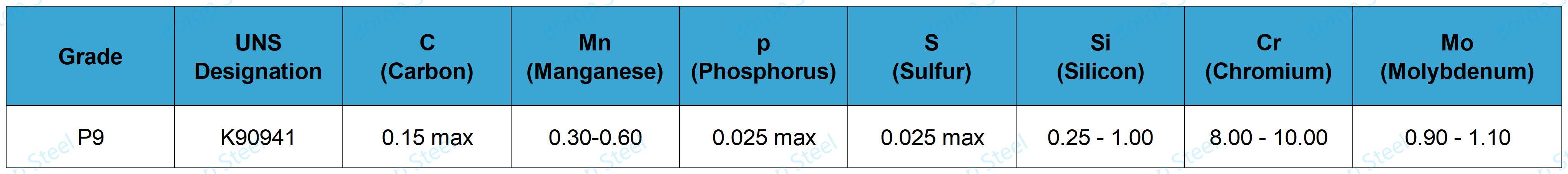

ASTM A335 P9, wanda kuma aka sani da ASME SA335 P9, bututu ne mai ƙarfe mai kama da ferritic wanda ba shi da matsala don aiki mai zafi mai yawa tare da ingantaccen aiki mai kyau.Lambar UNS K90941.

Sinadaran da ke haɗa sinadarai sune chromium da molybdenum. Yawan sinadarin chromium yana tsakanin kashi 8.00 - 10.00%, yayin da adadin sinadarin molybdenum yana tsakanin kashi 0.90 - 1.10%.

P9yana da ƙarfi mai kyau da juriya ga tsatsa a cikin yanayin zafi mai yawa kuma ana amfani da shi sosai a cikin tukunyar ruwa, kayan aikin petrochemical, da tashoshin wutar lantarki inda ake buƙatar yanayin zafi mai yawa da matsin lamba mai yawa.

⇒ Kayan aiki: ASTM A335 P9 / ASME SA335 P9 bututun ƙarfe mara shinge.

⇒Diamita na waje: 1/8"- 24".

⇒Kauri a bango: Bukatun ASME B36.10.

⇒Jadawalin Jadawalin: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 da SCH160.

⇒Ganowa: STD (misali), XS (ƙarfi mai ƙarfi), ko XXS (ƙarfi mai ƙarfi biyu).

⇒Tsawon: Tsawon takamaiman ko bazuwar.

⇒Keɓancewa: Diamita na waje mara daidaito, kauri na bango, tsayi, da sauransu bisa ga buƙatu.

⇒Kayan aiki: Za mu iya samar da lanƙwasa iri ɗaya na kayan aiki, flanges na tambari, da sauran samfuran da ke tallafawa bututun ƙarfe.

⇒Takardar shaidar IBR: Ana iya bayar da takardar shaidar IBR idan ana buƙata.

⇒Ƙarshe: Ƙarshen fili, ƙarshen da aka yanke, ko ƙarshen bututun da aka haɗa.

⇒shiryawa: akwati na katako, bel na ƙarfe ko fakitin waya na ƙarfe, mai kariya daga ƙarshen bututun filastik ko ƙarfe.

⇒Sufuri: ta hanyar ruwa ko jirgin sama.

Dole ne bututun ƙarfe na ASTM A335 ya kasance mara sumul.

Bututun ƙarfe mara sumul bututu ne na ƙarfe wanda ba shi da walda a ko'ina.

Tunda bututun ƙarfe mara shinge ba shi da dinkin walda a cikin tsarinsa, yana guje wa haɗarin tsaro da ka iya kasancewa da alaƙa da matsalolin ingancin walda. Wannan fasalin yana ba da damar bututun mara shinge ya jure matsin lamba mai yawa, kuma tsarin cikinsa iri ɗaya yana ƙara tabbatar da aminci da amincin bututun a cikin yanayin matsin lamba mai yawa.

