ASTM A519Za a ƙera bututun ta hanyar tsari mara matsala kuma za a gama su da zafi ko kuma a gama su da sanyi kamar yadda aka ƙayyade.

Ga bututun da ke zagaye da diamita na waje wanda bai wuce 12 3/4 inci (325 mm) ba.

Ana iya ƙera bututun ƙarfe a murabba'i, murabba'i mai kusurwa huɗu, ko wasu siffofi kamar yadda ake buƙata.

Ana iya rarraba ASTM A519 bisa ga kayan ƙarfe:Karfe na Carbonda kuma ƙarfe mai ƙarfe.

Karfe mai carbonan raba shi zuwaƘananan Carbon MT(Bututun Inji),Babban Karfe na CarbonkumaAn cire sulfur ko an sake fitar da su, ko duka biyunKarfe na Carbon, don dacewa da buƙatun masana'antu daban-daban da yanayin aikace-aikace.

Idan ba a ƙayyade wani matsayi ba, masana'antun suna da zaɓin bayarwaMT1015 ko MTX1020maki.

Diamita na waje: 13.7 - 325 mm;

Kauri daga bango: 2-100mm.

Ana iya yin ƙarfe ta kowace hanya.

Ana iya yin amfani da ƙarfe a cikin ingots ko kuma a yi amfani da shi a cikin simintin ƙarfe.

Za a yi bututu ta hanyar amfani da wanitsari mara matsalakuma za a yi shi da zafi ko sanyi, kamar yadda aka ƙayyade.

Bututun ƙarfe marasa sumul bututu ne marasa haɗin kai a ko'ina.

Bututun da aka gama da sanyiana ba da shawarar yin amfani da su don manyan buƙatu kan daidaiton girma da ingancin saman.

Babban abin damuwa shine ingancin farashi da kuma juriyar kayan aiki,bututun ƙarfe mai zafizai iya zama zaɓi mafi dacewa.

Na gaba shine tsarin samar da bututun ƙarfe mai zafi wanda ba shi da matsala.

Mai ƙera ƙarfe zai yi nazarin zafin kowanne ƙarfe don tantance adadin abubuwan da aka ƙayyade.

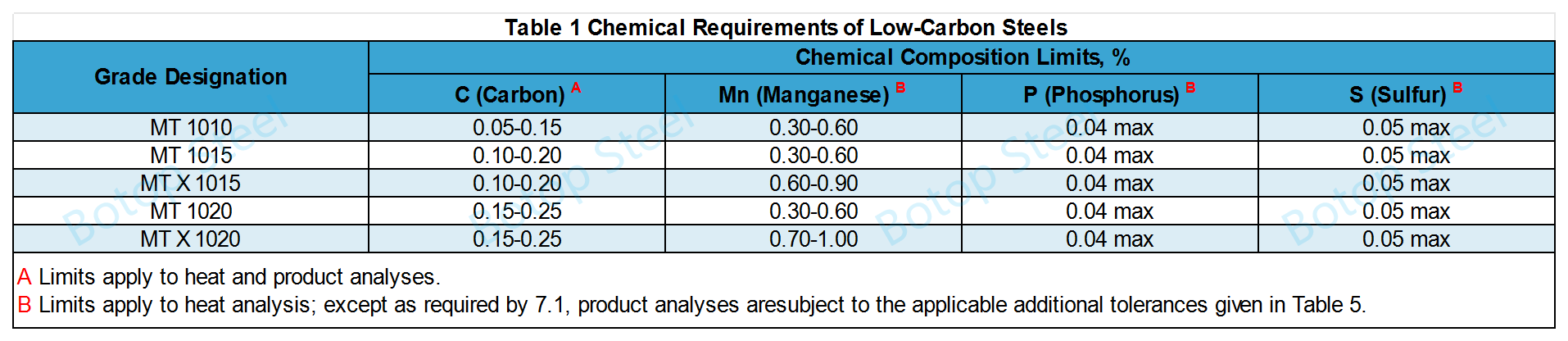

Tebur 1 Bukatun Sinadarai na Ƙananan Karfe

Karfe mai laushi ƙarfe ne mai yawan sinadarin carbon wanda yawanci ba ya wuce kashi 0.25% saboda ƙarancin sinadarin carbon, wannan ƙarfe yana da sauƙin sassauƙa da sassauƙa kuma ba shi da tauri da ƙarfi idan aka kwatanta da ƙarfe mai yawan carbon.

