ASTM A335 P9, inozivikanwawo seASME SA335 P9, ipombi yesimbi yeferritic alloy isina musono inoshandiswa pakupisa kwakanyanya neNhamba yeUNS K90941.

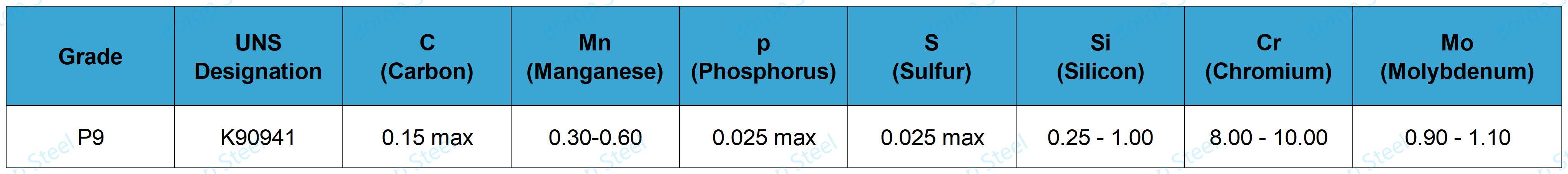

Zvinhu zvinosanganisa chromium nemolybdenum zvinonyanya kukosha. Chromium iri pakati pe8.00 - 10.00%, nepo molybdenum iri pakati pe0.90% - 1.10%.

P9ine simba rakanaka uye inodzivirira ngura zvakanaka munzvimbo dzinopisa zvakanyanya uye inoshandiswa zvakanyanya mumaboiler, michina yepetrochemical, uye nzvimbo dzemagetsi uko kunodiwa nzvimbo dzinopisa zvakanyanya uye dzine kumanikidzwa kwakanyanya.

⇒ Zvinyorwa: ASTM A335 P9 / ASME SA335 P9 pombi yesimbi isina musono.

⇒Dhayamita yekunze: 1/8"- 24".

⇒Ukobvu hwemadziro: Zvinodiwa zveASME B36.10.

⇒Purogiramu: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 uye SCH160.

⇒Kuzivikanwa: STD (yakajairika), XS (yakasimba zvakanyanya), kana XXS (yakasimba zvakanyanya kaviri).

⇒Kureba: Hurefu hwakatarwa kana husina kurongeka.

⇒Kugadzirisa: Dhayamita yekunze isiri yakajairika, ukobvu hwemadziro, kureba, nezvimwewo zvichienderana nezvinodiwa.

⇒Zvishandiso: Tinogona kupa zvinhu zvakafanana zvinokombama, ma stamping flanges, nezvimwe zvigadzirwa zvesimbi zvinotsigira mapaipi.

⇒Chitupa cheIBR: Chitupa cheIBR chinogona kupihwa kana zvichidikanwa.

⇒Kuguma: Mugumo usina kujeka, mugumo wakachekwa, kana mugumo wepombi yakasanganiswa.

⇒Kurongedza: bhokisi remapuranga, bhandi resimbi kana waya yesimbi, chidziviriro chepurasitiki kana simbi.

⇒Kutakurwa: nendege kana kuti nendege.

Pombi yesimbi yeASTM A335 inofanira kunge isina musono.

Pombi yesimbi isina musono ipombi yesimbi isina welds mukati.

Sezvo pombi yesimbi isina musono isina misono yakasungirirwa muchimiro chayo, inodzivirira njodzi dzinogona kuchengetedzeka dzingangobatanidzwa nematambudziko emhando yeweld. Chinhu ichi chinobvumira pombi isina musono kumira kumanikidzwa kwakanyanya, uye chimiro chayo chemukati chakafanana chinowedzera kuvimbisa kusimba uye kuchengetedzeka kwepombi munzvimbo dzine kumanikidzwa kwakanyanya.

Pamusoro pezvo, kuvimbika kwemachubhu eASTM A335 kunowedzerwa nekuwedzera zvinhu zvakati wandei zvekusanganisa mvura kuti zvikwanise kupisa zvakanyanya uye kumanikidzwa kwakanyanya.

