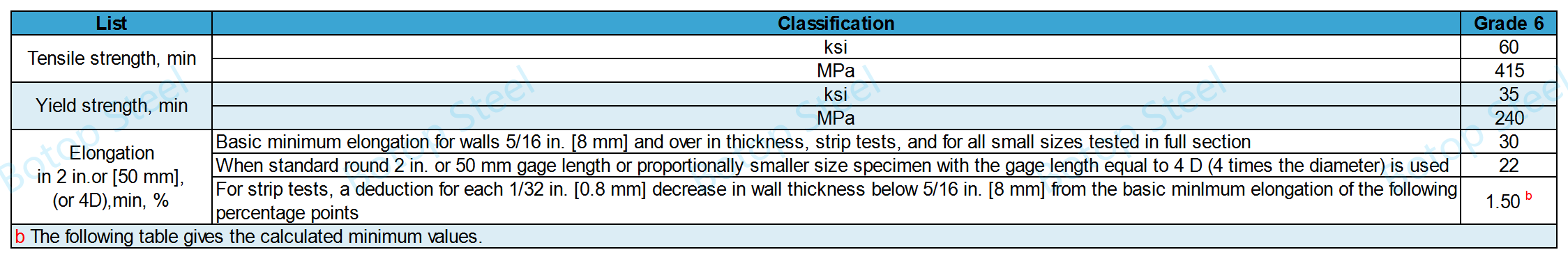

I-ASTM A334Ibanga lesi-6ngumbhobho wentsimbi yekhabhoni onamandla aphezulu, oshushu kancinci onomxholo ophezulu wekhabhoni oyi-0.30%, umxholo we-manganese oyi-0.29-1.06%, amandla okutsalwa aphantsi angama-415Mpa (60ksi), kunye namandla okuvelisa angama-240Mp (35ksi).

Isetyenziswa kakhulu kwicandelo leendawo zegesi yendalo ezinyibilikisiweyo, ubunjineli be-polar, kunye netekhnoloji yokukhenkcisa, ivumelane neendawo ezishushu kakhulu.

I-ASTM A334yinkcazo eqhelekileyo yeetyhubhu zekhabhoni kunye nentsimbi ye-alloy ezingenamthungo nezidibeneyo kwizicelo ze-cryogenic.

Kukho amanqanaba ahlukeneyo ukuhlangabezana neemfuno ezahlukeneyo.

Ibanga loku-1, iBanga lesi-3, iBanga lesi-6, iBanga lesi-7, iBanga lesi-8, iBanga lesi-9, kunye neBanga le-11.

Ibanga loku-1kunye neBanga lesi-6 zombini ziipayipi zentsimbi yekhabhoni.

Umbhobho wentsimbi we-ASTM A334 Grade 6 unokwenziwa ngeenkqubo ezingenamthungo okanye ezidityanisiweyo.

