DIN 17100 St52.3 cov kav hlau sib dhos tau raug xa mus rau Australia.

DIN 17100 yog tus qauv siv rau cov seem hlau, cov hlau tuav, cov hlau xaim, cov khoom tiaj tustsis muaj qhov tsis sib xwsthiab welded, square thiab rectangular hollow sections, forgings, thiab semi-finished products nyob rau hauv cov hlau qauv dav dav uas tau xa tuaj rau hauv qhov kub tsim lossis normalized mob tom qab ntau lawm.

St52.3 yog ib qho ntawm cov qib, thiab tus lej khoom siv yog 1.0570.

Ua ntej xa khoom, Botop npaj rau cov neeg ua haujlwm zoo los tshuaj xyuas cov khoom kom zoo kom ntseeg tau tias cov khoom zoo ua tau raws li cov neeg siv khoom xav tau.

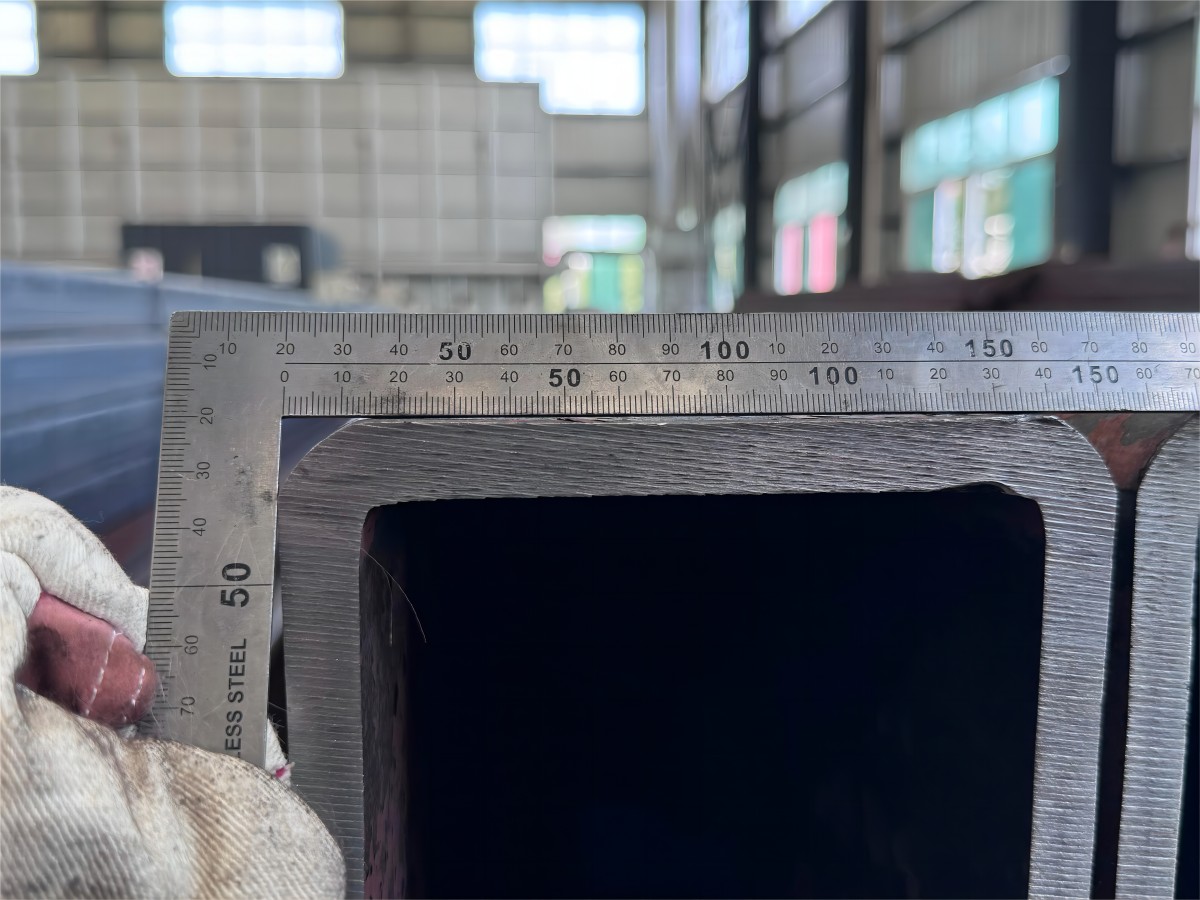

Ua ntej, qhov zoo ntawm qhov chaw, qhov dav, qhov siab, qhov ntev, qhov sib npaug, thiab lwm yam qhov loj ntawm cov yeeb nkab hlau raug tshuaj xyuas kom zoo kom ntseeg tau tias ua raws li cov qauv thiab cov neeg siv khoom xav tau.

Tom ntej no, cov khoom siv tshuaj lom neeg thiab cov khoom siv kho tshuab ntawm cov yeeb nkab hlau raug kuaj xyuas.

EN 17100 St52.3 muaj cov kev cai hauv qab no txog cov tshuaj lom neeg:

| Qib | Cov tshuaj lom neeg muaj pes tsawg leeg hauv% los ntawm wt. | ||||||||

| C | P | S | Cov ntsiab lus sib xyaw ua ke ntawm nitrogen ntxiv (piv txwv li tsawg kawg 0.020% Al rau tag nrho) | ||||||

| rau cov khoom tuab hauv mm | |||||||||

| ≤16 | >16 ≤30 | > 30 ≤ 40 | >40 ≤63 | >63 ≤100 | > 100 | ||||

