| Sunan Samfuri | Bututun Karfe na Carbon/Bututun Karfe |

| Kayan Aiki | A53 GrB,A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65,X70 |

| Daidaitacce | API 5L, ASTM A106 Gr.B, ASTM A53 Gr.B, ASTMA179/A192, ASTM A335 P9, ASTM A210, ASTM A333 |

| Takaddun shaida | API 5L, ISO9001, SGS,BV,CCIC |

| Diamita na waje | 13.7mm-762mm |

| Kauri a Bango | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS |

| Tsawon | 1m, 4m, 6m, 8m, 12m bisa ga buƙatar mai siye |

| Maganin Fuskar | fenti baƙi, varnish, mai, galvanized, mai rufi mai hana lalata |

| Alamar | Alamar da aka saba, ko kuma bisa ga buƙatarku. Hanyar Alamar: Fesa fenti mai launin fari |

| Maganin Ƙarshe | Ƙarshen da aka sassaka/Ƙarshen da aka sassaka/Ƙarshen da aka sassaka/Ƙarshen da aka zare da murfi na filastik |

| Fasaha | Mai Birgima Mai Zafi ko Mai Sanyi ERW |

| Kunshin | Kunshin da aka sassauta; An saka shi cikin fakiti (Tan 2 Max); bututun da aka haɗa da majajjawa a ƙarshen biyudon sauƙin lodawa da fitar da kaya; katakolokuta; jakar saka mai hana ruwa |

| Gwaji | Binciken Sinadaran, Halayen Inji, Halayen Fasaha, Girman Waje Dubawa, gwajin na'ura mai aiki da ruwa, Gwajin X-ray |

| Aikace-aikace | Isarwa ta ruwa, bututun tsari, gini, fashewar mai, bututun mai, bututun iskar gas |

API 5L X42-X80, PSL1&PSL2 Mai da Iskar GasBututun Karfe mara sumulana amfani da shi wajen jigilar iskar gas, ruwa, da man fetur na masana'antar mai da iskar gas.

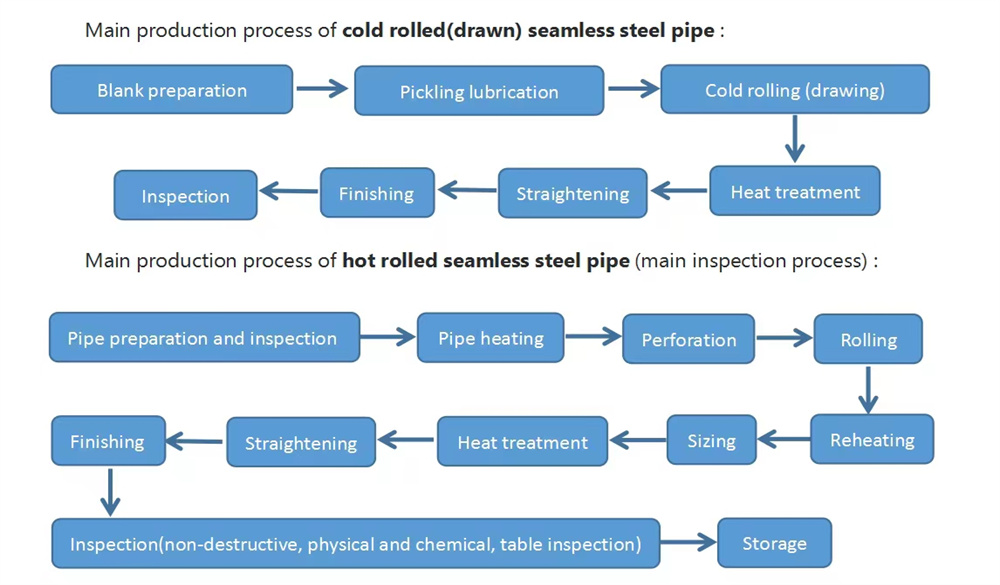

Ana yin bututun mai na API 5L X42-X80, PSL1&PSL2 na mai da iskar gas na Carbon mara sumul ko dai ta hanyar amfani da sanyi ko kuma na birgima mai zafi, kamar yadda abokan ciniki suka buƙata.

