ASTM A178Cov kav hlau yog cov hluav taws xob tsis kam welded (ERW) raj ntawmcov hlau carbon thiab carbon-manganesesiv ua cov raj boiler, cov raj boiler, cov raj superheater, thiab qhov kawg kev nyab xeeb.

Nws yog qhov tsim nyog rau cov kav hlau nrog sab nraud txoj kab uas hla ntawm 12.7-127mm thiab phab ntsa tuab ntawm 0.9-9.1mm.

ASTM A178 cov kav dej yog tsim rau cov kav dej uas tsis kam vuam nrogsab nraud txoj kab uas hla ntawm 1/2 - 5 nti [12.7 - 127 hli] thiab phab ntsa tuab ntawm 0.035 - 0.360 nti [0.9 - 9.1 hli], txawm hais tias lwm qhov ntau thiab tsawg kuj muaj raws li qhov xav tau, yog tias cov kav dej no ua tau raws li txhua yam kev cai ntawm qhov kev qhia no.

Muaj peb qib los daws teeb meem rau ntau qhov chaw siv sib txawv.

Qib A, Qib C, thiab Qib D.

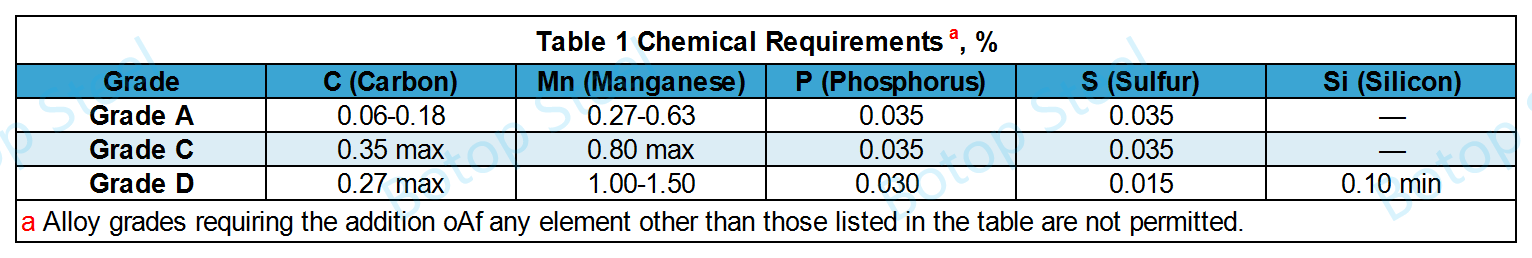

| Qib | Hom Hlau Carbon |

| Qib A | Cov Hlau Uas Muaj Carbon Tsawg |

| Qib C | Hlau Carbon Nruab Nrab |

| Qib D | Cov Hlau Carbon-Manganese |

Cov ntaub ntawv muab los ntawm cov lus qhia no yuav tsum ua raws li cov kev cai ntawm tsab tam sim no ntawm Cov Lus Qhia A450 / A450M. tshwj tsis yog tias muaj lwm yam hauv no.

Qib AthiabQib Ctsis txhob teev cov hlau tshwj xeeb; xaiv cov khoom siv raw kom haum raws li qhov xav tau.

Cov hlau rauQib Dyuav raug tua pov tseg.

Cov hlau tua yog tsim los ntawm kev ntxiv cov deoxidizers (piv txwv li, silicon, txhuas, manganese, thiab lwm yam) rau cov hlau molten thaum lub sijhawm tsim cov hlau, yog li txo lossis tshem tawm cov pa oxygen ntawm cov hlau.

Txoj kev kho no txhim kho qhov sib xws thiab kev ruaj khov ntawm cov hlau, txhim kho nws cov khoom siv kho tshuab, thiab txhim kho kev tiv thaiv corrosion.

Yog li ntawd, cov hlau tua tau siv dav hauv cov ntawv thov uas xav tau qib siab ntawm kev sib xws thiab cov khoom siv kho tshuab zoo heev, xws li kev tsim cov hlab ntsha siab, boilers, thiab cov khoom loj.

Cov kav hlau yog tsim los ntawm kev siv covERWcov txheej txheem tsim khoom.

ERW (Hluav Taws Xob Tiv Thaiv Welded)yog ib qho txheej txheem zoo tshaj plaws rau kev tsim cov yeeb nkab carbon steel.

