JIS G 3455Tsarin Masana'antu na Japan (JIS) ne don yin aiki mai ƙarfi a yanayin zafi na 350 °C ko ƙasa da haka, galibi ga sassan injina.

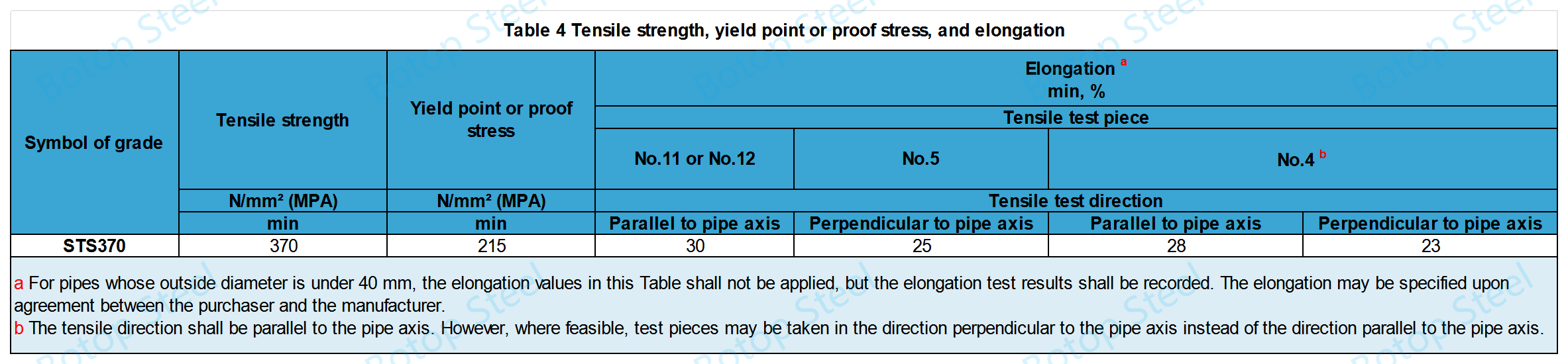

bututun ƙarfe na STS370bututun ƙarfe ne mai ƙarancin ƙarfin tauri na 370 MPa da ƙaramin ƙarfin samarwa na 215 MPa, tare da sinadarin carbon wanda bai wuce 0.25% ba da kuma sinadarin silicon tsakanin 0.10% da 0.35%, kuma ana amfani da shi galibi a aikace-aikacen da ke buƙatar ƙarfi mai yawa da ingantaccen walda, kamar gine-gine, gadoji, tasoshin matsi, da kayan aikin jirgin ruwa.

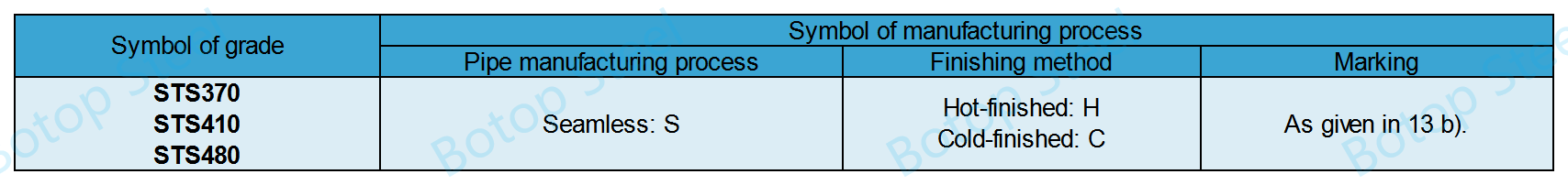

JIS G 3455 yana da maki uku.STS370, STS410, STA480.