API 5L X52 PSL1&PSL2 Man Fetur da Iskar Gas Ana yin bututun ƙarfe mara sumul na Carbon ko dai ta hanyar jan sanyi ko kuma ta hanyar birgima mai zafi, yawanci ƙananan girma ana yin su ta hanyar jan sanyi, manyan girma kuma ana yin su ta hanyar birgima mai zafi.

Daraja da Sinadaran da Aka Haɗa (%)Don API 5L PSL1

| Daidaitacce |

Matsayi | Sinadarin sinadarai(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.28 | ≤1.30 | ≤0.030 | ≤0.030 |

| X46, X52, X56 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X60, X65 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X70 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X52 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

Daraja da Sinadaran da Aka Haɗa (%)Don API 5L PSL2

| Daidaitacce |

Matsayi | Sinadarin sinadarai(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.24 | ≤1.30 | ≤0.025 | ≤0.015 |

| X46, X52, X56 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X60, X65 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X70,X80 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X52 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

Halayen Inji na API 5L GR.B X42-X80/X52(PSL1):

| Matsayi | Ƙarfin Ba da Kyauta(MPa) | Ƙarfin Taurin Kai(MPa) | Ƙarawa A% | ||

|

| psi | MPa | psi | MPa | Tsawo (Ƙananan) |

| X42 | 42,000 | 290 | 60,000 | 414 | 21~27 |

| X46 | 46,000 | 317 | 63,000 | 434 | 20~26 |

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

| X56 | 56,000 | 386 | 71,000 | 490 |

|

| X60 | 60,000 | 414 | 75,000 | 517 |

|

| X65 | 65,000 | 448 | 77,000 | 531 |

|

| X70 | 70,000 | 483 | 82,000 | 565 |

|

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

Halayen Inji na API 5L/X52Bututun Layin GR.B Mara Sumul (PSL2):

| Matsayi | Ƙarfin Ba da Kyauta(MPa) | Ƙarfin Taurin Kai(MPa) | Ƙarawa A% | Tasiri (J) | ||

|

| psi | MPa | psi | MPa | Tsawo (Ƙananan) | Minti |

| X42 | 290 | 496 | 414 | 758 | 21~27 | 41(27) |

| X46 | 317 | 524 | 434 | 758 | 20~26 | 41(27) |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27) |