Nrog rau qhov zoo ntawm lub zog vuam siab, qhov chaw du thiab sab hauv, kev tsim khoom sai, thiab tus nqi qis, nws yog siv dav hauv ntau qhov chaw lag luam thiab kev tsim kho.

ASTM A178yeeb nkab hlauyuav tsum tau kho cua sovthaum lub sijhawm tsim khoom. Nws yog siv los txhim kho cov khoom siv kho tshuab thiab kev ruaj khov ntawm cov yeeb nkab, nrog rau kev tshem tawm cov kev ntxhov siab uas yuav tau tshwm sim thaum lub sijhawm vuam.

Tom qab vuam, tag nrho cov raj yuav tsum tau kho cua sov ntawm qhov kub ntawm 1650 ° F [900 ° C] lossis siab dua thiab ua raws li kev txias hauv huab cua lossis hauv chav txias ntawm lub cub tawg tswj huab cua.

Cov raj xa dej txiasyuav tsum tau kho cua sov tom qab qhov kawg txias-dhau ntawm qhov kub ntawm 1200 ° F [650 ° C] lossis siab dua.

Thaum ua qhov kev tshuaj xyuas khoom, qhov zaus ntawm kev tshuaj xyuas yog txiav txim siab raws li hauv qab no.

| Kev faib tawm | Kev Tshuaj Xyuas Zaus |

| Txoj kab uas hla sab nraud ≤ 3in [76.2mm] | 250 daim/lub sijhawm |

| Txoj kab uas hla sab nraud > 3 nti [76.2 hli] | 100 daim/lub sijhawm |

| Sib txawv los ntawm tus lej cua sov ntawm lub raj | Ib tus lej cua sov |

Cov kev cai txog khoom siv kho tshuab tsis siv rau cov raj me dua 1/8 nti [3.2 hli] hauv txoj kab uas hla sab hauv lossis 0.015 nti [0.4 hli] hauv tuab.

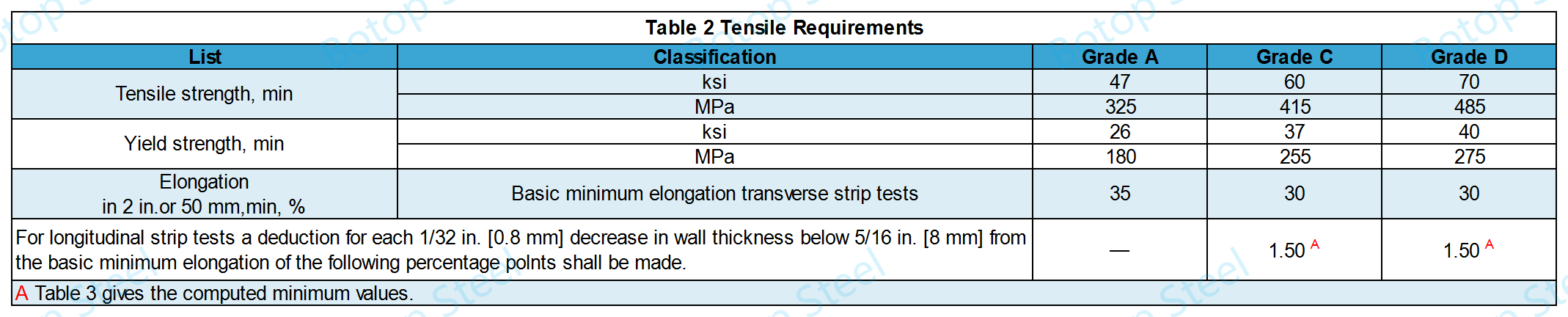

1. Khoom Siv Tensile

Rau Cov Chav Kawm C thiab D, yuav tsum muaj kev sim tensile rau ob lub raj hauv txhua pawg.

Rau cov kav dej Qib A, feem ntau tsis tas yuav kuaj tensile. Qhov no yog vim qhov tseeb tias cov kav dej Qib A feem ntau yog siv rau kev siv qis thiab kub tsawg.