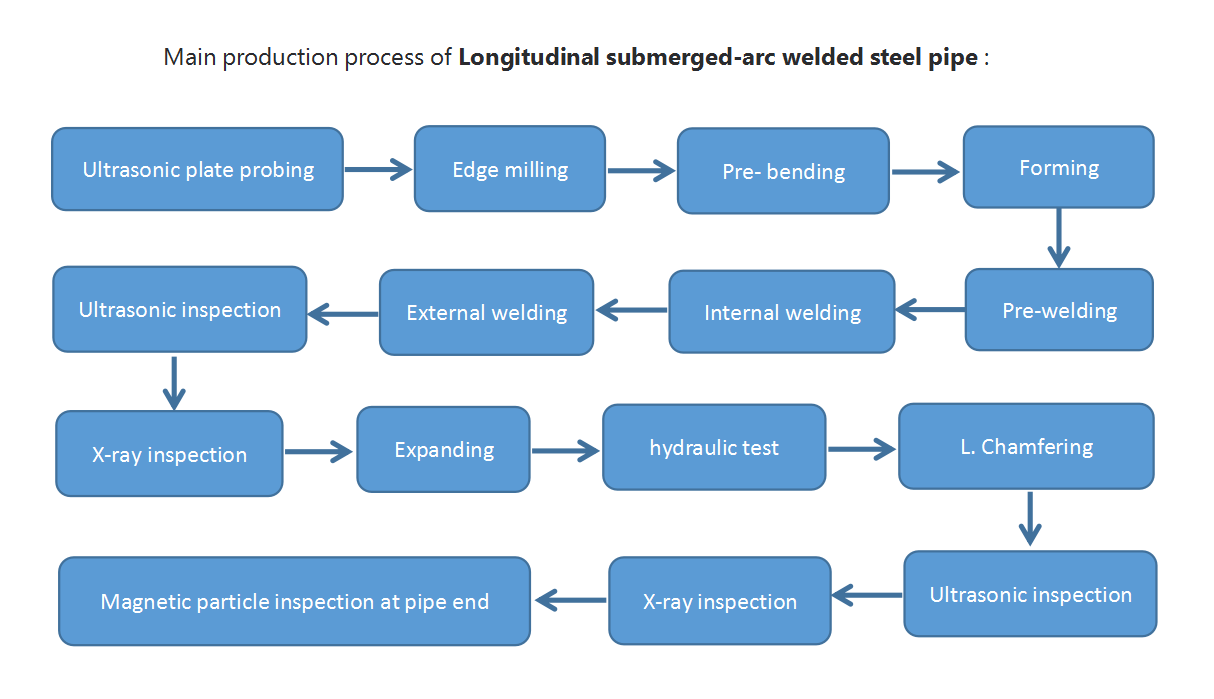

Iinkqubo zokuwelda ziquka iindlela ezahlukeneyo ezifanaukuwelda kokumelana nombane (ERW)kwayeukuwelda kwe-arc engaphantsi komhlaba (i-SAW).

Ngezantsi, kukho inkqubo yemveliso yeUkuwelda kwe-Arc engaphantsi komhlaba eLongitudinal (LSAW).

Njengomvelisi weetyhubhu zentsimbi ezidityanisiweyo, siyakwazi ukuhlangabezana neemfuno ezithile zabathengi bethu abahlukeneyo, sinika uluhlu olwahlukeneyo lweenketho zemveliso ukuqinisekisa ukusebenza okuhle kunye nomgangatho kuyo yonke into esetyenziswayo.

I-weld ye-single-piece ye-LSAW tube iphucula kakhulu amandla etyhubhu iyonke, ivumela ukuba imelane noxinzelelo oluphezulu.

Ukongeza, ifanelekile kakhulu ekuvelisweni kwemibhobho yentsimbi enobubanzi obukhulu kunye nodonga oluqinileyo ehlangabezana neemfuno ze-ASTM A334 Grade 6 kwiinkqubo ezinkulu zokuhambisa amandla nemizi-mveliso, njengasekwakhiweni kwezixhobo ezinkulu zegesi yendalo enyibilikisiweyo (LNG).

Kwangaxeshanye, ulawulo oluchanekileyo lobukhulu luqinisekisa ububanzi bemibhobho kunye nobukhulu bodonga obuhambelanayo ukuphucula ukuthembeka koqhagamshelo kunye nokuthintela ukuvuza kwiinkqubo zemibhobho.

Lungisa ubushushu ngokubufudumeza bufikelele kwiqondo lobushushu elifanayo elingaphantsi kwe-1550 °F [845 °C] uze upholise emoyeni okanye kwigumbi lokupholisa lesithando esilawulwa ngumoya.

Ukuba kuyimfuneko ukucocwa kwesimo, kuya kufuneka kuxoxiswane ngako.

Ulwakhiwo lweekhemikhali zombhobho wentsimbi we-ASTM A334 Grade 6 luyilelwe ukuqinisekisa iipropati ezilungileyo zoomatshini kumaqondo obushushu aphantsi kunye nokuqina okwaneleyo kwenkonzo ethembekileyo phantsi kweemeko ezinzima.

| Ibanga | C (Ikhabhoni) | Mn (IManganese) | P (I-phosphorus) | S (Isalfure) | Si (Isilicon) |

| Ibanga lesi-6 | ubuninzi 0.30 | 0.29-1.06 | ubuninzi 0.025 | ubuninzi 0.025 | ubuncinci 0.10 |

| Kwixabiso ngalinye lokunciphisa i-0.01% yekhabhoni ngaphantsi kwe-0.30%, ukunyuka kwe-0.05% yemanganese ngaphezu kwe-1.06% kuya kuvunyelwa ukuya kuthi ga kwi-1.35% yemanganese. | |||||

Kwizinyithi zeBanga loku-1 okanye leBanga lesi-6, akuvumelekanga ukubonelela ngamabakala okudibanisa naziphi na izinto ngaphandle kwezo zifunekayo ngokucacileyo. Nangona kunjalo, kuvumelekile ukongeza izinto ezifunekayo ekususeni i-oxidation kwintsimbi.