| X56 | 386 | 544 | 490 | 758 |

|

|

| X60 | 414 | 565 | 517 | 758 |

|

|

| X65 | 448 | 600 | 531 | 758 |

|

|

| X70 | 483 | 621 | 565 | 758 |

|

|

| X80 | 552 | 690 | 621 | 827 |

| |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27) |

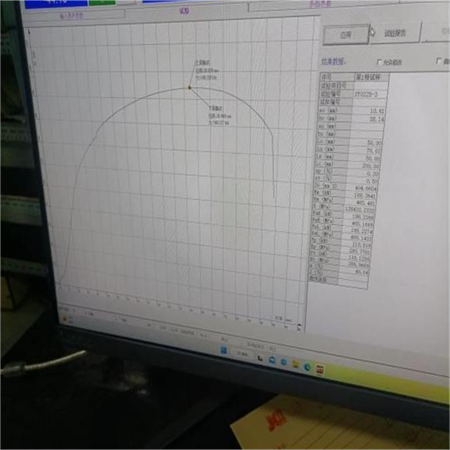

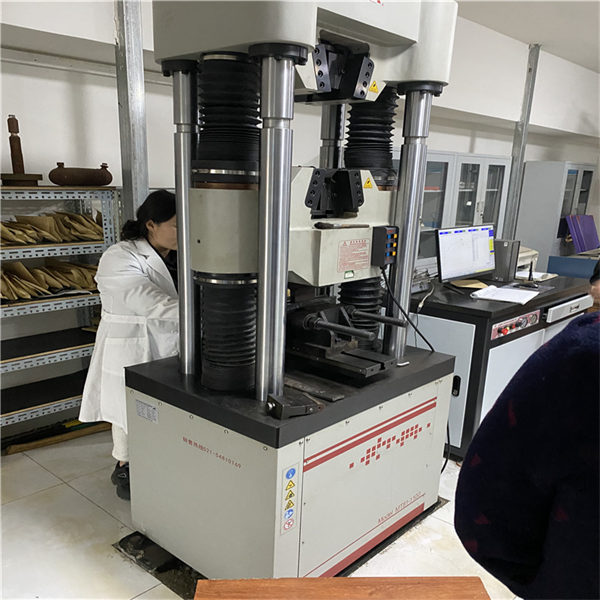

Gwajin Inji

Gwajin Tauri

Gwajin Lanƙwasa

Gwajin tensile na jikin bututun—Ya kamata a yi gwajin tensile bisa ga ISO6892 ko ASTM A370. Ya kamata a yi amfani da samfuran tsayi. Sau biyu a kowace na'urar gwaji ta bututu tare da rabon faɗaɗa sanyi da abd iri ɗaya.

Gwajin Faɗi—Za a yi gwajin faɗi ɗaya akan samfura daga kowane ƙarshen bututu biyu da aka zaɓa daga kowane fili

Gwajin tasirin CVN—Ya kamata a yi gwajin Charpy bisa ga ASTM A370. Sau biyu a kowace na'urar gwaji wadda ba ta wuce tsawon bututu 100 ba tare da rabon faɗaɗa sanyi da abd iri ɗaya.

Gwajin Tauri—Idan aka gano alamun tauri ta hanyar duba gani, za a yi gwajin tauri bisa ga ISO 6506, ISO 6507, ISO 6508 ko ASTM A 370 ta amfani da kayan aikin gwajin tauri da hanyoyin da suka dace da ASTM A 956, ASTM A 1038 ko ASTM E 110 bi da bi, ya danganta da hanyar da aka yi amfani da ita.

Gwajin Hydro-static—Kowane bututu za a yi masa gwajin matsin lamba na hydro-static

Gwajin Lanƙwasawa - tsawon bututu mai isasshen tsayi zai tsaya yayin da aka lanƙwasa shi a cikin sanyi har zuwa digiri 90 a kusa da mandrel mai siffar silinda.

Gwajin X-ray 100% don dinkin walda

Gwajin Ultrasonic

Jarrabawar Eddy Current

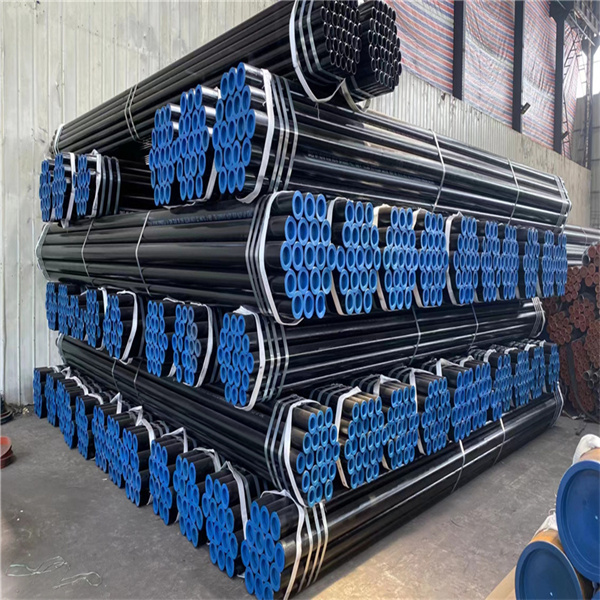

Bututun da ba a iya gani ko kuma shafa mai baƙi/varnish (bisa ga buƙatun abokin ciniki);

6" da ƙasa a cikin fakiti tare da majajjawa biyu na auduga;

Duk ƙarshen biyu tare da masu kare ƙarshen;

Ƙarshen fili, ƙarshen bevel (2" da sama da ƙarshen bevel, digiri: 30 ~ 35°), zare da haɗin kai;

Alamar.

