| Inkcazo | Umgangatho | Ibanga |

| Umbhobho ongenamthungo wentsimbi yecarbon/Intsimbi ye-Alloy Umbhobho ongenamthungo | I-API 5L PSL1 kunye nePSL2 | GR.B,X42,X46,X52,X60,X65,X70,njl. |

| I-ASTM A53 | GR.A,GR.B | |

| I-ASTM A106 | GR.A, GR.B,GR.C | |

| I-API 5CT | J55, K55, N80, L80, P110 ,njl. | |

| I-ASTM A179 | A179 | |

| I-ASTM A192 | A192 | |

| I-ASTM A210/SA210 | GR.A-1,GR.C | |

| I-ASTM A252 | GR.1, GR.2,GR.3 | |

| I-BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,njl. | |

| I-JIS G3454 | STPG370, STPG410 | |

| I-DIN2391 | ST35,ST37,ST37.4,ST45,ST52,ST52.4 | |

| I-DIN1629 | ST37,ST44,ST52 | |

| I-JIS G3456 | STPG370, STPG410, STPG480 | |

| I-ASTM A213 | GR.T11 ,GR.T12,GR.T13 | |

| I-ASTM A519 | GR.1020, GR.1026, GR.1045,GR.4130, njl. | |

| I-ASTM A335 | GR.P9,GR.P11,GR.P5,GR.P22,GR.P91, njl. | |

| I-ASTM A333 | GR.1, GR.3, GR.4,GR.6, njl. |

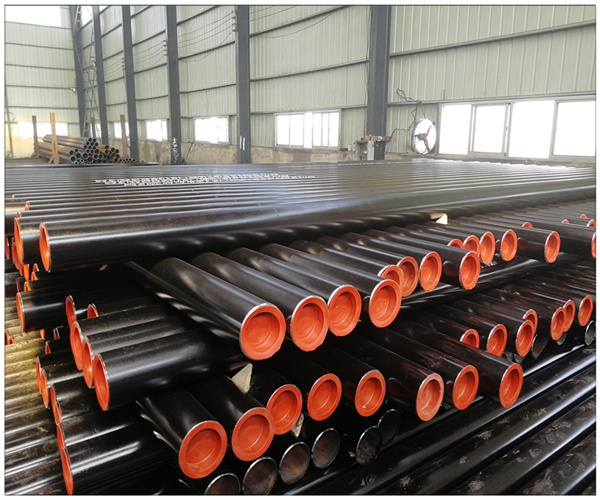

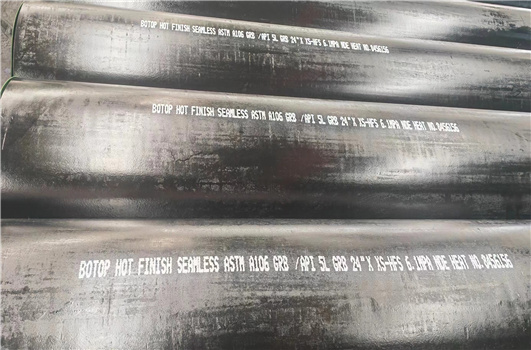

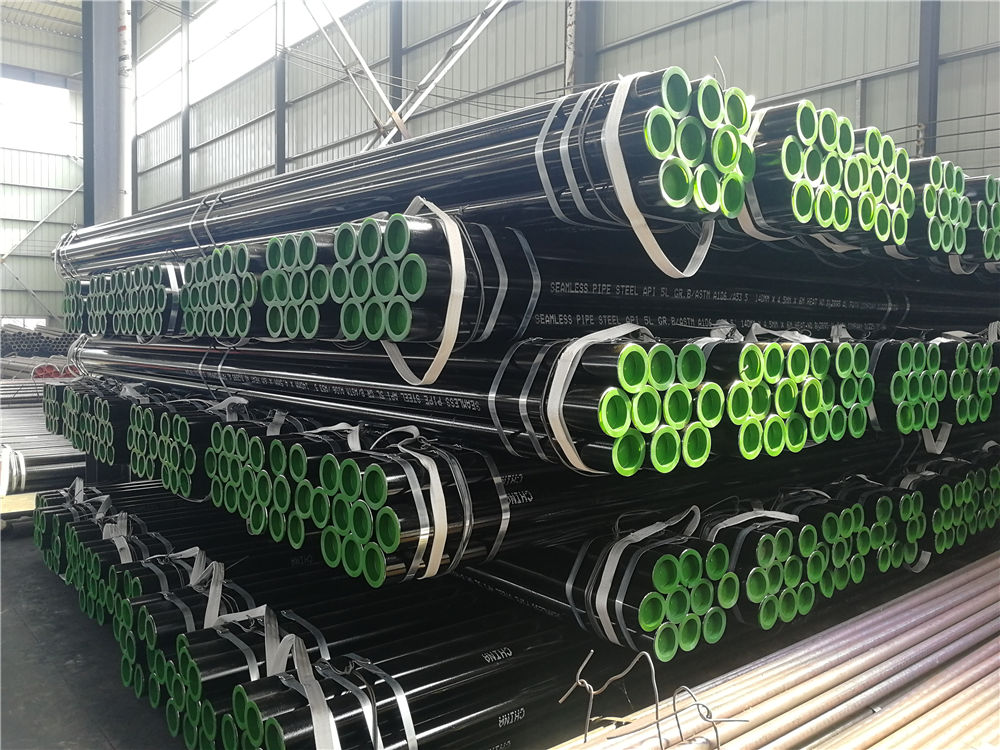

I-Botop Steel ngumvelisi ohamba phambili kunye nomthengisi weepayipi zentsimbi kunye neetyhubhu eTshayina, sigcina kwaye sinikezela ngepayipi yentsimbi yekhabhoni engenamthungo ejikelezayo