ASTM A335 P11Cov yeeb nkab hlau yog cov yeeb nkab hlau ferritic tsawg uas tsis muaj qhov sib txuas rau kev pabcuam kub siab, UNS lub npe K11597.

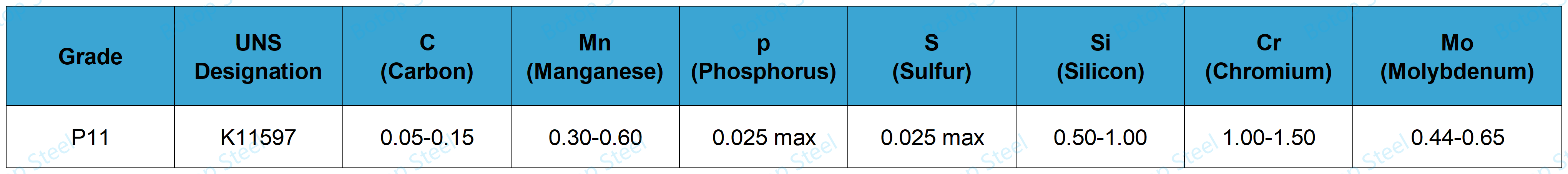

P11 yog chromium-molybdenum alloy nrog cov ntsiab lus chromium ntawm 1.00-1.50% thiab cov ntsiab lus molybdenum ntawm 0.44-0.65%.

Nws feem ntau siv rau hauv boilers, superheaters, thiab cov cua sov sib pauv hauv cov chaw tsim hluav taws xob thiab cov nroj tsuag tshuaj.

Cov kev cai ntawm kev siv tshuabASME SA335thiabASTM A335yog tib yam, yog li ntawd rau qhov yooj yim ntawm kev nthuav qhia, peb yuav siv "ASTM A335" los xa mus rau ob tus qauv no.

Khoom sivl: ASTM A335 P11 seamless hlau yeeb nkab;

OD: 1/8"- 24";

WT: raws liASME B36.10cov cai;

Teem sijhawmSCH10, SCH20, SCH30,SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 thiab SCH160;

Kev txheeb xyuas: STD, XS, XXS;

Kev Kho Kom Haum: Cov yeeb nkab loj uas tsis yog tus qauv kuj muaj, cov qhov loj uas hloov kho tau raws li qhov xav tau;

Ntev: Qhov ntev tshwj xeeb thiab random;

Daim Ntawv Pov Thawj IBRPeb tuaj yeem tiv tauj lub koom haum tshuaj xyuas thib peb kom tau txais daim ntawv pov thawj IBR raws li koj xav tau, peb cov koom haum tshuaj xyuas kev koom tes yog BV, SGS, TUV, thiab lwm yam.

Xaus: Qhov kawg tiaj tus, beveled, lossis composite yeeb nkab kawg;

Nto: Cov yeeb nkab teeb, xim, thiab lwm yam kev tiv thaiv ib ntus, tshem tawm xeb thiab polishing, galvanized thiab yas coated, thiab lwm yam kev tiv thaiv mus sij hawm ntev;

Ntim khoom: Rooj ntoo, siv hlau los yog hlau hlau ntim, yas los yog hlau yeeb nkab kawg tiv thaiv, thiab lwm yam.

Tshwj tsis yog hais lwm yam hauv A335, cov ntaub ntawv muab los ntawm cov lus qhia no yuav tsum ua raws li cov kev cai ntawm tsab ntawv tam sim no ntawm Cov Lus Qhia.A999/A999M.

ASTM A335 cov yeeb nkab hlau yuav tsum yogtsis muaj qhov tsis sib xwsCov kav hlau tsis muaj qhov tsis sib haum xeeb muab kev ntseeg siab thiab kev sib npaug zoo dua thaum raug rau qhov chaw siab thiab kub.

Seamless tuaj yeem raug cais tshwj xeeb ua txias kos thiab kub tiav, nyob ntawm daim ntawv thov thiab qhov loj me.