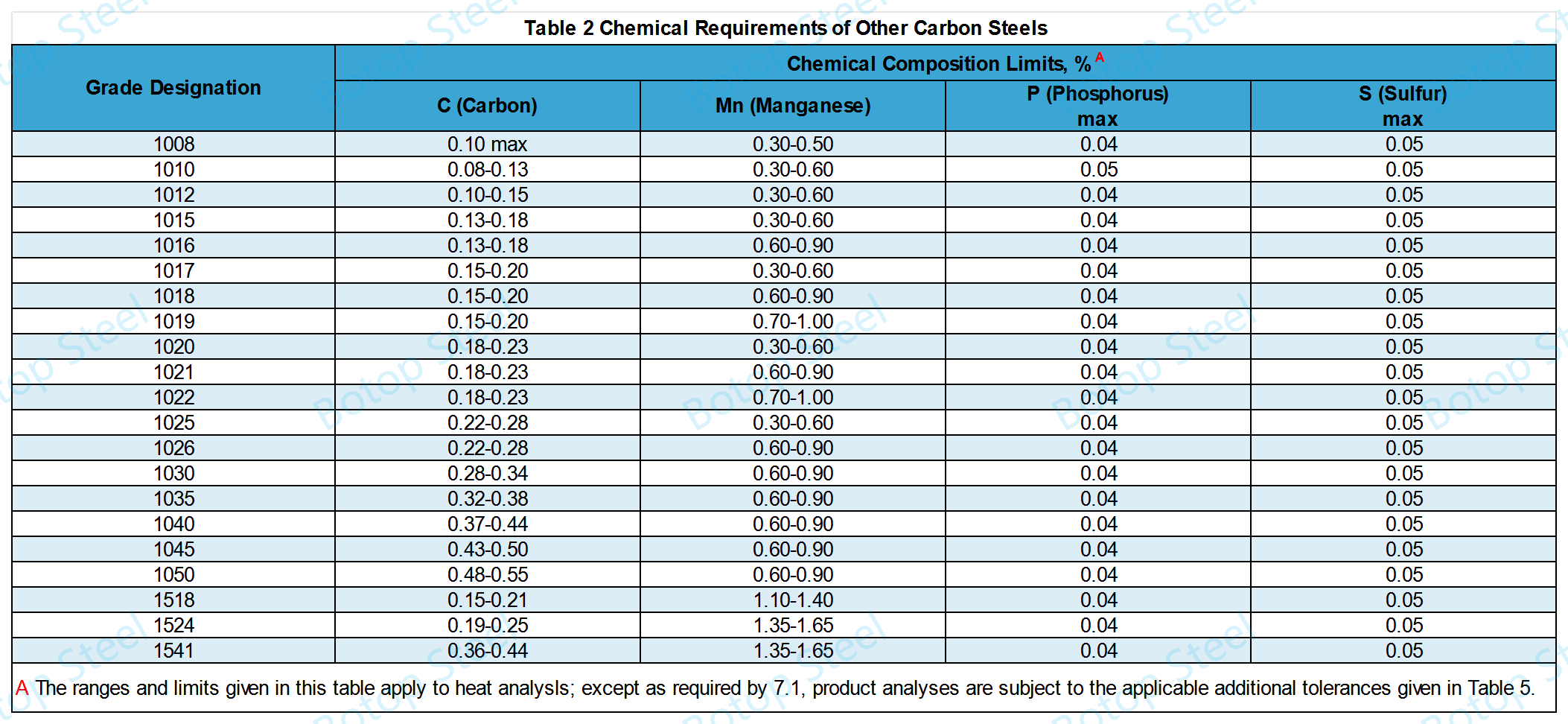

Tebur na 2 Bukatun Sinadarai na Sauran Karfe na Carbon

Karfe mai matsakaicin carbon: Suna ɗauke da tsakanin kashi 0.25% zuwa 0.60% na carbon, suna ba da ƙarfi da tauri mafi girma kuma suna buƙatar maganin zafi don inganta halaye.