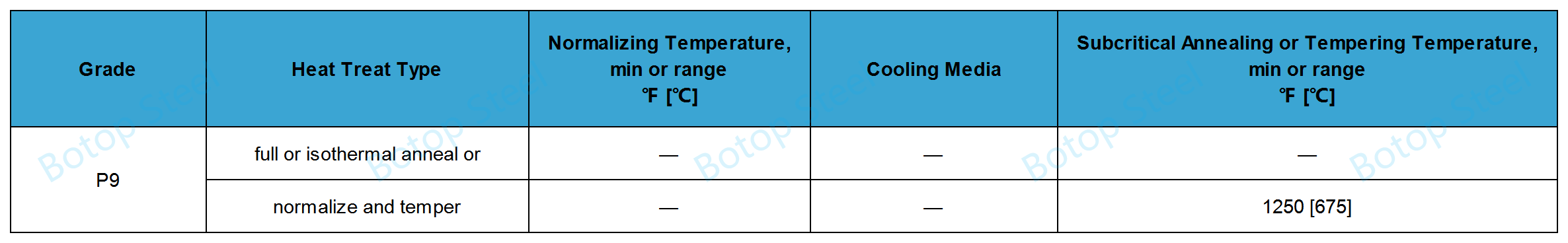

Mhando dzemishonga yekupisa inowanikwa yezvinhu zveP9 dzinosanganisira kunyorovesa kwakazara kana kuti kunopisa, pamwe nekuita kuti zvinhu zvisanyanya kuomarara. Maitiro ekugadzirisa nekunyorovesa ane tembiricha ye1250°F [675°C].

Zvinhu zvikuru zveP9 zvinosanganisa zvinhu ndeizvi:CruyeMo, idzo dziri chromium-molybdenum alloys.

Cr (Chromium): Sechinhu chikuru che alloy, Cr inopa simba rakanaka kwazvo pakupisa kwepamusoro uye kuramba kuoxidation. Inogadzira firimu re chromium oxide rakakora pamusoro pesimbi, zvichiita kuti pombi irambe yakasimba uye ichiramba ngura pakupisa kwakanyanya.

Mo (Molybdenum): Kuwedzerwa kweMo kunovandudza zvakanyanya kusimba uye kusimba kwe alloys, kunyanya munzvimbo dzinopisa zvakanyanya. Mo inobatsirawo kuvandudza kusimba kwechinhu chacho, kureva kugona kuramba kushanduka kana chikapiswa kwenguva refu.