| Girman | Juriya (tare da girmamawa)t to takamaiman wajediamita) |

| <2 3/8 | + inci 0.016, - inci 0.031 (+ 0.41 mm, - 0.79 mm) |

| > 2 3/8 da ≤4 1/2, an haɗa shi da welded akai-akai | ±1.00% |

| > 2 3/8 da < 20 | ±0.75% |

| > 20. babu matsala | ± 1.00% |

| >20 da <36, an haɗa su | + 0.75%.-0.25% |

| > 36, an haɗa shi da walda | + 1/4 inci.. - 1/8 inci. (+ 6.35 mm, -3.20 mm) |

Idan aka gwada bututun da ruwa ya yi amfani da shi wajen matsi fiye da matsin lamba na gwaji na yau da kullun, ana iya amincewa da wasu jurewar tsakanin masana'anta da mai siye.

| Ba a Zagaye Ba | |||||

| Girman | Rage haƙuri | Ƙari haƙuri | Juriya Daga Ƙarshe Zuwa Ƙarshe | Diamita, Juriyar Axis (Kashi na OD da aka ƙayyade) | Bambancin Mafi Girma Tsakanin Mafi Girma da Mafi Girma (Ya shafi Bututu Mai D/t≤75 kawai) |

| ≤10 3/4 lita da V4 | 1/64(0.40mm) | 1/16(1.59mm) | — | — | |

| >10 3/4 da ≤20 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | — | — | — |

| > 20 da ≤ 42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | <0.500 inci (12.7 mm) |

| >42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | £ Q625 inci (15.9 mm) |

Juriyar da ba ta zagaye ba ta shafi matsakaicin diamita da mafi ƙarancin diamita kamar yadda aka auna ta da ma'aunin sanda, caliper, ko na'urar da ke auna ainihin matsakaicin diamita da mafi ƙarancin diamita.

Matsakaicin diamita (kamar yadda aka auna da tef ɗin diamita) na ƙarshen bututu ɗaya ba zai bambanta da fiye da inci 3/32 (2.38 mm) daga na ɗayan ƙarshen ba.

| Girman | Nau'in Bututu | Juriya1 (Kashi na Kauri na Bango da aka ƙayyade} | |

| Aji B ko Ƙasa | Aji X42 ko sama da haka | ||

| <2 7/8 | Duk | +20.- 12.5 | + 15.0.-12.5 |

| >2 7/8 kuma <20 | Duk | + 15,0,-12.5 | + 15-I2.5 |

| >20 | An haɗa | + 17.5.-12.5 | + 19.5.-8.0 |

| >20 | Ba shi da sumul | + 15.0.-12.5 | + 17.5.-10,0 |

Idan mai siye ya ƙayyade juriyar rashin daidaito fiye da waɗanda aka lissafa, za a ƙara haƙuri mai kyau zuwa jimlar haƙurin da aka yi amfani da ita a cikin kashi ƙasa da kauri na juriyar rashin daidaito.

| Adadi | Tohaƙuri (kashi) |

| Tsawonsa ɗaya, bututu na musamman mai faɗi ko bututun A25Tsawon guda ɗaya, sauran bututuNauyin mota.Grade A25,40,000lb(18 144kg) ko fiyeNauyin motoci, banda Grade A25,40.0001b (18 144 kg) ko fiyeNauyin motoci, duk matakan da ba su kai lb 40000 ba (kilogiram 18 144) Yi odar kayayyaki. Matsayi A25. 40,000 lb (18 144 kg) ko fiye Yi odar kayayyaki, banda Grade A25,40,000 lb (18 144 kg) ko fiye Yi odar kayayyaki, duk maki, ƙasa da 40,000 lb (18 144 kg) | + 10.-5.0 + 10,- 35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Bayanan kula:

1. Juriyar nauyi tana aiki ga nauyin da aka ƙididdige na bututun da aka zare da aka haɗa da kuma nauyin da aka lissafa ko aka ƙididdige na bututun da ba shi da tushe. Idan mai siye ya ƙayyade juriyar kauri bango mara kyau fiye da waɗanda aka lissafa a cikin teburin da ke sama, ƙarin juriyar nauyi don tsayi ɗaya za a ƙara zuwa kashi 22.5 cikin ɗari ƙasa da juriyar kauri mara tushe.

2. Ga kayan da aka yi da bututu daga fiye da abu ɗaya na oda, za a yi amfani da juriyar kayan da aka yi bisa ga kayan da aka yi oda.

3. Juriyar kayayyakin oda ta shafi jimillar adadin bututun da aka aika don kayan oda.