ASTM A335 P91, wanda kuma aka sani daASME SA335 P91, bututun ƙarfe ne mai laushi wanda ba shi da matsala don hidimar zafi mai yawa, UNS No. K91560.

Yana da mafi ƙarancinƘarfin tensile na 585 MPa(85 ksi) da mafi ƙarancinƘarfin yawan amfanin ƙasa na 415 MPa(ksi 60).

P91galibi yana ƙunshe da abubuwan haɗin gwiwa kamar chromium da molybdenum, kuma ana ƙara wasu abubuwa masu haɗin gwiwa, waɗanda suka haɗa daƙarfe mai ƙarfi, don haka yana da ƙarfi sosai da kuma juriya mai kyau ga tsatsa.

Bugu da ƙari, P91 yana samuwa a cikin nau'i biyu,Nau'i na 1kumaNau'i na 2, kuma ana amfani da shi sosai a masana'antun wutar lantarki, matatun mai, kayan aiki masu mahimmanci na cibiyoyin sinadarai, da kuma bututun mai a cikin yanayi mai zafi da matsin lamba mai yawa.

An rarraba bututun ƙarfe na P91 zuwa nau'i biyu, Nau'i na 1 da Nau'i na 2.

Duk nau'ikan biyu iri ɗaya ne dangane da halayen injiniya da sauran buƙatu kamar maganin zafi,tare da ƙananan bambance-bambance a cikin abun da ke cikin sinadarai da kuma takamaiman mai da hankali kan aikace-aikacen.

Sinadarin sinadarai: Idan aka kwatanta da Nau'i na 1, sinadaran da ke cikin Nau'i na 2 sun fi tsauri kuma sun ƙunshi ƙarin abubuwan haɗin gwiwa don samar da ingantaccen juriya ga zafi da tsatsa.

Aikace-aikace: Saboda ingantaccen tsarin sinadarai, Nau'in 2 ya fi dacewa da yanayin zafi mai tsanani ko yanayin da ke lalata muhalli, ko kuma a aikace inda ake buƙatar ƙarfi da dorewa mai yawa.

Dole ne a sanya bututun ƙarfe na ASTM A335 a cikin bututun ƙarfebabu matsala.

Tsarin kera kayayyaki mara matsala an rarraba shi zuwa cikinƙare mai zafikumasanyi da aka jawo.

A ƙasa akwai zane na tsarin kammalawa mai zafi.

Musamman ma, P91, bututun ƙarfe mai yawan ƙarfe, wanda galibi ana amfani da shi a cikin mawuyacin yanayi wanda ke fuskantar yanayin zafi da matsin lamba mai yawa, bututun ƙarfe mara shinge yana da matsin lamba iri ɗaya kuma ana iya yin shi da kauri mai kauri, don haka yana tabbatar da aminci mafi girma da ingantaccen farashi.

P91 Dole ne a yi wa dukkan bututun magani da zafi don inganta tsarin bututun, inganta halayensa na injiniya, da kuma ƙara juriya ga zafin jiki da matsin lamba mai yawa.

| Matsayi | Nau'in Maganin Zafi | Daidaita Zafin Jiki | Zafin Zafin Jiki |

| Nau'in P91 na 1 da Nau'in 2 | normalize da kuma daidaita yanayin ko | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 ~ 1470 ℉ [730 - 800 ℃] |

| rage kiba da kuma rage kiba | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 - 1470 ℉ [730 - 800 ℃] |

Sinadaran P91 Nau'in 1

| Matsayi | Abun da aka haɗa, % | ||||||

| Nau'in P91 1 | C | Mn | P | S | Si | Cr | Mo |

| 0.08 - 0.12 | 0.30 - 0.60 | matsakaicin 0.020 | 0.010 mafi girma | 0.20 - 0.50 | 8.00 - 9.50 | 0.85 - 1.05 | |

| V | N | Ni | Al | Nb | Ti | Zr | |

| 0.18 - 0.25 | 0.030 - 0.070 | matsakaicin 0.40 | 0.02 mafi girma | 0.06 - 0.10 | 0.01 mafi girma | 0.01 mafi girma | |

Sinadaran P91 Nau'in 2

| Matsayi | Abun da aka haɗa, % | ||||||

| Sinadaran Samfurin P91 Nau'in 2 | C | Mn | P | S | Si | Cr | Mo |

| 0.07 - 0.13 | 0.30 - 0.50 | matsakaicin 0.020 | matsakaicin 0.005 | 0.20 - 0.40 | 8.00 - 9.50 | 0.80 - 1.05 | |

| V | Ni | Al | N | Rabon N/Al | Nb | Ti | |

| 0.16 - 0.27 | 0.20 mafi girma | 0.02 mafi girma | 0.035 - 0.070 | ≥ 4.0 | 0.05 - 0.11 | 0.01 mafi girma | |

| Zr | Sn | Sb | As | B | W | Cu | |

| 0.01 mafi girma | 0.01 mafi girma | 0.003 mafi girma | 0.01 mafi girma | matsakaicin 0.001 | matsakaicin 0.05 | 0.10 mafi girma | |

Da hotunan biyu da ke sama, yana da sauƙin ganin bambanci tsakanin sinadaran Type 1 da Type 2 da kuma ƙuntatawa.

