EN 10210 S355J2Hyog ib qho hlau hollow section uas kub-ua tiav raws liEN 10210nrog rau qhov tsawg kawg nkaus ntawm 355 MPa (rau phab ntsa tuab ≤ 16 hli) thiab cov khoom cuam tshuam zoo ntawm qhov kub qis mus rau -20 ° C, ua rau nws zoo tagnrho rau kev siv hauv ntau yam kev tsim kho thiab kev tsim kho vaj tse.

Yog, EN 10210 =BS EN 10210.

BS EN 10210 thiab EN 10210 zoo ib yam hauv cov ntsiab lus kev siv tshuab thiab ob qho tib si sawv cev rau cov qauv European rau kev tsim qauv, kev tsim khoom, thiab cov kev cai rau cov ntu thermoformed structural hollow.

BS EN 10210 yog qhov version uas tau txais yuav hauv UK, thaum EN 10210 yog tus qauv thoob plaws Tebchaws Europe. Cov koom haum tsim qauv hauv tebchaws sib txawv yuav ua ntej tus qauv nrog cov lus luv luv hauv tebchaws, tab sis cov ntsiab lus tseem ceeb ntawm tus qauv tseem zoo ib yam.

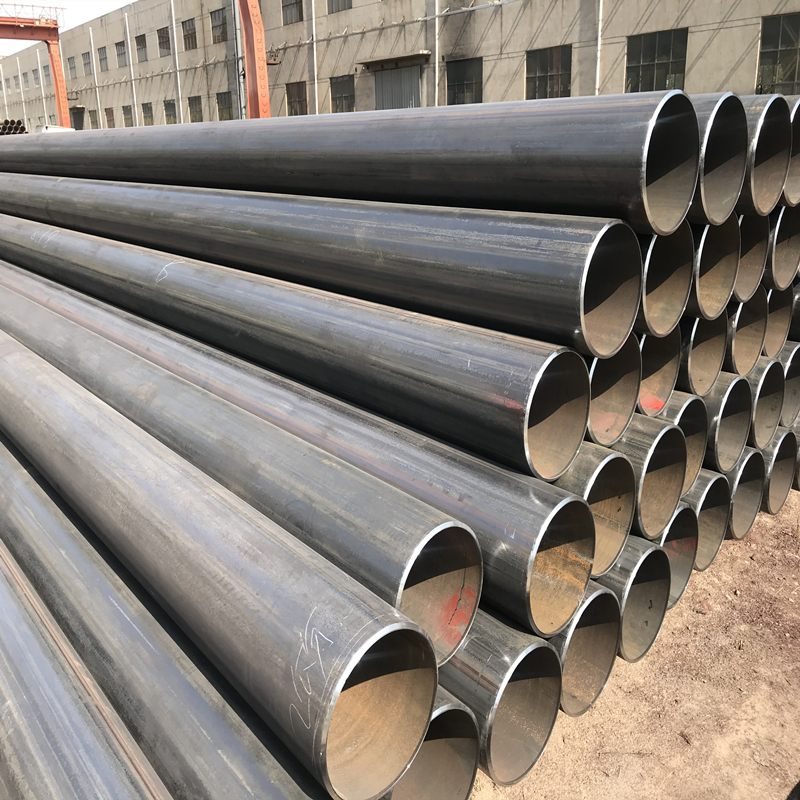

Cov ntu hollow tuaj yeem raug cais ua voj voog, square lossis rectangular, lossis elliptical.

Tsis tas li ntawd vim tias nws yog ib qho txheej txheem kub tiav raws li EN 10210, cov lus luv hauv qab no tuaj yeem siv tau.

HFCHS= kub tiav lawm voj voog hollow seem;

HFRHS= kub tiav lawm square lossis rectangular hollow sections;

HFEHS= cov seem elliptical hollow kub tiav lawm.

