ASTM A519Tuubooyinka waa in lagu sameeyaa habka aan kala go 'lahayn waana in lagu sameeyaa kuleyl ama qabow sida ku cad.

Tuubooyinka wareegsan ee dhexroorkoodu aanu ka badnayn 12 3/4 inji (325 mm).

Tuubooyinka birta ah waxaa sidoo kale lagu samayn karaa qaab afargeesle ah, qaab leydi ah, ama qaabab kale sida loogu baahdo.

ASTM A519 waxaa loo kala saari karaa iyadoo loo eegayo maaddada birta:Bir Kaarboon ahiyo Birta Daawaha.

Bir kaarboon ahwaxaa loo qaybiyaaKaarboon Yar(Tuubada Farsamada),Bir Kaarboon Sare lehiyoLa baabi'iyay ama la dib u fosfooreeyay, ama labadabaBir Kaarboon ah, si loogu waafajiyo baahiyaha warshadaha ee kala duwan iyo xaaladaha codsiga.

Marka aan la cayimin darajada, soosaarayaashu waxay leeyihiin ikhtiyaarka ah inay bixiyaanMT1015 ama MTX1020darajooyin.

Dhexroorka dibadda: 13.7 - 325 mm;

Dhumucda derbiga: 2-100mm.

Birta waxaa lagu samayn karaa hab kasta.

Birta waxaa lagu shubi karaa qaybo ama waxaa lagu shubi karaa qaybo.

Tuubooyinka waxaa samayn doona ageeddi-socod aan kala go 'lahaynwaana in lagu dhammeeyaa kuleyl ama qabow, sida ku cad.

Tuubooyinka birta ah ee aan tolnayn waa tuubooyin aan lahayn tolmo la isku tolay oo dhan.

Tuubooyinka qabow-dhammaadaywaxaa lagula talinayaa baahiyaha sare ee saxnaanta cabbirka iyo tayada dusha sare.

Walaaca ugu weyn waa kharash-oolnimada iyo adkeysiga agabka,tuubo bir ah oo kulul oo dhammaataywaxay noqon kartaa doorasho ku habboon.

Xiga waa habka wax soo saarka ee tuubooyinka birta ah ee kulul ee aan kala go 'lahayn.

Soo-saaraha birta waa inuu falanqeeyo kulaylka bir kasta si uu u go'aamiyo boqolkiiba walxaha la cayimay.

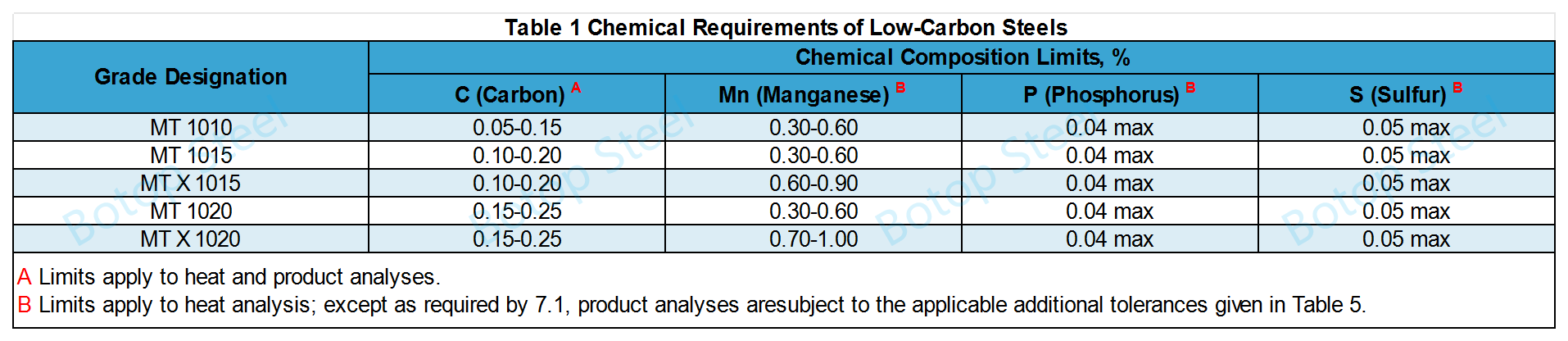

Shaxda 1 Shuruudaha Kiimikada ee Biraha Kaarboon-yar

Birta khafiifka ah waa bir leh kaarboon aan caadiyan ka badnayn 0.25%. Sababtoo ah kaarboon yar awgeed, birtani waxay leedahay dabacsanaan iyo dabacsanaan wanaagsan, waana mid aan adkeyn oo ka xoog badan marka loo eego birta kaarboon badan.

