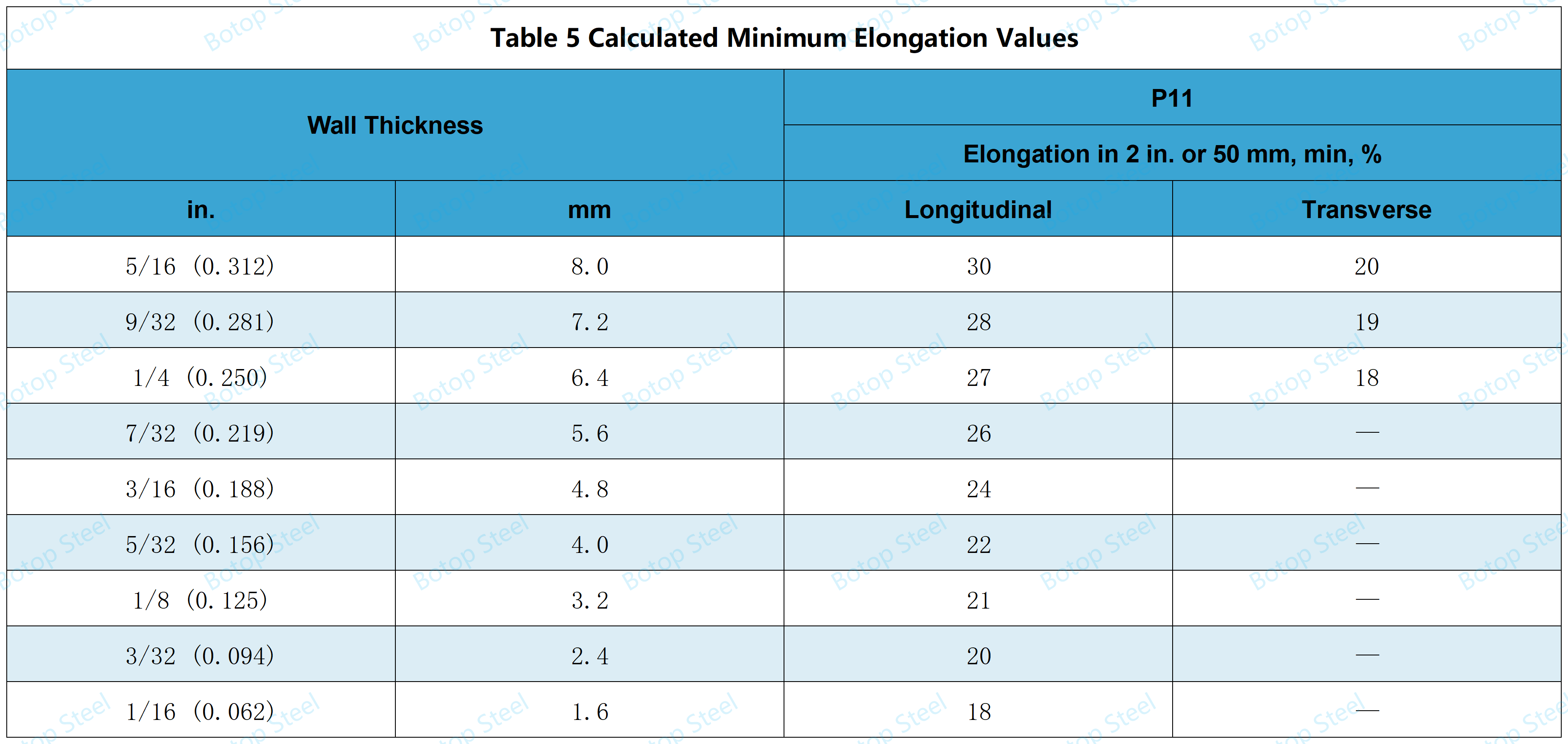

AItheyibhile 5 inika amaxabiso aphantsi abaliweyo.