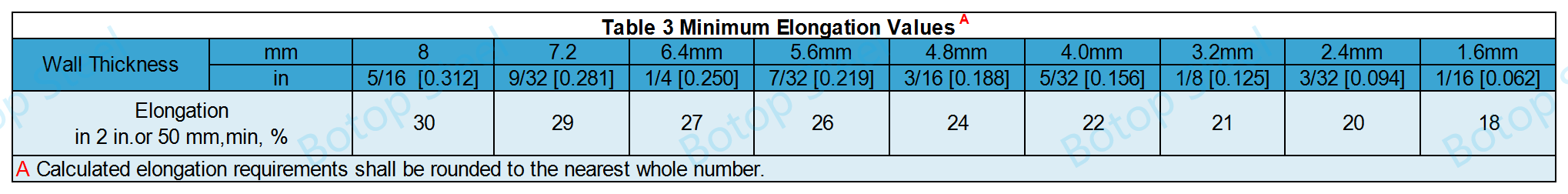

Rooj 3 muab cov nqi elongation tsawg kawg nkaus uas tau xam rau txhua qhov txo qis 1/32 nti [0.8 hli] ntawm phab ntsa tuab.

Yog tias qhov tuab ntawm phab ntsa ntawm cov yeeb nkab hlau tsis yog ib qho ntawm cov tuab ntawm phab ntsa no, nws kuj tseem tuaj yeem suav los ntawm cov mis.

Chav Nti: E = 48t + 15.00los yogISI Chav: E = 1.87t + 15.00

E = kev ntev hauv 2 nti lossis 50 hli, %,

t = qhov tuab ntawm cov qauv tiag tiag, hauv. [hli].

2. Kev Ntsuas Qhov Sib Tsoo

Kev ntsuam xyuas extrusion yog ua rau ntawm cov yeeb nkab seem 2 1/2 nti [63 hli] ntev uas yuav tsum tiv taus qhov extrusion ntev yam tsis muaj kev tawg, tawg, lossis tawg ntawm cov welds.

Rau cov yeeb nkab uas tsawg dua 1 nti [25.4 hli] hauv txoj kab uas hla sab nraud, qhov ntev ntawm cov qauv yuav tsum yog 2 1/2 npaug ntawm txoj kab uas hla sab nraud ntawm lub yeeb nkab. Kev kuaj xyuas me me ntawm qhov chaw yuav tsis yog qhov ua rau tsis lees txais.

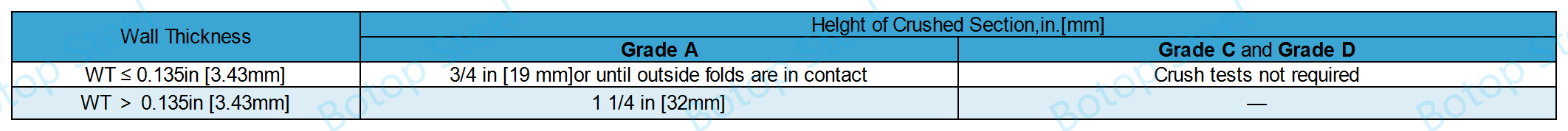

3. Kev Ntsuas Kom Sib Nqus

Txoj kev sim ua raws li cov kev cai ntawm ASTM A450 Tshooj 19.

4. Kev Ntsuas Flange

Txoj kev sim ua raws li cov kev cai ntawm ASTM A450 Tshooj 22.

5. Kev Ntsuas Rov Qab Flattening

Txoj kev sim ua raws li cov kev cai ntawm ASTM A450, Tshooj 20.

Kev kuaj hluav taws xob hydrostatic lossis tsis ua puas tsuaj yog ua rau txhua lub yeeb nkab hlau.

Cov kev cai yog raws li ASTM A450, Tshooj 24 lossis 26.

Cov ntaub ntawv hauv qab no yog los ntawm ASTM A450 thiab ua tau raws li cov kev cai tsim nyog rau cov yeeb nkab hlau welded xwb.

Qhov hnyav sib txawv

0 - +10%.

Kev Sib Txawv ntawm Phab Ntsa Thickness

0 - +18%.

Kev Sib Txawv Sab Nraud

| Sab Nraud Txoj Kab uas hla | Kev Hloov Pauv Uas Tso Cai | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1<OD ≤1½ | 25.4 <OD ≤ 38.4 | ±0.006 | ±0.15 |

| 1½<OD<2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD <2½ | 50.8≤ OD <63.5 | ±0.010 | ±0.25 |

| 2½≤ OD <3 | 63.5≤ OD <76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6 <OD ≤ 190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Tom qab muab tso rau hauv lub boiler, lub raj yuav tsum muaj peev xwm tiv taus kev nthuav dav thiab khoov yam tsis muaj qhov tawg lossis tawg ntawm cov welds.