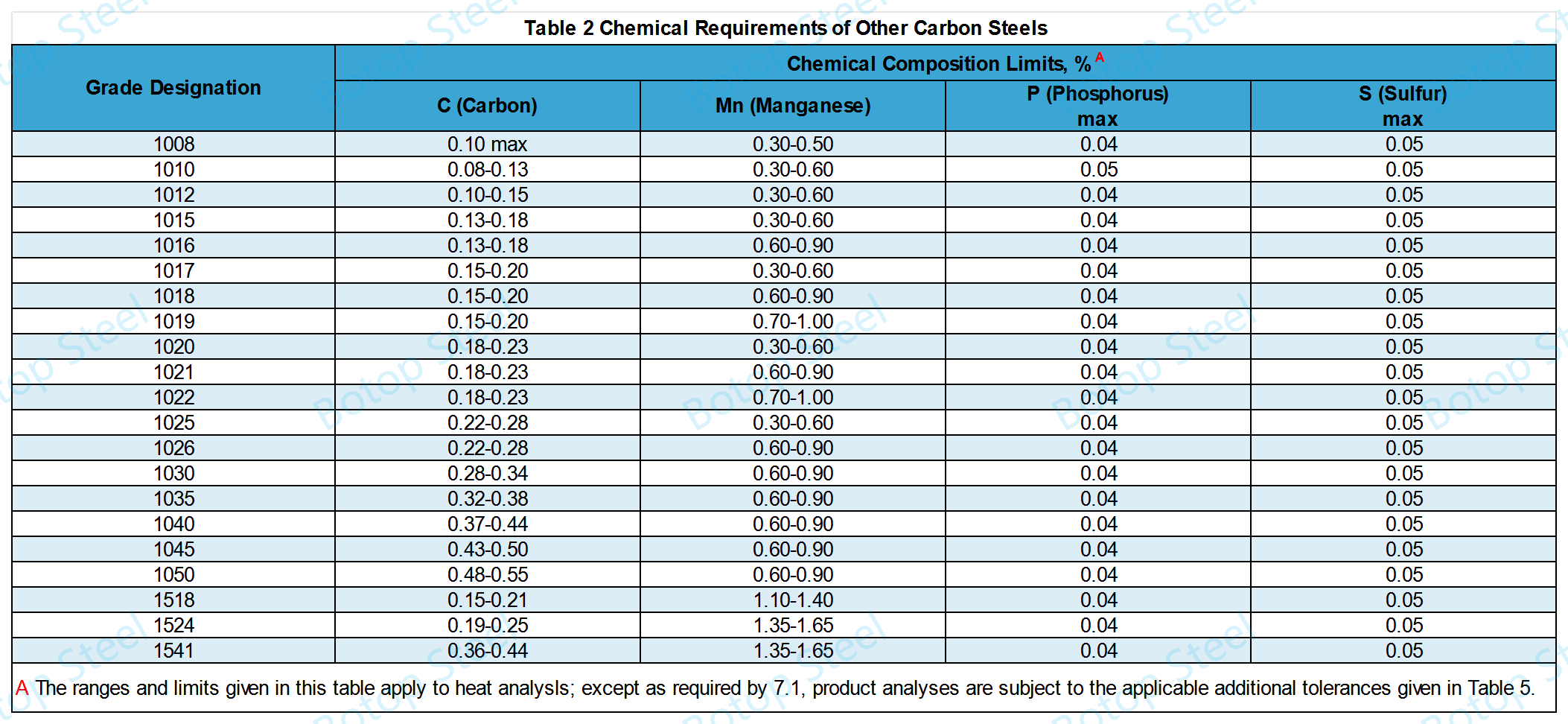

Shaxda 2 Shuruudaha Kiimikada ee Biraha Kaarboonka Kale

Biraha kaarboonka dhexdhexaadka ah: Iyagoo ka kooban inta u dhaxaysa 0.25% iyo 0.60% kaarboon, waxay bixiyaan adkeysi iyo xoog sare waxayna u baahan yihiin daaweyn kulayl si loo hagaajiyo sifooyinka.

Bir kaarboon sare leh: Waxay ka kooban tahay inta u dhaxaysa 0.60% iyo 1.0% ama ka badan kaarboon, waxayna bixisaa adkeysi iyo xoog aad u sarreeya, laakiin adkeysi hooseeya.