Apho ubukhulu bodonga buphakathi kwamaxabiso amabini angentla, ixabiso elincinci lokwandiswa limiselwa yile fomyula ilandelayo:

I-Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

I-Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

apho:

E = ubude obuziisentimitha ezi-2 okanye ezingama-50 mm, %,

t = ubukhulu bokwenyani beesampuli, kwi. [mm].

2. Ukuqina

Umbhobho we-Grade P11 awudingi vavanyo lobunzima.

Ixabiso lobunzima obubhekisele kulo libonelelwe ngezantsi.

Imeko eyongeziweyo:

Ubunzima buhlala buphakathi kwe-150 kunye ne-200 HB.

Imeko eqhelekileyo neyomeleleyo:

Ubunzima buqala kwi-170 ukuya kwi-220 HB.

Imeko eqinileyo neyomeleleyo:

Ukuqina kunokufikelela kwi-250 ukuya kwi-300 HB nangaphezulu, kuxhomekeke kubushushu kunye nexesha lokufudumala.

3. Iinkqubo zovavanyo ezikhethwayo

Ezi zinto zilandelayo zovavanyo azifuneki, ukuba kuyimfuneko zinokumiselwa ngokuxoxisana.

Uhlalutyo lweMveliso

Uvavanyo lokuTyatya

Uvavanyo lwe-Bend

Uvavanyo lweSitayile kunye novavanyo lokuGcina

Iifotomicrographs

Iifotomicrographs zeeMpawu eziZodwa

I-P11 hydrotest kufuneka ihambelane neemfuno ezilandelayo.

Ububanzi bangaphandle >10in. [250mm] kunye nobukhulu bodonga ≤ 0.75in. [19mm]: olu kufuneka lube luvavanyo lwe-hydrostatic.

Ezinye iisayizi zovavanyo lombane olungatshabalalisiyo.

Ezi mfuno zilandelayo zovavanyo lwe-hydrostatic ziqokelelwe kwiimfuno ze-ASTM A999:

Kwimibhobho yentsimbi ye-ferritic alloy kunye ne-stainless steel, udonga luphantsi koxinzelelo olungaphantsiI-60% yamandla amancinci esivuno akhankanyiweyo.

Uxinzelelo lovavanyo lwe-hydro kufuneka lugcinwe ubuncinane 5sngaphandle kokuvuza okanye ezinye iziphene.

Uxinzelelo lwe-hydraulicingabalwa kusetyenziswa le fomula:

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S = uxinzelelo lodonga lwepayipi kwi-psi okanye kwi-[MPa];

t = ubukhulu bodonga obuchaziweyo, ubukhulu bodonga obuqhelekileyo ngokwenombolo yeshedyuli ye-ANSI echaziweyo okanye amaxesha ayi-1.143 ubukhulu bodonga obuchaziweyo, ngo. [mm];

D = ububanzi obuchaziweyo bangaphandle, ububanzi obungaphandle obuhambelana nobungakanani bombhobho we-ANSI obuchaziweyo, okanye ububanzi obungaphandle obubalwe ngokongeza i-2t (njengoko kuchaziwe ngasentla) kububanzi obuchaziweyo bangaphakathi, kwi. [mm].

Umbhobho ngamnye kufuneka uhlolwe ngendlela yokuhlola engonakalisiyo ngokweMisebenziE213, UkuziqhelanisaE309, okanye UkuziqhelanisaE570.

Utshintsho oluvumelekileyo kwiDayamitha

Kwipayipi e-odolwe ukubaububanzi bangaphakathi, ububanzi bangaphakathi abuyi kwahluka ngaphezu kwe-±1% ukusuka kububanzi bangaphakathi obuchaziweyo.

