I-ASTM A335 P91, kwaziwa njengeI-ASME SA335 P91, ngumbhobho wentsimbi ye-ferritic alloy engenamthungo yenkonzo yobushushu obuphezulu, i-UNS No. K91560.

Inobuncinciamandla okutsalwa angama-585 MPa(85 ksi) kunye nobuncinciamandla okuvelisa angama-415 MPa(60 ksi).

I-P91ikakhulu iqulethe izinto zokudibanisa ezifana ne-chromium kunye ne-molybdenum, kwaye kongezwa ezinye izinto ezahlukeneyo zokudibanisa, ezizezakhointsimbi ene-alloy ephezulu, ngoko ke inamandla kakhulu kwaye inokumelana nokugqwala okugqwesileyo.

Ukongeza, i-P91 ifumaneka kwiindidi ezimbini,Uhlobo 1kwayeUhlobo 2, kwaye isetyenziswa rhoqo kwizikhululo zamandla, kwiindawo zokucoca, kwiindawo zeekhemikhali izixhobo ezibalulekileyo, nakwiindawo zokufaka imibhobho kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu.

Umbhobho wentsimbi we-P91 wahlulwe waba ziintlobo ezimbini, Uhlobo 1 kunye noHlelo 2.

Zombini ezi ntlobo ziyafana ngokweempawu zoomatshini kunye nezinye iimfuno ezifana nonyango lobushushu,ngomahluko omncinci kulwakhiwo lweekhemikhali kunye nogxininiso oluthile lwesicelo.

Ukwakheka kweekhemikhali: Xa kuthelekiswa nohlobo loku-1, ukwakheka kweekhemikhali zohlobo lwesi-2 kuqinile ngakumbi kwaye kuqulethe izinto ezidibanisayo ukuze kubonelelwe ngokumelana nobushushu nokugqwala okungcono.

IziceloNgenxa yokwakheka kweekhemikhali okwenziwe ngcono, uhlobo lwesibini lufanelekile ngakumbi kumaqondo obushushu aphezulu kakhulu okanye kwiindawo ezinobungozi ngakumbi, okanye kwiindawo apho kufuneka amandla aphezulu kunye nokuqina.

Umbhobho wentsimbi we-ASTM A335 kufuneka ubeingenamthungo.

Inkqubo yokuvelisa engenamthungo ihlulwe ngokwezigabaukugqiba okushushukwayeitsalwa kubanda.

Apha ngezantsi kukho umzobo wenkqubo yokugqiba eshushu.

Ngokukodwa, i-P91, umbhobho wentsimbi one-alloy ephezulu, odla ngokusetyenziswa kwiindawo ezinzima phantsi kobushushu obuphezulu kunye noxinzelelo, umbhobho wentsimbi ongenamthungo uxinezelekile ngokulinganayo kwaye unokwenziwa ube neendonga ezixineneyo, ngaloo ndlela kuqinisekiswa ukhuseleko oluphezulu kunye nokusebenza kakuhle kweendleko.

P91 Zonke iipayipi kufuneka zilungiswe ngobushushu ukuze kuphuculwe ulwakhiwo lwepayipi, kuphuculwe iimpawu zayo zoomatshini, kwaye konyuswe ukumelana nobushushu obuphezulu kunye noxinzelelo.

| Ibanga | Uhlobo lokunyanga ubushushu | Ukutshintsha Ubushushu | Ubushushu bokuTshisa |

| Uhlobo lwe-P91 kunye nohlobo lwe-2 | ukwenza izinto zibe zesiqhelo kwaye zivuselele okanye | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 ~ 1470 ℉ [730 - 800 ℃] |

| ukuthomalalisa kunye nomsindo | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 - 1470 ℉ [730 - 800 ℃] |

Iinxalenye zeekhemikhali zohlobo lwe-P91 Uhlobo 1

| Ibanga | Ulwakhiwo, % | ||||||

| Uhlobo lwe-P91 1 | C | Mn | P | S | Si | Cr | Mo |

| 0.08 - 0.12 | 0.30 - 0.60 | Ubuninzi be-0.020 | Ubuninzi be-0.010 | 0.20 - 0.50 | 8.00 - 9.50 | 0.85 - 1.05 | |

| V | N | Ni | Al | Nb | Ti | Zr | |

| 0.18 - 0.25 | 0.030 - 0.070 | Ubuninzi obuyi-0.40 | Ubuninzi obuyi-0.02 | 0.06 - 0.10 | Ubuninzi obuyi-0.01 | Ubuninzi obuyi-0.01 | |