Shaxda 3 Shuruudaha Kiimikada ee Biraha Daawaha

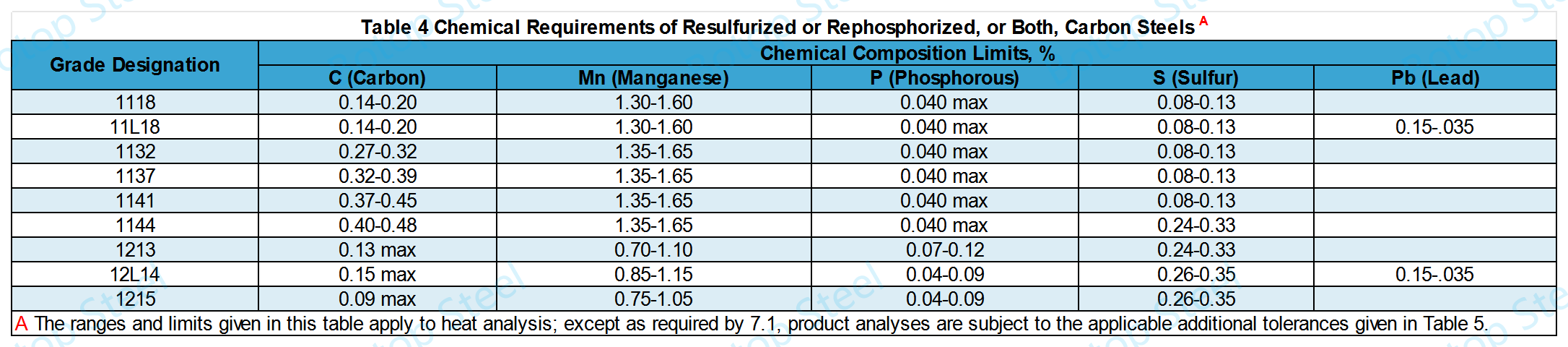

Shaxda 4 Shuruudaha Kiimikada ee Biraha Kaarboon ee Dib loo Sulfurized ama Dib loo Fosfooraskay, ama Labadaba

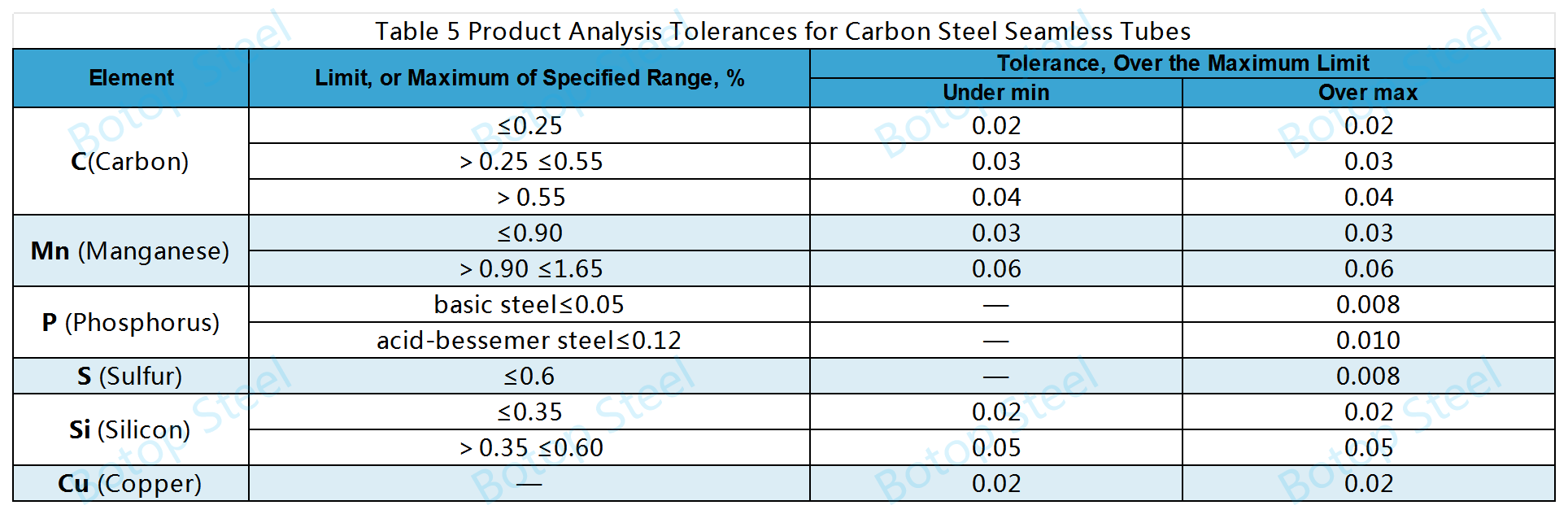

JADDIGA 5 Dulqaadka Falanqaynta Badeecada ee ka badan ama ka hooseeya baaxadda ama xadka la cayimay