Feem ntau siv cov yeeb nkab uas me me los yog cov yeeb nkab uas xav tau kev ua kom raug thiab zoo. Feem ntau siv cov yeeb nkab kub los ua cov yeeb nkab loj thiab tuab.

Hauv qab no yog daim ntawv qhia txog cov txheej txheem tsim khoom rau cov yeeb nkab hlau kub-ua tiav seamless.

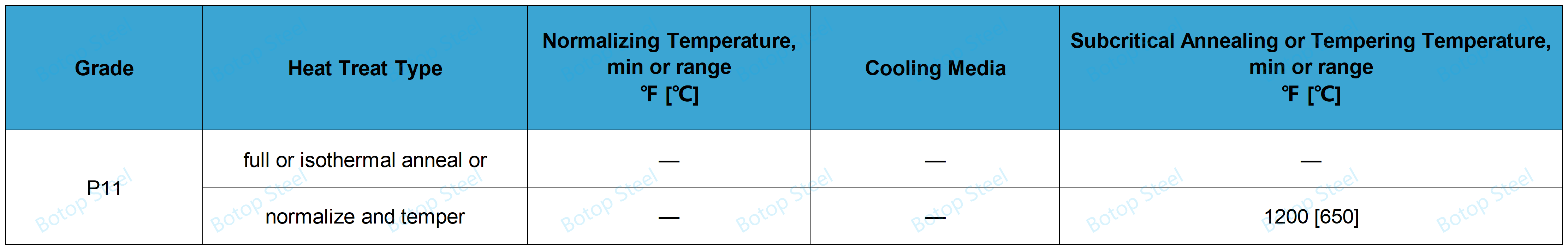

Kev kho cua sov ntawm cov ntaub ntawv P11 yuav yog tag nrho lossis isothermal annealing lossis tempering tom qab normalizing, thiab thaum normalizing thiab tempering, qhov kub tempering yuav tsum yog tsawg kawg 1200 ° F (650 ° C).

Los ntawm cov tshuaj lom neeg sib xyaw, peb tuaj yeem pom tau yooj yim tiasP11 yog ib qho hlau chromium-molybdenum.

Cov hlau chromium-molybdenum yog ib chav kawm ntawm cov hlau uas muaj chromium (Cr) thiab molybdenum (Mo) ua cov ntsiab lus tseem ceeb ntawm kev sib xyaw. Kev ntxiv cov ntsiab lus no ua rau lub zog, qhov nyuaj, kev hnav tsis kam, thiab kev tiv thaiv corrosion ntawm cov hlau ntau ntxiv. Thaum kub siab, Cr-Mo alloys muaj peev xwm tswj tau cov khoom siv kho tshuab zoo thiab cov qauv ruaj khov.

Cr: txhim kho qhov oxidation tsis kam thiab corrosion tsis kam ntawm cov alloy, pab tsim cov zaj duab xis oxide muaj zog dua, thiab tiv thaiv cov khoom los ntawm cov xov xwm corrosive.

Mo: Ua kom lub zog ntawm cov hlau alloy zoo dua, tshwj xeeb tshaj yog thaum kub siab, txhim kho kev tiv thaiv kab nkag, thiab ua kom lub zog ntawm cov khoom siv kub siab dua.