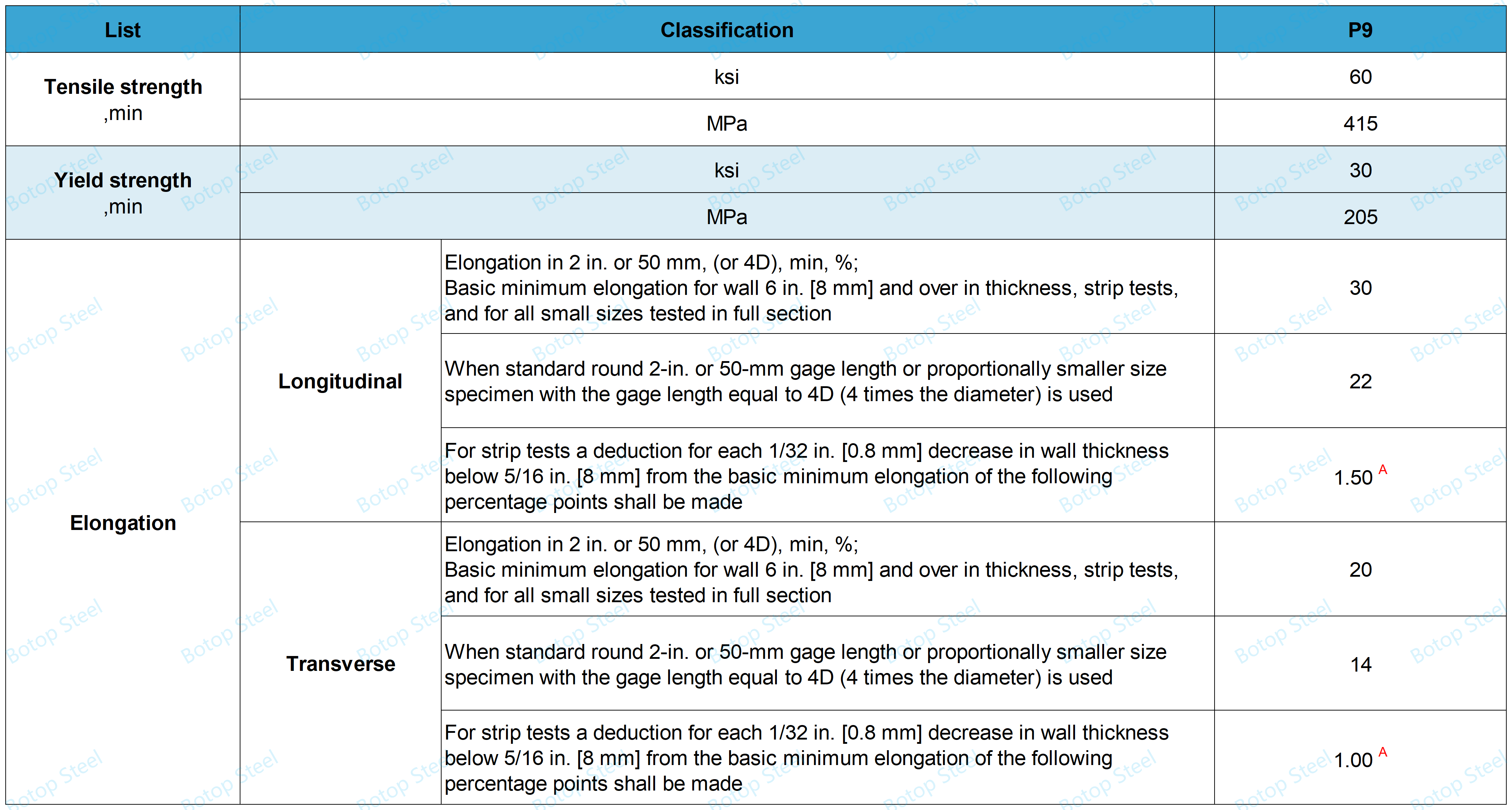

Zvivakwa zveKusimba

P5, P5b, P5c, P9,P11, P15, P21, uye P22: Simba rekukwesha uye kugona kwayo kusimba zvakafanana.

P1, P2, P5, P5b, P5c,P9, P11, P12, P15, P21, uye P22: Kureba kwakafanana.