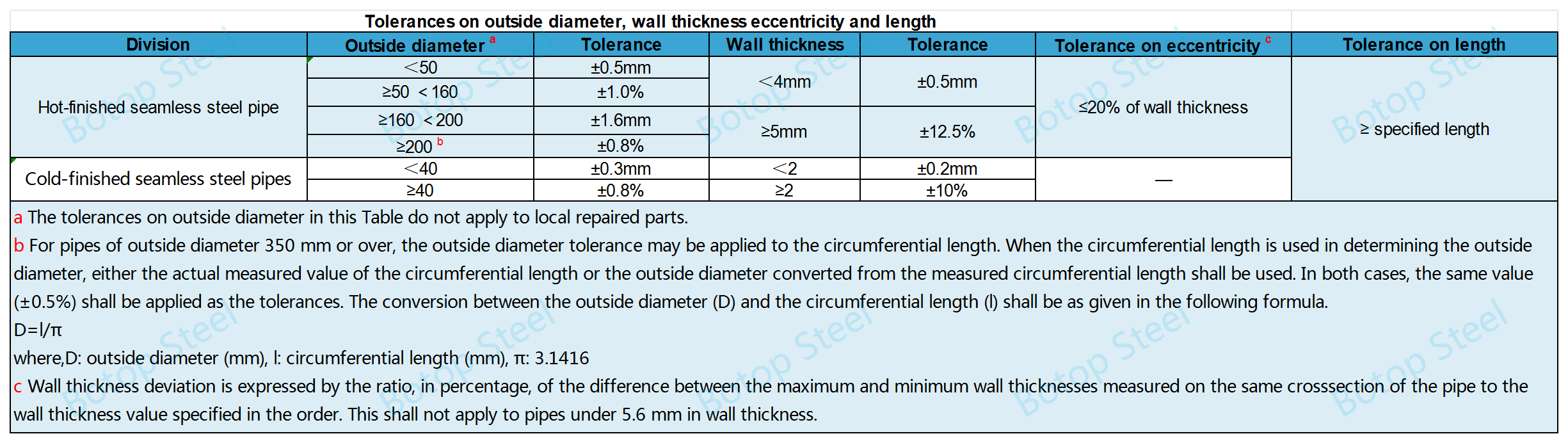

Diamita na waje na 10.5-660.4mm (6-650A) (1/8-26B).

Za a yi bututu daga ƙasaƙarfe da aka kashe.

Karfe da aka kashe ƙarfe ƙarfe ne da aka cire shi gaba ɗaya kafin a jefa shi cikin ingots ko wasu siffofi. Tsarin ya ƙunshi ƙara wani abu mai hana iskar oxygen kamar silicon, aluminum, ko manganese a cikin ƙarfen kafin ya taurare. Kalmar "kashe" tana nuna cewa babu wani iskar oxygen da ke faruwa a cikin ƙarfen yayin aikin ƙarfafawa.

Ta hanyar kawar da iskar oxygen, ƙarfe da aka kashe yana hana samuwar kumfa iska a cikin ƙarfen da aka narke, don haka yana guje wa porosity da kumfa iska a cikin samfurin ƙarshe. Wannan yana haifar da ƙarfe mai kama da juna da kauri tare da ingantattun halayen injiniya da amincin tsarin.

Karfe da aka kashe ya dace musamman don aikace-aikace masu buƙatar inganci da dorewa, kamar tasoshin matsi, manyan gine-gine, da bututun mai buƙatu masu inganci.

Ta hanyar amfani da ƙarfe da aka kashe don samar da bututu, za ku iya tabbatar da ingantaccen aiki da tsawon rai na sabis, musamman a cikin yanayin da ke fuskantar nauyi da matsin lamba.

An samar da shi ta hanyar amfani da tsarin kera kayayyaki marasa matsala tare da hanyar kammalawa.

Bututun ƙarfe mai zafi wanda ba shi da matsala: SH;

Bututun ƙarfe mara shinge wanda aka gama da sanyi: SC.

Don tsarin kera shi ba tare da matsala ba, ana iya raba shi zuwa bututun ƙarfe marasa sumul waɗanda diamita na waje ya fi 30mm ta amfani da samar da ƙarewa mai zafi, da kuma 30mm ta amfani da samar da ƙarewa mai sanyi.

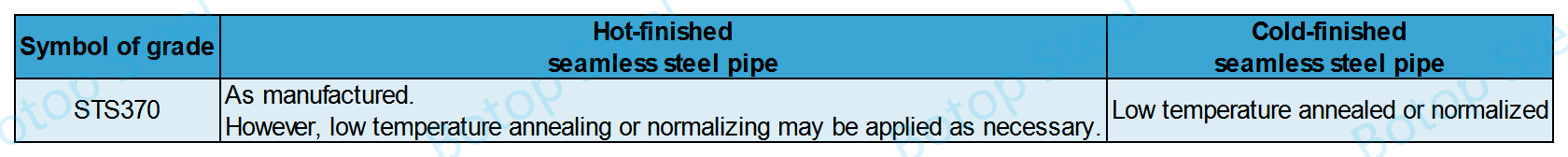

Ga yadda ake samar da ruwan zafi mai kyau.