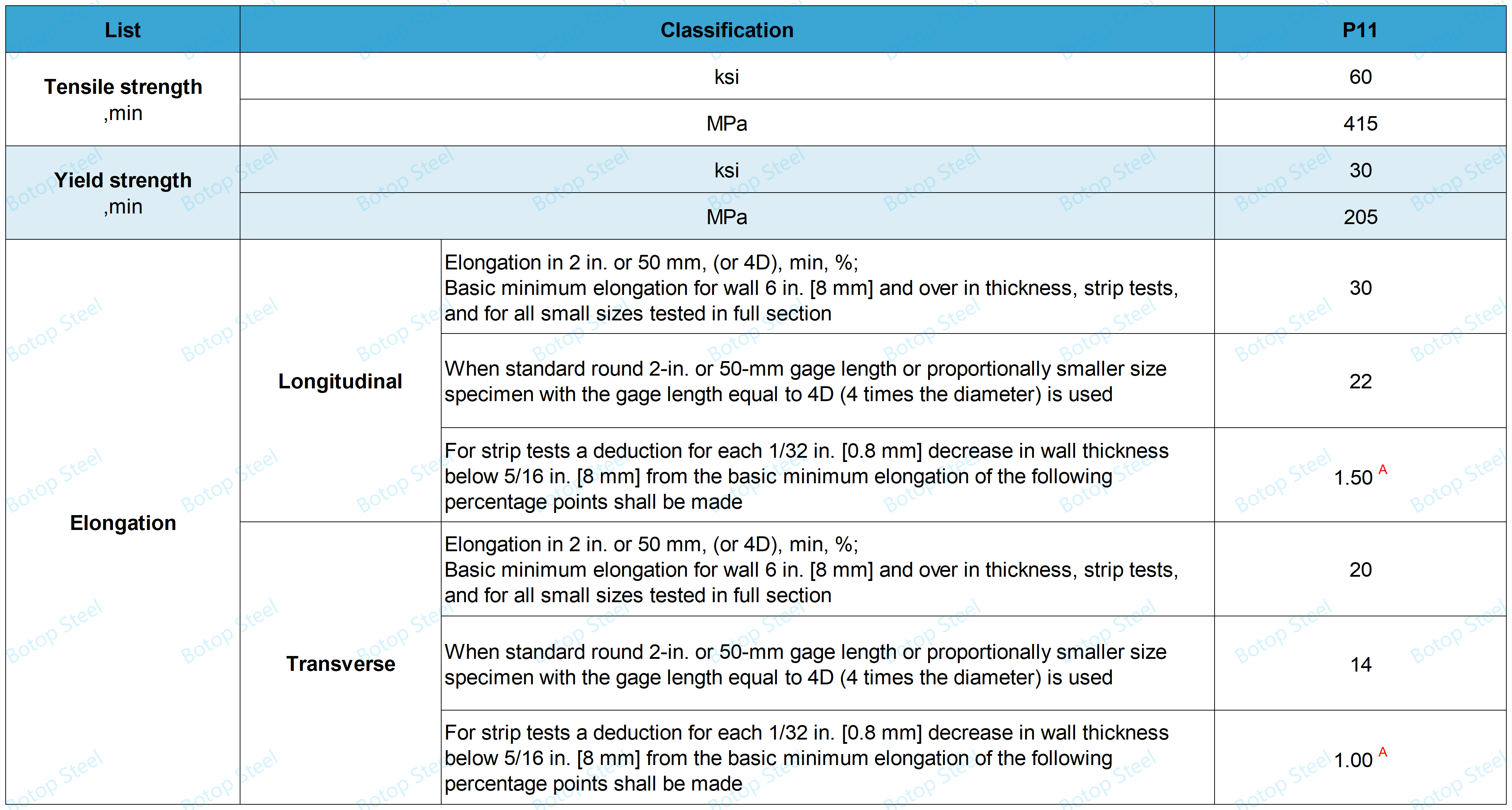

1. Khoom Siv Tensile

Qhov kev sim tensile feem ntau yog siv los ntsuas qhovlub zog tawm los, lub zog tensile, thiabkev ncabn ntawm cov yeeb nkab hlau sim kev pab cuam, thiab yog dav siv nyob rau hauv cov khoom siv ntawm qhov kev xeem.