Bugu da ƙari, ingancin bututun ASTM A335 yana ƙaruwa ta hanyar ƙara wasu abubuwan haɗin gwiwa don yanayin zafi mai yawa da matsin lamba mai yawa.

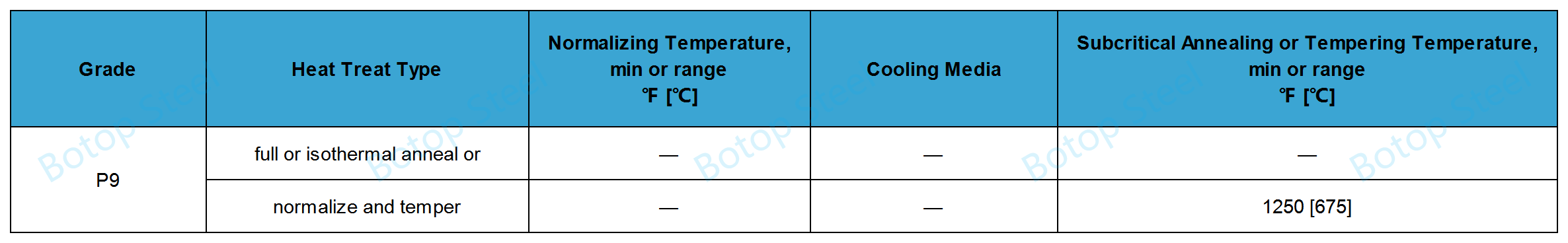

Nau'ikan maganin zafi da ake samu don kayan P9 sun haɗa da cikakken ko isothermal annealing, da kuma daidaita da kuma daidaita yanayin zafi. Tsarin daidaitawa da daidaitawa yana da zafin jiki na 1250°F [675°C].

Babban abubuwan haɗin P9 suneCrkumaMo, waɗanda sune ƙarfe na chromium-molybdenum.

Cr (Chromium): A matsayin babban sinadarin da ke cikin ƙarfen, Cr yana ba da ƙarfi mai kyau na zafin jiki da juriya ga iskar shaka. Yana samar da fim ɗin chromium oxide mai yawa a saman ƙarfen, yana ƙara kwanciyar hankali da juriyar tsatsa na bututun a yanayin zafi mai yawa.

Mo (Molybdenum): Ƙara Mo yana inganta ƙarfi da tauri na ƙarfe, musamman a yanayin zafi mai yawa. Mo kuma yana taimakawa wajen inganta ƙarfin rarrafe na kayan, wato ikon tsayayya da nakasa a lokacin da ake ɗaukar zafi na dogon lokaci.

