JIS G 3454est norma industrialis Iaponica pro tubis chalybis carbonis destinatis systematibus pressoriis cum temperatura operandi maxima 350°C. Haec norma duos gradus includit:STPG 370etSTPG 410Ad tubos electrica resistentia conglutinatos (ERW) vel sine suturis, diametro nominali 10.5 mm ad 660.4 mm (id est, 6A ad 650A, vel 1/8B ad 26B) pertinet.

Tubi ferrei secundum normam JIS G 3454 fabricandi sunt utens apta combinatione methodorum fabricationis tuborum ferreorum et methodorum finitionis in tabula infra.

| Symbolum gradus | Symbolum processus fabricationis | ||

| Processus fabricationis tuborum | Methodus perficiendi | Classificatio zinci obductionis | |

| STPG370 STPG410 | Sinsutura: S Resistentia electrica conglutinata: E | Calido perfecto: H Frigido perfecto: C Ut resistentia electrica conglutinata: G | Tubi nigri: tubi zinco non obducti Tubi albi: tubi zinco obducti |

Speciatim, quinque modi fabricationis sunt:

SHTubus ferreus sine suturis calido-perfectus;

SCTubus ferreus sine suturis frigido conflatus;

EHTubus ferreus resistentia electrica calido conflatus;

ECTubus ferreus resistentia electrica frigida confectus et sudatus;

EGTubus ferreus resistentia electrica sudatus, praeter eos qui calido et frigido perficiuntur.

Chalybs Botopest fabricator et praebitor tuborum chalybis carbonis conglutinatorum altae qualitatis ex Sinis, necnon venditor tuborum chalybis sine suturis. Si quas necessitates habes, libenter nobiscum communicare potes et tibi auxilium technicum professionale gratuitum praebebimus.

| Symbolum gradus | C | Si | Mn | P | S |

| maximum | maximum | — | maximum | maximum | |

| STPG 370 | 0.25% | 0.35% | 0.30-0.90% | 0.040% | 0.040% |

| STPG 410 | 0.30% | 0.35% | 0.30-1.00% | 0.040% | 0.040% |

Additionem aliorum elementorum mixturae permittit.

Robur Tensilis, Punctum Cedendi sive Tensio Probationis, et Elongatio

| Symbolum gradus | Robur tensile | Punctum cedendi vel probatio accentus | Elongatio minimum, % | |||

| Pars probationis tensilis | ||||||

| Numerus XI vel duodecim | Numerus 5 | Numerus 4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Directio probationis tensilis | ||||

| minutum | minutum | Parallela ad axem tubi | Perpendicularis ad axem tubi | Parallela ad axem tubi | Perpendicularis ad axem tubi | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Examen Applanationis

Cum distantia inter duas laminas ad distantiam definitam H pervenerit, nulla vitia aut fissurae in superficie tubi ferrei apparebunt.

Pro tubis ferreis sine suturis: H = (1 + e)t/(e + t/D);

Pro tubis chalybeis ERW: H = 1/3 D (pro sutura) vel H = 2/3 D (pro parte sine sutura);

H: spatium inter laminas applanantes (mm);

e: constans pro quolibet gradu tubi singillatim definita, 0.08 pro STPG 370, 0.07 pro STPG 410;

t: crassitudo parietis tubi (mm);

D: diameter externus tubi (mm);

Examen Planificationis ad tubos ferreos diametro nominali maiore quam 40A (48.6mm) applicatur.

Flexibilitas

Flexibilitas ad tubos diametro nominali 40 A (48.6) vel minorem pertinet.

Tubus 90° ad radiom sextuplo diametri exterioris flecti debet. Paries tubi vitiis vel fissuris carere debet.

Quaeque fistula ferrea probationem pressionis hydrostaticae vel probationem non destructivam subire debet.

Examen Hydrostaticum

Pressionem certam per saltem quinque secundas sine effluvio serva.

Valor pressionis ad numerum schedulae tubi ferrei pertinet.

| Crassitudo parietis nominalis | Numerus Schedulae: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Minima pressio probationis hydraulicae, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Examen Non Destructivum

Si inspectio ultrasonica adhibeatur, norma strictiore quam signum classis UD in JIS G 0582 fundari debet.