Babban ƙarfe mai carbon: Ya ƙunshi tsakanin 0.60% zuwa 1.0% ko fiye da carbon, kuma yana ba da tauri da ƙarfi sosai, amma ƙarancin tauri.

Tebur 3 Bukatun Sinadarai don Karfe Mai Alloy

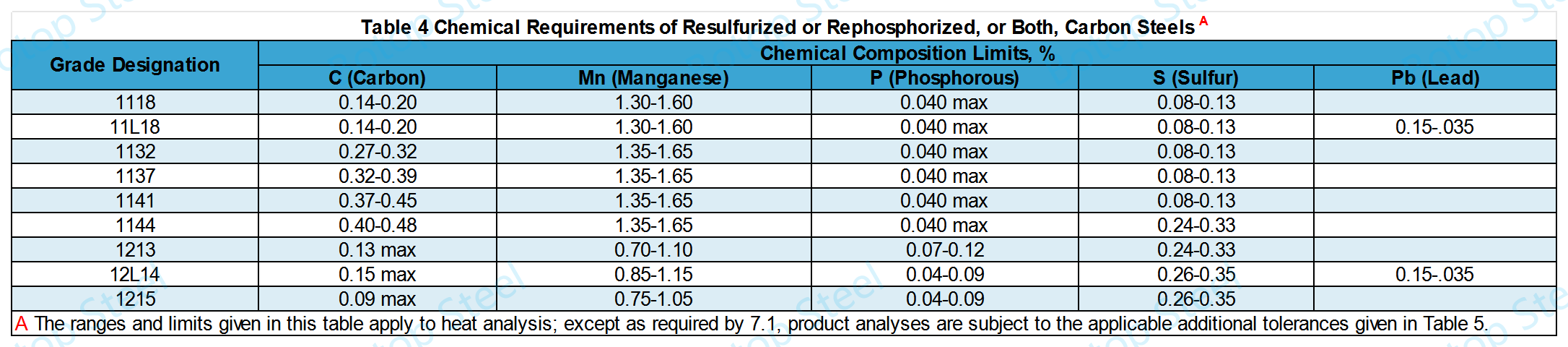

Tebur 4 Bukatun Sinadarai na Karfe Mai Ruwa Mai Ruwa ko Mai Ruwa Mai Ruwa, ko Dukansu