Halayen Tashin Hankali

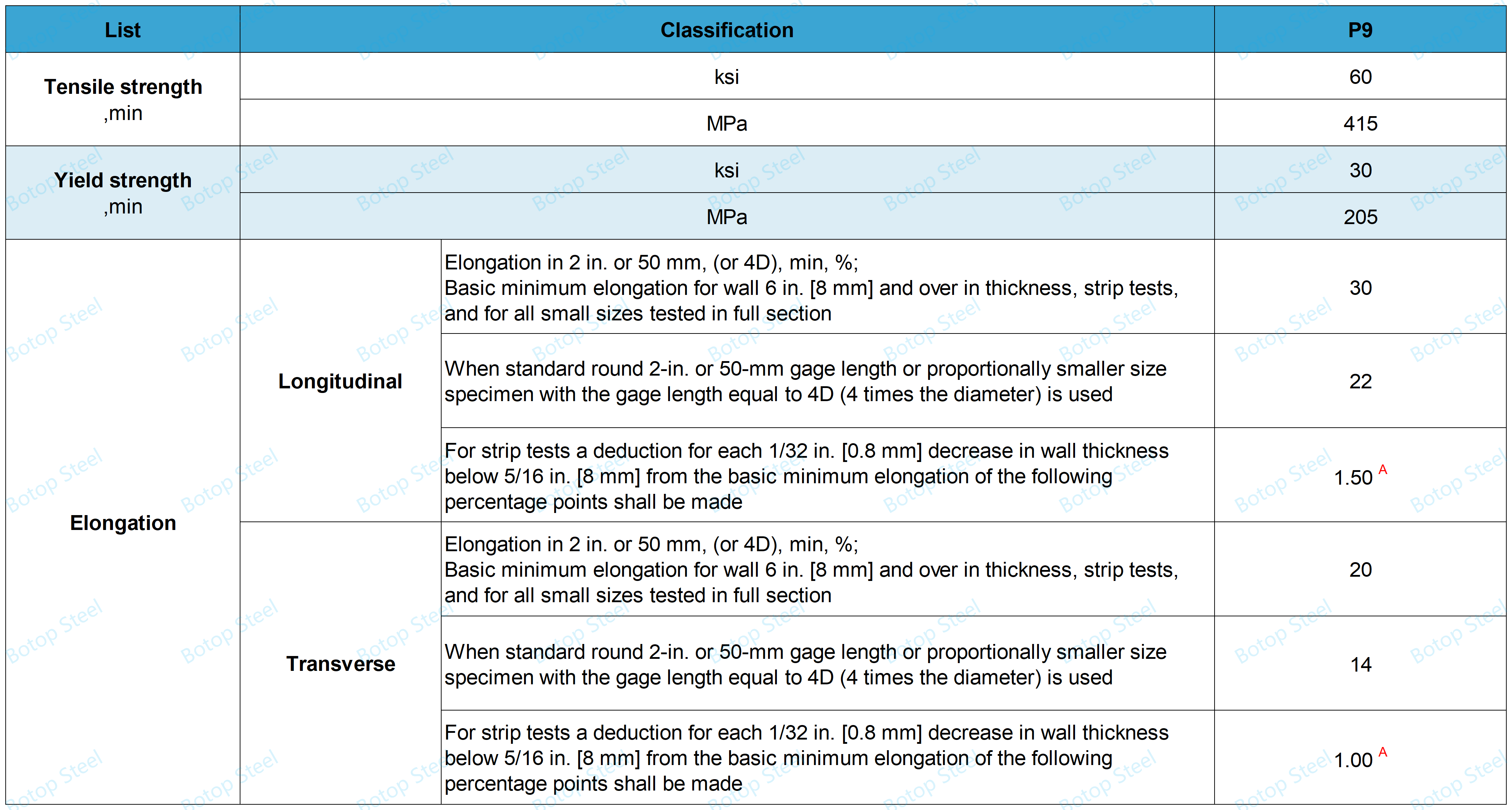

P5, P5b, P5c, P9,P11, P15, P21, da P22: Ƙarfin juriya da ƙarfin yawan amfanin ƙasa iri ɗaya ne.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, da P22: Tsawon lokaci ɗaya.

