JIS G 3452ma'auni ne na ƙasar Japan wanda ke ƙayyade bututun ƙarfe na carbon da aka haɗa don jigilar tururi, ruwa, mai, iskar gas, iska, da sauransu a ƙarancin matsin lamba na aiki. JIS G 3452 ya ƙunshi aji ɗaya kawai, SGP, wanda za'a iya ƙera shi ta hanyar walda mai juriya (ERW) ko walda mai ƙarfi.

Za a ƙera bututun ƙarfe na JIS G 3452 ta amfani da hanyoyin ƙera bututu da hanyoyin kammalawa masu dacewa.

| Alamar na maki | Alamar tsarin masana'antu | Rarraba shafi na zinc | |

| Tsarin kera bututu | Hanyar kammalawa | ||

| SGP | Juriyar wutar lantarki: E Butt ɗin da aka haɗa: B | An gama da kyau: H An gama sanyi: C Kamar yadda juriyar lantarki ta welded: G | Bututun baƙi: bututun da ba a ba su maganin zinc ba Bututun fari: bututun da aka yi wa fenti mai launin zinc |

Yawanci ana isar da bututun ne kamar yadda aka ƙera. Ana buƙatar a rufe bututun da aka gama da sanyi bayan an ƙera su.

Idan bututun an yi shi ne ta hanyar ERW, za a cire walda da ke saman ciki da waje na bututun don samun walda mai santsi tare da layin bututun.

Idan aka iyakance saboda diamita na bututu ko kayan aiki, da sauransu, ba za a iya cire walda da ke saman ciki ba.

Shiri: Kafin a yi amfani da galvanization mai zafi, dole ne a tsaftace saman bututun ƙarfe sosai ta hanyar amfani da yashi, tsinken tsinkewa, da sauransu.

Kauri: Don shafa sinadarin zinc, za a yi amfani da sinadarin zinc mai narkewa Class 1 da aka ƙayyade a cikin JIS H 2107 ko kuma sinadarin zinc mai aƙalla inganci iri ɗaya da wannan.

Sauran: Sauran buƙatun gabaɗaya don yin galvanizing sun yi daidai da JIS H 8641.

Gwaji: Auna daidaiton rufin galvanized bisa ga JIS H 0401 Mataki na 6.

Baya ga abubuwan da aka bayar, ana iya ƙara wasu abubuwan haɗin gwiwa kamar yadda ake buƙata.

| Alamar daraja | P (Fosphorus) | S (Silfur) |

| SGP | matsakaicin 0.040% | matsakaicin 0.040% |

JIS G 3452 yana da ƙarancin ƙuntatawa akan abubuwan da ke cikin sinadarai saboda ana amfani da JIS G 3452 galibi don aikace-aikacen gabaɗaya kamar jigilar tururi, ruwa, mai, da iskar gas. Haɗin sinadarai na kayan ba shine mafi mahimmancin abu ba, amma a maimakon haka halayen injiniya na bututun don jure matsin lamba na aiki.

Halayen Tashin Hankali

| Alamar daraja | Ƙarfin tauri | Tsawaita, minti, % | ||||||

| Gwaji na gwaji | Gwaji alkibla | Kauri bango, mm | ||||||

| N/mm² (MPA) | >3 ≤ 4 | >4 ≤ 5 | >5 ≤ 6 | >6 ≤ 7 | >7 | |||

| SGP | Minti 290 | Lamba ta 11 | Daidai da ma'aunin bututu | 30 | 30 | 30 | 30 | 30 |

| Lamba ta 12 | Daidai da ma'aunin bututu | 24 | 26 | 27 | 28 | 30 | ||

| Lamba ta 5 | Daidai zuwa ga bututun bututu | 19 | 20 | 22 | 24 | 25 | ||

Ga bututun da diamitansu bai kai 32A ko ƙasa da haka ba, ƙimar tsawaitawa da ke cikin wannan tebur ba ta aiki, kodayake za a rubuta sakamakon gwajin tsawaitawa. A wannan yanayin, ana iya amfani da buƙatar tsawaitawa da aka amince da ita tsakanin mai siye da masana'anta.