yokusetyenziswa kolwelo kunye nepetroliyam kuluhlu lobukhulu obuphakathi kwe-10 OD ukuya kwi-660 OD kuluhlu lobukhulu obuphakathi kwe-1mm ukuya kwi-100mm. Senza iipayipi zentsimbi zekhabhoni ze-LSAW ngokungqongqo ngokwemigangatho yamazwe ngamazwe efana ne-ASTM, API kunye ne-DIN. Sinepayipi yomgca engenamthungo engaphezulu kweetoni ezingama-8000 ezifumaneka rhoqo ngenyanga, ngokubanzi sinokuzisa iimpahla ngoko nangoko. Nangona kunjalo, kwiimeko ezikhethekileyo, ukuba kukho isitokhwe seimibhobho yentsimbi yekhabhoniayifumaneki, singazisa iimpahla ngexesha elifutshane kakhulu ngokusebenzisa imithombo yemizi-mveliso yasekuhlaleni okanye ukungenisa impahla kwamanye amazwe.

Zonke zethuimibhobho yentsimbikunye neemveliso zeetyhubhu zibonelelwa ngeziqinisekiso zovavanyo ezithile ze-3.1, ngokwe-EN 10204. Isiqinisekiso ngokwe-3.2 sinokuvunyelwana ngaso ngexesha loku-odola. Uhlolo lomntu wesithathu luyamkelwa (i-BV, i-SGS, njl.njl.)

Inani elaneleyo leziphene zomphezulu ezibonakalayo

ukubonelela ngesiqinisekiso sexesha elifanelekileyo kuyimfuneko.

Isiphene kufuneka sisuswe okanye sinqunyulwe ngaphakathi

imida yeemfuno zobude. Umbhobho ogqityiweyo

kuya kuba ngokuthe tye ngokufanelekileyo.