Soo-saaraha waa in la weydiiyaa oo keliya inuu falanqeeyo badeecada haddii loo baahdo dalabka.

ASTM A519 wuxuu daboolayaa walxaha tijaabada ah ee soo socda:

Tijaabada Adkaanta; Tijaabada Xiisadda; Tijaabada aan burburin; Tijaabada Dabka; Nadiifinta Birta iyo Adkaanta.

| Magacaabista Darajada | Nooca Tuubada | Xaalad | Xoogga Ugu Yar | Xoogga Wax Soo Saarka | Kordhinta 2in.[50mm],% | Rockwell, Miisaanka Adkaanta B | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Bir Kaarboon ah | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Bir Kaarboon ah | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Bir Kaarboon ah | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Bir Kaarboon ah | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Bir Kaarboon ah | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Dib loo warshadeeyay ama Dib loo habeeyey, ama Labadaba, Biraha Kaarboonka | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Dib loo warshadeeyay ama Dib loo habeeyey, ama Labadaba, Biraha Kaarboonka | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Biraha Daawaha | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Biraha Daawaha | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Duub kulul, CW-Qabow shaqeeyey, SR-Walaaca yareeyey, A-Annealed iyo N-Normalized.

Dulqaadka Dhexroorka Dibadda

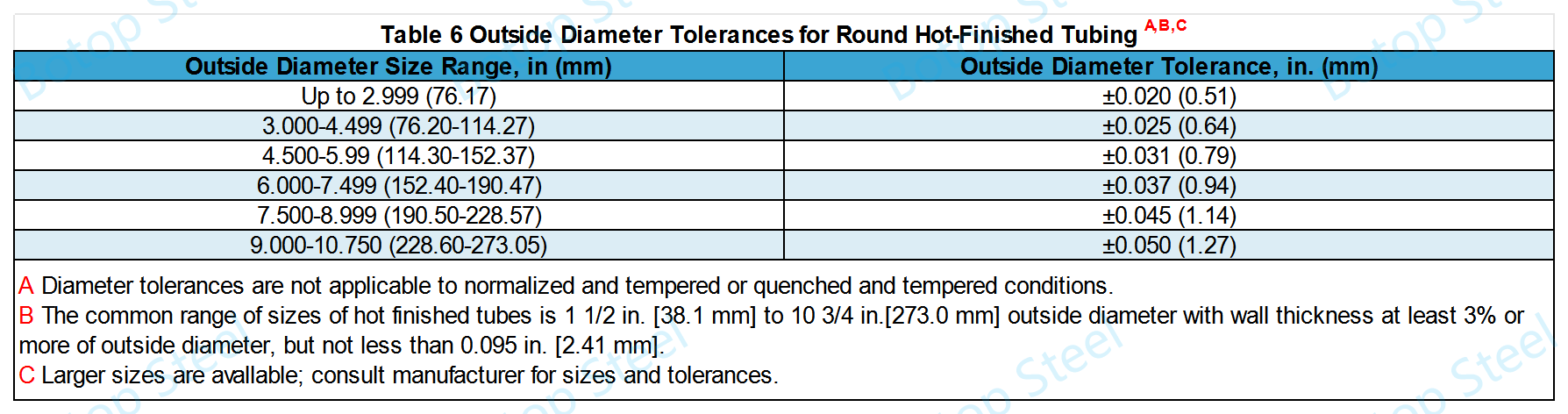

Shaxda 6 Dulqaadka Dhexroorka DibaddaTuubada Wareega ee Kulul-Dhammaystiran

Shaxda 12 Dulqaadka Dhexroorka Dibadda eeTuubo aan kala go 'lahayn oo dhulka ah

| Cabbirka Dhexroorka Dibadda, gudaha.[mm] | Dulqaadka Dhexroorka Dibadda ee Cabbirrada iyo Dhererka La bixiyay, gudaha [mm] | |||

| Dhammaad | Hoos | Dhammaad | Hoos | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] marka L≤16ft[4.9m] | 0.000 | 0.004 [0.10] marka L> 16ft [4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] marka L≤16ft[4.9m] | 0.000 | 0.006 [0.15] marka L> 16ft [4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] marka L≤12ft[3.7m] | 0.000 | 0.006 [0.15] marka L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] marka L≤12ft[3.7m] | 0.000 | 0.006 [0.15] marka L≤16ft[4.9m] | 0.000 |