Kadarar Faɗaɗa

Faɗin: Ga bututun da diamitansu ya fi 50A (2B).

Babu tsagewa idan bututun ya lanƙwasa zuwa 2/3 na diamita na waje na bututun.

Lanƙwasawa

Faɗi: Ga bututun ƙarfe masu diamita mara iyaka ≤ 50A (2B).

Lanƙwasa samfurin zuwa digiri 90 tare da radius na ciki na ninki shida na diamita na waje na bututun ba tare da haifar da wani tsagewa ba.

Kowace bututun ƙarfe ya kamata ta sami gwajin matsin lamba na hydrostatic ko gwajin da ba zai lalata ta ba.

Gwajin Hydrostatic

Matsi: 2.5 MPa;

Lokaci: A riƙe na aƙalla daƙiƙa 5;

Hukunci: bututun ƙarfe a ƙarƙashin matsin lamba ba tare da ɓuya ba.

Gwajin da Ba Ya Lalatawa

Za a yi amfani da gwajin ultrasonic da aka ƙayyade a cikin JIS G 0582. Matsayin gwajin na iya zama mafi tsanani fiye da Nau'in UE.

Za a yi amfani da gwajin eddy current da aka ƙayyade a cikin JIS G 0583. Matsayin gwajin na iya zama mafi tsanani fiye da Nau'in EZ.

