BS EN 10210 S355J0H, simbi nhamba 1.0547, ndeyechikamu chesimbi ine gomba rinopisa uye inogona kunge isina musono kana kuti yakasungirirwa, inonyanya kushandiswa muzvivakwa zvinoda simba rakawanda uye kusimba kwakanaka, zvakaita semafuremu makuru ekuvaka nemabhiriji.

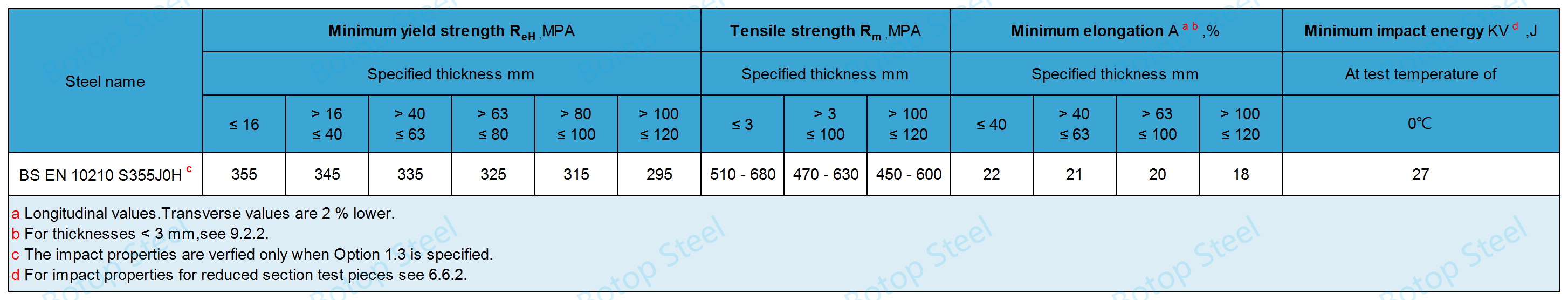

Zvinhu zveS355J0H zvine hunhu hwemakanika hwekuti simba remugoho wepasi i355MPa kana ukobvu hwemadziro husingapfuuri 16 mm uye huchisangana nesimba remugoho repasi re27J pa0℃.

BS EN 10210 ine maumbirwo akasiyana-siyana, akadai sedenderedzwa, sikweya, rectangular, kana elliptical, Botop Steel inonyanya kugadzira machubhu esimbi akatenderera muhukuru hwakasiyana, ichikupa zvinhu zvemachubhu esimbi zvemhando yepamusoro uye zvinoenderana nezvinodiwa nevatengi pamwe nekutengesa zvakananga mufekitori uye mutengo unokwikwidzana.

Cherechedza: Zvese zvinodiwa mugwaro iri zvinoshandawo kuEN 10210.

Ukobvu hwemadziro ≤120mm.

Denderedzwa (HFCHS): Dhayamita dzekunze dzinosvika 2500 mm;

Sikweya (HFRHS): Zviyero zvekunze zvinosvika 800 mm x 800 mm;

Rectangular (HFRHS): Zviyero zvekunze zvinosvika 750 mm x 500 mm;

Eripitiki (HFEHS): Zviyero zvekunze zvinosvika 500 mm x 250 mm.

| Giredhi resimbi | Rudzi rwe kubvisa oxidationa | % nehuremu, huwandu hwepamusoro | |||||||

| C | Si | Mn | P | S | Nb,c | ||||

| Zita resimbi | Nhamba yesimbi | Ukobvu hwakatarwa (mm) | |||||||

| ≤40 | >40 ≤120 | ||||||||

| BS EN 10210 S355J0H | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

aFN = Simbi yekuisa rimming haibvumidzwe;

bZvinotenderwa kudarika kukosha kwakatarwa chero bedzi pakuwedzera kwega kwega kwe0.001 % N iyo P, huwandu hwepamusoro hunoderedzwawo ne0.005 %. Zvisinei, huwandu hweN hweongororo ye cast hahufanirwe kupfuura 0.012 %;

cKukosha kwakanyanya kwenitrogen hakushandi kana makemikari ari muchikamu ichi achiratidza huwandu hweAl hushoma hwe0.020% nechiyero cheAl/N che2:1, kana kana paine zvimwe zvinhu zveN-binding zvakakwana. Zvinhu zveN-binding zvinofanira kunyorwa muGwaro reKuongorora.

Magadzirirwo ezvinhu muBS EN 10210 anobva pakusimba kwadzo kwekukura kwemadziro ne16mm ukobvu uye hunhu hwekurova patembiricha dzakatarwa. Simba rekukura, simba rekudhonza, uye kureba kweBS EN 10210 S355J0H kunoderera sezvo ukobvu hwemadziro huchiwedzera.