Dulqaadka Dhumucda Darbiga

Shaxda 7aad Dulqaadka Dhumucda DarbigaTuubada Wareega ee Kulul-Dhammaystiran

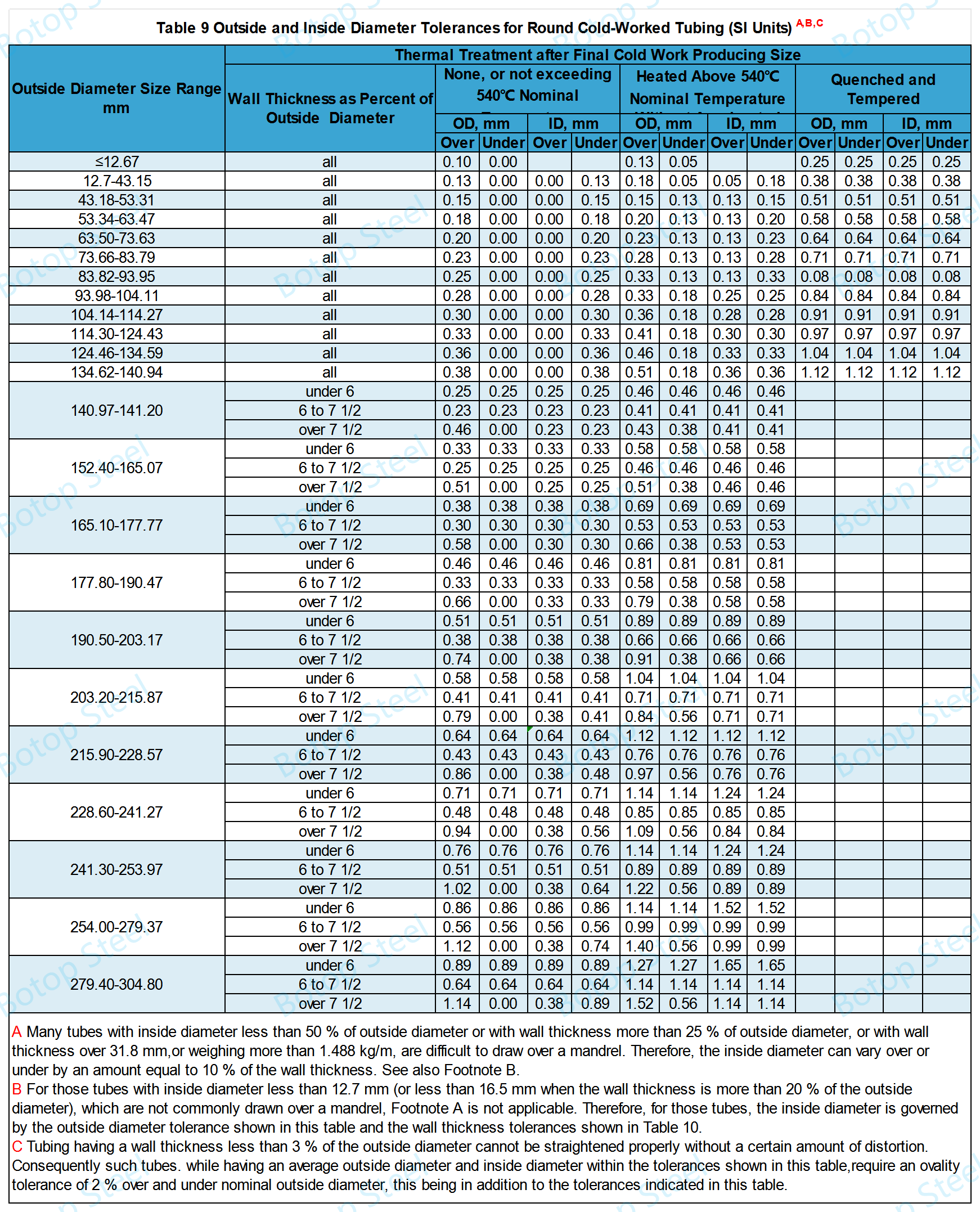

Shaxda 10 Dulqaadka Dhumucda DarbigaTuubada Qabow ee Wareega ah

| Dhumucda Darbiga waxay u dhaxaysaa sida Boqolleyda Dhexroorka Dibadda | Dulqaadka Dhumucda Derbiga In ka badan iyo Ka Hoos Magacaaban,% | |