Iinxalenye zeekhemikhali zohlobo lwe-P91 Uhlobo lwesi-2

| Ibanga | Ulwakhiwo, % | ||||||

| Iinxalenye zeekhemikhali zemveliso yohlobo lwe-P91 Uhlobo lwesi-2 | C | Mn | P | S | Si | Cr | Mo |

| 0.07 - 0.13 | 0.30 - 0.50 | Ubuninzi be-0.020 | Ubuninzi be-0.005 | 0.20 - 0.40 | 8.00 - 9.50 | 0.80 - 1.05 | |

| V | Ni | Al | N | Umlinganiselo we-N/Al | Nb | Ti | |

| 0.16 - 0.27 | Ubuninzi obuyi-0.20 | Ubuninzi obuyi-0.02 | 0.035 - 0.070 | ≥ 4.0 | 0.05 - 0.11 | Ubuninzi obuyi-0.01 | |

| Zr | Sn | Sb | As | B | W | Cu | |

| Ubuninzi obuyi-0.01 | Ubuninzi obuyi-0.01 | 0.003 ubuninzi | Ubuninzi obuyi-0.01 | 0.001 ubuninzi | Ubuninzi be-0.05 | Ubuninzi be-0.10 | |

Ngemifanekiso emibini engentla, kulula ukubona umahluko phakathi kwezinto zekhemikhali zohlobo 1 kunye nohlobo 2 kunye nemiqathango.

1. Ipropati yokuThatha

Uvavanyo lokuxinana lusetyenziswa rhoqo ukulinganisaunikeze Amandla, tensile strengthkunyeubuden yenkqubo yovavanyo lombhobho wentsimbi, kwaye isetyenziswa kakhulu kwiimpawu zezinto zovavanyo.

| Uhlobo lwe-P91 kunye nohlobo lwe-2 | |||

| Tensile strength | 85 ksi [585 MPa] min | ||

| Unikeze Amandla | 60 ksi [415 MPa] min | ||

| Ukwandiswa | Iimfuneko zoLongezo | I-Longitudinal | I-Transverse |

| Ukwandiswa kwe-2 in. okanye i-50 mm, (okanye i-4D), min, %; Ukwandiswa okusisiseko kodonga oluyi-6 intshi [8 mm] nangaphezulu ngobukhulu, iimvavanyo ze-strip, kunye nazo zonke iisayizi ezincinci ezivavanyiweyo kwicandelo elipheleleyo | 20 | — | |

| Xa kusetyenziswa isampuli eqhelekileyo ejikelezileyo enobude obuziisentimitha ezi-2 okanye ezingama-50 okanye ubungakanani obuncinci ngokulinganayo enobude obuziisentimitha ezi-4 (ubude obuphindwe kane kunobubanzi) | 20 | 13 | |

| Kwiimvavanyo ze-strip, kufuneka kuncitshiswe ukwehla ngakunye kwe-1/32 intshi. [0.8 mm] kobukhulu bodonga obungaphantsi kwe-5/16 intshi. [8 mm] ukusuka ekunyuseni okusisiseko kwamanqaku alandelayo epesenti. | 1 | — | |

2. Ukuqina

Iindlela ezahlukeneyo zokuvavanya ubulukhuni zingasetyenziswa, kuquka uVickers, uBrinell, kunye noRockwell.

| Ibanga | UBrinell | uVickers | uRockwell |

| Uhlobo lwe-P91 kunye nohlobo lwe-2 | 190 - 250 HBW | 196 - 265 HV | 91 HRBW - 25HRC |

Ubukhulu bodonga <0.065 in. [1.7 mm]: Akukho mfuneko yovavanyo lobunzima;

0.065 in. [1.7 mm] ≤ ubukhulu bodonga <0.200 in. [5.1 mm]: Kufuneka kusetyenziswe uvavanyo lokuqina kweRockwell;

Ubukhulu bodonga ≥ 0.200 in. [5.1 mm]: ukusetyenziswa kovavanyo lobunzima beBrinell okanye uvavanyo lobunzima beRockwell ngokuzithandela.