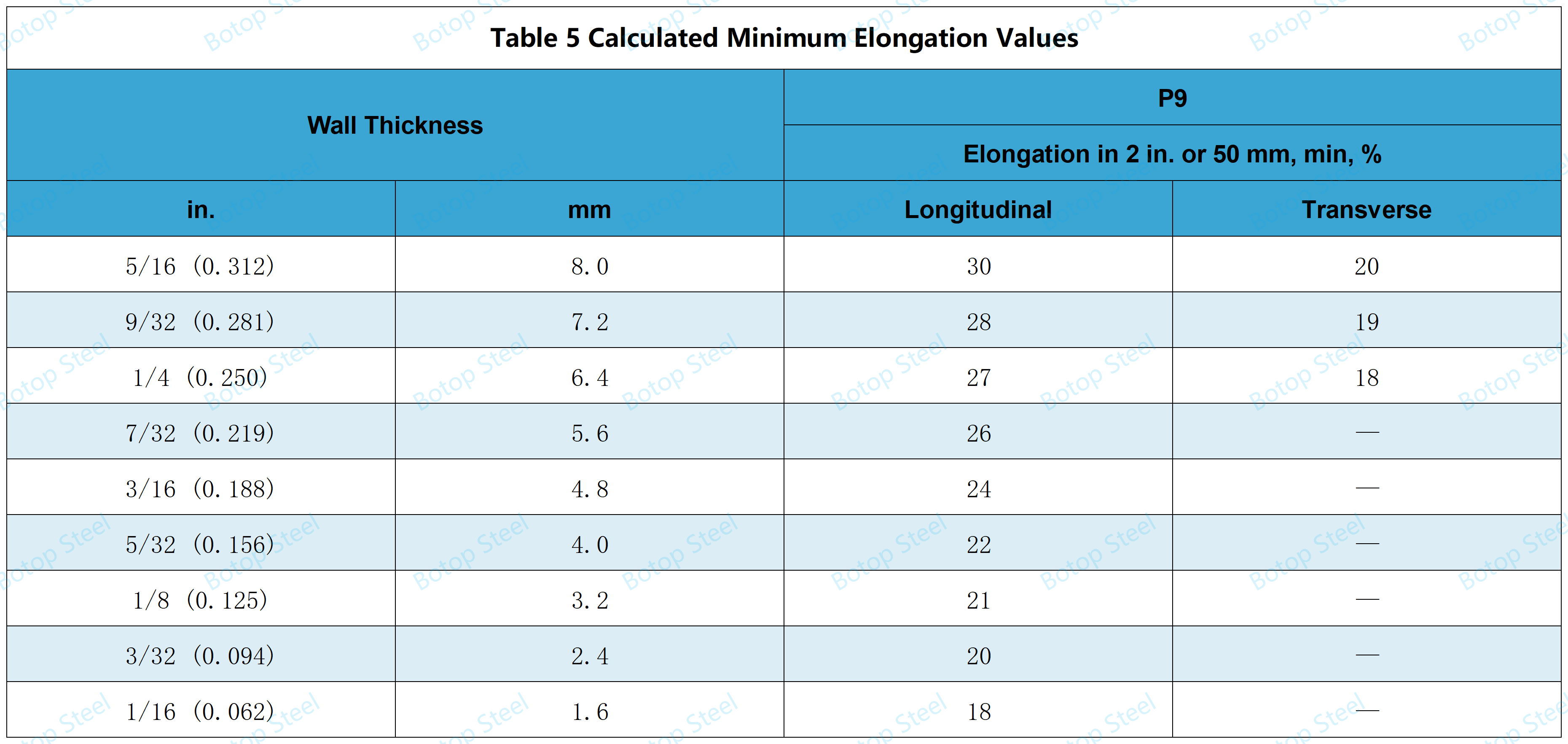

ATebur na 5 ya ba da ƙimar da aka ƙididdige mafi ƙarancin.

Inda kauri bango yake tsakanin dabi'u biyu da ke sama, mafi ƙarancin ƙimar tsawaitawa ana ƙayyade shi ta hanyar dabarar da ke ƙasa:

Tsawon Lokaci, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Mai juyawa, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

inda:

E = tsawaitawa a cikin inci 2 ko 50 mm, %,

t = ainihin kauri na samfuran, a cikin. [mm].

Tauri

P9 baya buƙatar gwajin tauri.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, da P921: Ba a buƙatar gwajin tauri.

Idan diamita na waje ya fi inci 10 [250 mm] da kauri na bango ≤ inci 0.75 [19 mm], duk za a gwada su ta hanyar amfani da hydrostatic.

Ana iya ƙididdige matsin lambar gwaji ta amfani da lissafin da ke ƙasa.

P = 2St/D

P= matsin lamba na gwajin hydrostatic a cikin psi [MPa];

S= matsin lamba a bangon bututu a cikin psi ko [MPa];

t= kauri na bango da aka ƙayyade, kauri na bango bisa ga lambar jadawalin ANSI da aka ƙayyade ko kuma sau 1.143 mafi ƙarancin kauri na bango da aka ƙayyade, in. [mm];

D= diamita ta waje da aka ƙayyade, diamita ta waje da ta yi daidai da girman bututun ANSI da aka ƙayyade, ko diamita ta waje da aka ƙididdige ta hanyar ƙara 2t (kamar yadda aka bayyana a sama) zuwa diamita ta ciki da aka ƙayyade, in. [mm].