Ana amfani da injin rage zafi sosai wajen ƙara ƙarfin aiki, rage tauri, da kuma inganta tauri, kuma ya dace da ƙarfe mai sanyi.

Ana amfani da daidaita ƙarfe don inganta ƙarfi da tauri na kayan, don haka ƙarfen ya fi dacewa don jure matsin lamba na injiniya da gajiya, wanda galibi ana amfani da shi don inganta aikin ƙarfe mai sanyi.

Ta hanyar waɗannan hanyoyin sarrafa zafi, an inganta tsarin ciki na ƙarfen kuma an inganta halayensa, wanda hakan ya sa ya fi dacewa don amfani a aikace-aikacen masana'antu masu wahala.

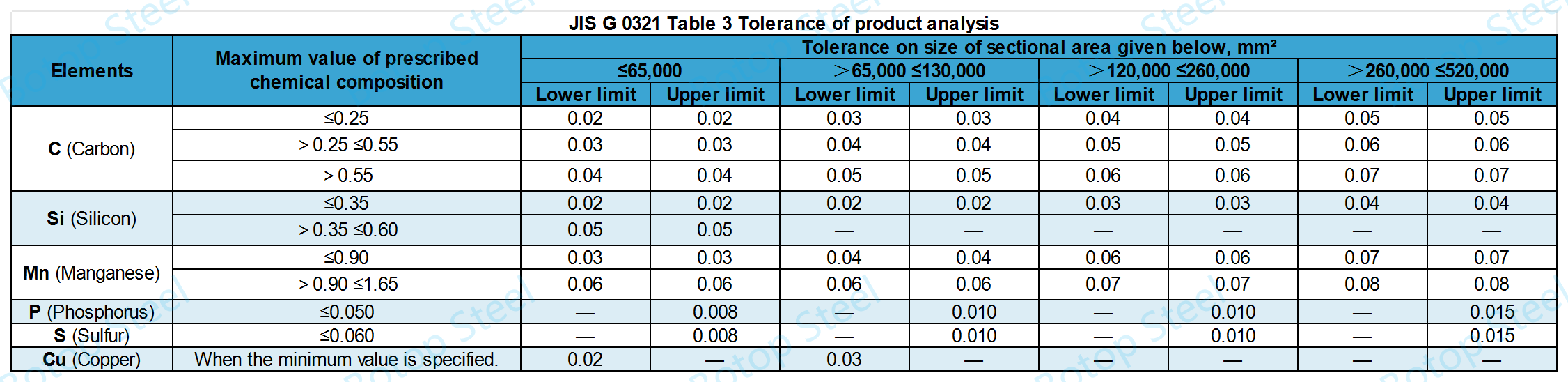

Binciken zafi zai yi daidai da JIS G 0320. Binciken samfurin zai yi daidai da JIS G 0321.

| maki | C (Kabon) | Si (Silikon) | Mn (Manganese) | P (Fosphorus) | S (Silfur) |

| STS370 | matsakaicin 0.25% | 0.10-0.35% | 0.30-1.10% | 0.35% mafi girma | 0.35% mafi girma |

Binciken zafian fi mayar da hankali ne kan gwada sinadaran da ke cikin kayan da aka yi amfani da su.

Ta hanyar nazarin sinadaran da ke cikin kayan masarufi, yana yiwuwa a yi hasashen da kuma daidaita matakan sarrafawa da yanayin da za a iya buƙata a cikin tsarin samarwa, kamar sigogin maganin zafi da kuma ƙara abubuwan haɗin gwiwa.

Binciken samfuryana nazarin sinadaran da aka gama don tabbatar da bin ƙa'idodi da ingancin samfurin ƙarshe.

Binciken samfura yana tabbatar da cewa duk wani canji, ƙari ko duk wani ƙazanta da zai iya faruwa a cikin samfurin yayin aikin ƙera shi yana ƙarƙashin iko kuma samfurin ƙarshe ya cika ƙa'idodin fasaha da buƙatun aikace-aikacen.

