I-ASTM A178iityhubhu zentsimbi ziityhubhu ze-ERW ezijijekileyo ezichasene nombaneintsimbi yekhabhoni kunye nekhabhoni-manganesezisetyenziswa njengeetyhubhu zebhoyila, iiflue zebhoyila, iiflue ze-superheater, kunye neziphelo zokhuseleko.

Ifanelekile kwiityhubhu zentsimbi ezinobubanzi obungaphandle obuyi-12.7-127mm kunye nobukhulu bodonga obuphakathi kwe-0.9-9.1mm.

Iityhubhu ze-ASTM A178 zifanelekile kwiityhubhu ezidityanisiweyo eziqinileyo ezine-resistance weldedububanzi bangaphandle buphakathi kwe-1/2 - 5 in [12.7 - 127 mm] kunye nobukhulu bodonga buphakathi kwe-0.035 - 0.360 in [0.9 - 9.1 mm], nangona ezinye iisayizi zifumaneka njengoko kufuneka, ukuba ezi tyhubhu ziyahlangabezana nazo zonke ezinye iimfuno zale nkcazo.

Kukho amanqanaba amathathu okujongana neendawo ezahlukeneyo zokusetyenziswa.

Ibanga A, iBanga C, kunye neBanga D.

| Ibanga | Uhlobo lwentsimbi yekhabhoni |

| Ibanga A | Intsimbi yeKhabhoni ephantsi |

| Ibanga C | Intsimbi yeKhabhoni ephakathi |

| Ibanga D | Intsimbi yeCarbon-Manganese |

Izinto ezinikezelwe phantsi kwale nkcazelo ziya kuhambelana neemfuno ezifanelekileyo zohlelo lwangoku lweSpecification A450/A450M. Ngaphandle kokuba kubonelelwe ngenye indlela apha.

Ibanga AkwayeIbanga CMusa ukukhankanya intsimbi ethile; khetha izinto ezikrwada ezifanelekileyo njengoko kufuneka.

Intsimbi yeIbanga Duya kubulawa.

Intsimbi ebuleweyo iveliswa ngokongeza ii-deoxidizers (umz., i-silicon, i-aluminium, i-manganese, njl.njl.) kwintsimbi enyibilikisiweyo ngexesha lenkqubo yokuvelisa intsimbi, ngaloo ndlela kunciphisa okanye kuphelise umxholo weoksijini kwintsimbi.

Olu nyango luphucula ukulingana kunye nokuzinza kwentsimbi, luphucula iimpawu zayo zoomatshini, kwaye luphucula ukumelana nokugqwala.

Ngenxa yoko, iintsimbi ezibuleweyo zisetyenziswa kakhulu kwiindawo apho kufuneka umgangatho ophezulu wokulingana kunye neempawu ezintle zoomatshini, njengokwenziwa kweenqanawa zoxinzelelo, iibhoyila, kunye nezinto ezinkulu zokwakha.

Iityhubhu zentsimbi zenziwe kusetyenziswaI-ERWinkqubo yokuvelisa.

I-ERW (I-Welded yokumelana nombane)yinkqubo efanelekileyo kakhulu yokwenza imibhobho yentsimbi yekhabhoni.

Ngenxa yeenzuzo zokuba namandla aphezulu okuwelda, iindawo zangaphakathi nezangaphandle ezigudileyo, isantya sokuvelisa esikhawulezayo, kunye nexabiso eliphantsi, isetyenziswa kakhulu kwiindawo ezininzi zoshishino nezokwakha.

I-ASTM A178umbhobho wentsimbikufuneka inyangwe ngobushushungexesha lenkqubo yokuvelisa. Isetyenziselwa ukuphucula iipropati zoomatshini kunye nokuzinza kwesakhiwo sombhobho, kunye nokususa uxinzelelo olunokuba lungeniswe ngexesha lenkqubo yokudibanisa.

Emva kokuwelda, zonke iityhubhu kufuneka ziphathwe ngobushushu obuyi-1650°F [900°C] okanye ngaphezulu kwaye kulandele ukupholisa emoyeni okanye kwigumbi lokupholisa lesithando somoya esilawulwayo.

Iityhubhu ezitsalwa ngumoya obandayokufuneka inyangwe ngobushushu emva kokuba idlulile okokugqibela ekutsaleni okubandayo kubushushu obuyi-1200°F [650°C] okanye ngaphezulu.