Lokacin gwaji: kiyaye aƙalla 5s, babu ɓuɓɓuga.

Idan ba za a yi gwajin bututun ruwa ba, za a yi gwajin da ba zai lalata ba a kan kowace bututu domin gano lahani.

Ya kamata a yi gwajin kayan P9 mara lalata ta hanyar ɗayan hanyoyinE213, E309 or E570.

E213: Yi gwajin Ultrasonic na bututun ƙarfe da bututun ƙarfe;

E309: Yin gwaji na Eddy na yanzu na samfuran ƙarfe ta amfani da Magnetic Saturation;

E570: Aikin Binciken Zubar da Ruwa na Kayayyakin Tubular Karfe Mai Suna Ferromagnetic;

Bambancin da Za a Iya Yi a Diamita

Ana iya rarraba karkacewar diamita bisa ga ko dai 1. bisa ga diamita na ciki ko 2. bisa ga diamita mara suna ko na waje.

1. Diamita na ciki: ±1%.

2. NPS [DN] ko diamita na waje: Wannan ya yi daidai da karkacewar da aka yarda a cikin teburin da ke ƙasa.

Bambancin da Aka Yarda a Kauri Bango

Kauri na bangon bututu a kowane lokaci ba zai wuce ƙayyadadden haƙuri ba.

Mafi ƙarancin kauri na bango da diamita na waje don dubawa don bin wannan buƙata ta bututun da NPS [DN] ta umarta da lambar jadawali an nuna a cikinASME B36.10M.

Abubuwan da ke cikin alamar: Sunan masana'anta ko alamar kasuwanci; lambar misali; daraja; tsayi da ƙarin alamar "S".

