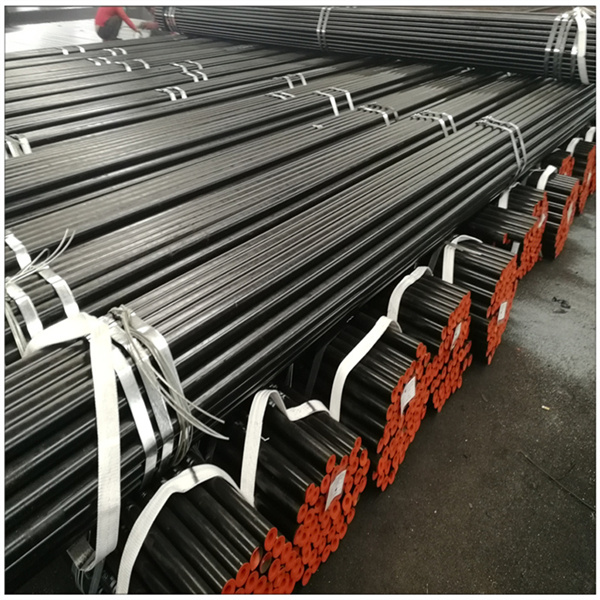

| Sunan Samfuri | Bututun Karfe Mara Sumul / Ms |

| Daidaitacce | ASTM A106, ASTM A53, API 5L Gr.B, DIN17175, DIN1629 |

| Diamita na waje: | 13.7mm-762mm |

| Kauri a Bango | 2mm-80mm |

| Haƙuri tsakanin Dia | Sarrafa tare da a cikin misali, OD:+-1%,WT:+-10% |

| Kayan Aiki | 10#,20#,45#,16Mn,A106(B,C),A53(A,B),API 5L (GR.B,X42/X52/X56/X65) API 5CT(H40,J55,K55,N80,P110),Q235,Q345,ST35.8,ST37,ST42,ST45,ST52 |

| Dubawa | ISO, BV, SGS, MTC |

| shiryawa | Zane mai launin 3LPE/3PP/FBE/BAƘI/VARNISH, da kuma zare mai ƙarfe, Kunshin da ya dace da fitarwa na yau da kullun, ko kuma kamar yadda ake buƙata |

| Ikon Samarwa | Tan 1000 na metric/wata |

| Matsakaicin kudin shiga (MOQ) | Tan 5metric, an karɓi odar samfurin |

| Lokacin jigilar kaya | A cikin kwanakin aiki 7-10 bayan karɓar ajiya ko L/C |

| Biyan kuɗi | T/T,LC |

| Ƙarfin aiki | Tan 250,000/shekara |

API 5L Gr. X52NS PSL 2Bututun Karfe Mara Sumul ACC. Zuwa ga IPS-M-PI-190(3) da NACE MR-01-75 ana amfani da su koyaushe a cikin yanayi mai tsami musamman a filayen mai da iskar gas mai dauke da H2S da iskar gas mai dauke da CO2.

Bututun ƙarfe mara sumul na API 5L X52NS PSL 2 ACC. Zuwa ga IPS-M-PI-190(3) da NACE MR-01-75 don maganin zafi dole ne a yi maganin zafi bayan an samar da shi. Kuma ya kamata a yi gwajin HIC da SSC.

Daraja da Sinadaran da Aka Haɗa (%)Don API 5LPSL2

| Daidaitacce |

| Sinadarin sinadarai(%) |

|

| ||||

| C | Mn | P | S | Si | V | |||

| API 5L | X52 NS | ≤0.16 | ≤1.65 | ≤0.02 | ≤0.003 | ≤0.45 | V ≤0.10 | |

CEⅡW=C+Mn /6+(Cr+Mo+V) /5+(Cu+Ni) /15 ≤0.39

Nb+V+Ti≤0.15%

Nb+V≤0.06%

Lokacin da ake yin nazarin sinadarai na samfurin, ana yin nazari biyu a kowane zafin ƙarfe da aka ɗauka daga samfuran daban-daban

Kayayyakin Inji na API 5LX52NSBututun Karfe Mai Sumul 2 na PSL ACC. Zuwa ga IPS-M-PI-190(3) &NACE MR-01-75 don maganin tsami:

| Ƙarfin Ba da Kyauta(MPa) | Ƙarfin Taurin Kai(MPa) | Ƙarawa A% |

| MPa | MPa | Tsawo (Ƙananan) |

| 36O-530MPa | 460-760MPa | 20 |

Gwajin Lanƙwasa

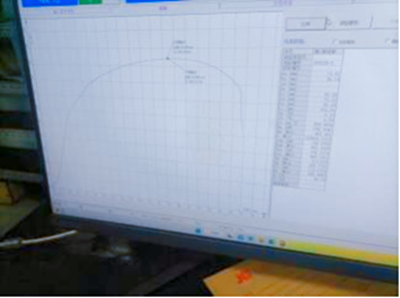

Gwajin Kayayyakin Inji

Gwajin Tauri

Bututun da aka gama OD Tsawonsa, ingancin samansa, Daidaito, goge bututun da ya lalace Dubawa da Girma.

1. Haƙurin OD: (-0.75% D + 0.75% D).

Juriyar bututun OD: ±0.005D.

2.Juriyar WT: (+15%t, -12.5%t).

3. Tsarin bututun da ya dace da yanayinsa: ±0.020D, Tsarin ƙarshensa: ±0.015D.

WT a kowane wuri na bututun zai zama fiye da kashi 87.5% na kauri na bango na musamman.

Ana auna WT akan ƙarshen bututu da micrometer.

Ana yin auna kauri na bango a jikin bututu ta hanyar amfani da hannu UT don WT wanda ke rufe zobba 3 ko sashe a duk faɗin jikin bututun tare da karantawa 6 a kowane sashe.

4. Matsayin lanƙwasa jikin bututu: 0.20% na tsawon bututun. An auna shi da layin da aka koya.

5. Matakin lanƙwasa ƙarshen bututu: Bai kamata ya wuce 3.0mm a cikin mita 1.2 ba. An auna shi da sandar madaidaiciya.

Binciken Diamita na Waje

Duba Kauri a Bango

Binciken Ƙarshe

Duba Daidaito

Binciken UT

Duba Bayyanar

Bututun da ba a saka ba ko kuma shafa mai baƙi/varnish (bisa ga buƙatun abokin ciniki);

6" da ƙasa a cikin fakiti tare da majajjawa biyu na auduga;

Duk ƙarshen biyu tare da masu kare ƙarshen;

Ƙarshen fili, ƙarshen bevel (2" da sama da ƙarshen bevel, digiri: 30 ~ 35°), zare da haɗin kai;

Alamar.

Jirgin Bututu Mara Sumul zuwa Qatar

Jirgin ruwa mara sulke zuwa Pakistan

Jirgin Bututu Mara Sumul zuwa Afirka ta Kudu

Jirgin ruwa mara sulke zuwa Ecuador