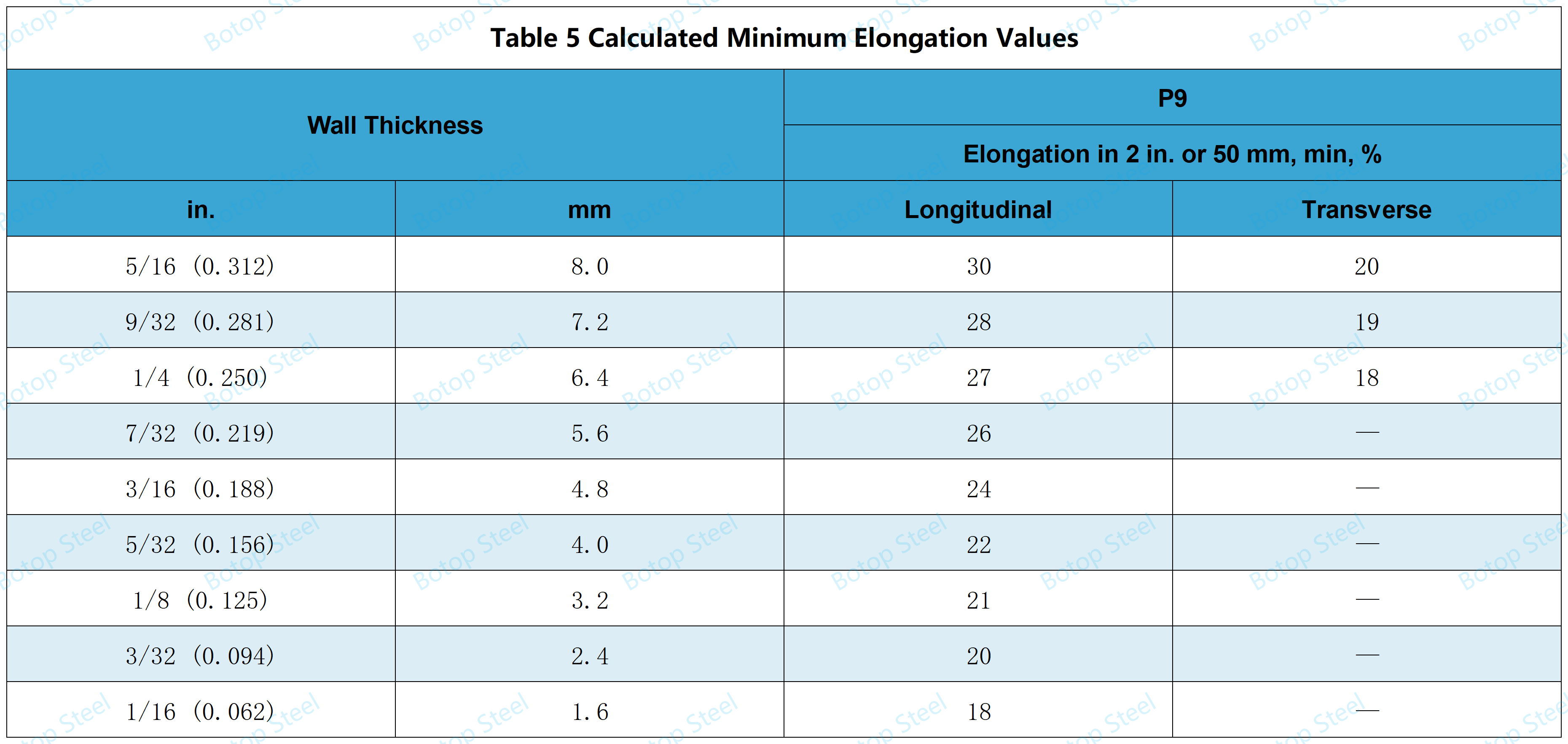

ATafura 5 inopa huwandu hushoma hwakaverengerwa.

Kana ukobvu hwemadziro huri pakati pezvinhu zviviri zviri pamusoro apa, kukosha kwehurefu hushoma kunosarudzwa nefomura inotevera:

Yenguva refu, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

kupi:

E = kureba mu 2 in. kana 50 mm, %,

t = ukobvu chaihwo hwezvienzaniso, mu. [mm].

Kuoma

P9 haidi kuyedzwa kwekuomarara.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, uye P921: Hapana bvunzo yekuomarara inodiwa.

Kana dhayamita yekunze iri > 10 in. [250 mm] uye ukobvu hwemadziro huri ≤ 0.75 in. [19 mm], zvese zvinofanira kuongororwa ne hydrostatic.

Kumanikidzwa kwekuyedza kunogona kuverengerwa uchishandisa equation inotevera.

P = 2St/D

P= kumanikidzwa kwekuyedza kwehydrostatic mu psi [MPa];

S= kumanikidzwa kwemadziro epombi mu psi kana [MPa];

t= ukobvu hwemadziro hwakatarwa, ukobvu hwemadziro hunoenderana nenhamba yakatarwa yeANSI kana ka1.143 kakapetwa ukobvu hwemadziro hushoma hwakatarwa, mu. [mm];

D= dhayamita yekunze yakatarwa, dhayamita yekunze inoenderana nehukuru hwepombi yeANSI yakatarwa, kana dhayamita yekunze yakaverengerwa nekuwedzera 2t (sezvakatsanangurwa pamusoro) kune dhayamita yemukati yakatarwa, mu. [mm].

Nguva yekuyedza: chengeta kanenge 5s, hapana kubuda kwemvura.