Puag ncig: Sab nraud txoj kab uas hla mus txog 2500 hli;

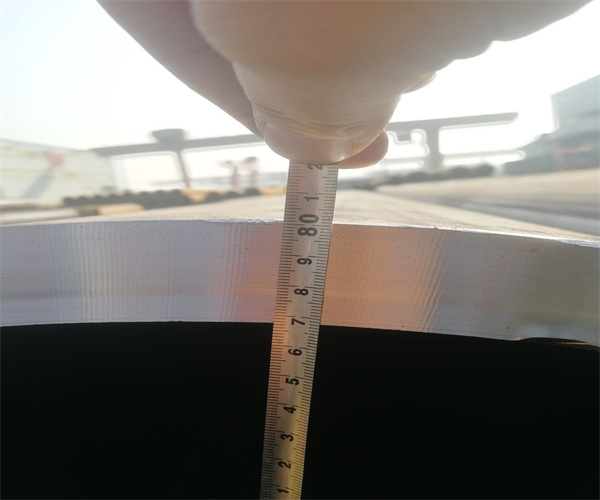

Phab ntsa thicknesses txog li 120 hli.

Tau kawg, tsis muaj txoj hauv kev los tsim cov raj ntawm qhov loj me thiab phab ntsa no yog tias siv cov txheej txheem ERW vuam.

ERW tuaj yeem tsim cov raj txog li 660mm nrog phab ntsa tuab ntawm 20mm.

Cov hlau tuaj yeem tsim los ntawm kev sivseamless los yog vuamtxheej txheem.

Ntawm covcov txheej txheem vuam, cov txheej txheem vuam feem ntau suav nrogERW(kev vuam hluav taws xob tsis kam) thiabSAW(submerged arc vuam).

Ntawm lwm tus,ERWyog ib txoj kev vuam uas txuas cov khoom hlau ua ke los ntawm kev siv cua sov thiab siab. Txoj kev no siv tau rau ntau yam khoom siv thiab tuab thiab ua rau muaj kev vuam zoo.

SAW, ntawm qhov tod tes, yog ib txoj kev vuam uas siv cov kua nplaum granular los npog lub arc, uas muab kev nkag mus tob dua thiab zoo dua qhov vuam zoo thiab tshwj xeeb tshaj yog tsim rau vuam cov phaj tuab.

Tom ntej no, yog cov txheej txheem ERW, uas yog cov txheej txheem tsim khoom zoo heev uas siv dav los tsim ntau yam yeeb nkab hlau thiab cov profile.

Yuav tsum nco ntsoov tias rau cov seem tsis muaj hlau thiab cov khoom me me uas ua los ntawm cov txheej txheem vuam, kev kho vuam tsis raug tso cai tsuas yog kev vuam submerged arc xwb.

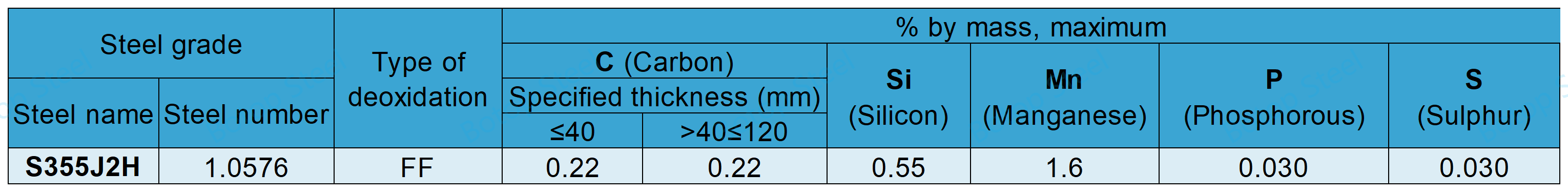

Cov Qauv JR, JO, J2 thiab K2 - kub tiav lawm,

Lub zog tsawg kawg nkaus ntawm S355J2H steel yeeb nkab tsis ruaj khov, nws yuav hloov pauv nrog cov phab ntsa sib txawv.

Tshwj xeeb, lub zog tso zis ntawm S355J2H raug teeb tsa raws li tus qauv thaum lub phab ntsa tuab tsawg dua lossis sib npaug rau 16 hli, tab sis thaum lub phab ntsa tuab nce ntxiv, lub zog tso zis yuav raug txo qis, yog li tsis yog txhua lub yeeb nkab hlau S355J2H tuaj yeem ncav cuag lub zog tso zis tsawg kawg nkaus ntawm 355MPa.

