Qib thiab Cov Tshuaj Lom Zem (%)

| Qib | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Cu≤ | Mo≤ | Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15

| 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Cov Khoom Siv Kho Tshuab:

|

|

|

| A% |

|

| A | ≥330 | ≥205 | 20 | Annealed |

| B | ≥415 | ≥240 | 20 | Annealed |

| C | ≥485 | ≥275 | 20 | Annealed |

| Lub Npe Khoom | Cov yeeb nkab hlau tsis muaj qhov txuas |

| Khoom siv | Cov hlau carbon thiab cov hlau alloy |

| Tus Qauv | ASTMA53, ASTMA106, ASTMA179, ASTMA192, ASTMA210, ASTM A213, ASTM A335, DIN2391-2, DIN1629. DIN2448, DIN 17175, EN 10219, EN 10210 |

| Qib | Cov qib carbon steel zoo li A53 Gr.B, A106 GrA, B, C, A210 GrA1.Gr.C. API 5L Gr.B.X42, X52.X56, thiab lwm yam; Cov qib hlau sib xyaw xws li T5, T9, T11, T12, T22, T23, T91, P1, P2, P5, P9.P11, P12 P22.P91, P92,25CrMo4.34CrMo4,42CrMo4SAE4130, SAE4140, SAE4145, SAE4340, thiab lwm yam |

| Qhov loj me | 10 * 1-810 * 25, WT txog li 120 hli max |

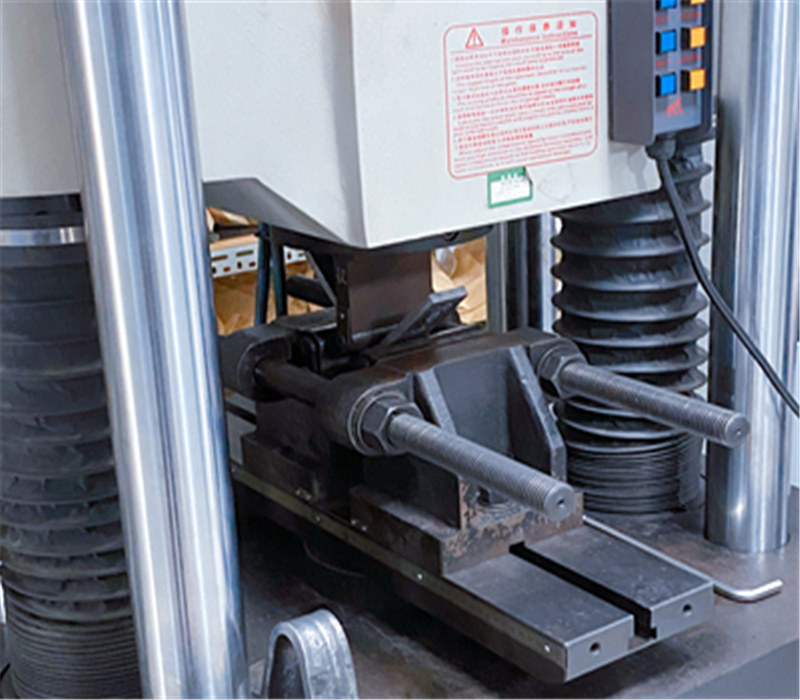

| Txoj kev tsim khoom | Txias kos, txias dov, hydraulic txias kos, Kub dov, kub nthuav dav |

| Kev xa khoom | Raws li dov, Kev Nyuaj Siab txo qis, Annealed, Normalized, Quenched + Tempered |

| Xaus tiav | Cov xaus tiaj tiaj nrog cov txiav suqare, cov xaus bevelled, cov xaus threaded |

| Kev Siv/Daim Ntawv Thov | Cov hlab ntsha siab, Kev xa dej, Kev siv cov qauv. Machinery. Roj & roj kev thauj mus los, Kev Tshawb Fawb & Kev Tshawb Fawb, thiab lwm yam |

| Cov yam ntxwv ntawm cov raj | Lub raj xa dejraj precision, raj tshuab. raj kheej kheej.cov kav dej kab.lwm yam. |

-

-

Kev kam rau siab ntawm qhov ntev:

Hom Yeeb Nkab

Qhov Loj ntawm Cov Yeeb Nkab Kev kam rau siab Txias Kos

OD ≤48.3 hli ±0.40 hli ≥60.3 hli ±1% hli Qhov hnyav ±12.5%

-