bututun ƙarfe na JIS G 3461bututun ƙarfe ne mai sumul (SMLS) ko kuma bututun ƙarfe mai juriya ga lantarki (ERW), wanda galibi ana amfani da shi a cikin tukunyar ruwa da masu musayar zafi don aikace-aikace kamar fahimtar musayar zafi tsakanin ciki da wajen bututun.

STB340Tsarin bututun ƙarfe ne na carbon a cikin ma'aunin JIS G 3461. Yana da mafi ƙarancin ƙarfin tauri na 340 MPa da mafi ƙarancin ƙarfin fitarwa na 175 MPa.

Shi ne kayan da aka fi so ga aikace-aikacen masana'antu da yawa saboda ƙarfinsa mai girma, kwanciyar hankali mai kyau na zafi, daidaitawa, juriya ga tsatsa, inganci mai kyau, da kuma kyakkyawan sarrafawa.

JIS G 3461yana da maki uku.STB340, STB410, STB510.

STB340: Mafi ƙarancin ƙarfin juriya: 340 MPa; Mafi ƙarancin ƙarfin yawan amfanin ƙasa: 175 MPa.

STB410: Mafi ƙarancin ƙarfin taurin kai: 410 MPa; Mafi ƙarancin ƙarfin da aka samu: 255 MPa.

STB510:Mafi ƙarancin ƙarfin taurin kai: 510 MPa; Mafi ƙarancin ƙarfin da aka samu: 295 MPa.

A gaskiya ma, ba abu ne mai wahala a gano cewa an rarraba nau'in JIS G 3461 bisa ga mafi ƙarancin ƙarfin tururin bututun ƙarfe ba.

Yayin da matakin kayan ke ƙaruwa, ƙarfinsa da ƙarfinsa suna ƙaruwa daidai gwargwado, wanda ke ba da damar kayan su jure wa manyan kaya da matsin lamba don yanayin aiki mai wahala.