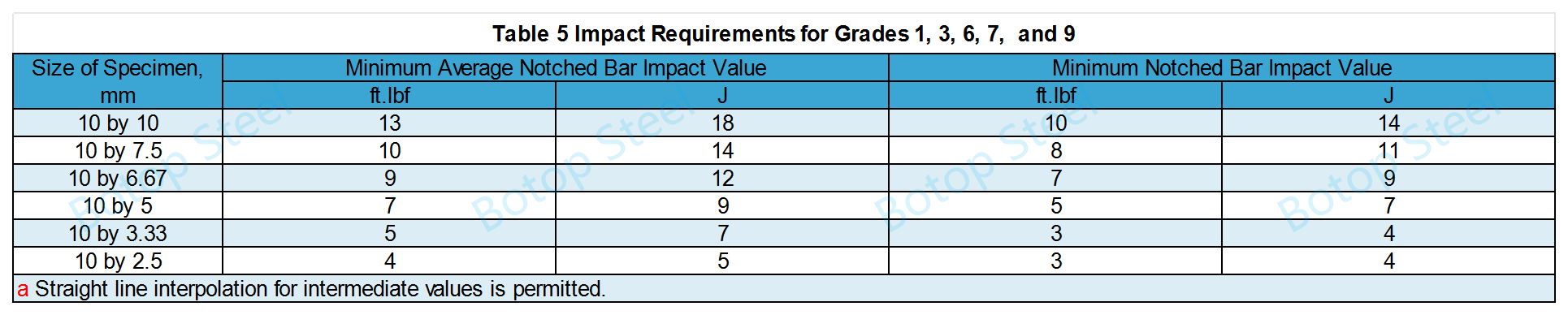

Uvavanyo lwempembelelo kumbhobho wentsimbi weBanga lesi-6 lwenziwa kwi--45°C [-50°F] njengendlela yokuqinisekisa ukuqina kunye nokumelana nempembelelo kwezinto kwiindawo ezishushu kakhulu.

Uvavanyo lwenziwe ngokukhetha amandla afanelekileyo okuchaphazeleka ngokusekelwe kubukhulu bodonga lombhobho wentsimbi.

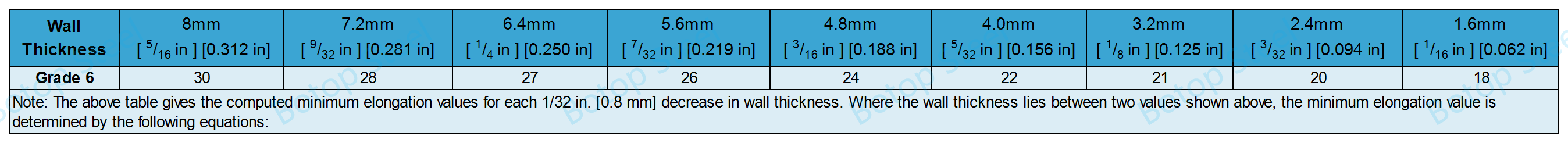

Amaxabiso aphantsi okwandiswa kodonga aqikelelweyo kwi-1/32 intshi nganye [0.80 mm] yokwehla kobukhulu bodonga.

| Ibanga | uRockwell | UBrinell |

| I-ASTM A334 Ibanga lesi-6 | B 90 | 190 |

Umbhobho ngamnye kufuneka uvavanywe ngombane okanye ngamanzi ngaphandle kokutshatyalaliswa ngokuhambelana neNkcazelo A1016/A1016M.

Ngaphandle kokuba kuchazwe ngenye indlela kwi-odolo yokuthenga, uhlobo lovavanyo oluza kusetyenziswa luya kuba lolwenziwe ngumvelisi.

Uvavanyo lokuTyatya

Uvavanyo lweFlare (iityhubhu ezingenamthungo)

Uvavanyo lweFlange (iityhubhu ezidibeneyo)

Uvavanyo lokuBuya kweFlattening

1. Izixhobo zeGesi yendalo enyibilikisiweyo (LNG)Ngenxa yeempawu zayo ezintle zobushushu obuphantsi, umbhobho wentsimbi weBanga lesi-6 usetyenziswa kakhulu kwimveliso ye-LNG, indawo yokugcina kunye neyokuthutha. Ezi zixhobo zifuna izixhobo ezigcina amandla aphezulu kunye nokuqina okuhle kumaqondo obushushu aphantsi kakhulu.