Si probatio currentium turbulentarum adhibetur, ea fundari debet in norma quae strictiore est quam signum classis EY in JIS G 0583.

| Diameter nominalis | Diameter externus | Crassitudo parietis | Massa unitatis | Numerus schedulae (Schema No.) | |

| A | B | mm | mm | kg/m² | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | Quarta pars | 13.8 | 2.2 | 0.629 | 40 |

| 8 | Quarta pars | 13.8 | 2.4 | 0.675 | 60 |

| 8 | Quarta pars | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | Dimidium | 21.7 | 2.8 | 1.31 | 40 |

| 15 | Dimidium | 21.7 | 3.2 | 1.46 | 60 |

| 15 | Dimidium | 21.7 | 3.7 | 1.64 | 80 |

| 20 | Tres quartae partes | 27.2 | 2.9 | 1.74 | 40 |

| 20 | Tres quartae partes | 27.2 | 3.4 | 2.00 | 60 |

| 20 | Tres quartae partes | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | Quarta pars | 42.7 | 3.6 | 3.47 | 40 |

| 32 | Quarta pars | 42.7 | 4.5 | 4.24 | 60 |

| 32 | Quarta pars | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | Duo et dimidium | 76.3 | 4.5 | 7.97 | 20 |

| 65 | Duo et dimidium | 76.3 | 5.2 | 9.12 | 40 |

| 65 | Duo et dimidium | 76.3 | 6.0 | 10.4 | 60 |

| 65 | Duo et dimidium | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | Tres et dimidium | 101.6 | 4.5 | 10.8 | 20 |

| 90 | Tres et dimidium | 101.6 | 5.7 | 13.5 | 40 |

| 90 | Tres et dimidium | 101.6 | 7.0 | 16.3 | 60 |

| 90 | Tres et dimidium | 101.6 | 8.1 | 18.7 | 80 |

| centum | 4 | 114.3 | 4.9 | 13.2 | 20 |

| centum | 4 | 114.3 | 6.0 | 16.0 | 40 |

| centum | 4 | 114.3 | 7.1 | 18.8 | 60 |

| centum | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| CL | 6 | 165.2 | 5.5 | 21.7 | 20 |

| CL | 6 | 165.2 | 7.1 | 27.7 | 40 |

| CL | 6 | 165.2 | 9.3 | 35.8 | 60 |

| CL | 6 | 165.2 | 11.0 | 41.8 | 80 |

| ducenti | 8 | 216.3 | 6.4 | 33.1 | 20 |

| ducenti | 8 | 216.3 | 7.0 | 36.1 | 30 |

| ducenti | 8 | 216.3 | 8.2 | 42.1 | 40 |

| ducenti | 8 | 216.3 | 10.3 | 52.3 | 60 |

| ducenti | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| trecenti | 12 | 318.5 | 6.4 | 49.3 | 20 |

| trecenti | 12 | 318.5 | 8.4 | 64.2 | 30 |

| trecenti | 12 | 318.5 | 10.3 | 78.3 | 40 |

| trecenti | 12 | 318.5 | 14.3 | 107 | 60 |

| trecenti | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | CLVIII | 80 |

| quadringenti | 16 | 406.4 | 6.4 | 63.1 | 10 |

| quadringenti | 16 | 406.4 | 7.9 | 77.6 | 20 |

| quadringenti | 16 | 406.4 | 9.5 | 93.0 | 30 |

| quadringenti | 16 | 406.4 | 12.7 | 123 | 40 |

| quadringenti | 16 | 406.4 | 16.7 | CLX | 60 |

| quadringenti | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | CLVI | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| quingenti | 20 | 508.0 | 6.4 | 79.2 | 10 |

| quingenti | 20 | 508.0 | 9.5 | 117 | 20 |

| quingenti | 20 | 508.0 | 12.7 | CLV | 30 |

| quingenti | 20 | 508.0 | 15.1 | CLXXXIV | 40 |

| quingenti | 20 | 508.0 | 20.6 | 248 | 60 |

| quingenti | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | CLXXI | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| DC | 24 | 609.6 | 6.4 | 95.2 | 10 |

| DC | 24 | 609.6 | 9.5 | 141 | 20 |

| DC | 24 | 609.6 | 14.3 | 210 | 30 |

| DCCL | 26 | 660.4 | 7.9 | 127 | 10 |

| DCCL | 26 | 660.4 | 12.7 | 203 | 20 |

JIS G 3454 includitschedula 10, schedula XX, schedula 30, schedula 40, schedula 60, etschedula 80.