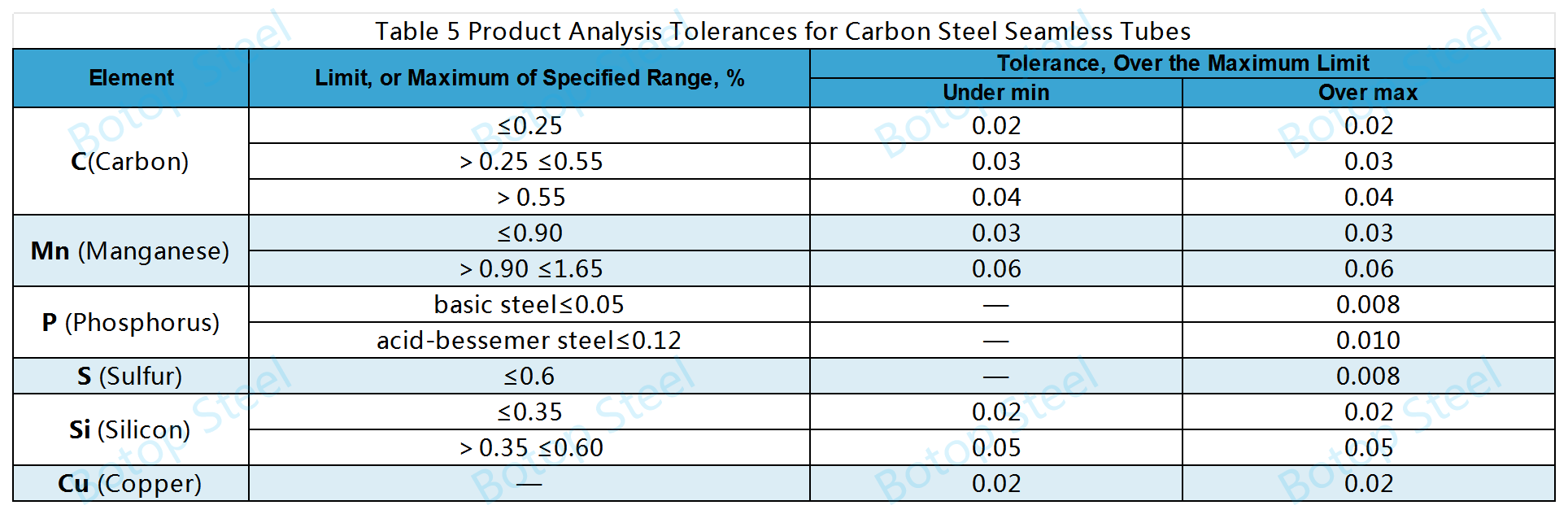

TABLE 5 Nazarin Samfura Juriya ko Ƙarƙashin Kewaya ko Iyaka da aka ƙayyade

Ya kamata a nemi mai ƙera ya yi nazarin samfurin ne kawai idan an buƙata ta hanyar oda.

ASTM A519 ya ƙunshi waɗannan abubuwan gwaji:

Gwajin Tauri; Gwajin Tauri; Gwajin Ba Ya Lalacewa; Gwajin Ƙarfe; Tsabta da Tauri.

| Nadin Maki | Nau'in Bututu | Yanayi | Ƙarfin Utimate | Ƙarfin Ba da Kyauta | Tsawaita a cikin inci 2.[50mm],% | Rockwell, Taurin B Sikeli | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Karfe na Carbon | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Karfe na Carbon | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Karfe na Carbon | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Karfe na Carbon | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Karfe na Carbon | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | An sake samar da sinadarin sulfur ko kuma an sake yin amfani da fosforozu, ko kuma duka biyun, Karfe na Carbon | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | An sake samar da sinadarin sulfur ko kuma an sake yin amfani da fosforozu, ko kuma duka biyun, Karfe na Carbon | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Karfe na Alloy | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Karfe na Alloy | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-An yi amfani da zafi, CW-Cold Worked, SR-An rage damuwa, A-An yi amfani da A kuma N-An daidaita.

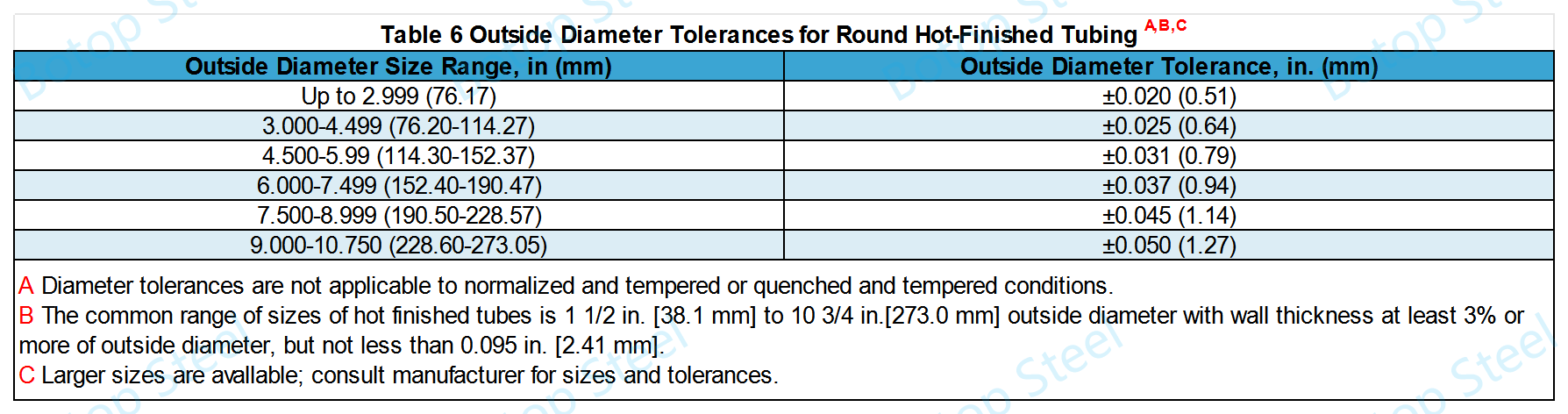

Juriyar Diamita ta Waje

Tebur 6 Juriyar Diamita ta Wajedon Zagaye Mai Zafi Mai Kammalawa

Tebur 12 Juriyar Diamita ta Waje donBututun Ruwa Mara Sumul

| Girman Diamita na Waje, a cikin.[mm] | Juriyar Diamita na Waje don Girma da Tsawonsa. An bayar, a cikin. [mm] | |||