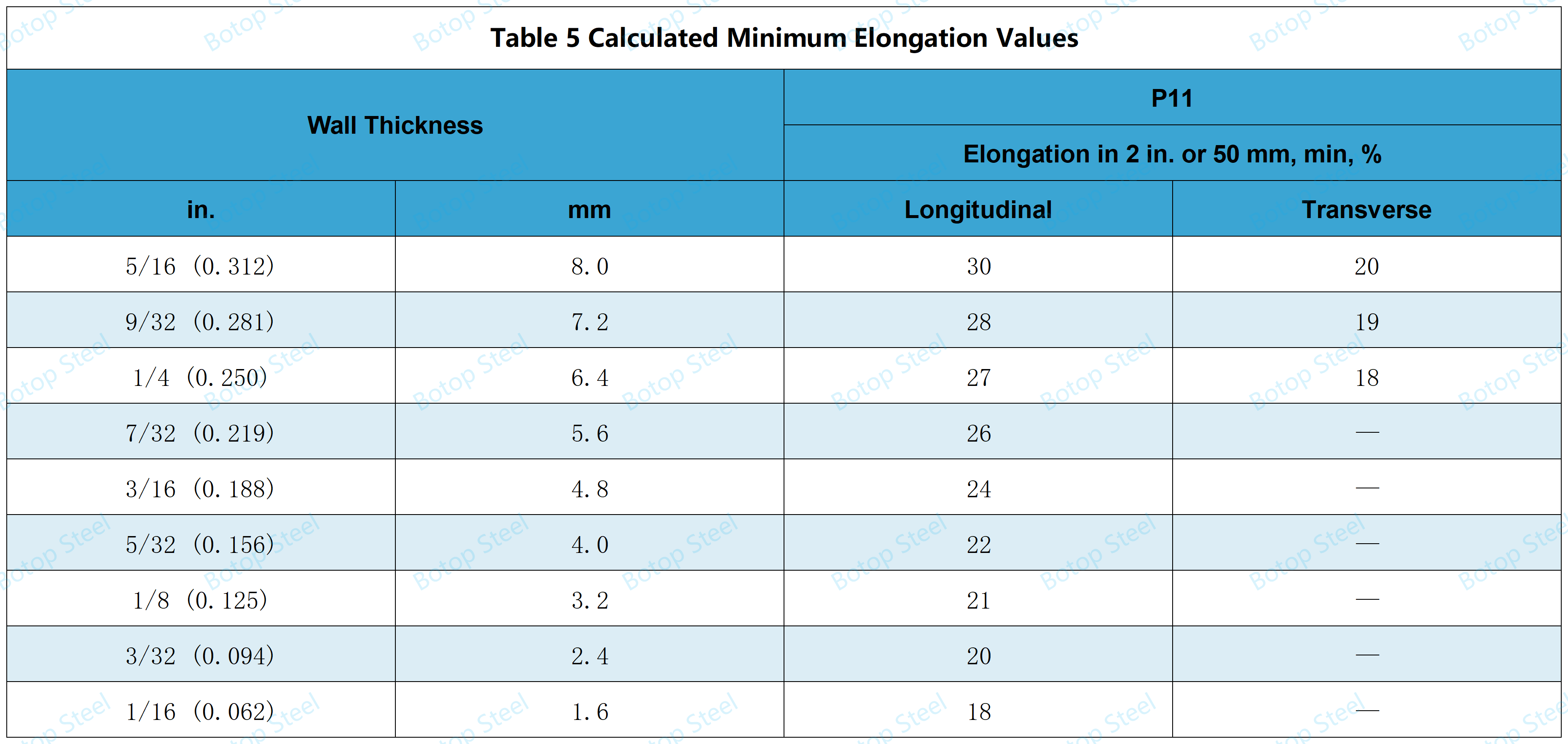

ARooj 5 muab cov nqi tsawg kawg nkaus uas tau xam tawm.

Qhov twg phab ntsa tuab nyob nruab nrab ntawm ob qho nqi saum toj no, qhov tsawg kawg nkaus elongation tus nqi yog txiav txim siab los ntawm cov mis hauv qab no:

Ntev, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Kab rov tav, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

qhov twg:

E = kev ntev hauv 2 nti lossis 50 hli, %,

t = qhov tuab tiag tiag ntawm cov qauv, hauv. [hli].