1. Kadarar Tashin Hankali

Ana amfani da gwajin tensile akai-akai don auna ma'auninƙarfin yawan amfanin ƙasa, ƙarfin juriya, kumamai tsayin na shirin gwaji na bututun ƙarfe, kuma ana amfani da shi sosai a cikin kayan aikin gwajin.

| Nau'in P91 na 1 da Nau'in 2 | |||

| Ƙarfin tauri | 85 ksi [585 MPa] minti | ||

| Ƙarfin bayarwa | 60 ksi [415 MPa] minti | ||

| Ƙarawa | Bukatun Ƙarawa | Tsawon lokaci | Mai wucewa |

| Tsawaita a cikin inci 2 ko 50 mm, (ko 4D), minti, %; Mafi ƙarancin tsawaitawa na asali don kauri na bango mai inci 6 [8 mm] ko sama da haka, gwaje-gwajen tsiri, da kuma ga duk ƙananan girma dabam-dabam da aka gwada a cikakken sashe | 20 | — | |

| Lokacin da aka yi amfani da daidaitaccen tsawon ma'aunin zagaye mai inci 2 ko 50 mm ko ƙaramin samfurin girman da ya yi daidai da 4D (sau 4 diamita) | 20 | 13 | |

| Ga gwaje-gwajen tsiri, za a yi ragi ga kowane inci 1/32 [0.8 mm] a raguwar kauri a bango ƙasa da inci 5/16 [8 mm] daga mafi ƙarancin tsawaitawa na maki masu zuwa. | 1 | — | |

2. Taurin kai

Ana iya amfani da hanyoyi daban-daban na gwajin tauri, ciki har da Vickers, Brinell, da Rockwell.

| Matsayi | Brinell | Vickers | Rockwell |

| Nau'in P91 na 1 da Nau'in 2 | 190 - 250 HBW | 196 - 265 HV | 91 HRBW - 25HRC |

Kauri bango <0.065 inci [1.7 mm]: Ba a buƙatar gwajin tauri;

Inci 0.065 [1.7 mm] ≤ kauri na bango <0.200 inci. [5.1 mm]: Za a yi amfani da gwajin taurin Rockwell;

Kauri daga bango ≥ inci 0.200 [5.1 mm]: amfani da gwajin taurin Brinell ko gwajin taurin Rockwell ba tare da wani zaɓi ba.

Gwajin taurin Vickers ya shafi dukkan kauri na bututun bango. Ana gudanar da hanyar gwajin ne bisa ga buƙatun E92.

3. Gwajin Faɗi

Za a gudanar da gwaje-gwajen ne bisa ga Sashe na 20 na ƙa'idar ASTM A999.

4. Gwajin Lanƙwasa

Lanƙwasa 180° a zafin ɗaki, kada a sami tsagewa a wajen ɓangaren da aka lanƙwasa.

Girma > NPS25 ko D/t ≥ 7.0: Ya kamata a yi gwajin lanƙwasa ba tare da gwajin lanƙwasa ba.

5. Shirye-shiryen Gwaji na Zaɓaɓɓu na P91

Ba a buƙatar waɗannan abubuwan gwaji a gwaje-gwajen ba, idan ya cancanta za a iya tantance su ta hanyar tattaunawa.

S1: Nazarin Samfura

S3: Gwajin Faɗin Ƙasa

S4: Gwaje-gwajen Tsarin Karfe da Ƙirƙirar Ƙarfe

S5: Hotunan micrographs

S6: Hotunan micrographs don Guda ɗaya

S7: Madadin Maganin Zafi-Matsayin P91 Nau'i na 1 da Nau'i na 2

Gwajin ruwa na P91 zai cika waɗannan buƙatu.

Diamita na waje >in 10 [250mm] da kauri na bango ≤ inci 0.75 [19mm]: wannan ya kamata ya zama gwajin hydrostatic.

Sauran girma dabam dabam don gwajin lantarki mara lalatawa.

Ga bututun ƙarfe na ferritic da bututun ƙarfe na bakin ƙarfe, bangon yana fuskantar matsin lamba na ba ƙasa da haka baKashi 60% na ƙayyadadden ƙarfin yawan amfanin ƙasa.