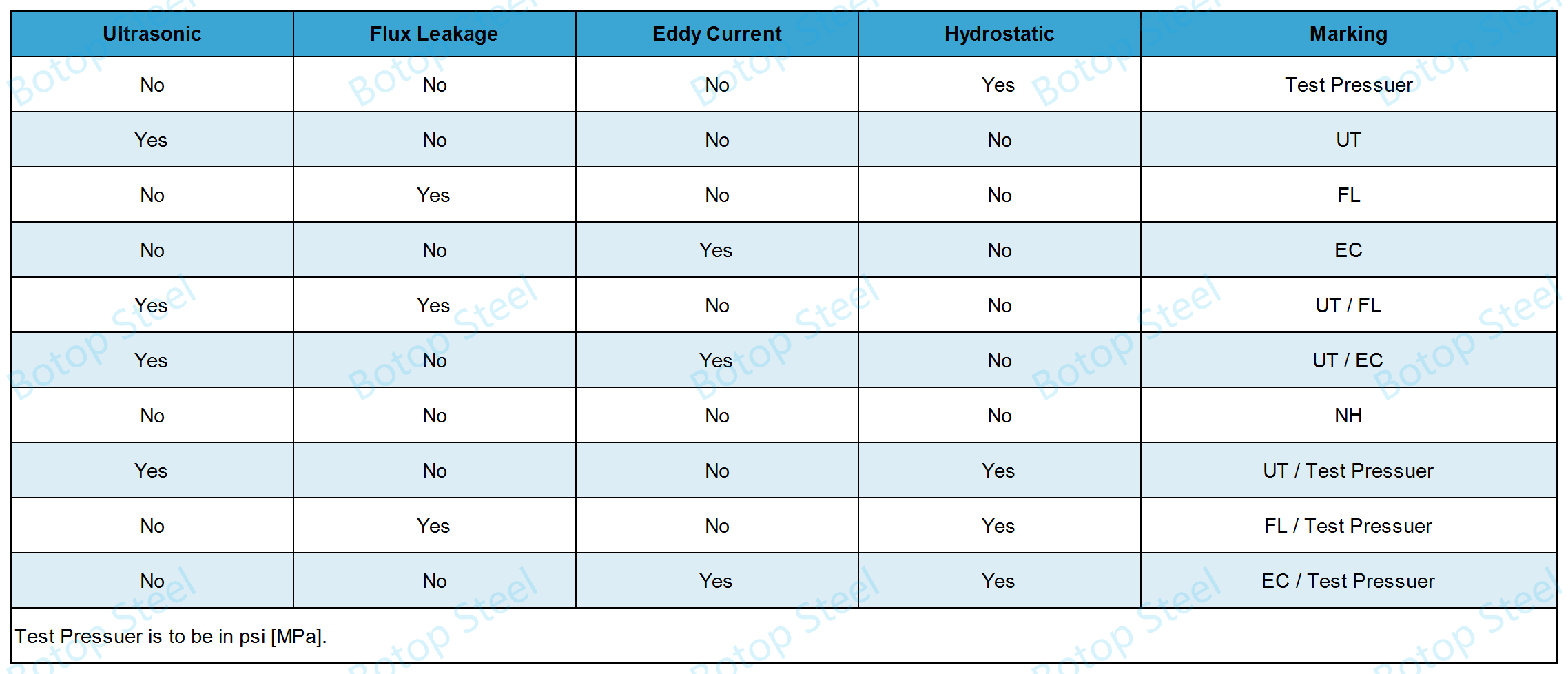

Ya kamata a haɗa da alamun matsin lamba na hydrostatic da gwajin da ba ya lalatawa a cikin teburin da ke ƙasa.

Wurin yin alama: Ya kamata a fara yin alama da misalin inci 12 (mm 300) daga ƙarshen bututun.

Ga bututun da suka kai tsawon NPS 2 ko ƙasa da ƙafa 3 (mita 1), ana iya haɗa alamar bayanin da alamar.

Ana amfani da bututun ƙarfe na ASTM A335 P9 sosai a cikin tukunyar ruwa, tashoshin wutar lantarki na kayan aikin mai, da sauransu, waɗanda ke buƙatar jure yanayin zafi mai yawa da matsin lamba mai yawa saboda yanayin zafinsa mai kyau da juriyarsa mai yawa.

Tafasassun ruwaMusamman a cikin manyan bututun tururi da na sake dumama bututun mai na supercritical da ultra-critical boilers don yanayin zafi da matsin lamba mai yawa.

Kayan aikin mai: Kamar bututun cracker da bututun mai yawan zafin jiki, waɗanda ke sarrafa tururin da sinadarai masu yawan zafin jiki, suna buƙatar kayan da ke da kyakkyawan juriya ga zafin jiki da tsatsa.

Tashoshin wutar lantarki: Don manyan bututun tururi da masu dumama mai matsin lamba, da kuma bututun turbine na ciki don jure wa yanayin zafi da matsin lamba mai tsawo.

Kayan aiki na P9 suna da nasu ma'auni na yau da kullun a cikin tsarin daidaitattun ƙasashe daban-daban.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

GOST 550: 12ChM;

Kafin a zaɓi wani abu makamancin haka, ana ba da shawarar a yi cikakken kwatancen aiki da gwaji don tabbatar da cewa madadin kayan zai cika buƙatun ƙirar asali.

Tun lokacin da aka kafa ta a shekarar 2014,Botop Karfeya zama babban mai samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli.

Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa sulɓi, da kuma cikakken jerin kayan haɗin bututu da flanges. Kayayyakinsa na musamman sun haɗa da ƙarfe masu inganci da ƙarfe marasa austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.

Da fatan za ku iya tuntubar mu idan kuna da wasu buƙatu ko tambayoyi game da bututun ƙarfe. Muna fatan samun bayananku kuma muna fatan taimaka muku.