2. Iinkqubo zothutho lweoyile negesi: isetyenziselwa ukuthutha iihydrocarbon ezingamanzi okanye zegesi, ezifana negesi yepetroleum enyibilikisiweyo (LPG) kunye nezinye izinto ezimanzi ezinobushushu obuphantsi kwindawo enobushushu obuphantsi.

3. Itekhnoloji yefriji kunye neendawo zokugcina izinto ezibandayoOku kusebenza nakwezinye iindawo zobuchwepheshe bokukhenkceza, ezifana neenkqubo zokugcina ukutya okubandayo nokubandayo ekulungisweni kokutya kunye nezinye iinkqubo zeekhemikhali ezifuna ukusebenza kubushushu obuphantsi.

4. Ubunjineli bePolar: Kwiiprojekthi zobunjineli kwiindawo eziphantsi komhlaba, ezifana nezikhululo zophando lwezenzululwazi kwiArctic okanye kwiAntarctica, zisetyenziselwa ukwakha iinkqubo zokuhambisa ezizinzileyo nezithembekileyo kunye nezakhiwo ekufuneka zikwazi ukumelana namaqondo obushushu abandayo kakhulu kunye neemeko ezinzima zokusingqongileyo.

5. Iinkqubo zomoya opholileyo kunye nezixhobo zokutshintshiselana ubushushu: Ikwasetyenziswa kakhulu kwiinkqubo ezinkulu zomoya-moya kunye nezitshintshi zobushushu, ekufuneka zisebenze ngokufanelekileyo kumaqondo obushushu aphantsi ukuqinisekisa ukusebenza kakuhle kwenkqubo kunye nokhuseleko.

6. Ubunjineli bamandla kunye nezikhululo zamandla: Kwiiprojekthi zobunjineli bamandla ezikhethekileyo, njengeentlobo ezithile zezikhululo zamandla, iityhubhu zentsimbi zeBakala 6 zingasetyenziselwa ukuphatha ulwelo okanye iigesi kumaqondo obushushu aphantsi ukuqinisekisa ukusebenza ngokukhuselekileyo nangokufanelekileyo kwenkqubo.

EN 10216-4:P265NL: Isetyenziswa kakhulu kwimithambo yoxinzelelo lwe-cryogenic kunye neenkqubo zemibhobho ye-cryogenic, inokuqina okuhle kunye namandla kwaye ifanelekile ukusetyenziswa kwiindawo ze-cryogenic.

I-DIN 17173:TTSt41N: Yenzelwe ukusetyenziswa kumaqondo obushushu aphantsi, inika ukusebenza okuhle kakhulu kumaqondo obushushu aphantsi kwaye isetyenziswa kakhulu kwizixhobo kunye nemibhobho efuna iindawo zokusebenza kumaqondo obushushu aphantsi kakhulu.

I-JIS G3460:STPL46: Isetyenziselwa iinkqubo zothutho lwemibhobho kwiindawo ezinobushushu obuphantsi, ezikwaziyo ukumelana neempembelelo ezithile zobushushu obuphantsi kunye noxinzelelo.

GB/T 18984:09Mn2V: Le nto ikhethekileyo ekuveliseni iityhubhu zentsimbi ezingenamthungo ezisetyenziselwa kwiindawo ezinobushushu obuphantsi, ezinobunzima obuhle kubushushu obuphantsi kunye nokumelana nokuqhekeka.

Xa ukhetha ezi zinto zilinganayo, kubalulekile ukuqinisekisa ukuba ukwakheka kweekhemikhali kunye neempawu zazo zoomatshini ziyahlangabezana neemfuno zokusebenza ezifunekayo.

Ezi parameters kufuneka zithelekiswe ngokweenkcukacha kwaye iinkqubo ezongezelelweyo zovavanyo kunye neziqinisekiso zinokufuneka ukuqinisekisa ukufaneleka nokusebenza kwezinto.

Ukususela oko yasekwa ngo-2014, iBotop Steel ibe ngumthengisi ophambili weumbhobho wentsimbi yekhabhonieMntla China, eyaziwa ngenkonzo egqwesileyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi. Le nkampani inikezela ngeentlobo ngeentlobo zeepayipi zentsimbi yekhabhoni kunye neemveliso ezinxulumene nazo, kubandakanya ipayipi yentsimbi engenamthungo, i-ERW, i-LSAW, kunye ne-SSAW, kunye noluhlu olupheleleyo lwee-fittings zepayipi kunye nee-flanges.

Iimveliso zayo ezikhethekileyo ziquka ii-alloys zodidi oluphezulu kunye neentsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.