Za a ci gaba da matsin lamba na gwajin ruwa na akalla tsawon akalla 5sba tare da ɓuya ko wasu lahani ba.

Matsi na ruwaana iya ƙididdige shi ta amfani da dabarar:

P = 2St/D

P= matsin lamba na gwajin hydrostatic a cikin psi [MPa];

S = matsin lamba a bangon bututu a cikin psi ko [MPa];

t = kauri na bango da aka ƙayyade, kauri na bango bisa ga lambar jadawalin ANSI da aka ƙayyade ko kuma sau 1.143 mafi ƙarancin kauri na bango da aka ƙayyade, in. [mm];

D = diamita ta waje da aka ƙayyade, diamita ta waje da ta yi daidai da girman bututun ANSI da aka ƙayyade, ko diamita ta waje da aka ƙididdige ta hanyar ƙara 2t (kamar yadda aka bayyana a sama) zuwa diamita ta ciki da aka ƙayyade, in. [mm].

Ana duba bututun P91 ta hanyar amfani da hanyar gwajin E213. Ma'aunin E213 ya fi mayar da hankali ne kan gwajin ultrasonic (UT).

Idan an ƙayyade shi musamman a cikin tsari, ana iya duba shi bisa ga hanyar gwajin E309 ko E570.

Ma'aunin E309 yawanci yana hulɗa da duba lantarki (eddy current), yayin da E570 hanya ce ta dubawa da ta shafi jerin wutar lantarki na eddy.

Bambancin da Za a Iya Yi a Diamita

Don bututun da aka yi odadiamita na ciki, diamita na ciki ba zai bambanta fiye da ±1% daga diamita na ciki da aka ƙayyade ba.

Bambancin da Aka Yarda a Kauri Bango

Za a yi ma'aunin kauri bango ta amfani da na'urorin gwaji na inji ko kuma na'urorin gwaji marasa lalata da aka daidaita da kyau, waɗanda suka dace da daidaito. Idan aka samu takaddama, ma'aunin da aka ƙayyade ta amfani da na'urorin aunawa na inji zai yi nasara.

An nuna mafi ƙarancin kauri na bango da diamita na waje don dubawa don bin wannan buƙata ta bututun da NPS [DN] ta umarta da lambar jadawali a cikinASME B36.10M.

Lalacewa

Ana ɗaukar kurakuran saman a matsayin lahani idan sun wuce kashi 12.5% na kauri na bango ko kuma sun wuce mafi ƙarancin kauri na bango.

Rashin daidaito

Alamun injiniya, gogewa, da ramuka, waɗanda duk wani lahani ya fi zurfin inci 1/16 [1.6 mm].

Ana bayyana alamun da gogewa a matsayin alamun kebul, ƙuraje, alamun jagora, alamun birgima, ƙyallen ƙwallo, maki, alamun mutuwa, da makamantansu.

Gyara

Ana iya cire lahani ta hanyar niƙawa, muddin kauri na bango da ya rage bai gaza mafi ƙarancin kauri na bango ba.

Ana iya yin gyare-gyare ta hanyar walda amma dole ne ya cika sharuɗɗan A999 masu dacewa.

Duk walda na gyara a cikin P91 za a yi su da ɗaya daga cikin hanyoyin walda da abubuwan amfani masu zuwa: SMAW, A5.5/A5.5M E90XX-B9:SAW, A5.23/A5.23M EB9 + kwararar tsaka-tsaki; GTAW, A5.28/A5.28M ER90S-B9; da FCAW A5.29/A5.29M E91TI-B9. Bugu da ƙari, jimlar abun ciki na Ni+Mn na duk abubuwan da ake amfani da su wajen walda da ake amfani da su don gyaran walda P91 Type 1 da Type 2 ba zai wuce 1.0% ba.

Ya kamata a yi wa bututun P91 magani a zafin 1350-1470 °F [730-800 °C] bayan an gyara walda.

Fuskar waje ta bututun ƙarfe da aka duba za ta ƙunshi waɗannan abubuwa:

Sunan mai ƙera ko alamar kasuwanci; lambar misali; daraja; tsayi da ƙarin alama "S".