Uvavanyo lokuqina kweVickers lusebenza kuzo zonke iindonga ezinkulu zeetyhubhu. Indlela yovavanyo yenziwa ngokuhambelana neemfuno ze-E92.

3. Uvavanyo lokuThabatha

Uvavanyo luza kwenziwa ngokuhambelana neCandelo 20 lomgangatho we-ASTM A999.

4. Uvavanyo lokugoba

Goba nge-180° kubushushu begumbi, akukho mifantu iya kuvela ngaphandle kwenxalenye egobileyo.

Ubungakanani > NPS25 okanye D/t ≥ 7.0: Uvavanyo lokugoba kufuneka lwenziwe ngaphandle kovavanyo lokucaba.

5. Iinkqubo zovavanyo eziKhethekileyo ze-P91

Ezi zinto zilandelayo zovavanyo azifuneki, ukuba kuyimfuneko zinokumiselwa ngokuxoxisana.

S1: Uhlalutyo lweMveliso

S3: Uvavanyo lokuThabatha

S4: Uvavanyo loLwakhiwo lweSinyithi kunye nokuQongwa

S5: Iifotomicrographs

S6: Iifotomicrographs zeeMpawu eziZodwa

S7: Unyango lobushushu olungeyoNcedo-Udidi lwe-P91 Uhlobo 1 kunye noHlobo 2

Uvavanyo lwe-P91 hydro kufuneka luhambelane neemfuno ezilandelayo.

Ububanzi bangaphandle >10in. [250mm] kunye nobukhulu bodonga ≤ 0.75in. [19mm]: olu kufuneka lube luvavanyo lwe-hydrostatic.

Ezinye iisayizi zovavanyo lombane olungatshabalalisiyo.

Kwimibhobho yentsimbi ye-ferritic alloy kunye ne-stainless steel, udonga luphantsi koxinzelelo olungaphantsiI-60% yamandla amancinci esivuno akhankanyiweyo.

Uxinzelelo lovavanyo lwe-hydro kufuneka lugcinwe ubuncinane 5sngaphandle kokuvuza okanye ezinye iziphene.

Uxinzelelo lwe-hydraulicingabalwa kusetyenziswa le fomula:

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S = uxinzelelo lodonga lwepayipi kwi-psi okanye kwi-[MPa];

t = ubukhulu bodonga obuchaziweyo, ubukhulu bodonga obuqhelekileyo ngokwenombolo yeshedyuli ye-ANSI echaziweyo okanye amaxesha ayi-1.143 ubukhulu bodonga obuchaziweyo, ngo. [mm];

D = ububanzi obuchaziweyo bangaphandle, ububanzi obungaphandle obuhambelana nobungakanani bombhobho we-ANSI obuchaziweyo, okanye ububanzi obungaphandle obubalwe ngokongeza i-2t (njengoko kuchaziwe ngasentla) kububanzi obuchaziweyo bangaphakathi, kwi. [mm].

Umbhobho we-P91 uhlolwa ngendlela yovavanyo lwe-E213. Umgangatho we-E213 ujongene kakhulu novavanyo lwe-ultrasonic (UT).

Ukuba ichazwe ngokukodwa kulandelelwano, ingahlolwa ngokwendlela yovavanyo ye-E309 okanye ye-E570.

Umgangatho we-E309 udla ngokujongana nokuhlolwa kwe-electromagnetic (eddy current), ngelixa i-E570 yindlela yokuhlola equka ii-arrays ze-eddy current.

Utshintsho oluvumelekileyo kwiDayamitha

Kwipayipi e-odolwe ukubaububanzi bangaphakathi, ububanzi bangaphakathi abuyi kwahluka ngaphezu kwe-±1% ukusuka kububanzi bangaphakathi obuchaziweyo.