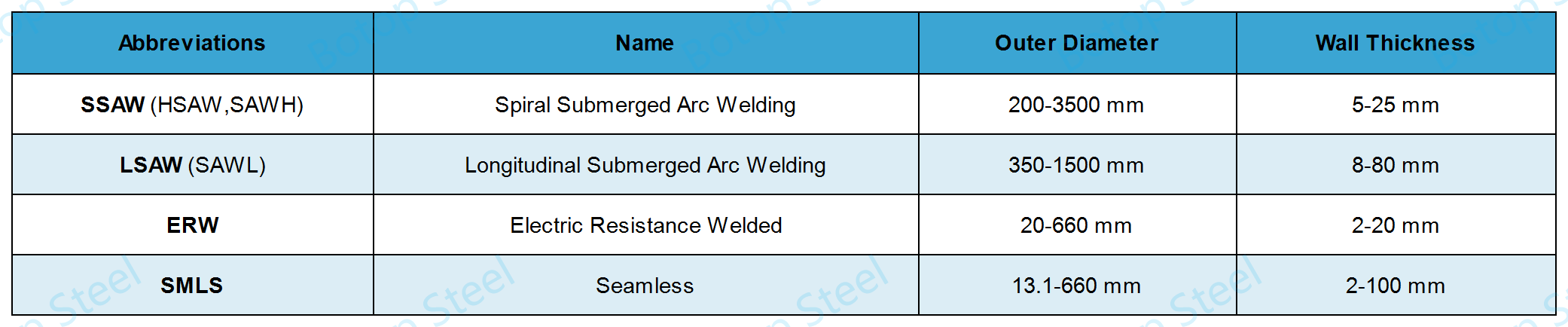

BS EN 10210 inobvumira kugadzirwa uchishandisa nzira dzakasiyana-siyana dzekugadzira, dzinowanzo sanganisira nzira dzisina musono, LSAW, SSAW, uye ERW welding.

Pazasi pane mhando dzakasiyana dzehukuru hwemaitiro akajairika ekugadzira.

Kubva pakuenzanisa kuri pamusoro apa, zvinoonekwa kuti mapaipi esimbi asina musono ane mukana wekugadzirwa kwemapaipi esimbi ane madziro akakora, kunyanya mapaipi esimbi ane dhayamita diki ane madziro akakora, asi saizi yawo ichave shoma. Kana uchida kugadzira mapaipi esimbi ane dhayamita inopfuura 660mm, zvichave zvakaoma.

Pombi Nhema

Izvi zvinoreva pombi yesimbi isina kugadziriswa pamusoro.

Kupfeka Kwekudzivirira Kwenguva Pfupi

Kuti mapaipi esimbi asaparare panguva yekuchengetera, kutakurwa, kana kuiswa, nzira inowanzo shandiswa ndeyekuputira pamusoro pemapaipi nependi kana varnish.

Kuputira Kunodzivirira ngura

Kune mhando dzakasiyana-siyana dzemachira ekudzivirira ngura, kusanganisira pendi, FBE,3LPE, uye galvanized. Rudzi rumwe nerumwe rwekuputira rune hunhu hwakasiyana uye nzvimbo dzakakodzera. Kuora nengura zvinogona kudzivirirwa zvinobudirira nekuisa chifukidziro chakakodzera chekudzivirira ngura pamusoro pesimbi.

EN 10210 Machira ekupisa anodzika pamusoro pemapaipi esimbi anofanira kutevedzera zvinodiwa zveEN ISO 1461.