Xa kusenziwa uhlalutyo lwemveliso, ubuninzi bokuhlolwa bumiselwa ngolu hlobo lulandelayo.

| Ulwahlulo | Uvavanyo oluQhelekileyo |

| Ububanzi obungaphandle ≤ 3in [76.2mm] | 250 ii-pcs/ixesha |

| Ububanzi obungaphandle > 3in [76.2mm] | 100 ii-pcs/ixesha |

| Yahlula ngenani lobushushu betyhubhu | Ngenani lobushushu ngalinye |

Iimfuneko zepropathi yoomatshini azisebenzi kwiityhubhu ezincinci kune-1/8 intshi [3.2 mm] ububanzi bangaphakathi okanye i-0.015 intshi [0.4 mm] ubukhulu.

1. Ipropati yokuThatha

KwiKlasi C kunye no-D, uvavanyo lokuxinana kufuneka lwenziwe kwiityhubhu ezimbini kwindawo nganye.

Kwimibhobho yeBanga A, uvavanyo lokutsalwa kwentambo alusoloko luyimfuneko. Oku kungenxa yokuba imibhobho yeBanga A isetyenziswa kakhulu kwizicelo zoxinzelelo oluphantsi kunye nobushushu obuphantsi.

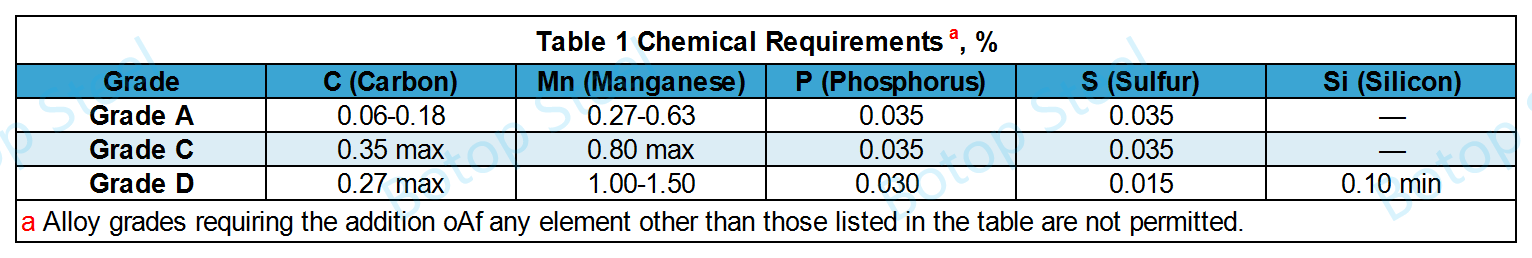

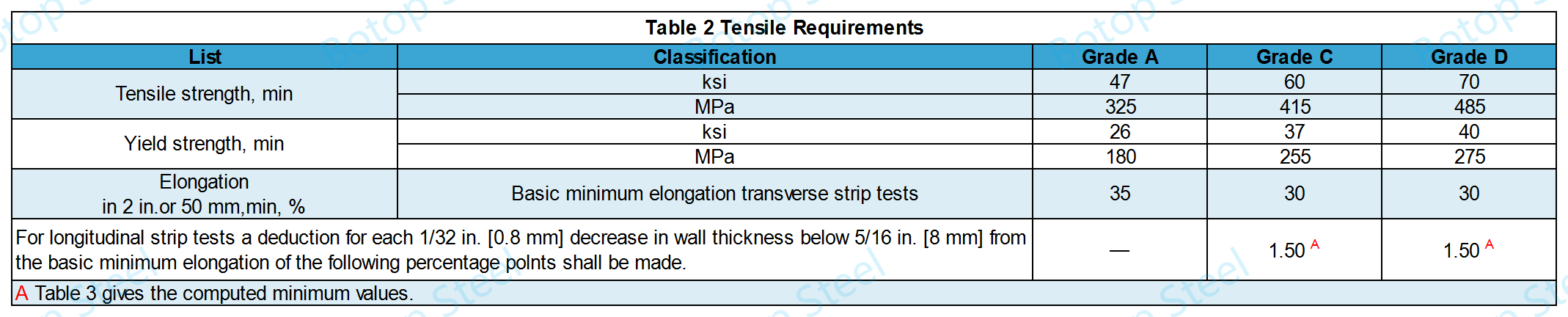

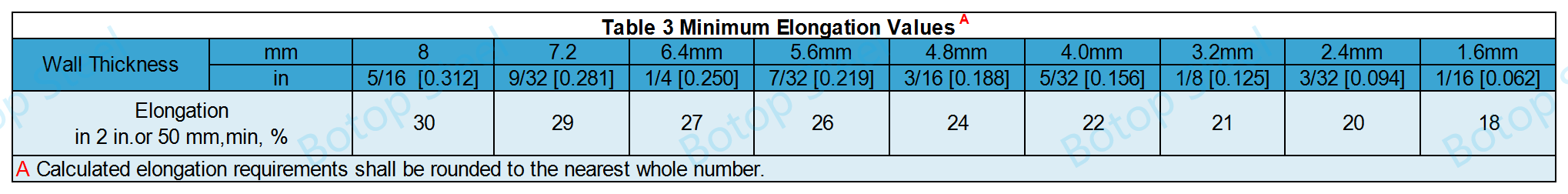

Itheyibhile 3 inika amaxabiso aphantsi okwandiswa kodonga aqikelelweyo kwi-1/32 intshi nganye [0.8 mm] yokwehla kobukhulu bodonga.

Ukuba ubukhulu bodonga lombhobho wentsimbi abuyonto imbi kangako, bunokubalwa ngefomula.

Iiyunithi ze-intshi: E = 48t + 15.00okanyeIiyunithi ze-ISI: E = 1.87t + 15.00

E = ubude obuziisentimitha ezi-2 okanye ezingama-50 mm, %,

t= ubukhulu bokwenyani besampuli, kwi. [mm].

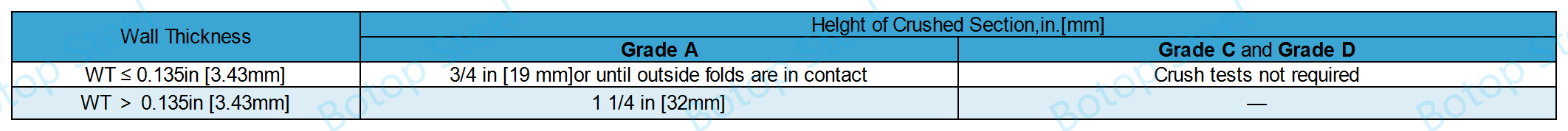

2. Uvavanyo lokuCrush

Uvavanyo lokukhupha izinto luqhutywa kwiindawo zemibhobho ezinobude obungama-63 mm ezimele zimelane nokukhupha izinto ezinde ngaphandle kokuqhekeka, ukuqhekeka, okanye ukuqhekeka kwiindawo zokuwelda.