Utshintsho oluvumelekileyo kuBungqingqwa bodonga

Ukulinganiswa kobukhulu bodonga kufuneka kwenziwe kusetyenziswa ii-calipers zoomatshini okanye izixhobo zokuvavanya ezingatshabalalisiyo ezilinganiswe ngokufanelekileyo ngokuchanekileyo. Kwimeko yengxabano, ukulinganiswa okumiselwe kusetyenziswa ii-calipers zoomatshini kuya kusebenza.

Ubukhulu obuncinci bodonga kunye nobubanzi bangaphandle bokuhlolwa ukuze kujongwe ukuthotyelwa kwalo mfuneko yombhobho o-odolwe yi-NPS [DN] kunye nenombolo yeshedyuli kuboniswe aphaI-ASME B36.10M.

Iziphene

Iziphene zomphezulu zithathwa njengeziphene ukuba zidlula i-12.5% yobukhulu bodonga obuqhelekileyo okanye zidlula ubukhulu bodonga obuncinci.

Ukungafezeki

Iimpawu zoomatshini, imivumbo, kunye nemingxunya, apho naziphi na iziphene zinzulu kune-1/16 intshi. [1.6 mm].

Iimpawu kunye nokukrazulwa zichazwa njengeempawu zekhebula, ii-dinges, iimpawu zesikhokelo, iimpawu zokuqengqeleka, imikrwelo yebhola, amanqaku, iimpawu zokufa, njl.njl.

Ukulungiswa

Iziphene zingasuswa ngokusila, ukuba ubukhulu bodonga obuseleyo abungaphantsi kobukhulu bodonga obuncinci.

Ukulungiswa kungenziwa nangokudibanisa kodwa kufuneka kuhambelane neemfuno ezifanelekileyo ze-A999.

Zonke ii-weld zokulungisa kwi-P91 mazisetyenziswe ngenye yezi nkqubo zilandelayo zokuwelda kunye nezinto ezisetyenziswayo: i-SMAW, i-A5.5/A5.5M E90XX-B9:SAW, i-A5.23/A5.23M EB9 + i-neutral flux; i-GTAW, i-A5.28/A5.28M ER90S-B9; kunye ne-FCAW A5.29/A5.29M E91TI-B9. Ukongeza, isimbuku somxholo we-Ni+Mn wazo zonke izinto ezisetyenziswayo zokuwelda ezisetyenziselwa ukulungisa i-P91 Type 1 kunye ne-Type 2 aziyi kudlula i-1.0%.

Umbhobho we-P91 kufuneka ufudunyezwe kubushushu obuyi-1350-1470 °F [730-800°C] emva kokulungiswa kwe-weld.

Umphezulu wangaphandle wombhobho wentsimbi ohloliweyo kufuneka uqulathe ezi zinto zilandelayo:

Igama lomenzi okanye uphawu lorhwebo; inombolo eqhelekileyo; ibakala; ubude kunye nophawu olongezelelweyo "S".