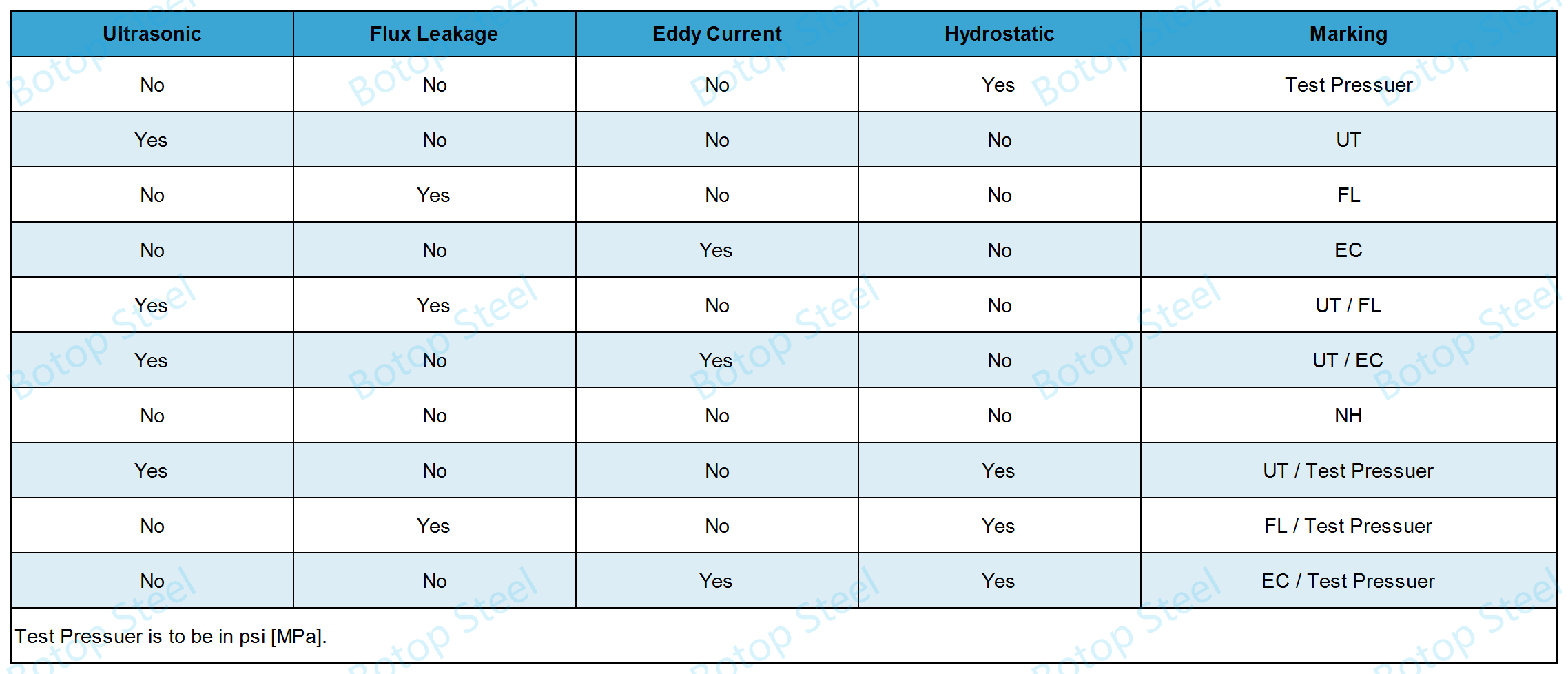

Kana pombi isingazoedzwa nemvura, bvunzo isingaparadze inofanira kuitwa papombi yega yega kuti ione zvikanganiso.

Kuedza zvinhu zveP9 kusingaparadze kunofanirwa kuitwa neimwe yenzira idzi.E213, E309 or E570.

E213: Dzidzira Kuyedzwa kweUltrasonic kweMapaipi esimbi neMachubhu;

E309: Dzidzira Kuongorora Kwemazuva Ano kweEddy kweSimbi Tubular Products Uchishandisa Magnetic Saturation;

E570: Dzidziso yeKuongorora Kubuda Kwemvura muFlux yeZvigadzirwa zveFerromagnetic Steel Tubular;

Kusiyana Kunobvumidzwa muDhayamita

Kutsauka kwedhayamita kunogona kurongwa zvichienderana ne 1. zvichibva padhayamita yemukati kana 2. zvichibva padhayamita yezita kana yekunze.