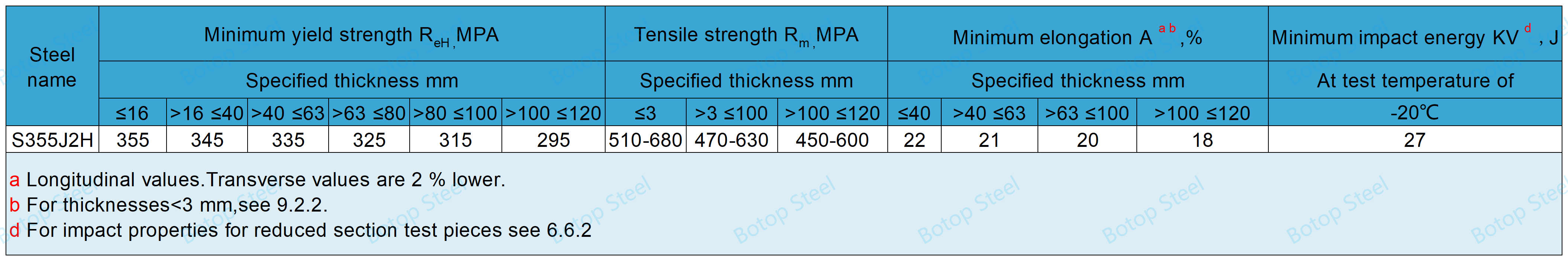

Kev kam rau siab rau cov duab, kev ncaj thiab qhov hnyav

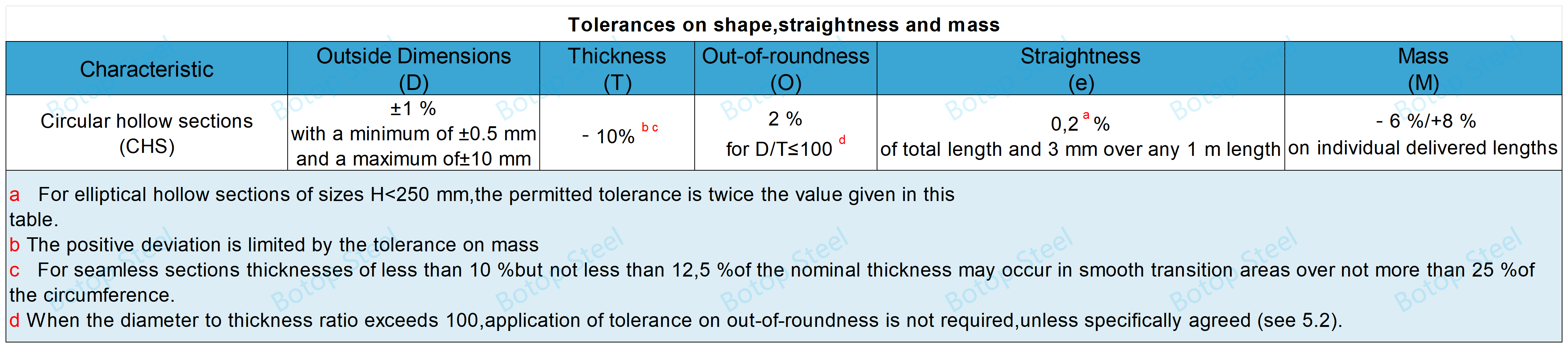

Kev kam rau siab ntev

| Hom nteva | Qhov ntev ntawm qhov ntev lossis qhov ntev L | Kev kam rau siab |

| Qhov ntev tsis xaiv | 4000≤L≤16000 nrog rau ntau yam ntawm 2000 rau ib yam khoom xaj | 10% ntawm cov ntu uas tau muab tuaj yeem qis dua qhov tsawg kawg nkaus rau qhov ntau yam uas tau txiav txim tab sis tsis luv dua 75% ntawm qhov ntev tsawg kawg nkaus |

| Kwv yees li ntev | 4000≤L≤16000 | ±500 hlib |

| Qhov ntev tseeb | 2000≤L≤6000 | 0 - +10 hli |

| 6000c | 0 - +15 hli | |

| aThaum lub sijhawm nug, tus neeg tsim khoom yuav tsum tsim kom muaj hom ntev uas xav tau thiab qhov ntev uas xav tau. bOntion 21 qhov kev kam rau siab ntawm annrevimata ntev yog 0 - + 150mm cQhov ntev uas siv tau yog 6 m thiab 12 m. | ||

S355J2H cov yeeb nkab steel yog cov yeeb nkab steel muaj zog siab nrog kev ua haujlwm vuam zoo thiab qhov kub qis cuam tshuam, yog li nws muaj ntau yam kev siv hauv ntau qhov chaw lag luam.