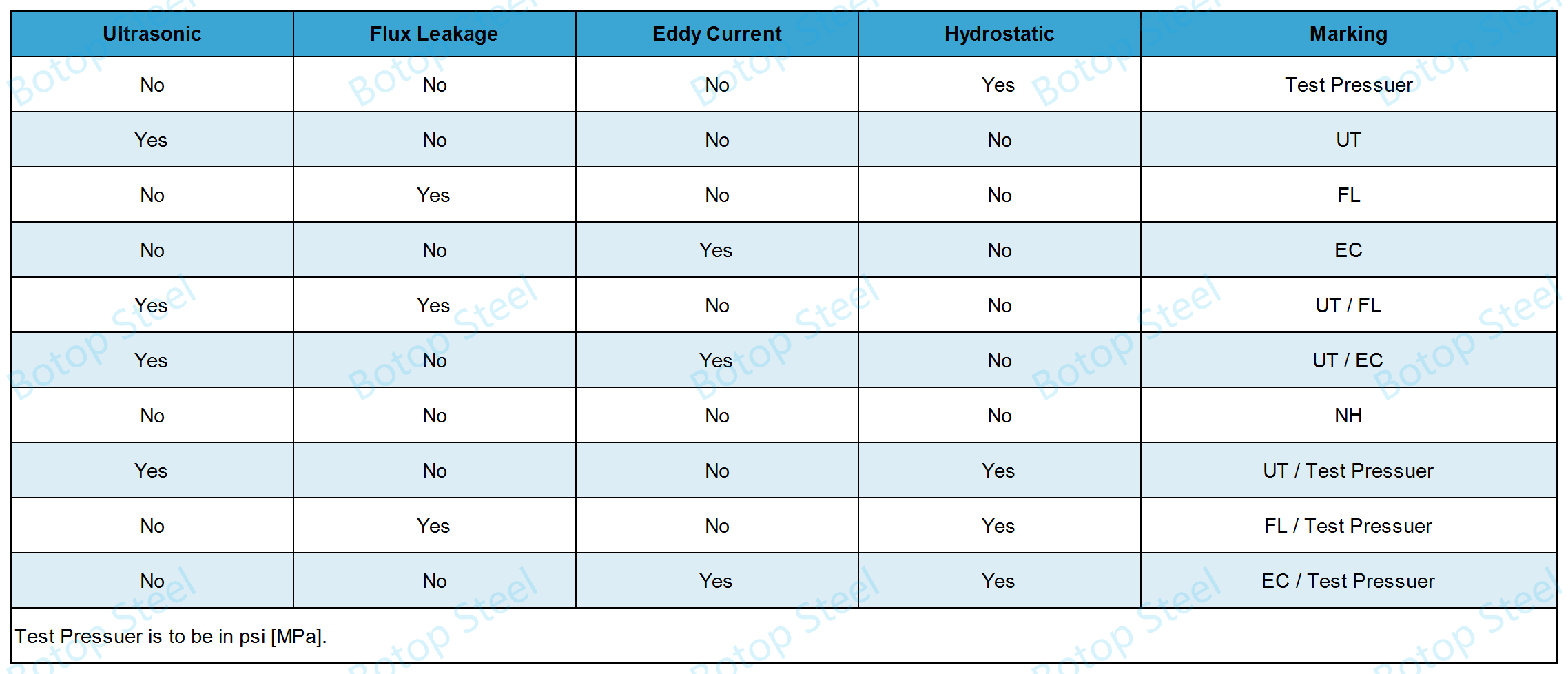

Iimpawu zoxinzelelo lwe-hydrostatic kunye novavanyo olungonakalisiyo kwitheyibhile engezantsi nazo mazifakwe.

Ukuba umbhobho ulungiswa ngokuwelda, kufuneka uphawulwe "WR".

p91 Uhlobo (Uhlobo 1 okanye Uhlobo 2) kufuneka luboniswe.

| I-ASME | I-ASTM | EN | GB |

| I-ASME SA335 P91 | I-ASTM A213 T91 | I-EN 10216-2 X10CrMoVNb9-1 | GB/T 5310 10Cr9Mo1VNbN |

Izintol: Umbhobho wentsimbi engenamthungo we-ASTM A335 P91;

OD: 1/8"- 24";

WT: ngokwenxa yeI-ASME B36.10iimfuno;

Ishedyuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kunye neSCH160;

Ukuchongwa:STD (eqhelekileyo), XS (enamandla kakhulu), okanye XXS (ephindwe kabini enamandla kakhulu);

Ukwenziwa ngokwezifiso: Kukho nobukhulu beepayipi obungengomgangatho, ubungakanani obulungiselelwe wena bufumaneka xa buceliwe;

Ubude: Ubude obuthile nobungacwangciswanga;

Isiqinisekiso se-IBR: Singaqhagamshelana nombutho wokuhlola wesithathu ukuze sifumane isiqinisekiso se-IBR ngokweemfuno zakho, imibutho yethu yokuhlola intsebenziswano yi-BV, i-SGS, i-TUV, njl.njl.;

Isiphelo: Isiphelo esithe tyaba, esibhityiweyo, okanye esidityanisiweyo sombhobho;

Umphezulu: Umbhobho olula, ipeyinti, kunye nolunye ukhuselo lwexeshana, ukususwa nokupholishwa komhlwa, ukugqunywa nge-galvanized kunye neplastiki, kunye nolunye ukhuselo lwexesha elide;

Ukupakisha: Ibhokisi yomthi, ibhande lentsimbi okanye ucingo lwentsimbi, iplastiki okanye umkhuseli wombhobho wentsimbi, njl.njl.