JIS G 3455 ƙimar nazarin samfurin ba wai kawai za ta bi buƙatun abubuwan da ke cikin teburin da ke sama ba, har ma da kewayon haƙuri zai bi buƙatun JIS G 3021 Tebur na 3.

Ƙimar tsayi don kayan gwaji mai lamba 12 (daidai da gadar bututu) da kayan gwaji mai lamba 5 (daidai da gadar bututu) da aka ɗauka daga bututun da kaurinsu bai wuce mm 8 ba.

| Alamar daraja | An yi amfani da gwajin da aka yi amfani da shi | Ƙarawa minti, % | ||||||

| Kauri a bango | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | −7 −8 mm | ||

| STS370 | Lamba ta 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Lamba ta 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Ana samun ƙimar tsawaitawa a cikin wannan tebur ta hanyar cire kashi 1.5% daga ƙimar tsawaitawa da aka bayar a cikin Jadawali na 4 ga kowane raguwar mm 1 a cikin kauri na bango daga mm 8, da kuma zagaye sakamakon zuwa lamba bisa ga Dokar A ta JIS Z 8401. | ||||||||

Ana iya cire gwajin da aka yi amfani da shi wajen daidaita lanƙwasa sai dai idan mai siye ya ƙayyade wani abu daban.

Sanya samfurin a cikin injin kuma a daidaita shi har sai nisan da ke tsakanin dandamali biyu ya kai ƙimar da aka ƙayyade H. Sannan a duba samfurin don ganin ko akwai tsagewa.

Lokacin gwada bututun da aka yi wa walda mai ƙarfi, layin da ke tsakanin walda da tsakiyar bututun yana daidai da alkiblar matsi.

H=(1+e)t/(e+t/D)

H: Tazara tsakanin faranti (mm)

t: kauri na bututun bango (mm)

D: diamita na waje na bututun (mm)

’:an ayyana shi akai-akai ga kowane matakin bututun.0.08 ga STS370: 0.07 ga STS410 da STS480.

Ya dace da bututun da diamita na waje ya kai ≤ 50 mm.

Samfurin zai kasance babu tsagewa idan an lankwasa shi a digiri 90 tare da diamita na ciki sau 6 diamita na waje na bututun.

Za a auna kusurwar lanƙwasa a farkon lanƙwasa.

Kowace bututun ƙarfe tana buƙatar a gwada ta hanyar hydrostatic ko kuma ba ta hanyar lalata badon tabbatar da inganci da amincin bututun da kuma cika ƙa'idodin amfani.

Gwajin Na'ura Mai Aiki

Idan ba a ƙayyade matsin lamba na gwaji ba, za a ƙayyade mafi ƙarancin matsin lamba na gwajin ruwa bisa ga Jadawalin Bututu.

| Kauri na bango mara iyaka | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Mafi ƙarancin matsin lamba na gwajin hydraulic, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Idan kauri na bango na diamita na waje na bututun ƙarfe ba ƙimar da aka saba gani ba ce a cikin teburin nauyin bututun ƙarfe, ya zama dole a yi amfani da dabarar don ƙididdige ƙimar matsi.

P=2st/D

P: matsin lamba na gwaji (MPa)

t: kauri na bututun bango (mm)

Ddiamita na bututun waje (mm)

s: Kashi 60% na mafi ƙarancin ƙimar ma'aunin yawan amfanin ƙasa ko damuwa ta shaida da aka bayar.

Idan mafi ƙarancin matsin lamba na gwajin hydrostatic na lambar shirin da aka zaɓa ya wuce matsin lamba na gwajin P da aka samu ta hanyar dabarar, za a yi amfani da matsin lamba na P a matsayin mafi ƙarancin matsin lamba na gwajin hydrostatic maimakon zaɓar mafi ƙarancin matsin lamba na gwajin hydrostatic a cikin teburin da ke sama.

Gwajin da Ba Ya Lalatawa

Ya kamata a yi gwajin bututun ƙarfe mara lalatawa ta hanyar amfani da na'urar auna zafin jikigwajin ultrasonic ko eddy current.