1. Dhayamita yemukati: ± 1%.

2. NPS [DN] kana dhayamita yekunze: Izvi zvinoenderana nekutsauka kunobvumirwa mutafura iri pazasi.

Kusiyana Kunobvumidzwa muKukora kweMadziro

Ukobvu hwemadziro epombi chero kupi zvako haufanirwe kudarika kushivirira kwakataurwa.

Ukobvu hwemadziro hushoma uye dhayamita yekunze yekutarisa kuti ienderane nezvinodiwa zvepaipi yakarairwa neNPS [DN] uye nhamba yehurongwa zvinoratidzwa muASME B36.10M.

Zviri mukati mekumaka: Zita remugadziri kana chiratidzo chekutengeserana; nhamba yakajairika; giredhi; kureba uye chiratidzo chekuwedzera "S".

Zviratidzo zvekumanikidzwa kwemvura uye bvunzo dzisingaparadzi zviri patafura iri pazasi zvinofanirawo kuiswa.

Nzvimbo yekuisa chiratidzoKuisa chiratidzo kunofanira kutanga pamakiromita angangoita 300 mm kubva kumagumo epombi.

Pamapaipi anosvika NPS 2 kana pasi pe 3 ft (1 m) pakureba, chiratidzo cheruzivo chinogona kunamirwa pa tag.

Pombi yesimbi yeASTM A335 P9 inoshandiswa zvakanyanya mumaboiler, zviteshi zvemagetsi zvemidziyo yepetrochemical, nezvimwewo, zvinoda kutsungirira tembiricha yakakwira uye kumanikidzwa kwakakwira nekuda kwekupisa kwayo kwakanyanya uye kuramba kwayo kumanikidzwa kwakakwira.

Mabhoira: Kunyanya mukuisa mapombi makuru emhepo uye kuisazve mapombi ekupisa e supercritical uye ultra-supercritical boilers pakupisa kwakanyanya uye kumanikidzwa.

Midziyo yePetrochemical: Zvakaita semapaipi ecracker nemapaipi anodziya zvakanyanya, anobata utsi hwemvura nemakemikari anodziya zvakanyanya, zvinoda zvinhu zvine simba rekudzivirira kupisa uye ngura.

Zviteshi zvemagetsi: Yemapaipi makuru emhepo inopfungaira uye mahita ane simba guru, pamwe chete nemapaipi emukati me turbine kuti akwanise kurarama kwenguva refu yekupisa kwakanyanya uye kumanikidzwa.

Zvinhu zveP9 zvine mamakisi azvo akajairwa muhurongwa hwakasiyana hwenyika.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

GOST 550: 12ChM;

Usati wasarudza chero chinhu chakaenzana nacho, zvinokurudzirwa kuti uenzanise mashandiro uye uedze zvinhu zvakadzama kuti uve nechokwadi chekuti chimwe chinhu chichaenderana nezvinodiwa nedhizaini yekutanga.

Kubva payakavambwa muna 2014,Simbi yeBotopyava mutengesi anotungamira wemapaipi esimbi yekabhoni kuChamhembe kweChina, inozivikanwa nebasa rakanaka kwazvo, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Kambani iyi inopa mapaipi akasiyana-siyana esimbi yekabhoni nezvimwe zvigadzirwa zvinoenderana nazvo, zvinosanganisira mapaipi esimbi asina musono, ERW, LSAW, uye SSAW, pamwe chete nehurongwa hwakazara hwemapipi nemaflange. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisirawo alloys dzemhando yepamusoro nesimbi dzisina ngura dzinogadzirwa neaustenitic, dzakagadzirirwa kusangana nezvinodiwa nemapurojekiti akasiyana-siyana emapaipi.

Ndapota inzwa wakasununguka kutibata kana muine zvaunoda kana mibvunzo nezvemachubhu esimbi. Tinotarisira kugamuchira ruzivo rwenyu uye tinotarisira kukubatsirai.