Igama okanye uphawu lomenzi

Inombolo yenkcazo (umhla wonyaka okanye efunekayo)

Ubungakanani (OD, WT, ubude)

Udidi (A okanye B)

Uhlobo lombhobho (F, E, okanye S)

Uxinzelelo lovavanyo (umbhobho wentsimbi ongenamthungokuphela)

Inombolo yobushushu

Naluphi na ulwazi olongezelelweyo oluchazwe kwi-odolo yokuthenga.

Udidi kunye noBume beeKhemikhali (%)

| Ibanga | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Cu≤ | Mo≤ | I-Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Iipropati zoomatshini:

|

|

|

| A% |

|

| A | ≥330 | ≥205 | 20 | I-Annealed |

| B | ≥415 | ≥240 | 20 | I-Annealed |

| C | ≥485 | ≥275 | 20 | I-Annealed |

Ukuhlolwa kobubanzi obungaphandle

Ukuhlolwa koBungqingqwa bodonga

Ukuhlolwa kokugqibela

Ukuhlolwa Kokuthe Tye

Uhlolo lwe-UT

Ukuhlolwa kweNkangeleko

Ukuphela kwePipe Beveling

Iikhephu zeplastiki

Umzobo Omnyama Onophawu

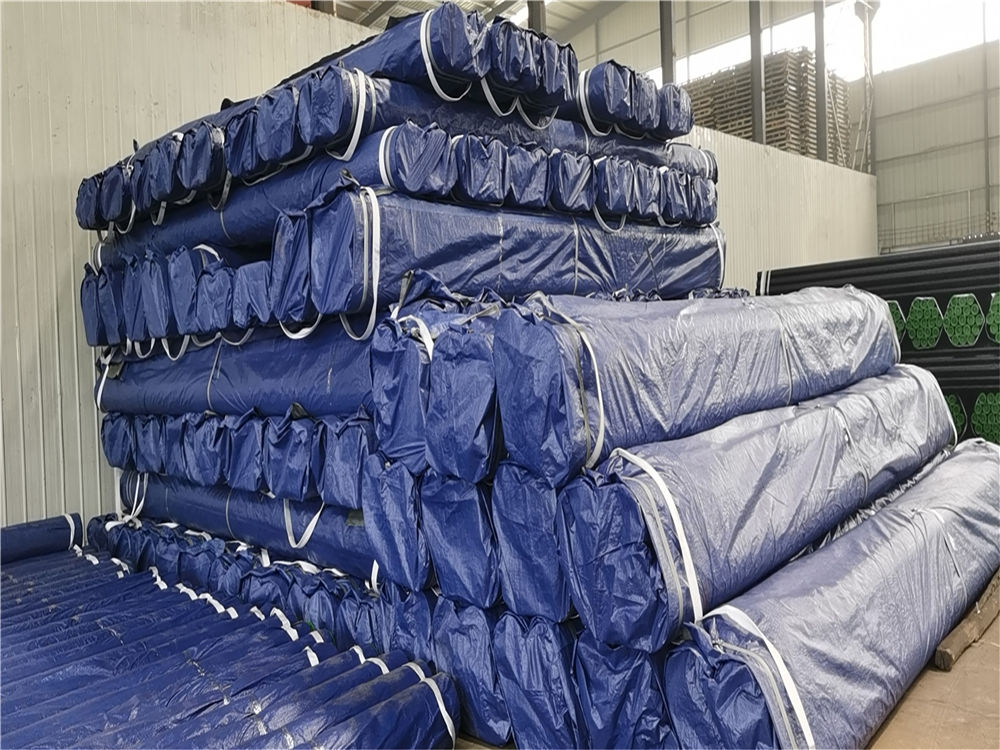

Isisongeli

Ukubopha kunye neSling

Inkangeleko yePhakheji

Inqanawa yePipe engenamthungo eya eQatar

Inqanawa yePipe engenamthungo eya ePakistan

Inqanawa yePipe engenamthungo eya eMzantsi Afrika

Inqanawa yePipe engenamthungo eya e-Ecuador