Dominultrasonichalayen dubawa, siginar daga samfurin tunani wanda ke ɗauke da ma'aunin tunani na aji UD kamar yadda aka ƙayyade a cikinJIS G 0582za a ɗauke shi a matsayin matakin faɗakarwa kuma zai kasance yana da siginar asali daidai ko sama da matakin faɗakarwa.

Daidaitaccen fahimtar ganowa doneddy currentjarrabawar za ta kasance nau'in EU, EV, EW, ko EX da aka ƙayyade a cikinJIS G 0583, kuma ba za a sami sigina da suka yi daidai ko suka fi sigina daga samfurin tunani da ke ɗauke da ma'aunin tunani na wannan rukuni ba.

Don ƙarin bayaniJadawalin Nauyin Bututu da Jadawalin Bututua cikin daidaitattun, zaka iya dannawa ta ciki.

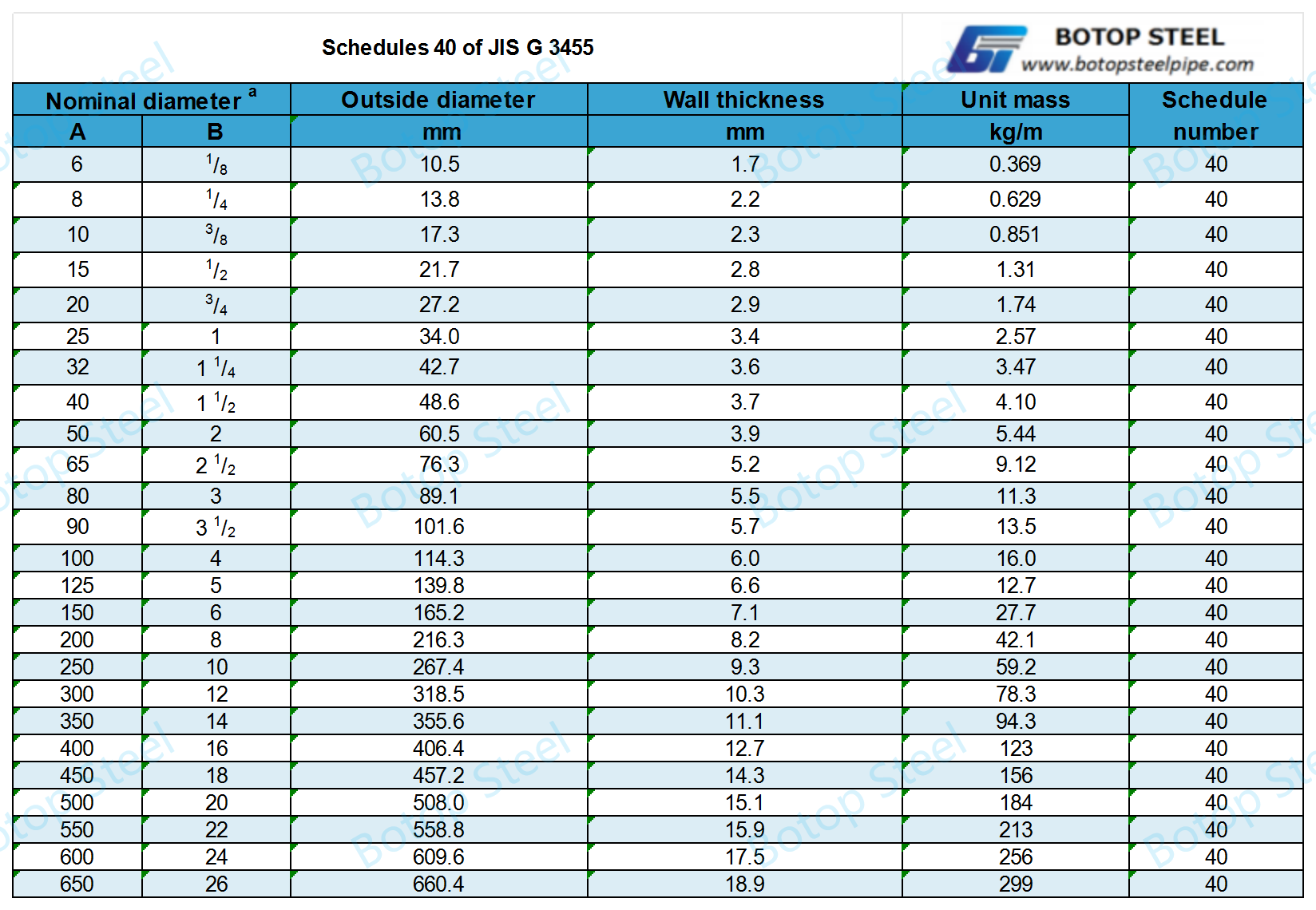

Bututun Jadawali 40 ya fi dacewa da aikace-aikacen ƙasa zuwa matsakaici saboda yana ba da kauri mai matsakaici wanda ke guje wa nauyi mai yawa da farashi yayin da yake tabbatar da isasshen ƙarfi.