| OD≤1.499in[38.07mm] | OD≥1.500 inji [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT> 25 | 12.5 | 10.0 |

Dulqaadka Dhexroorka Dibadda iyo Gudaha

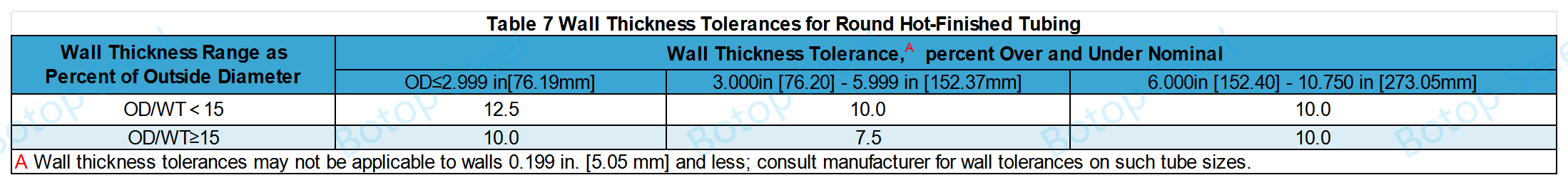

Shaxda 8. Dulqaadka Dhexroorka Dibadda iyo Gudaha eeTuubo Wareegan oo Qabow-Shaqeysa (Cutubyo Inji ah)