Kwimibhobho engaphantsi kwe-1 intshi [25.4 mm] ububanzi bangaphandle, ubude besampuli bufanele bube ngama-2 1/2 ubukhulu bangaphandle bombhobho. Ukuhlolwa okuncinci komphezulu akuyi kuba sisizathu sokwaliwa.

3. Uvavanyo lokuThabatha

Indlela yovavanyo iyahambelana neemfuno ezifanelekileyo ze-ASTM A450 Icandelo 19.

4. Uvavanyo lweFlange

Indlela yovavanyo iyahambelana neemfuno ezifanelekileyo ze-ASTM A450 Icandelo 22.

5. Uvavanyo lokuBuya eFlattening

Indlela yovavanyo iyahambelana neemfuno ezifanelekileyo ze-ASTM A450, iCandelo 20.

Uvavanyo lombane olusebenzisa amanzi okanye olungatshabalalisiyo lwenziwa kumbhobho ngamnye wentsimbi.

Iimfuneko zihambelana ne-ASTM A450, iCandelo 24 okanye 26.

Le datha ilandelayo ifunyenwe kwi-ASTM A450 kwaye ihlangabezana neemfuno ezifanelekileyo zombhobho wentsimbi odibeneyo kuphela.

Ukuphambuka kobunzima

0 - +10%.

Ukuphambuka koBungqingqwa bodonga

0 - +18%.

Ukuphambuka kobubanzi obungaphandle

| Ububanzi obungaphandle | Iinguqu Ezivumelekileyo | ||

| in | mm | in | mm |

| I-OD ≤1 | OD≤ 25.4 | ±0.004 | ± 0.1 |

| 1 OD ≤1½ | 25.4 ± OD ≤38.4 | ±0.006 | ± 0.15 |

| 1½ OD 2 | 38.1< OD<50.8 | ±0.008 | ± 0.2 |

| 2≤ OD<2½ | 50.8≤ OD<63.5 | ±0.010 | ± 0.25 |

| 2½≤ OD<3 | 63.5≤ OD <76.2 | ± 0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ± 0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Emva kokufakwa kwibhoyila, ityhubhu kufuneka ikwazi ukumelana nokwandiswa nokugoba ngaphandle kokuqhekeka okanye ukuqhekeka kwiiwelds.

