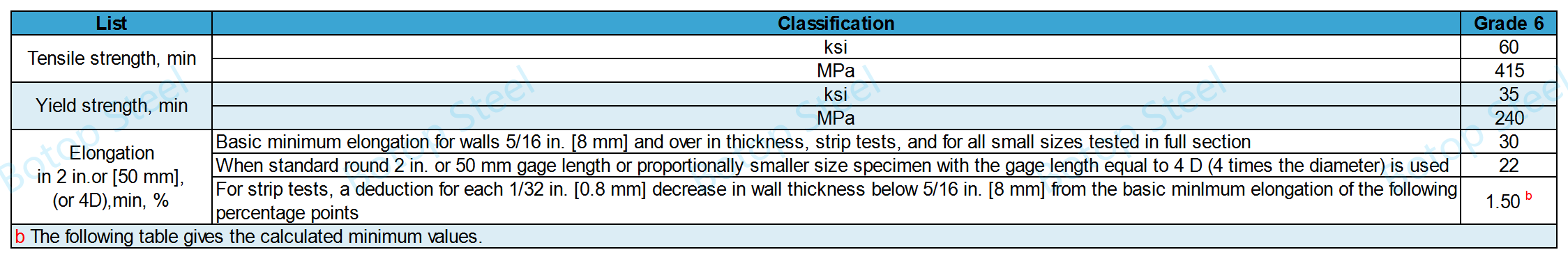

ASTM A334Aji na 6bututun ƙarfe ne mai ƙarfi, mai ƙarancin zafin jiki, tare da matsakaicin adadin carbon na 0.30%, abun ciki na manganese na 0.29-1.06%, mafi ƙarancin ƙarfin tauri na 415Mpa (60ksi), da ƙarfin yawan amfanin ƙasa na 240Mp (35ksi).

Ana amfani da shi galibi a fannin samar da iskar gas mai tsafta, injiniyancin sararin samaniya, da fasahar sanyaya, yana daidaitawa da yanayin zafi mai ƙarancin zafi.

ASTM A334ƙa'ida ce ta yau da kullun don bututun ƙarfe na carbon da ƙarfe masu laushi da aka haɗa don aikace-aikacen cryogenic.

Akwai matakai da yawa don biyan buƙatu daban-daban.

Aji na 1, Aji na 3, Aji na 6, Aji na 7, Aji na 8, Aji na 9, da Aji na 11.

Aji na 1kuma aji na 6 duka bututun ƙarfe ne na carbon.

Ana iya samar da bututun ƙarfe na ASTM A334 Grade 6 ta hanyar hanyoyin walda ko kuma na roba.

Tsarin walda ya haɗa da hanyoyi daban-daban kamarwalda mai juriya ga lantarki (ERW)kumawalda mai zurfi a ƙarƙashin ruwa (SAW).