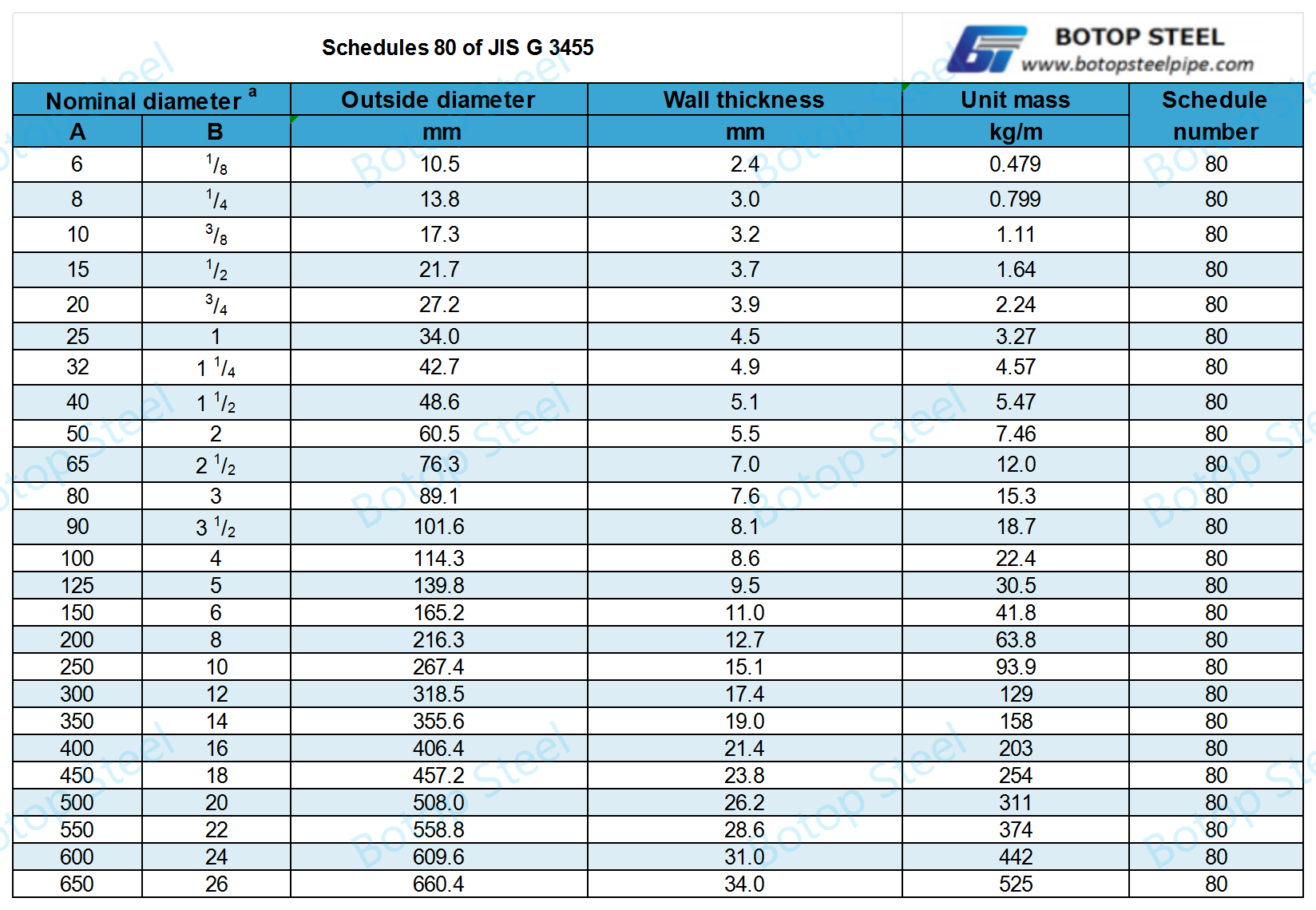

Ana amfani da bututun Jadawali na 80 sosai a cikin yanayin masana'antu waɗanda ke buƙatar sarrafa matsin lamba mai yawa, kamar tsarin sarrafa sinadarai da bututun watsa mai da iskar gas, saboda ikonsa na jure matsin lamba mai yawa da tasirin injiniya mai ƙarfi saboda kauri bango mai kauri, yana ba da ƙarin aminci, tsaro, da dorewa.

Kowace bututu za a yi mata lakabi da waɗannan bayanai.

a)Alamar daraja;

b)Alamar hanyar ƙera;

c)GirmaMisali 50AxSch80 ko 60.5x5.5;

d)Sunan mai ƙera ko alamar da ke tantance shi.

Idan diamita na waje na kowace bututu ya yi ƙanƙanta kuma yana da wuya a yi wa kowace bututu alama, ko kuma lokacin da mai siye ya buƙaci a yi wa kowace tarin bututu alama, ana iya yi wa kowace tarin alama ta hanyar da ta dace.

STS370 ya dace da tsarin canja wurin ruwa mai ƙarancin matsin lamba amma mai yawan zafin jiki.

Tsarin dumama: A cikin tsarin dumama birane ko manyan gine-gine, ana iya amfani da STS370 don jigilar ruwan zafi ko tururi saboda yana iya jure matsin lamba da canjin zafin jiki a cikin tsarin.

Cibiyoyin samar da wutar lantarki: A fannin samar da wutar lantarki, ana buƙatar adadi mai yawa na bututun tururi mai ƙarfi, kuma STS370 shine kayan da ya dace don ƙera waɗannan bututun domin yana iya jure wa yanayin zafi mai yawa da kuma yanayin aiki mai ƙarfi.

Tsarin iska mai matsewa: A cikin layukan samarwa da na'urorin sarrafawa ta atomatik, iska mai matsewa muhimmin tushen wutar lantarki ne, kuma ana amfani da bututun ƙarfe na STS370 don gina bututun waɗannan tsarin don tabbatar da isar da iska cikin aminci da inganci.