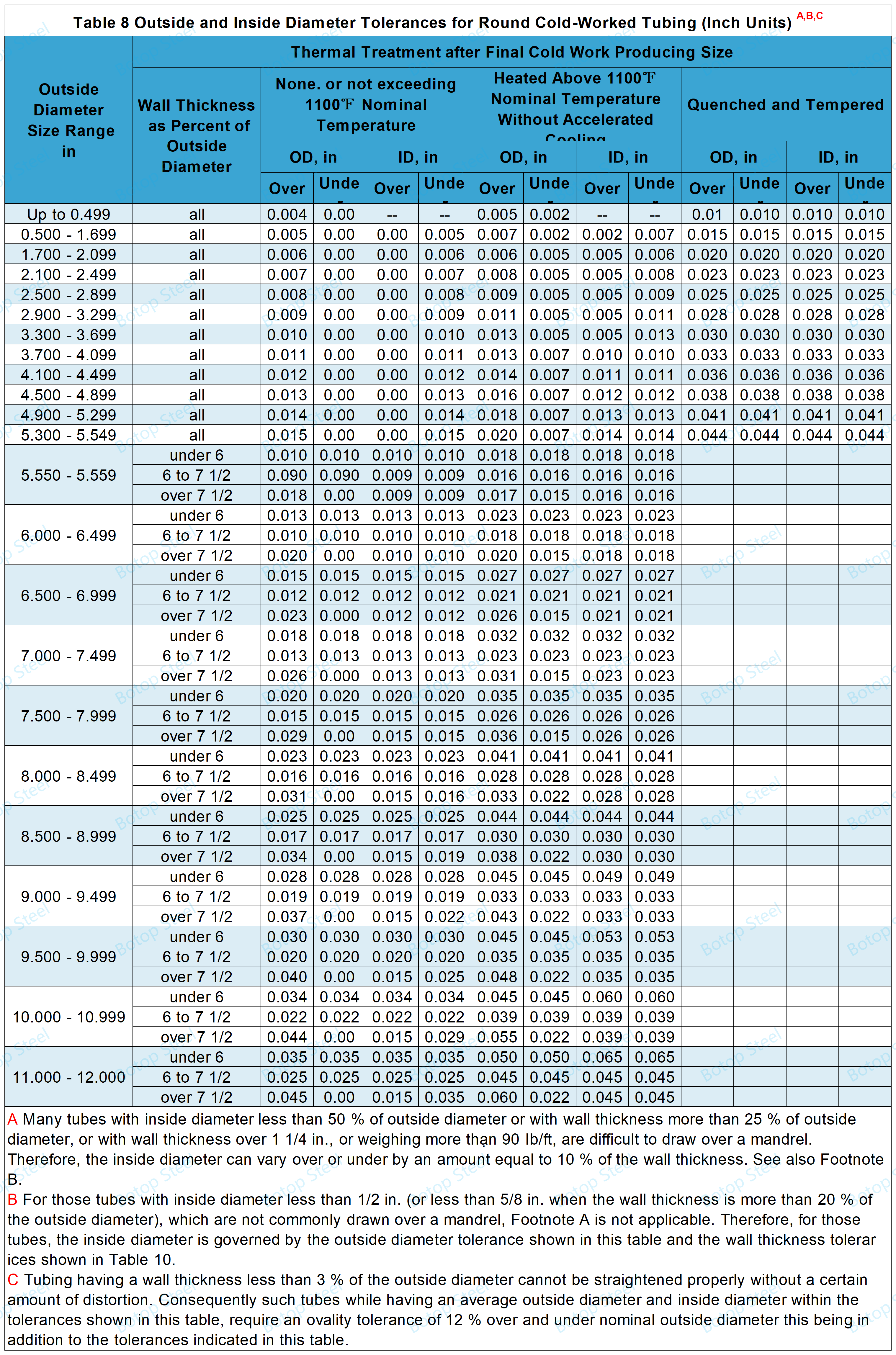

Shaxda 9. Dulqaadka Dhexroorka Dibadda iyo GudahaTuubooyinka Qabow ee Wareega ah (Cutubyada SI)

Dhexroorka Dibadda iyo Dulqaadka Dhumucda Darbiga

Shaxda 11 Dhexroorka Dibadda iyo Dulqaadka DarbigaTuubada Birta aan Toosanayn ee Qalafsan ee loo rogay

| Cabbirka La Cayimay ee Dhexroorka Dibadda, gudaha [mm] | Dhexroorka Dibadda, gudaha [mm] | Dhumucda Darbiga, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Dulqaadka Dhererka

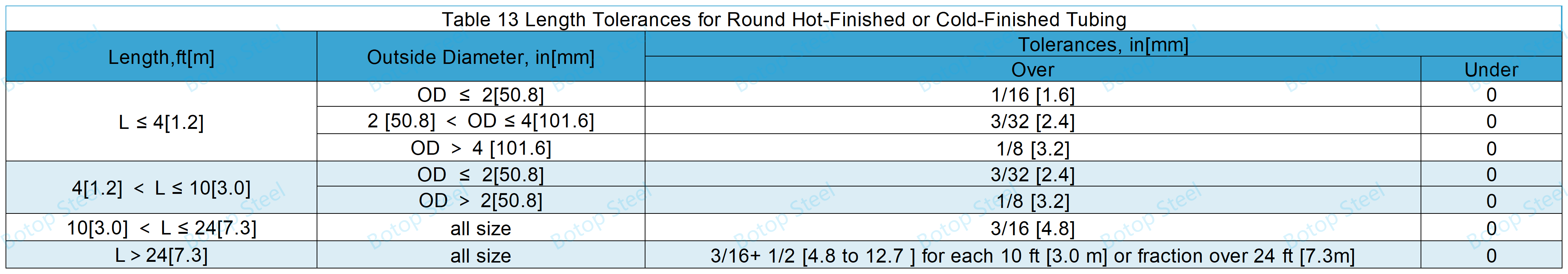

Shaxda 13 Dulqaadka DhererkaTuubbo Wareeg ah oo Kulul-dhammaaday ama Qabow-dhammaaday