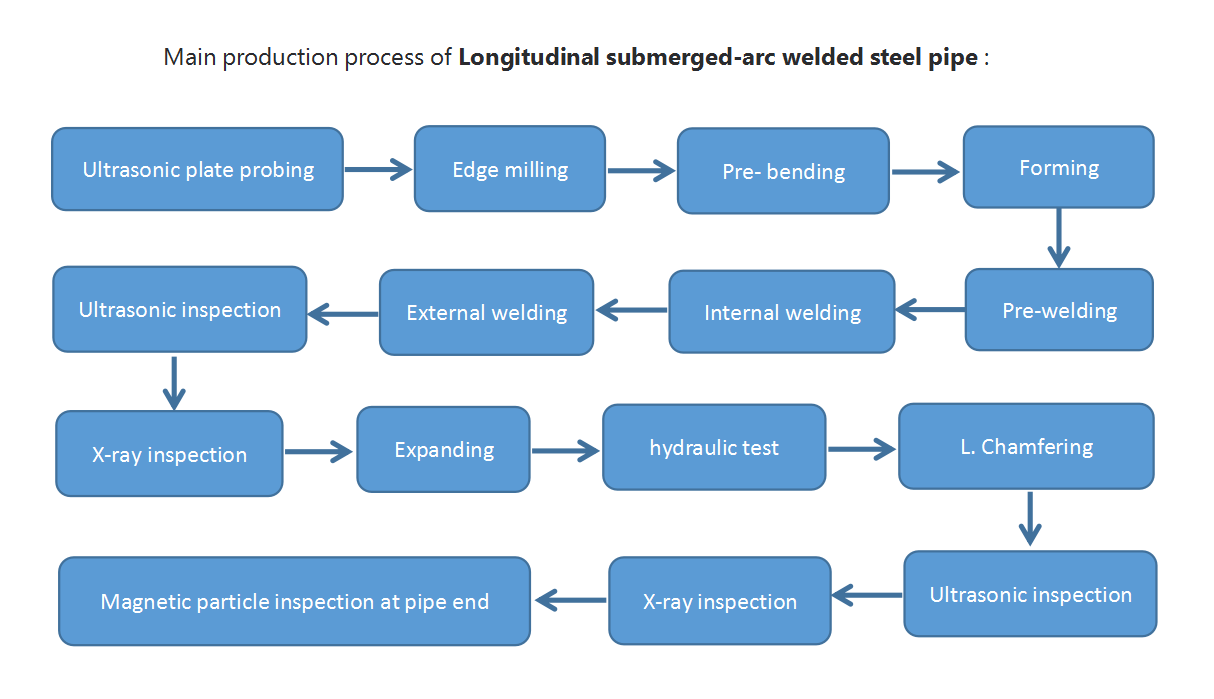

A ƙasa, akwai tsarin samarwa donWalda Mai Zurfin Ruwa Mai Tsawon Rai (LSAW).

A matsayinmu na masana'antun bututun ƙarfe masu walda, muna iya biyan buƙatun abokan cinikinmu daban-daban, muna ba da zaɓuɓɓukan samfura daban-daban don tabbatar da mafi kyawun aiki da inganci ga kowane aikace-aikace.

Walda ɗaya ta bututun LSAW tana inganta ƙarfin bututun gaba ɗaya, tana ba shi damar jure matsin lamba mai yawa.

Bugu da ƙari, ya dace da samar da bututun ƙarfe mai girman diamita da kauri wanda ya dace da buƙatun ASTM A334 Grade 6 a cikin manyan tsarin samar da masana'antu da makamashi, kamar gina manyan wuraren samar da iskar gas mai ruwa (LNG).

A lokaci guda, daidaitaccen tsarin sarrafawa yana tabbatar da daidaiton diamita na bututu da kauri na bango don ingantaccen aminci ga haɗi da hana zubewa a cikin tsarin bututu.

Daidaita ta hanyar dumama zuwa yanayin zafi iri ɗaya wanda bai gaza 1550 °F [845 °C] ba sannan a sanyaya a iska ko a cikin ɗakin sanyaya tanderu mai sarrafa yanayi.

Idan ana buƙatar yin gyaran fuska, dole ne a yi shawarwari.

An ƙera sinadarin sinadarin bututun ƙarfe na ASTM A334 Grade 6 don tabbatar da kyawawan halayen injiniya a ƙananan yanayin zafi da kuma isasshen ƙarfi don ingantaccen sabis a ƙarƙashin mawuyacin yanayi.

| Matsayi | C (Kabon) | Mn (Manganese) | P (Fosforus) | S (Sulfur) | Si (Silikon) |

| Aji na 6 | matsakaicin 0.30 | 0.29-1.06 | matsakaicin 0.025 | matsakaicin 0.025 | minti 0.10 |

| Ga kowace raguwar kashi 0.01% na carbon da ke ƙasa da kashi 0.30%, za a ba da damar ƙaruwar kashi 0.05% na manganese da ke sama da kashi 1.06% zuwa matsakaicin kashi 1.35% na manganese. | |||||

Ga ƙarfe na aji 1 ko na aji 6, ba a yarda a samar da matakan haɗa ƙarfe ga duk wani abu banda waɗanda ake buƙata a fili ba. Duk da haka, an yarda a ƙara abubuwan da ake buƙata don cire iskar gas daga ƙarfen.