2. Qhov nyuaj

Cov yeeb nkab qib P11 tsis tas yuav kuaj qhov nyuaj.

Tus nqi hardness siv tau muab rau hauv qab no.

Cov xwm txheej Annealed:

Qhov nyuaj feem ntau yog nruab nrab ntawm 150 thiab 200 HB.

Kev mob nkeeg thiab mob nkeeg:

Qhov nyuaj yog li ntawm 170 txog 220 HB.

Hardened thiab tempered mob:

Qhov nyuaj tuaj yeem ncav cuag 250 txog 300 HB lossis ntau dua, nyob ntawm qhov kub thiab sijhawm tempering.

3. Cov Kev Pab Cuam Sim Xaiv Tau

Cov khoom sim hauv qab no tsis yog cov khoom sim uas yuav tsum tau ua, yog tias tsim nyog tuaj yeem txiav txim siab los ntawm kev sib tham.

Kev Tshawb Fawb Txog Khoom

Kev Ntsuas Kom Sib Nqus

Kev Ntsuas Khoov

Kev Ntsuas Cov Qauv Hlau thiab Kev Sib Tsoo

Cov duab thaij me me

Cov Duab Micrographs rau Cov Khoom Ib Leeg

Qhov kev sim dej P11 yuav tsum ua raws li cov kev cai hauv qab no.

Sab nraud txoj kab uas hla > 10 nti [250 hli] thiab phab ntsa tuab ≤ 0.75 nti [19 hli]: qhov no yuav tsum yog qhov kev sim hydrostatic.

Lwm qhov ntau thiab tsawg rau kev sim hluav taws xob uas tsis ua puas tsuaj.

Cov kev cai xeem hydrostatic hauv qab no yog sau los ntawm cov kev cai ntawm ASTM A999:

Rau cov hlau ferritic alloy thiab cov kav hlau stainless hlau, phab ntsa raug rau qhov siab tsis tsawg dua60% ntawm qhov tsawg kawg nkaus ntawm lub zog tso zis.

Lub zog kuaj hydro yuav tsum tau tswj hwm tsawg kawg 5stsis muaj qhov xau lossis lwm yam tsis zoo.

Kev siab hydraulictuaj yeem suav nrog siv cov qauv:

P = 2St/D

P = qhov siab ntawm kev sim hydrostatic hauv psi [MPa];

S = kev ntxhov siab ntawm phab ntsa yeeb nkab hauv psi lossis [MPa];

t = qhov tuab ntawm phab ntsa uas tau teev tseg, qhov tuab ntawm phab ntsa raws li tus lej teem sijhawm ANSI uas tau teev tseg lossis 1.143 npaug ntawm qhov tuab tsawg kawg nkaus ntawm phab ntsa uas tau teev tseg, hauv. [hli];

D = txoj kab uas hla sab nraud uas tau teev tseg, txoj kab uas hla sab nraud uas sib raug rau qhov loj ntawm cov yeeb nkab ANSI uas tau teev tseg, lossis txoj kab uas hla sab nraud uas tau suav los ntawm kev ntxiv 2t (raws li tau txhais saum toj no) rau txoj kab uas hla sab hauv uas tau teev tseg, hauv. [mm].

Txhua lub yeeb nkab yuav tsum raug kuaj xyuas los ntawm txoj kev kuaj xyuas uas tsis ua puas tsuaj raws li Kev XyaumE213, Kev XyaumE309, los yog Kev XyaumE570.

Kev Hloov Pauv Tau Hauv Txoj Kab uas hla

Rau cov yeeb nkab uas tau xaj kom uasab hauv txoj kab uas hla, sab hauv txoj kab uas hla yuav tsum tsis txhob txawv ntau dua ± 1% ntawm sab hauv txoj kab uas hla uas tau teev tseg.