Ityhubhu ye-superheater mayikwazi ukumelana nayo yonke imisebenzi yokubumba, ukuwelda, kunye nokugoba efunekayo ngaphandle kweziphene.

Isetyenziswa kakhulu kwiityhubhu zebhoyila, iiflue zebhoyila, iiflue ze-superheater, kunye nee-safe ends.

I-ASTM A178 Ibanga AUmxholo wekhabhoni ephantsi yetyhubhu uyinika ukudityaniswa okuhle kunye nokuqina okuphezulu kwizicelo ezingafakwanga kuxinzelelo oluphezulu.

Isetyenziswa kakhulu kwii-intanethi ezinoxinzelelo oluphantsi kunye nobushushu obuphakathi ezifana nee-boilers ezinoxinzelelo oluphantsi (umz., ii-boilers zasekhaya, izakhiwo ezincinci zeofisi, okanye ii-boilers zefektri) kunye nezinye izinto zokutshintsha ubushushu kwiindawo ezinobushushu obuphantsi.

I-ASTM A178 Ibanga Cinomthamo ophezulu wekhabhoni kunye ne-manganese enika le tube amandla angcono kunye nokumelana nobushushu kwiimeko zokusebenza ezinzima ngakumbi.

Ifanelekile kwiindlela zokusetyenziswa koxinzelelo oluphakathi kunye nobushushu obuphakathi ezifana neebhoyila zamanzi ashushu kunye nezamashishini, ezihlala zifuna uxinzelelo oluphezulu kunye nobushushu kuneebhoyila zasekhaya.

I-ASTM A178 Ibanga DIityhubhu zinomxholo ophezulu we-manganese kunye nomxholo ofanelekileyo we-silicon ukubonelela ngamandla agqwesileyo kunye nokumelana nobushushu, okwenza zihlale zizinzile kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu kwaye zilungele ukumelana neemeko zokusebenza ezinzima.

Isetyenziswa rhoqo kwiindawo ezinoxinzelelo oluphezulu kunye nobushushu obuphezulu, njengeebhoyila zesikhululo samandla kunye nee-superheaters zoshishino.

1. I-ASTM A179 / ASME SA179: I-seamless mild steel heat exchanger kunye nee-condenser tubes zenkonzo ye-cryogenic. Isetyenziswa kakhulu kwiindawo eziphantsi koxinzelelo, ifana kakhulu neekhemikhali kunye neemechanical properties ne-ASTM A178.

2. I-ASTM A192 / ASME SA192: Iityhubhu zebhoyila zentsimbi yekhabhoni ezingenamthungo ezikwinkonzo yoxinzelelo oluphezulu. Ngokuyintloko zisetyenziswa ekwenzeni iindonga zamanzi, izinto ezigcina uqoqosho kunye nezinye izinto zoxinzelelo kwiibhoyila zoxinzelelo oluphezulu kakhulu.

3. I-ASTM A210 / ASME SA210: Igubungela ibhoyila yentsimbi yekhabhoni ephakathi kunye ne-alloy engenamthungo kunye neetyhubhu ze-superheater kwiinkqubo zebhoyila ezinobushushu obuphezulu kunye noxinzelelo oluphakathi.

4. I-DIN 17175: Iityhubhu zentsimbi ezingenamthungo kunye neepayipi ezisetyenziswa kwiindawo ezinoxinzelelo oluphezulu kunye nobushushu obuphezulu. Zisetyenziswa kakhulu ekwenzeni iipayipi zomphunga zeebhoyila kunye neenqanawa zoxinzelelo.

5. EN 10216-2: Imisela iimeko zobugcisa zeetyhubhu ezingenamthungo kunye neepayipi zeentsimbi ezingezizo ezo-alloy kunye neze-alloy ezineempawu ezichaziweyo zobushushu obuphezulu zokusetyenziswa phantsi koxinzelelo.

6. I-JIS G3461: Igubungela iityhubhu zentsimbi yekhabhoni zeebhoyila kunye nezitshintshi zobushushu. Ifanelekile kwiimeko zokutshintshiselana kobushushu eziphantsi neziphakathi.

Singumvelisi kunye nomthengisi wemibhobho yentsimbi yekhabhoni edityanisiweyo ekumgangatho ophezulu evela eTshayina, kwaye sikwangumthengisi wemibhobho yentsimbi engenamthungo, sikunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Ukuba unemibuzo okanye ufuna ukwazi okungakumbi malunga neenkonzo zethu, ungathandabuzi ukuqhagamshelana nathi. Izisombululo zakho zemibhobho yentsimbi ezifanelekileyo zifumaneka nje!