| Sama | A ƙarƙashin | Sama | A ƙarƙashin | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] lokacin da L≤ ƙafa 16[mita 4.9] | 0.000 | 0.004 [0.10] lokacin da L>ƙafa 16[mita 4.9] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] lokacin da L≤ ƙafa 16[mita 4.9] | 0.000 | 0.006 [0.15] lokacin da L>ƙafa 16[mita 4.9] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] lokacin da L≤ ƙafa 12[3.7m] | 0.000 | 0.006 [0.15] lokacin da L≤ ƙafa 16[mita 4.9] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] lokacin da L≤ ƙafa 12[3.7m] | 0.000 | 0.006 [0.15] lokacin da L≤ ƙafa 16[mita 4.9] | 0.000 |

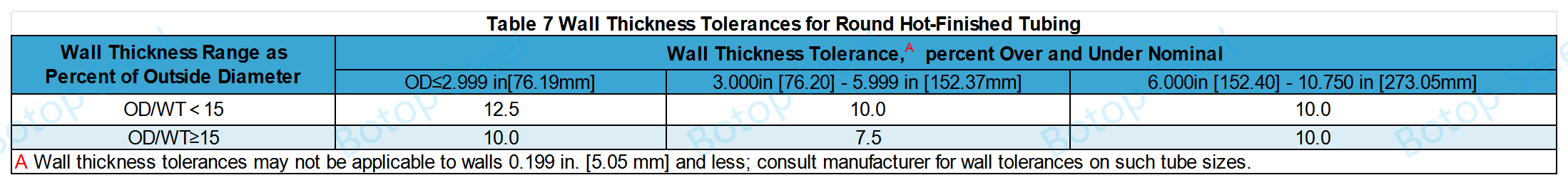

Juriyar Kauri a Bango

Tebur 7 Juriyar Kauri a Bangodon Zagaye Mai Zafi Mai Kammalawa

Tebur 10 Juriyar Kauri a Bangodon Bututun Aiki Mai Zagaye

| Kauri a Bango kamar yadda Kashi na Diamita na Waje | Juriya daga Kauri a Bango, Juriya daga Sama da Ƙasa, % | |

| OD≤1.499in[38.07mm] | OD≥1.500 inci [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT> 25 | 12.5 | 10.0 |