Cov kav dej superheater yuav tsum muaj peev xwm tiv taus txhua yam kev forging, welding, thiab bending yam tsis muaj qhov tsis zoo.

Feem ntau siv rau hauv cov raj boiler, cov raj boiler, cov raj superheater, thiab cov qhov kawg nyab xeeb.

ASTM A178 Qib Acov tubing cov pa roj carbon tsawg ua rau nws weldability zoo thiab muaj zog rau cov ntawv thov uas tsis raug kev nyuaj siab.

Nws yog siv rau cov ntawv thov uas tsis tshua muaj siab thiab nruab nrab kub xws li cov boilers uas tsis tshua muaj siab (piv txwv li, cov boilers hauv tsev, cov chaw ua haujlwm me, lossis cov boilers Hoobkas) thiab lwm yam khoom siv hloov pauv cua sov hauv cov chaw kub qis.

ASTM A178 Qib Cmuaj cov pa roj carbon thiab manganese ntau dua ua rau lub raj no muaj zog dua thiab tiv taus cua sov rau cov xwm txheej ua haujlwm ntau dua.

Haum rau cov ntawv thov siab nruab nrab thiab kub nruab nrab xws li cov boilers kev lag luam thiab dej kub, uas feem ntau xav tau siab dua thiab kub dua li cov boilers hauv tsev.

ASTM A178 Qib DCov raj muaj cov ntsiab lus manganese siab thiab cov ntsiab lus silicon tsim nyog los muab lub zog zoo heev thiab tiv taus cua sov, ua rau lawv ruaj khov hauv qhov kub thiab txias thiab siab thiab tsim nyog rau kev ua haujlwm hnyav.

Feem ntau siv rau hauv qhov chaw muaj kev kub siab thiab kub siab, xws li cov chaw tsim hluav taws xob boilers thiab cov superheaters hauv kev lag luam.

1. ASTM A179 / ASME SA179Cov raj xa dej kub thiab cov raj xa dej condenser uas ua los ntawm cov hlau tsis muaj hlau sib xyaw ua ke rau kev pabcuam cryogenic. Feem ntau siv rau hauv qhov chaw muaj kev kub siab qis dua, nws zoo ib yam li ASTM A178 hauv cov tshuaj lom neeg thiab cov khoom siv kho tshuab.

2. ASTM A192 / ASME SA192Cov kav dej boiler uas tsis muaj qhov sib txuas ua ke hauv kev pabcuam siab. Feem ntau siv rau hauv kev tsim cov phab ntsa dej, cov khoom siv txuag hluav taws xob thiab lwm yam khoom siv siab rau cov boilers siab heev.

3. ASTM A210 / ASME SA210: Npog cov raj xa dej boiler thiab superheater uas tsis muaj qhov sib txuas rau cov pa roj carbon nruab nrab thiab cov hlau sib xyaw rau cov tshuab boiler kub thiab nruab nrab.

4. DIN 17175Cov raj hlau tsis muaj qhov sib txuas thiab cov kav dej rau siv rau hauv qhov chaw siab thiab kub. Feem ntau siv rau hauv kev tsim cov kav dej rau cov boilers thiab cov hlab siab.

5. EN 10216-2: Teem cov xwm txheej kev siv rau cov raj xa dej thiab cov kav dej uas tsis yog hlau sib xyaw thiab hlau sib xyaw uas muaj cov yam ntxwv kub siab tshwj xeeb rau kev siv hauv qab kev siab.

6. JIS G3461: Npog cov kav hlau carbon rau cov boilers thiab cov khoom hloov pauv cua sov. Nws yog qhov tsim nyog rau cov xwm txheej pauv cua sov qis thiab nruab nrab.

Peb yog cov chaw tsim khoom thiab cov chaw muag khoom ntawm cov yeeb nkab carbon steel zoo los ntawm Tuam Tshoj, thiab peb kuj yog cov chaw muag khoom ntawm cov yeeb nkab steel seamless, muab ntau yam kev daws teeb meem rau koj!

Yog tias koj muaj lus nug lossis xav paub ntxiv txog peb cov khoom, thov tsis txhob yig tiv tauj peb. Koj cov kev daws teeb meem zoo tshaj plaws rau cov yeeb nkab hlau tsuas yog xa xov xwb!