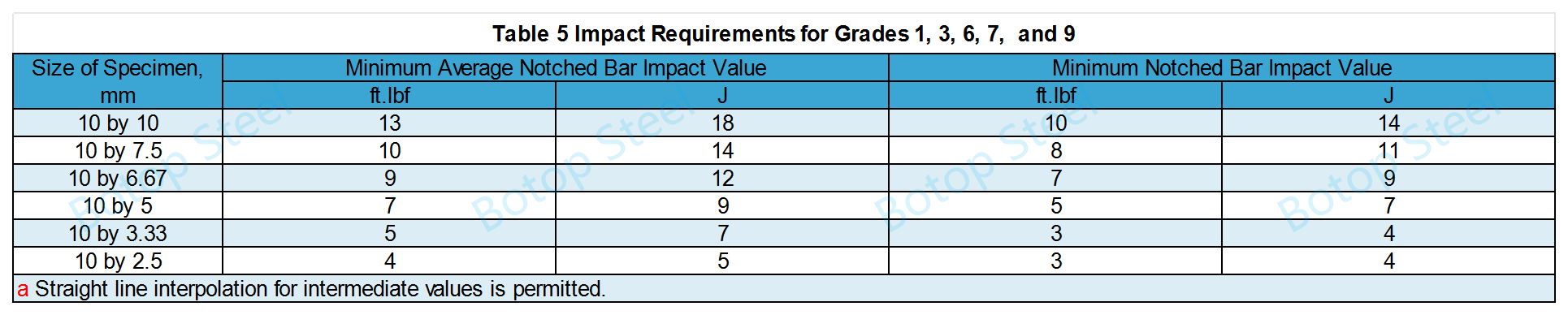

Ana gudanar da gwaje-gwajen tasiri akan bututun ƙarfe na Grade 6 a -45°C [-50°F] a matsayin hanyar tabbatar da tauri da juriyar tasirin kayan a cikin yanayin zafi mai ƙarancin zafi.

An gudanar da gwajin ta hanyar zaɓar ƙarfin tasirin da ya dace bisa ga kauri na bango na bututun ƙarfe.

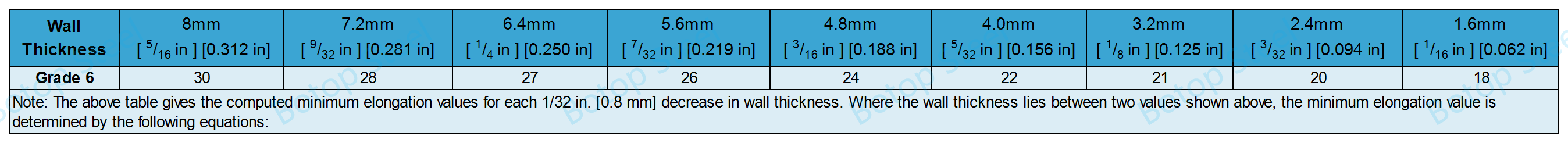

Ƙimar mafi ƙarancin tsawaitawa da aka ƙididdige ga kowace raguwar kauri na 1/32 in.[0.80 mm].

| Matsayi | Rockwell | Brinell |

| ASTM A334 Kashi na 6 | B 90 | 190 |

Za a gwada kowace bututu ta hanyar lantarki ko ta hanyar hydrostatic ba tare da lalata ta ba bisa ga Takamaiman Bayani na A1016/A1016M.

Sai dai idan an ƙayyade wani abu a cikin odar siyan, nau'in gwajin da za a yi amfani da shi zai kasance a zaɓin masana'anta.

Gwajin Faɗin Ƙasa

Gwajin Wuta (Bututun Ruwa Mara Sumul)

Gwajin Flange (Bututun Walda)

Gwajin Faɗin Juyawa

1. Cibiyoyin Iskar Gas Mai Iskar Gas (LNG): Saboda kyawawan halayensa na ƙarancin zafin jiki, ana amfani da bututun ƙarfe na aji 6 sosai a fannin samar da iskar gas, ajiya da jigilar kayayyaki. Waɗannan wuraren suna buƙatar kayan da ke kula da ƙarfi mai yawa da kuma kyakkyawan ƙarfi a yanayin zafi mai ƙanƙanta.