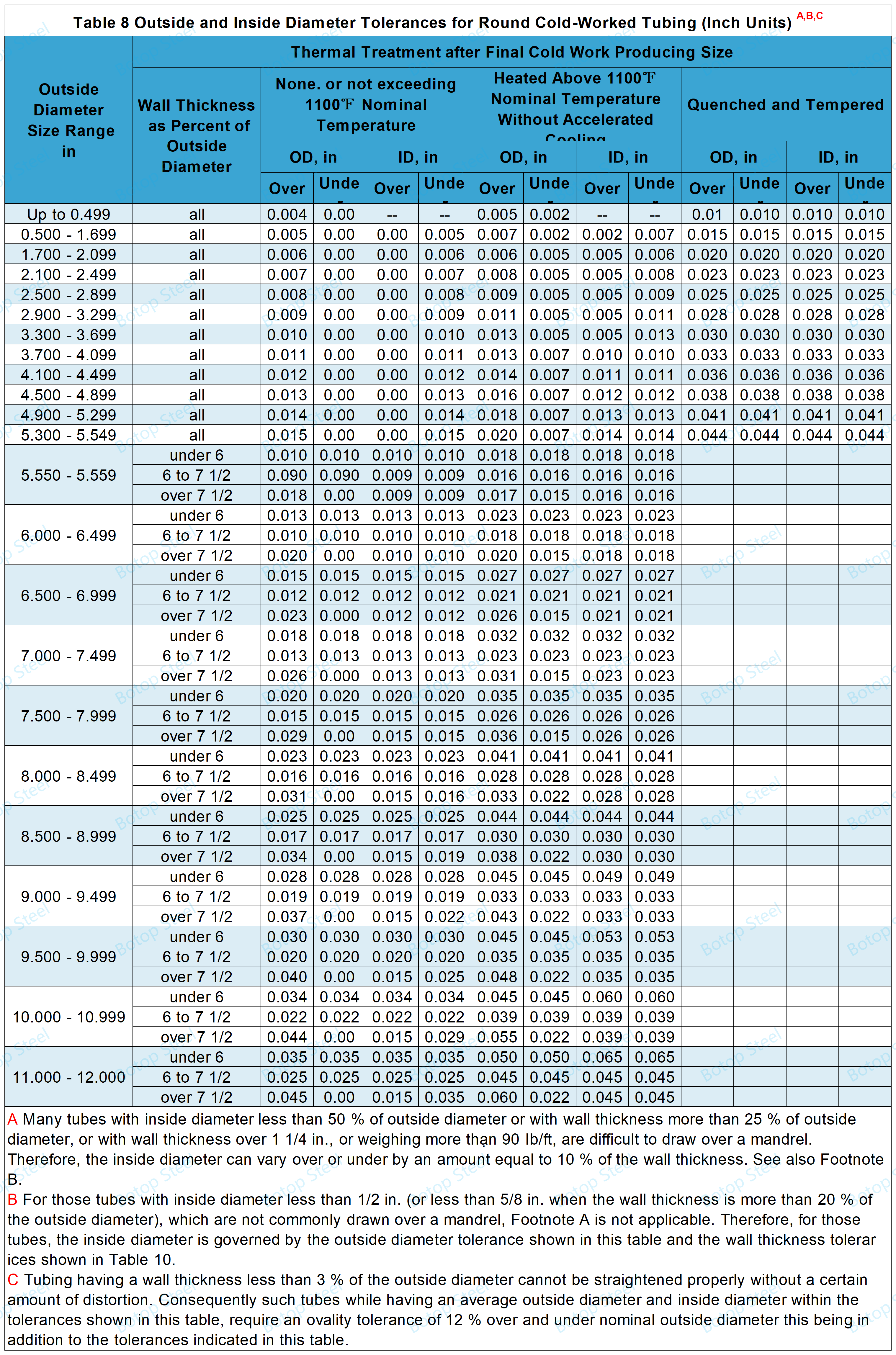

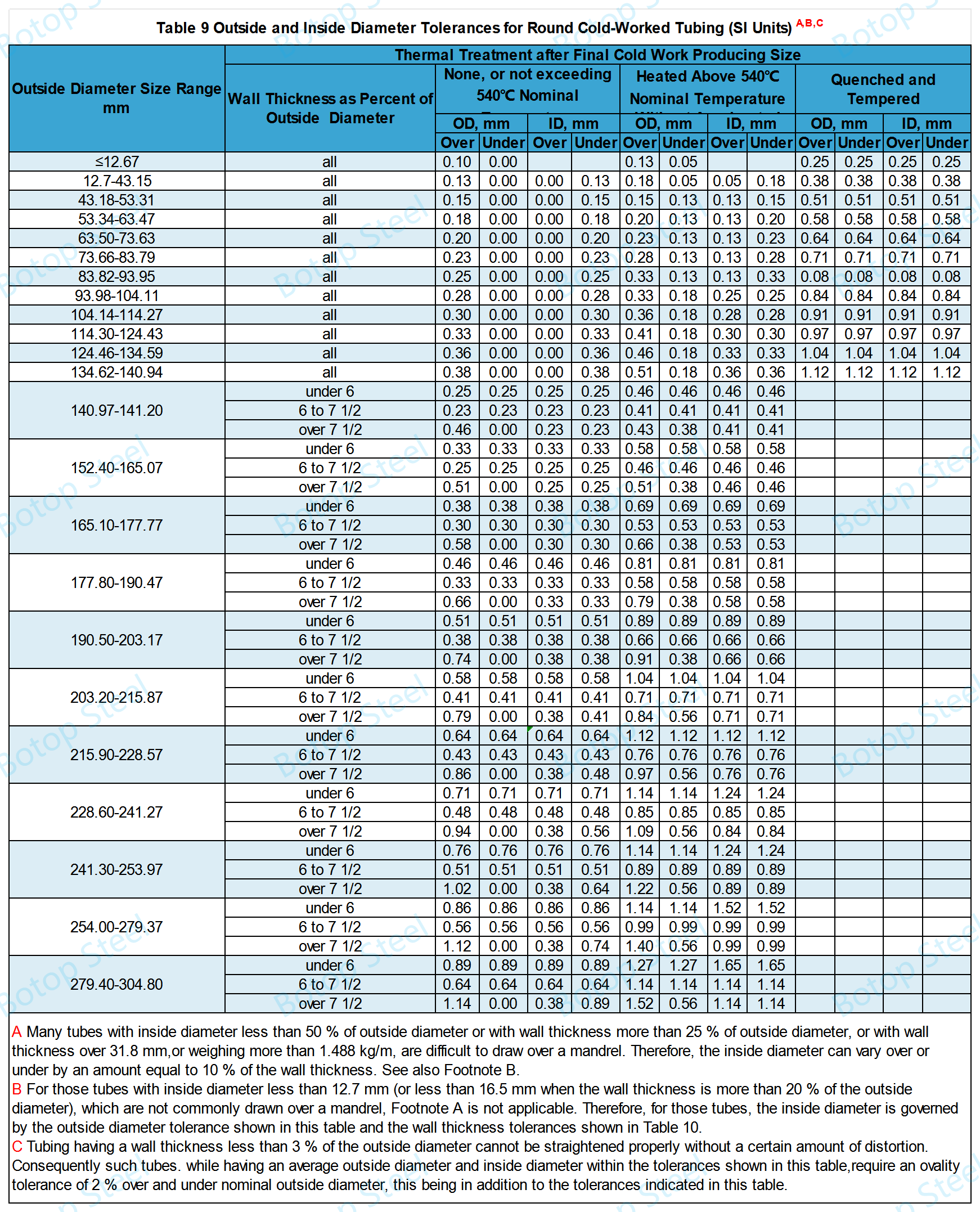

Juriya a Tsakanin Jiki da Waje

Tebur 8 Juriyar diamita ta waje da ciki donBututun Aiki Mai Sanyi Zagaye (Inci Raka'a)

Tebur 9 Juriyar diamita ta waje da cikidon Bututun Aiki Mai Zagaye da Sanyi (Si Units)

Diamita na Waje da Juriyar Kauri a Bango

Tebur 11 Diamita na Waje da Juriyar Bangodon Tubulen Karfe Mai Tauri Mai Juyawa

| Girman da aka ƙayyade Diamita na Waje, a cikin. [mm] | Diamita na waje, a cikin. [mm] | Kauri a Bango, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Juriyar Tsawon Lokaci