Dulqaadka Toosnaanta

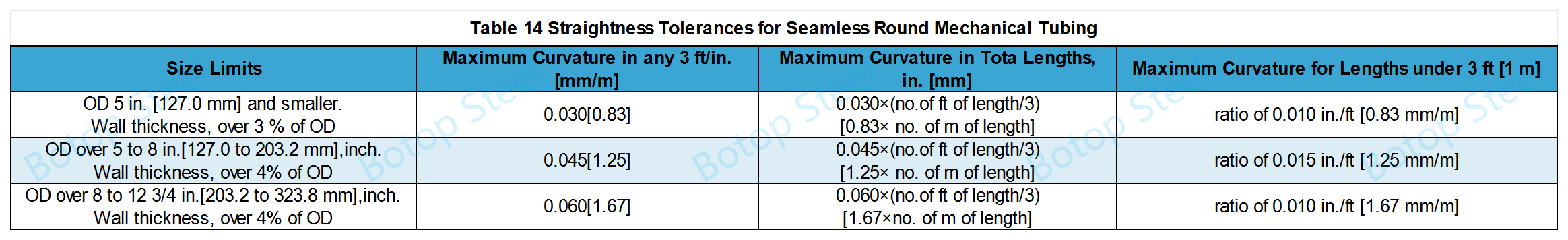

Shaxda 14 Dulqaadka ToosnaantaTuubada Farsamada Wareega ee aan kala go 'lahayn

Tuubada waa in lagu dahaadhaa filim saliid ah ka hor inta aan la samayn si looga hortago miridhku.

Saliid ka hortag ah oo miridhku leeyahay ayaa sidoo kale lagu mari karaa dusha sare ee gudaha iyo dibadda ee tuubada.

Duulista iyo hawada sare: soo saarista qaybaha muhiimka ah sida matoorada diyaaradaha iyo nidaamyada taageerada dayax-gacmeedka.

Warshadaha tamartaqalabka qodista iyo soo saarista tuubooyinka kuleyliyaha cadaadiska sare leh.

Soo saarista mashiinnada iyo qalabkaQaybaha asaasiga ah ee ka kooban mashiinno iyo qalab warshadeed oo kala duwan.

Qalabka ciyaaraha: Soo saarista qaababka baaskiiladaha ee waxqabadka sare leh iyo goobaha kale ee ciyaaraha.

Dhismaha iyo dhismaha: qaybaha taageerada qaab-dhismeedka ee dhismayaasha iyo codsiyada jawi cadaadis sare leh.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, iwm. Agabkan waxaa loo arki karaa inay la mid yihiin qaar ka mid ah birta kaarboon iyo birta daawaha ee ASTM A519.

2. DIN 1629: St52, St37.4, iwm. Badanaa waxaa loo isticmaalaa ujeeddooyin farsamo iyo qaab-dhismeed, kuwani waxay la mid yihiin heerarka birta khafiifka ah ee ASTM A519.

3. JIS G3445: STKM13A, STKM13B, iwm. Kuwani waa tuubooyin bir ah oo kaarboon ah oo loo isticmaalo ujeeddooyin farsamo iyo qaab-dhismeed.

4. BS 6323:CFS 3, CFS 4, CFS 8, iwm. Kuwani waa tuubooyin bir ah oo aan kala go 'lahayn oo loogu talagalay ujeeddooyinka injineernimada baabuurta, farsamada, iyo guud ahaan.

5. GB/T 8162:20#, 45#, 40Cr, 20CrMo, iwm. Tuubooyinka iyo tuubooyinka birta ah ee aan kala go 'lahayn ee loogu talagalay qaab-dhismeedka guud iyo qaab-dhismeedka farsamada.

6. ISO 683-17:100Cr6, iwm., oo si caadi ah loogu isticmaalo soo saarista booyadaha, waxay sidoo kale ka heli kartaa codsi injineerinka farsamada waxayna leedahay codsiyo la mid ah birta dahaarka qaarkood ee ASTM A519.

Marka la dooranayo walxo u dhigma, waxaa muhiim ah in la tixraaco halabuurka kiimikada ee faahfaahsan iyo qeexitaannada hantida farsamada si loo hubiyo in walaxda la doortay ay buuxin doonto shuruudaha waxqabadka ee codsiga gaarka ah.

Tan iyo markii la aasaasay 2014, Botop Steel waxay noqotay shirkad hormuud u ah soo-saarista tuubooyinka birta kaarboonka ee Waqooyiga Shiinaha, oo loo yaqaan adeeg heer sare ah, alaab tayo sare leh, iyo xalal dhammaystiran. Shirkaddu waxay bixisaa noocyo kala duwan oo tuubooyin bir kaarboon ah iyo alaabooyin la xiriira, oo ay ku jiraan tuubooyin bir ah oo aan kala go 'lahayn, ERW, LSAW, iyo SSAW, iyo sidoo kale saf dhammaystiran oo ah qalabka tuubooyinka iyo flanges.

Alaabteeda gaarka ah waxaa sidoo kale ka mid ah biraha heerka sare ah iyo biraha aan lahayn austenitic, oo loogu talagalay inay daboolaan baahiyaha mashaariicda dhuumaha kala duwan.