| EN 17100 St52.3 | 0.20 siab tshaj | 0.20 siab tshaj | 0.22 siab tshaj | 0.22 siab tshaj | 0.22 siab tshaj | los ntawm kev pom zoo | 0.040 siab tshaj plaws | 0.040 siab tshaj plaws | yog |

Cov tshuaj lom neeg ntawm St52.3 yog ntsuas los ntawm lub spectrometer, thiab txhua yam ntsiab lus ua tau raws li cov neeg siv khoom xav tau piv rau cov kev cai siv tau.

Cov khoom siv kho tshuab ntawm EN 17100 St52.3 feem ntau suav nrog lub zog tensile thiab lub zog yield, uas ntsuas los ntawm kev sim tensile.

| Qib | Lub zog tensile Rm | Qhov siab tshaj plaws ntawm cov qoob loo ReH | |||||||

| rau cov khoom tuab hauv mm | rau cov khoom tuab hauv mm | ||||||||

| <3 | ≥3 ≤100 | > 100 | ≤16 | >16 ≤30 | > 30 ≤ 40 | >40 ≤63 | >63 ≤100 | > 100 | |

| EN 17100 St52.3 | 510 - 680 MPa | 490 - 630 MPa | los ntawm kev pom zoo | 355 | 345 | 335 | 325 | 315 | los ntawm kev pom zoo |

Tom qab ua tiav tag nrho cov kev tshuaj xyuas thiab xyuas kom meej tias qhov zoo ua tau raws li cov qauv yuav tsum tau ua, daim ntawv pov thawj kuaj khoom siv (MTC) yuav muab. Tom qab ntawd, kev npaj rau kev xa khoom thiab lwm yam haujlwm cuam tshuam yuav ua.

Txij li thaum nws tau tsim tsa xyoo 2014, Botop Steel tau dhau los ua tus thawj coj ntawm cov kav hlau carbon hauv sab qaum teb Suav teb, paub txog nws cov kev pabcuam zoo heev, cov khoom lag luam zoo, thiab cov kev daws teeb meem dav dav.

Rau txhua qhov kev txiav txim, Botop ib txwm ua raws li lub tswv yim ntawm kev txhim khu kev qha zoo thiab tus nqi zoo, xaiv peb los muab cov khoom siv yeeb nkab rau koj.

Lub sijhawm tshaj tawm: Lub Kaum Hli-11-2024