Amfani da tsarin gini da injuna gabaɗaya: Saboda kyawawan halayen injina, ana iya amfani da STS370 wajen ƙera sassa daban-daban na gini da na inji, musamman a aikace-aikace inda ake buƙatar wani ƙarfin matsi.

JIS G 3455 STS370 kayan ƙarfe ne na carbon da ake amfani da shi wajen yin aiki mai ƙarfi. Ana iya ɗaukar waɗannan kayan a matsayin daidai ko kusan daidai:

1. ASTM A53 Matsayi B: Ya dace da aikace-aikacen gine-gine da na inji gabaɗaya da kuma jigilar ruwa.

2. API 5L Grade B: Don bututun jigilar mai da iskar gas mai ƙarfi.

3. DIN 1629 St37.0: Don injiniyan injiniya na gabaɗaya da ginin jiragen ruwa.

4. EN 10216-1 P235TR1: Bututun ƙarfe mara sumul don yanayin zafi mai yawa da matsin lamba mai yawa.

5. ASTM A106 Matsayi B: Bututun ƙarfe mara sumul don yin aiki mai zafi sosai.

6.ASTM A179: Bututun ƙarfe masu laushi da aka ja da sanyi ba tare da sulɓi ba don gyaran yanayin zafi mai ƙarancin zafi.

7. DIN 17175 St35.8Kayan bututu marasa sumul don tukunyar ruwa da tasoshin matsin lamba.

8. EN 10216-2 P235GH: Bututun da bututun ƙarfe marasa ƙarfe da na ƙarfe marasa ƙarfe don yanayin zafi mai yawa da matsin lamba mai yawa.

Tun lokacin da aka kafa kamfanin Botop Steel a shekarar 2014, ya zama babban kamfanin samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli. Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa matsala, da kuma cikakken jerin kayan haɗin bututu da flanges.

Kayayyakinta na musamman sun haɗa da ƙarfe masu inganci da ƙarfe masu bakin ƙarfe na austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.