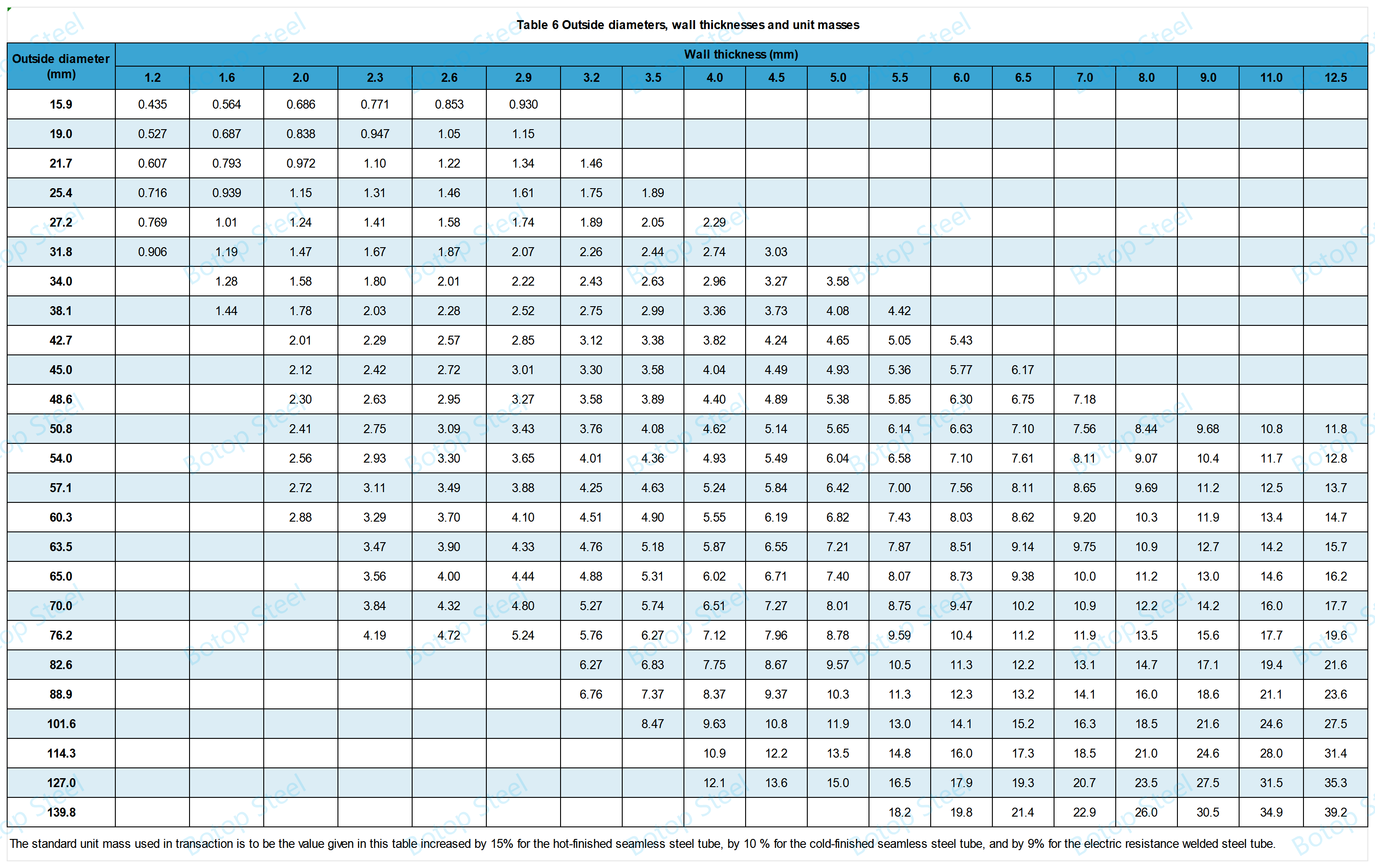

Diamita na waje na 15.9-139.8mm.

Amfani da shi a cikin tukunyar jirgi da na'urorin musanya zafi yawanci ba sa buƙatar manyan diamita na bututu. Ƙananan diamita na bututu suna ƙara ingancin zafi saboda rabon saman da girma na canja wurin zafi ya fi girma. Wannan yana taimakawa wajen canja wurin makamashin zafi cikin sauri da inganci.

Za a yi bututu daga ƙasaƙarfe da aka kashe.

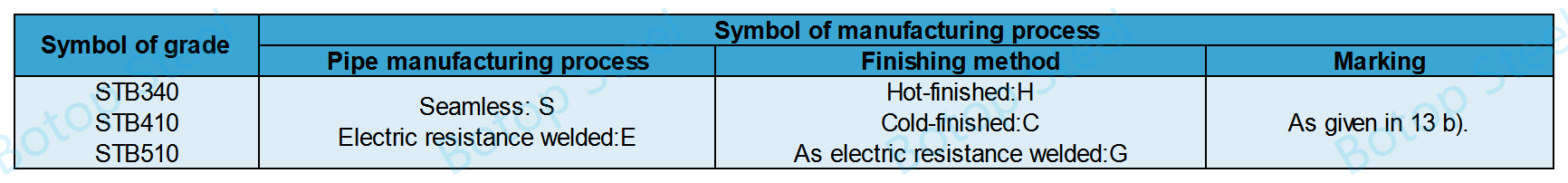

Haɗa hanyoyin ƙera bututu da hanyoyin kammalawa.

A takaice dai, ana iya rarraba su kamar haka:

Bututun ƙarfe mai laushi wanda aka gama da zafi: SH

Bututun ƙarfe mara sumul wanda aka gama da sanyi: SC

Kamar yadda bututun ƙarfe mai juriya na lantarki ya yi aiki: EG

Bututun ƙarfe mai welded mai juriya ga lantarki mai zafi: EH

Bututun ƙarfe mai welded mai juriya ga lantarki mai sanyi: EC

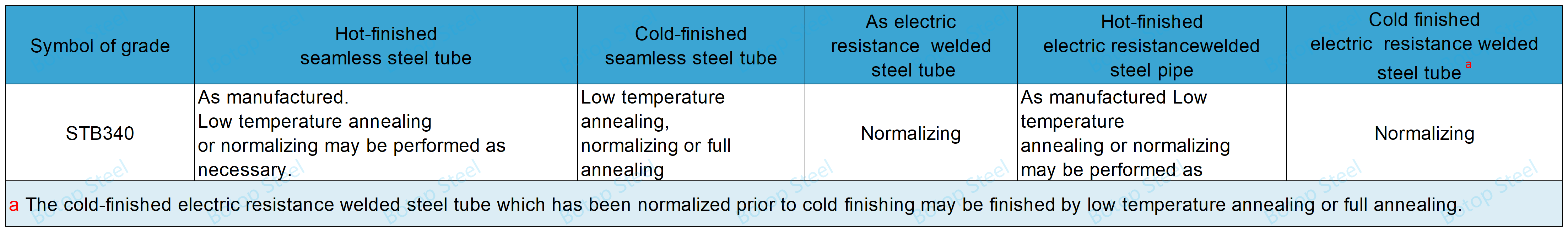

Ga yadda ake samar da ruwan zafi mai kyau.

Don tsarin kera shi ba tare da matsala ba, ana iya raba shi zuwa bututun ƙarfe marasa sumul waɗanda diamita na waje ya fi 30mm ta amfani da samar da ƙarewa mai zafi, da kuma 30mm ta amfani da samar da ƙarewa mai sanyi.