Kev Hloov Pauv Uas Tso Cai Hauv Phab Ntsa Thickness

Kev ntsuas qhov tuab ntawm phab ntsa yuav tsum tau ua los ntawm kev siv cov cuab yeej ntsuas lossis cov cuab yeej ntsuas uas tsis ua puas tsuaj uas tau ntsuas kom raug thiab raug. Yog tias muaj kev tsis sib haum xeeb, kev ntsuas uas txiav txim siab los ntawm kev siv cov cuab yeej ntsuas yuav tsum tau ua ntej.

Qhov tsawg kawg nkaus ntawm phab ntsa tuab thiab sab nraud txoj kab uas hla rau kev tshuaj xyuas kom ua raws li qhov yuav tsum tau ua no rau cov yeeb nkab uas NPS [DN] xaj thiab tus lej teem sijhawm tau qhia hauvASME B36.10M.

Feem ntau siv rau hauv boilers, superheaters, thiab cov cua sov sib pauv hauv cov chaw tsim hluav taws xob thiab cov chaw tsim tshuaj lom neeg.

Cov BoilersP11 yog siv dav hauv kev tsim cov boilers vim nws tiv taus qhov kub thiab txias siab, tshwj xeeb tshaj yog nyob rau hauv cov ntu uas raug rau qhov kub thiab txias heev.

Lub tshuab cua sov loj: Siv los ua kom lub pa kub ntxiv kom ua rau lub zog ua haujlwm thermal zoo dua. p11 ua kom ntseeg tau tias lub zog thiab kev ruaj khov ntawm cov khoom siv tseem nyob ruaj khov txawm tias nyob rau hauv qhov kub siab.

Cov khoom siv hloov cua sov: P11 ua rau kom muaj kev xeb thiab kub siab ntawm cov khoom siv hloov pauv cua sov, yog li txhim kho kev ntseeg siab thiab kev nyab xeeb ntawm cov khoom siv.

Cov kav dejCov kav dej hauv cov chaw tsim tshuaj feem ntau yuav tsum thauj cov kua dej kub lossis cov pa dej. lub zog kub thiab cov khoom siv kho tshuab zoo ntawm P11 ua rau nws zoo tagnrho rau cov ntawv thov no.

a) ASTM A335 P11 sib npaug li cas?

GB/T 5310: 12CrMo;

DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

BS 3604: 10CrMo9-10;

JIS G3462: STPA23;

GOST 550-75: 12Kh1MF.

b)P11 puas yog hlau uas tsis muaj hlau ntau?

Yog, P11 yog cov hlau tsis muaj hlau tsawg.

Cov hlau tsis tshua muaj hlau yog cov hlau-carbon uas ib lossis ntau cov khoom sib xyaw (piv txwv li, chromium, molybdenum, nickel, thiab lwm yam) tau ntxiv rau, nrog rau tag nrho cov ntsiab lus sib xyaw feem ntau yog li ntawm 1 txog 5%.

c)Lub zog tensile ntawm ASTM A335 P11 yog dab tsi?

Lub zog tensile tsawg kawg nkaus ntawm 415 MPa [60 ksi].

d)Lub zog tso zis ntawm ASTM A335 P11 yog dab tsi?

Lub zog tensile tsawg kawg nkaus ntawm 205 MPa [30 ksi].

e) Qhov kub txwv rau ASTM A335 P11 yog dab tsi?

Hauv cov chaw oxidizing: Qhov kub siab tshaj plaws ntawm kev pabcuam feem ntau yog li 593 ° C (1100 ° F).

Hauv cov chaw tsis oxidizing: qhov kub siab tshaj plaws ntawm kwv yees li 650 ° C (1200 ° F) tuaj yeem ua tiav.

f)Puas yog A335 P11 sib nqus?

Nws yog hlau nplaum thaum sov li chav tsev. Cov yam ntxwv no yuav pab tau rau qee yam kev siv, xws li thaum cov khoom siv yuav tsum sib xws nrog cov khoom siv nrhiav hlau nplaum.

g)ASTM A335 P11 nqe yog dab tsi?

Cov nqi sib txawv raws li kev ua lag luam, tiv tauj peb kom tau txais tus nqi tseeb.