Utshintsho oluvumelekileyo kuBungqingqwa bodonga

Ukulinganiswa kobukhulu bodonga kufuneka kwenziwe kusetyenziswa ii-calipers zoomatshini okanye izixhobo zokuvavanya ezingatshabalalisiyo ezilinganiswe ngokufanelekileyo ngokuchanekileyo. Kwimeko yengxabano, ukulinganiswa okumiselwe kusetyenziswa ii-calipers zoomatshini kuya kusebenza.

Ubukhulu obuncinci bodonga kunye nobubanzi bangaphandle bokuhlolwa ukuze kujongwe ukuthotyelwa kwalo mfuneko yombhobho o-odolwe yi-NPS [DN] kunye nenombolo yeshedyuli kuboniswe aphaI-ASME B36.10M.

Isetyenziswa rhoqo kwiibhoyila, ii-superheater, kunye nee-heat exchangers kwizikhululo zamandla kunye nezityalo zeekhemikhali.

Iibhoyila: I-P11 isetyenziswa kakhulu ekwakheni iibhoyila ngenxa yokuxhathisa kwayo kumaqondo obushushu aphezulu kunye noxinzelelo, ingakumbi kwiindawo eziphantsi kwamaqondo obushushu aphezulu kunye noxinzelelo.

I-Superheater: Isetyenziselwa ukonyusa ubushushu bomphunga ukuze kuphuculwe ukusebenza kakuhle kobushushu. I-p11 iqinisekisa ukuba amandla kunye nokuqina kwezinto zigcinwa nokuba kubushushu obuphezulu.

Izitshintshi zobushushu: I-P11 iphucula ukugqwala kunye nokumelana nobushushu obuphezulu kwezitshintshi zobushushu, ngaloo ndlela iphucula ukuthembeka kunye nokhuseleko lwezixhobo.

Iinkqubo zombhobho: Iinkqubo zokufaka imibhobho kwizityalo zeekhemikhali zihlala zifuna ukuthutha ulwelo olushushu kakhulu okanye umphunga. Amandla obushushu aphezulu kunye neempawu ezilungileyo zoomatshini ze-P11 zenza ukuba ilungele ezi zicelo.

a) Ilingana nantoni i-ASTM A335 P11?

GI-B/T 5310: 12CrMo;

I-DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

I-BS 3604: 10CrMo9-10;

I-JIS G3462: STPA23;

I-GOST 550-75: 12Kh1MF.

b)Ngaba i-P11 yintsimbi engenazo izinto ezininzi?

Ewe, i-P11 yintsimbi ethambileyo nengenamthungo.

Intsimbi ye-alloy ephantsi yi-alloy yentsimbi-yekhabhoni apho kongezwe khona enye okanye ngaphezulu kwezinto zokudibanisa (umz., i-chromium, i-molybdenum, i-nickel, njl.njl.), kunye nomxholo we-alloying iyonke ngokubanzi ukusuka kwi-1 ukuya kwi-5%.

c)Ingakanani amandla okuxinana e-ASTM A335 P11?

Ubuncinane bokutsalwa kwamandla yi-415 MPa [60 ksi].

d)Ingakanani amandla okuvelisa i-ASTM A335 P11?

Ubuncinane bokutsalwa kwamandla yi-205 MPa [30 ksi].

e) Ingakanani imida yobushushu ye-ASTM A335 P11?

Kwiindawo ezikhupha i-oxidation: Amaqondo obushushu aphezulu ahlala emalunga ne-593°C (1100°F).

Kwiindawo ezingena-oxidizing: amaqondo obushushu aphezulu enkonzo amalunga nama-650°C (1200°F) anokufikelelwa.

f)Ingaba i-A335 P11 yimagnethi?

Inomtsalane kubushushu begumbi. Le mpawu inokuba luncedo kwezinye iinkqubo, njengaxa kufuneka ukuba izinto zihambelane nezixhobo zokuchonga imagnethi.

g)Ixabiso le-ASTM A335 P11 lithini?

Amaxabiso ayahluka ngokwemarike, nxibelelana nathi ukuze ufumane ikowuteshini echanekileyo.