Hanyoyin nazarin zafi dole ne su kasance daidai da ƙa'idodin JIS G 0320.

Ana iya ƙara wasu abubuwan da ke haɗa sinadarai don samun takamaiman halaye.

Lokacin da aka yi nazarin samfurin, ƙimar karkacewar sinadaran da ke cikin bututun za ta cika buƙatun Tebur na 3 na JIS G 0321 don bututun ƙarfe marasa tsari da Tebur na 2 na JIS G 0321 don bututun ƙarfe masu juriya.

| Alamar daraja | C (Carbon) | Si (Silikon) | Mn (Manganese) | P (Fosphorus) | S (Silfur) |

| matsakaicin | matsakaicin | matsakaicin | matsakaicin | ||

| STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Mai siye zai iya ƙayyade adadin Si da zai kasance a cikin kewayon 0.10% zuwa 0.35%. | |||||

An tsara sinadarin STB340 don tabbatar da isasshen kayan aikin injiniya da kuma iya sarrafa su yayin da ake sanya kayan ya dace da walda da amfani a yanayin zafi mai yawa.

| Alamar daraja | Ƙarfin taurin kai a | Ma'aunin bayarwa ko damuwa mai tabbatar da inganci | Ƙara min, % | ||

| Diamita na waje | |||||

| <10mm | ≥10mm <20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Gwaji na gwaji | |||

| Lamba ta 11 | Lamba ta 11 | Lamba ta 11/Lamba ta 12 | |||

| minti | minti | Hanyar gwajin tensile | |||

| Daidai da ma'aunin bututu | Daidai da ma'aunin bututu | Daidai da ma'aunin bututu | |||

| STB340 | 340 | 175 | 27 | 30 | 35 |

Lura: musamman ga bututun musayar zafi, mai siye zai iya, inda ya cancanta, ƙayyade matsakaicin ƙimar ƙarfin tayar da hankali. A wannan yanayin, matsakaicin ƙimar ƙarfin tayar da hankali zai zama ƙimar da aka samu ta hanyar ƙara 120 N/mm² zuwa ƙimar da ke cikin wannan tebur.

Lokacin da aka yi gwajin tensile a kan gwajin da aka yi a lamba ta 12 don bututun da ke ƙasa da kauri na bango mm 8.

| Alamar daraja | An yi amfani da gwajin da aka yi amfani da shi | Ƙarawa minti, % | ||||||

| Kauri a bango | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | −7 −8 mm | ||

| STB340 | Lamba ta 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Ana ƙididdige ƙimar tsawaitawa a cikin wannan tebur ta hanyar cire kashi 1.5% daga ƙimar tsawaitawa da aka bayar a cikin Jadawali na 4 ga kowane raguwar mm 1 a cikin kauri na bangon bututu daga mm 8, da kuma zagaye sakamakon zuwa lamba bisa ga Dokar A ta JIS Z 8401.

Hanyar gwajin za ta yi daidai da JIS Z 2245. Za a auna taurin kayan gwajin a kan sashin giciye ko saman ciki a wurare uku a kowane kayan gwaji.

| Alamar daraja | Taurin Rockwell (matsakaicin ƙimar matsayi uku) HRBW |

| STB340 | 77 mafi girma. |

| STB410 | 79 mafi girma. |

| STB510 | 92 mafi girma. |

Ba za a yi wannan gwajin a kan bututun da kaurinsu ya kai mm 2 ko ƙasa da haka ba. Ga bututun ƙarfe da aka haɗa da ƙarfe masu juriya ga lantarki, za a yi gwajin a wani yanki daban da na walda ko wuraren da zafi ya shafa.

Ba ya shafi bututun ƙarfe marasa sumul.

Hanyar Gwaji Sanya samfurin a cikin injin kuma a daidaita shi har sai nisan da ke tsakanin dandamali biyu ya kai ƙimar da aka ƙayyade H. Sannan a duba samfurin don ganin ko akwai tsagewa.

Lokacin gwada bututun da aka yi wa walda mai ƙarfi, layin da ke tsakanin walda da tsakiyar bututun yana daidai da alkiblar matsi.

H=(1+e)t/(e+t/D)

H: Tazara tsakanin faranti (mm)

t: kauri na bututun bango (mm)

D: diamita na waje na bututun (mm)

’:an ayyana shi akai-akai ga kowane matakin bututun. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Ba ya shafi bututun ƙarfe marasa sumul.

Ana kunna ƙarshen samfurin a zafin ɗaki (5°C zuwa 35°C) da kayan aikin mazugi a kusurwar 60° har sai diamita na waje ya faɗaɗa da kashi 1.2 sannan a duba ko akwai tsagewa.