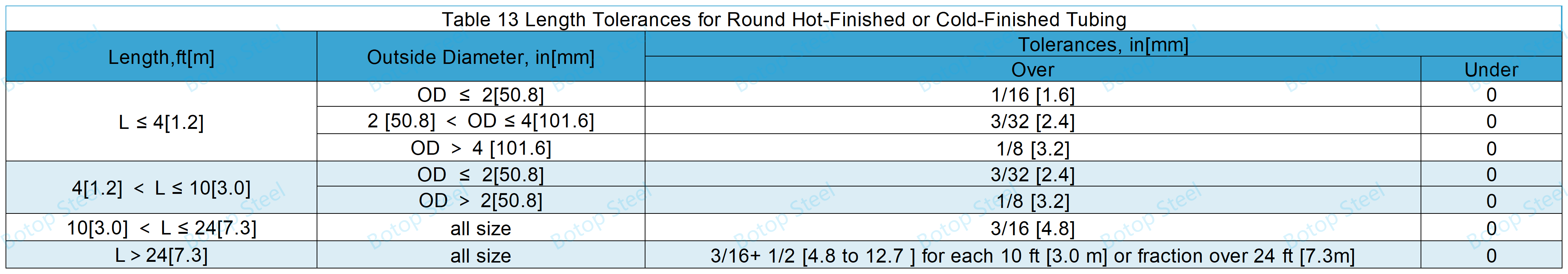

Tebur 13 Juriyar Tsawondon Zagaye na Bututun da aka Gama da Zafi ko Sanyi

Juriyar Daidaito

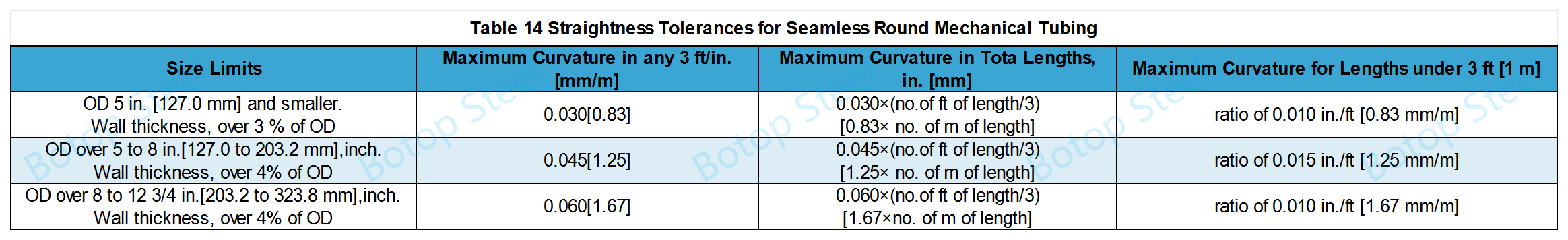

Tebur 14 Juriya Mai Daidaitodon Tubulen Inji Mai Zagaye Mara Sumul

Ya kamata a shafa bututun da man shafawa kafin a yi masa ƙera shi domin hana tsatsa.

Ana iya shafa man kariya daga tsatsa a saman bututun ciki da waje.

Jiragen Sama da sararin samaniya: ƙera muhimman abubuwa kamar injunan jiragen sama da tsarin tallafawa jiragen sama.

Masana'antar makamashi: kayan haƙa da kuma kera bututun boiler mai matsin lamba.

Injinan da kayan aiki kera: Babban kayan da suka ƙunshi nau'ikan injuna da kayan aiki na masana'antu iri-iri.

Kayan wasanni: Kera firam ɗin kekuna masu inganci da sauran wuraren wasanni.

Gine-gine da gini: abubuwan tallafi na tsarin gini don gine-gine da aikace-aikace a cikin yanayin matsin lamba mai yawa.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, da sauransu. Ana iya ɗaukar waɗannan kayan a matsayin daidai da wasu ƙarfe na carbon da ƙarfe a cikin ASTM A519.

2. DIN 1629: St52, St37.4, da sauransu. Yawanci ana amfani da su don dalilai na injiniya da gini, waɗannan suna kama da ƙananan matakan ƙarfe a cikin ASTM A519.

3. JIS G3445: STKM13A, STKM13B, da sauransu. Waɗannan bututun ƙarfe ne da ake amfani da su don dalilai na injiniya da gini.

4. BS 6323:CFS 3, CFS 4, CFS 8, da sauransu. Waɗannan bututun ƙarfe ne marasa sulɓi kuma waɗanda aka haɗa da walda don dalilai na mota, injiniya, da injiniya gabaɗaya.

5. GB/T 8162:20#, 45#, 40Cr, 20CrMo, da sauransu. Bututun ƙarfe marasa sumul don tsari da tsarin injiniya.

6. ISO 683-17:100Cr6, da sauransu, waɗanda aka saba amfani da su wajen kera bearing, suna iya samun aikace-aikace a injiniyan injiniya kuma suna da irin wannan aikace-aikacen ga wasu ƙarfe na ASTM A519.

Lokacin zabar kayan da suka yi daidai, yana da mahimmanci a koma ga cikakkun bayanai game da sinadaran da kuma takamaiman kayan aikin injiniya don tabbatar da cewa kayan da aka zaɓa zai cika buƙatun aiki na takamaiman aikace-aikacen.

Tun lokacin da aka kafa kamfanin Botop Steel a shekarar 2014, ya zama babban kamfanin samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli. Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa matsala, da kuma cikakken jerin kayan haɗin bututu da flanges.

Kayayyakinta na musamman sun haɗa da ƙarfe masu inganci da ƙarfe masu bakin ƙarfe na austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.