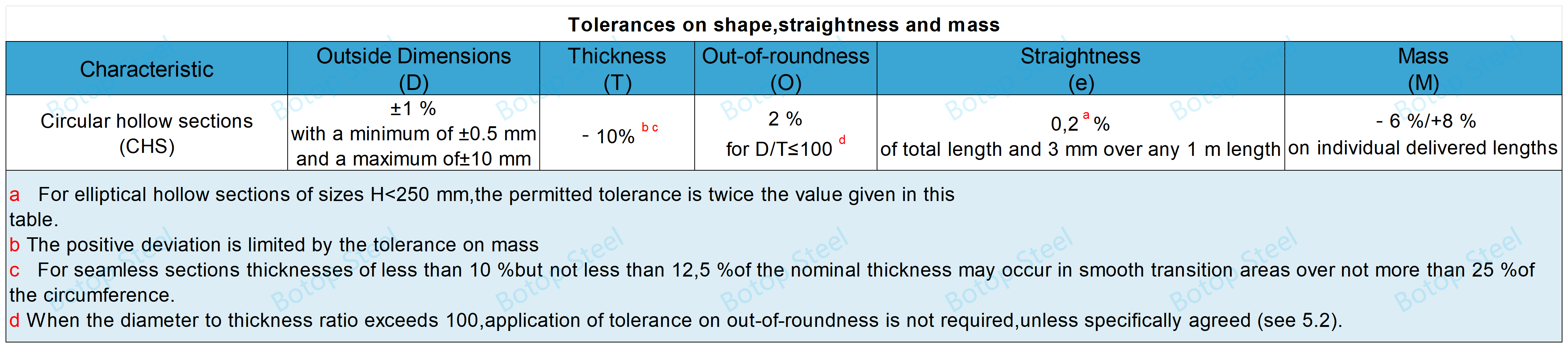

Kushivirira paChimiro, Kururama uye Huremu

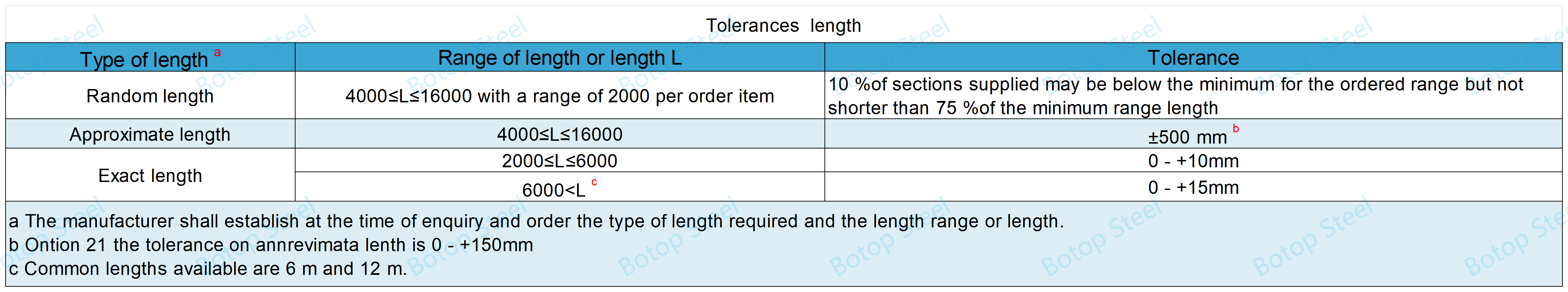

Kushivirira paKureba

Kureba kwemusono weSAW Weld

| Ukobvu, T | Kureba kwakanyanya kwe weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Kureba kwemusono we weld weld hakuwanzo pfuura pamusoro pepombi, uye panguva yekugadzira, musono we weld unogadziriswa kuitira kuti unyatso sangana nepamusoro pepombi uye usaonekwe seuri kuoneka.

BS EN 10210 S355J0H inoshandiswa zvakanyanya mukuvaka zvivakwa, kugadzira michina, mapaipi ekufambisa, kuvaka zvivakwa, ngarava, uye mainjiniya emugungwa. Simba rayo guru uye kusimba kwayo kwakanaka zvinoita kuti ive yakanaka mumapurojekiti akadai semabhiriji, zvivakwa zvirefu, mafekitori emaindasitiri, makireni, mapaipi emafuta negasi, uye mashongwe emagetsi emhepo.

| GB/T | GOST | ASTM | JIS |

| GB/T 1591 Q345B | GOST 19281 09G2S | ASTM A501 Giredhi C | JIS G 3101 SS490 |

Kubva payakatangwa muna 2014, Botop Steel yave kambani inotungamira mukutengesa mapaipi esimbi yekabhoni kuChamhembe kweChina, inozivikanwa nebasa rakanaka kwazvo, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Kambani iyi inopa mapaipi akasiyana-siyana esimbi yekabhoni nezvimwe zvigadzirwa zvinoenderana nazvo, zvinosanganisira mapaipi esimbi asina musono, ERW, LSAW, uye SSAW, pamwe chete nehurongwa hwakazara hwemapipi nemaflange. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisirawo alloys dzemhando yepamusoro nesimbi dzisina ngura dzinogadzirwa neaustenitic, dzakagadzirirwa kusangana nezvinodiwa nemapurojekiti akasiyana-siyana emapaipi.

Zvimwe zvigadzirwa zvine chekuita nazvo:

Tibatei kuti muwane mutengo wemahara uye mazano pamusoro peprojekiti yenyu.