Wannan buƙatar ta shafi bututun da diamita na waje ya fi mm 101.6.

Ana iya cire gwajin karkatar da baya yayin yin gwajin karkatar.

Yanke tsawon guntun gwaji mai tsawon mm 100 daga ƙarshen bututun sannan a yanke guntun gwajin a rabi 90° daga layin walda a ɓangarorin biyu na kewaye, a ɗauki rabin da ke ɗauke da waldan a matsayin guntun gwajin.

A zafin ɗaki (5°C zuwa 35°C), a miƙe samfurin a cikin faranti tare da walda a saman sannan a duba samfurin don ganin tsagewar walda.

Kowace bututun ƙarfe tana buƙatar a gwada ta hanyar hydrostatic ko kuma ba ta hanyar lalata badon tabbatar da inganci da amincin bututun da kuma cika ƙa'idodin amfani.

Gwajin Na'ura Mai Aiki

Riƙe cikin bututun a mafi ƙarancin matsi ko mafi girma na P (P max 10 MPa) na akalla daƙiƙa 5, sannan a tabbatar cewa bututun zai iya jure matsin ba tare da ya zube ba.

P=2st/D

P: matsin lamba na gwaji (MPa)

t: kauri na bututun bango (mm)

Ddiamita na waje na bututun (mm)

s: Kashi 60% na ƙayyadadden ƙimar ma'aunin yawan amfanin ƙasa ko damuwa mai tabbatarwa.

Gwajin da Ba Ya Lalatawa

Ya kamata a yi gwajin bututun ƙarfe mara lalatawa ta hanyar amfani da na'urar auna zafin jikigwajin ultrasonic ko eddy current.

Dominultrasonichalayen dubawa, siginar daga samfurin tunani wanda ke ɗauke da ma'aunin tunani na aji UD kamar yadda aka ƙayyade a cikinJIS G 0582za a ɗauke shi a matsayin matakin faɗakarwa kuma zai kasance yana da siginar asali daidai ko sama da matakin faɗakarwa.

Daidaitaccen fahimtar ganowa doneddy currentjarrabawar za ta kasance nau'in EU, EV, EW, ko EX da aka ƙayyade a cikinJIS G 0583, kuma ba za a sami sigina da suka yi daidai ko suka fi sigina daga samfurin tunani da ke ɗauke da ma'aunin tunani na wannan rukuni ba.

Don ƙarin bayaniJadawalin Nauyin Bututu da Jadawalin Bututua cikin daidaitattun, zaka iya dannawa ta ciki.

Yi amfani da hanyar da ta dace wajen yiwa waɗannan bayanai lakabi.

a) Alamar daraja;

b) Alamar hanyar ƙera kayayyaki;

c) Girma: diamita na waje da kauri na bango;

d) Sunan masana'anta ko alamar da ke nuna shi.

Idan alamar da ke kan kowace bututu ta yi wahala saboda ƙaramin diamita na waje ko kuma idan mai siye ya buƙata, ana iya ba da alamar a kan kowace tarin bututu ta hanyar da ta dace.

Ana amfani da STB340 sosai wajen kera bututun ruwa da bututun bututun hayaki ga injinan dumama ruwa daban-daban na masana'antu, musamman a wuraren da ake buƙatar juriya ga yanayin zafi mai yawa da matsin lamba.

Saboda kyawawan halayensa na isar da zafi, ya kuma dace da ƙera bututu don musayar zafi, wanda ke taimakawa wajen canja wurin zafi yadda ya kamata tsakanin kafofin watsa labarai daban-daban.

Ana iya amfani da shi wajen jigilar ruwa mai zafi ko mai ƙarfi, kamar tururi ko ruwan zafi, kuma ana amfani da shi sosai a masana'antar kera sinadarai, wutar lantarki, da injina.

ASTM A106 Matsayi A

DIN 17175 St35.8

DIN 1629 St37.0

BS 3059-1 Aji 320

EN 10216-1 P235GH

GB 3087 20#

GB 5310 20G

Ko da yake waɗannan kayan na iya zama iri ɗaya dangane da sinadaran da kuma halayensu na asali, takamaiman hanyoyin magance zafi da injina na iya shafar halayen samfurin ƙarshe.

Saboda haka, ya kamata a yi kwatancen da aka yi dalla-dalla da kuma gwaji mai dacewa yayin zaɓar kayan aiki iri ɗaya don aikace-aikacen aiki.

Tun lokacin da aka kafa kamfanin Botop Steel a shekarar 2014, ya zama babban kamfanin samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli. Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa matsala, da kuma cikakken jerin kayan haɗin bututu da flanges.

Kayayyakinta na musamman sun haɗa da ƙarfe masu inganci da ƙarfe masu bakin ƙarfe na austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.