1. Kev Tsim Kho: siv rau hauv cov choj, cov pej thuam, cov qauv thav duab, kev thauj mus los ntawm tsheb ciav hlau, cov tsheb ciav hlau hauv av, cov thav duab ru tsev, cov vaj huam sib luag phab ntsa, thiab lwm yam qauv tsev.

2. Lub kaw lus kav dejSiv ua cov kav dej rau kev thauj cov kua dej, tshwj xeeb tshaj yog thaum xav tau lub zog siab thiab kev tiv taus siab.

3. Kev tsim kho dej hiav txwv thiab ntug dej hiav txwv: siv rau hauv cov qauv nkoj, cov platforms offshore, thiab lwm yam qauv engineering marine.

4. Kev lag luam fais fab: siv rau hauv cov chaw tsim hluav taws xob xws li cua fais fab pej thuam, roj drilling platforms, thiab pipelines.

5. Cov hlab ntsha siab: siv rau hauv kev tsim cov hlab ntsha siab raws li cov kev cai tshwj xeeb ntawm kev vuam thiab kev kho cua sov.

6. Kev lag luam tsuas: siv rau cov khoom siv ntawm cov qauv txhawb nqa hauv av, cov tshuab conveyor, thiab cov khoom siv ua cov hlau.

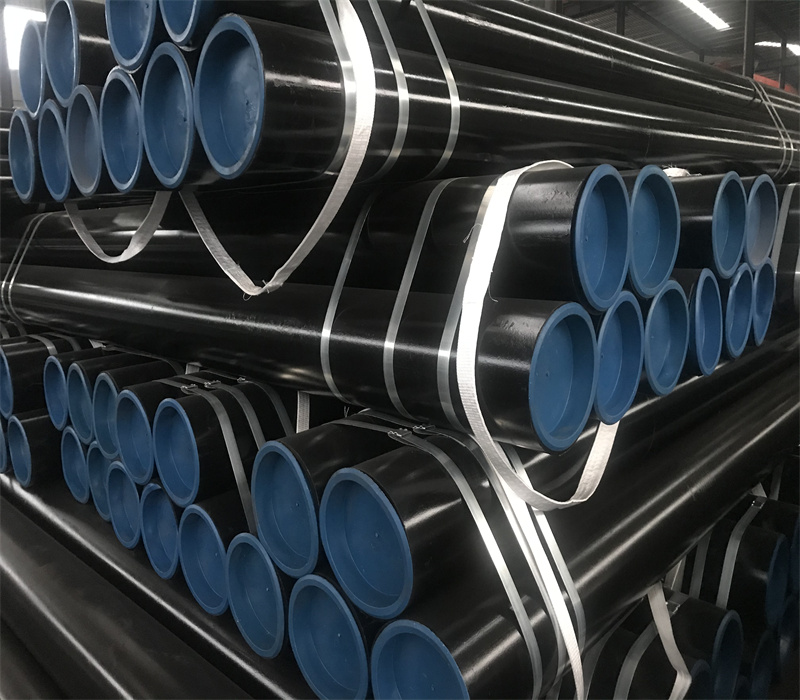

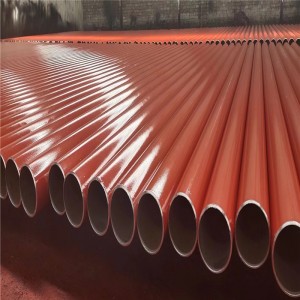

Cov yeeb nkab liab qab lossis Dub / Varnish txheej (kho kom haum);

hauv cov pob khoom los yog xoob;

Ob qho kawg nrog cov tiv thaiv kawg;

Qhov kawg tiaj tus, qhov kawg bevel (2 "thiab saum toj no nrog qhov kawg bevel, degree: 30 ~ 35 °), threaded thiab coupling;

Kev cim.