Numerum schedulae quem inspicere cupis premere potes; versiones PDF correspondentes pro commoditate tua ordinavimus.

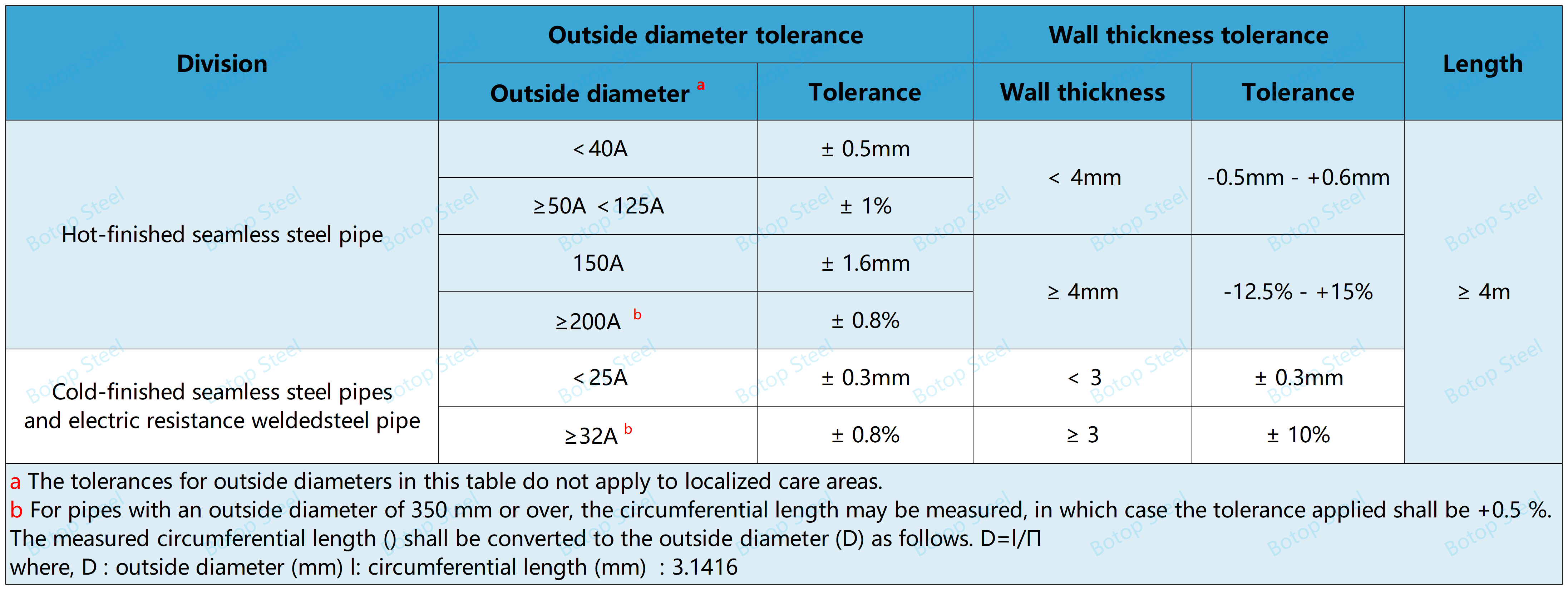

JIS G 3454 Tolerantiae pro diametro externo, crassitudine parietis, eccentricitate, et longitudine his requisitis satisfacere debent.

Ab anno MMXIV condita, Botop Steel princeps in Sinis Septentrionalibus tuborum chalybis carbonis praebitor facta est, ob servitium excellentem, producta summae qualitatis, et solutiones completas nota.

Societas varietatem tuborum chalybis carbonis et productorum similium offert, inter quos tubi chalybis sine suturis, ERW, LSAW, et SSAW, necnon seriem completam iuncturarum tuborum et flangarum.

Inter producta eius specialia etiam sunt mixturae metallorum summae qualitatis et chalybes inoxidabiles austeniticae, ad postulata variorum inceptorum fistularum aptatae.

Quaeso nobiscum communicare; tibi tubos ferreos summae qualitatis et normae, una cum servitio perito et efficaci, praebebimus. Botop tibi servire libenter exspectat.