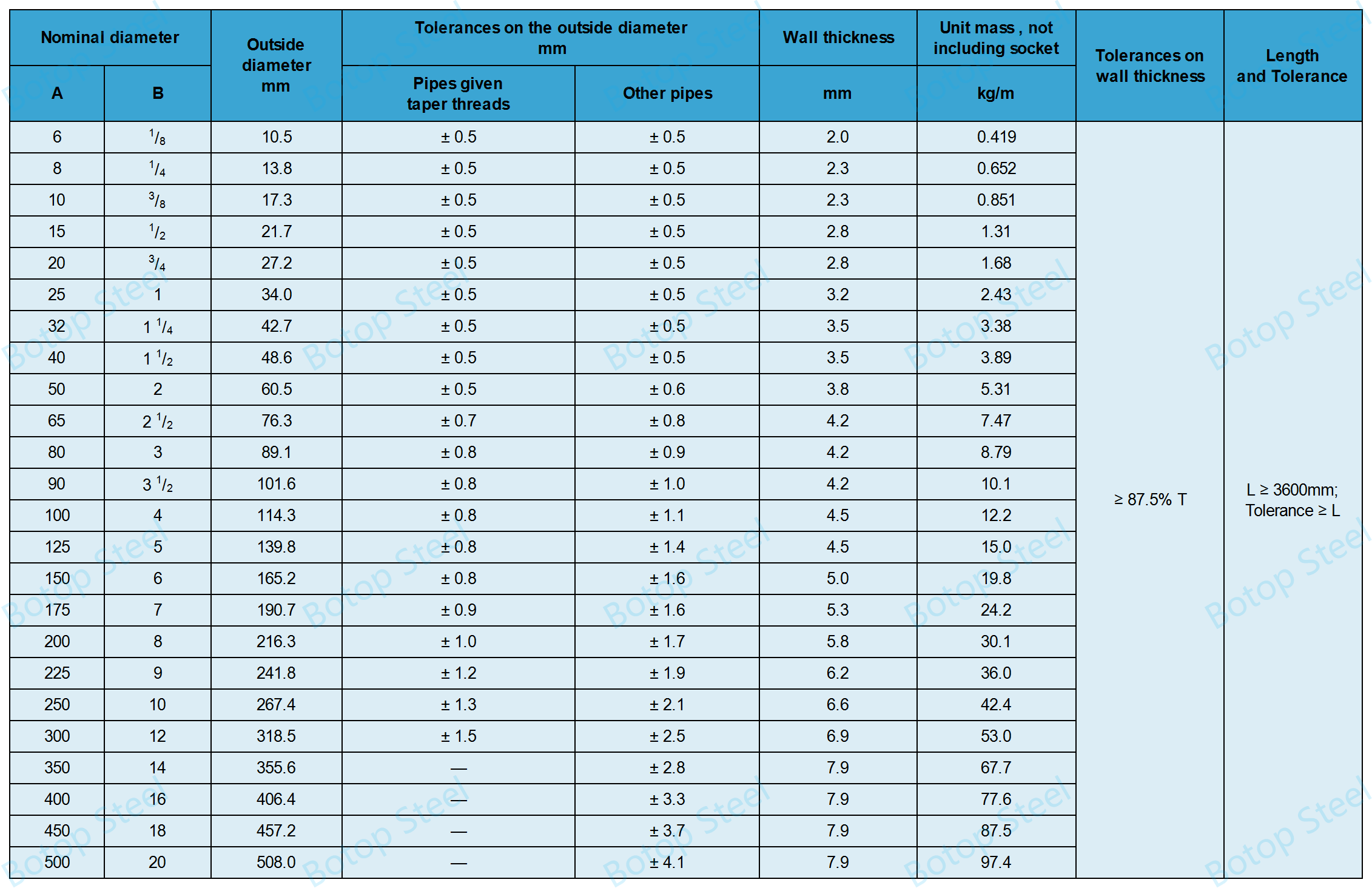

Ga bututu masu diamita marasa adadi ≥ 350A (14B), ƙididdige diamita ta hanyar auna kewaye, wanda a wannan yanayin haƙuri shine ± 0.5%.

Nau'in ƙarshen bututun DN≤300A/12B: ƙarshen zare ko lebur.

Nau'in ƙarshen bututu na DN≤350A/14B: ƙarshen lebur.

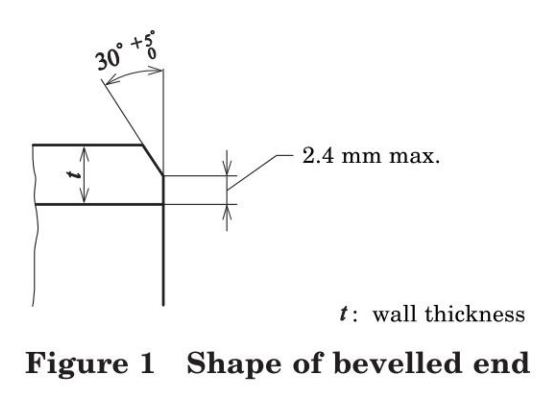

Idan mai siye yana buƙatar ƙarshen da aka yanke, kusurwar bevel ɗin shine 30-35°, faɗin bevel na gefen bututun ƙarfe: matsakaicin 2.4mm.

JIS G 3452 yana da daidai gwargwado a cikinASTM A53kumaGB/T 3091, kuma kayan bututun da aka ƙayyade a cikin waɗannan ƙa'idodi za a iya ɗaukar su daidai da juna dangane da aiki da aikace-aikacen.

Tun lokacin da aka kafa kamfanin Botop Steel a shekarar 2014, ya zama babban kamfanin samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli.

Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa sulɓi, da kuma cikakken jerin kayan haɗin bututu da flanges. Kayayyakinsa na musamman sun haɗa da ƙarfe masu inganci da ƙarfe marasa austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.

Tuntube mu, ƙungiyar ƙwararru a shirye take ta samar muku da ayyuka da mafita masu inganci, suna fatan cimma kyakkyawar haɗin gwiwa da ku, da kuma buɗe sabon babi na nasara tare.