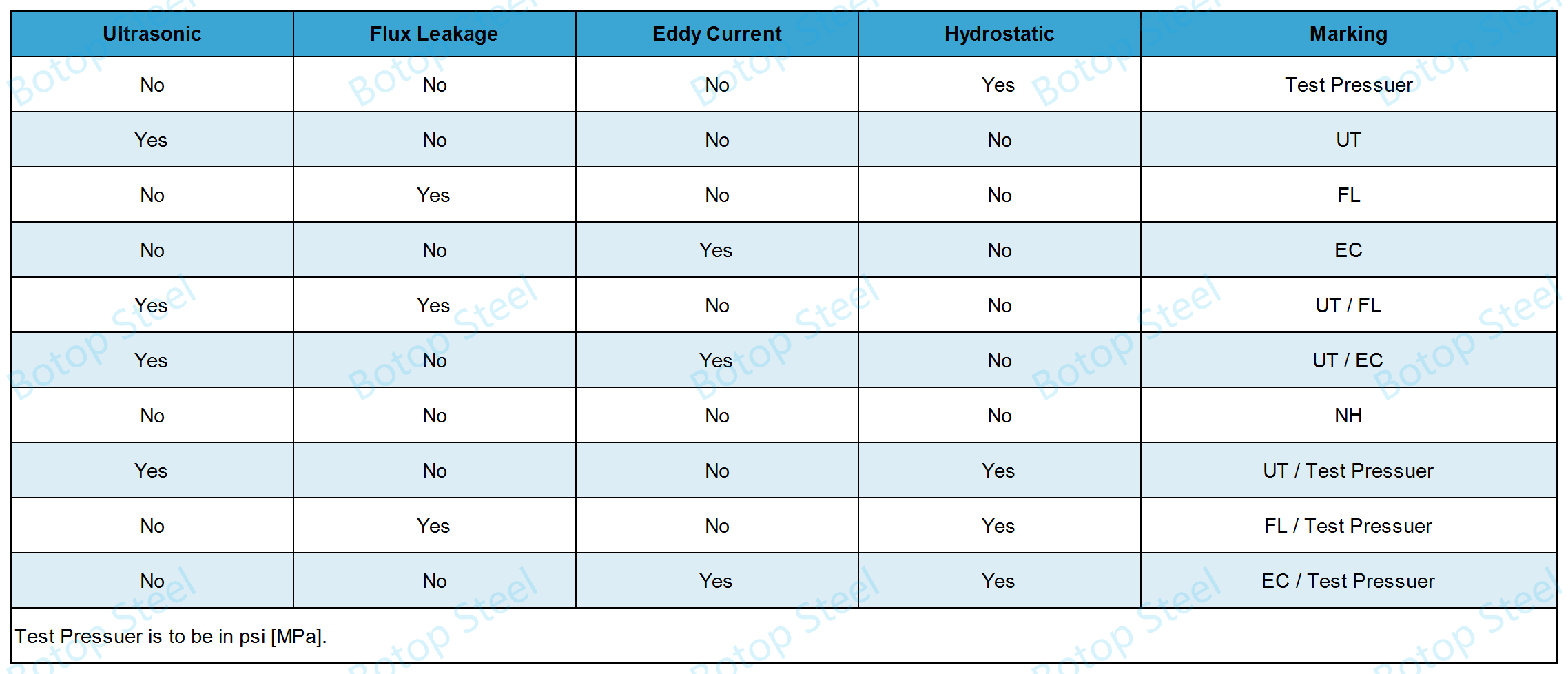

Ya kamata a haɗa da alamun matsin lamba na hydrostatic da gwajin da ba ya lalatawa a cikin teburin da ke ƙasa.

Idan an gyara bututun ta hanyar walda, za a yi masa alama "WR".

p91 Ya kamata a nuna nau'in (Nau'i na 1 ko Nau'i na 2).

| ASME | ASTM | EN | GB |

| ASME SA335 P91 | ASTM A213 T91 | EN 10216-2 X10CrMoVNb9-1 | GB/T 5310 10Cr9Mo1VNbN |

Abubuwal: bututun ƙarfe mara shinge na ASTM A335 P91;

OD: 1/8"- 24";

WT: daidai daASME B36.10buƙatu;

Jadawalin Jadawalin: SCH10, SCH20, SCH30,SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 da SCH160;

Ganowa:STD (misali), XS (ƙarfi mai yawa), ko XXS (ƙarfi mai yawa biyu);

Keɓancewa: Ana kuma samun girman bututun da ba na yau da kullun ba, ana samun girman da aka keɓance idan an buƙata;

Tsawon: Tsawon takamaiman da bazuwar;

Takaddun shaida na IBR: Za mu iya tuntuɓar ƙungiyar dubawa ta ɓangare na uku don samun takardar shaidar IBR bisa ga buƙatunku, ƙungiyoyin dubawa na haɗin gwiwarmu sune BV, SGS, TUV, da sauransu.

Ƙarshe: Ƙarshen bututu mai faɗi, mai yankewa, ko kuma mai haɗaka;

saman: Bututu mai sauƙi, fenti, da sauran kariya ta wucin gadi, cire tsatsa da gogewa, fenti mai galvanized da filastik, da sauran kariya ta dogon lokaci;

shiryawa: Akwatin katako, bel ɗin ƙarfe ko marufi na waya na ƙarfe, mai kare ƙarshen bututun filastik ko ƙarfe, da sauransu.