2. Tsarin jigilar mai da iskar gas: ana amfani da shi don jigilar hydrocarbons na ruwa ko iskar gas, kamar iskar gas mai ruwa (LPG) da sauran ruwaye masu ƙarancin zafin jiki a cikin yanayin zafi mai ƙarancin zafi.

3. Fasahar sanyaya da wuraren adana sanyi: Wannan kuma ya shafi wasu fannoni na fasahar sanyaya, kamar tsarin daskarewa da adanawa a cikin sanyi a fannin sarrafa abinci da sauran hanyoyin sinadarai waɗanda ke buƙatar aiki mai ƙarancin zafi.

4. Injiniyan Polar: A cikin ayyukan injiniya a yankunan da ke kewaye da teku, kamar tashoshin bincike na kimiyya a Arctic ko Antarctica, ana amfani da su don gina tsarin jigilar kaya masu karko da inganci waɗanda dole ne su iya jure yanayin sanyi mai tsanani da yanayin muhalli mai tsauri.

5. Tsarin sanyaya iska da na'urorin musanya zafi: Haka kuma ana amfani da shi a manyan tsarin sanyaya iska da na'urorin musanya zafi, waɗanda ke buƙatar yin aiki yadda ya kamata a ƙananan yanayin zafi don tabbatar da ingancin tsarin da aminci.

6. Injiniyan wutar lantarki da tashoshin wutar lantarki: A cikin ayyukan injiniyan wutar lantarki na musamman, kamar wasu nau'ikan tashoshin wutar lantarki, ana iya amfani da bututun ƙarfe na aji 6 don sarrafa ruwa ko iskar gas a yanayin zafi mai ƙarancin zafi don tabbatar da ingantaccen aiki na tsarin.

EN 10216-4:P265NL: Ana amfani da shi galibi don tasoshin matsin lamba na cryogenic da tsarin bututun cryogenic, yana da ƙarfi da ƙarfi mai kyau kuma ya dace da amfani a cikin mahalli na cryogenic.

DIN 17173:TTSt41N: An ƙera shi don aikace-aikacen ƙananan zafin jiki, yana ba da kyakkyawan aiki mai ƙarancin zafin jiki kuma ana amfani da shi sosai a cikin kayan aiki da bututu waɗanda ke buƙatar yanayin aiki mai ƙarancin zafin jiki.

JIS G3460:STPL46: Ana amfani da shi don tsarin jigilar bututun mai a cikin yanayin zafi mai ƙarancin zafi, wanda ke iya jure wasu tasirin zafi mai ƙarancin zafi da matsin lamba.

GB/T 18984:09Mn2V: Wannan kayan ya ƙware wajen kera bututun ƙarfe marasa shinge don amfani a cikin yanayin zafi mai ƙarancin zafi, tare da kyakkyawan tauri mai ƙarancin zafi da juriyar fashewa.

Lokacin zabar waɗannan kayan da suka yi daidai, yana da mahimmanci a tabbatar da cewa sinadaran da ke cikinsu da kuma halayen injina sun cika sharuɗɗan aikace-aikacen da ake buƙata da buƙatun aiki.

Ya kamata a kwatanta waɗannan sigogi dalla-dalla kuma ana iya buƙatar ƙarin gwaje-gwaje da hanyoyin ba da takardar shaida don tabbatar da dacewa da aikin kayan.

Tun lokacin da aka kafa kamfanin Botop Steel a shekarar 2014, kamfanin ya zama babban kamfanin samar da kayayyaki.bututun ƙarfe na carbona Arewacin China, an san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli. Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa matsala, da kuma cikakken jerin kayan haɗin bututu da flanges.

Kayayyakinta na musamman sun haɗa da ƙarfe masu inganci da ƙarfe masu bakin ƙarfe na austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.