Cyflenwad Dur BotopPibell Dur ERWoGR.B,X42,X46,GR.1,GR.2,S355J0H,S275JRH,SGP,ac ati

| Arddull | Safonol | Gradd | Defnydd |

| Pibell Dur ERW | API 5L PSL1 a PSL2 | GR.B, X42, X46, X52, X60, X65, X70, ac ati | Cludo olew a nwy |

| ASTM A53 | GR.A, GR.B | ||

| ASTM A252 | GR.1, GR.2, GR.3 | Ar gyfer Strwythur (Peilio) | |

| BS EN10210 | S275JRH, S275J0H, S355J0H, S355J2H, ac ati | ||

| BS EN10219 | S275JRH, S275J0H, S355J0H, S355J2H, ac ati | ||

| JIS G3452 | SGP, ac ati | Cludiant Hylif pwysedd isel | |

| JIS G3454 | STPG370, STPG410, ac ati | Cludiant Hylif pwysedd uchel | |

| JIS G3456 | STPG370, STPG410, STPG480, ac ati | Pibellau dur tymheredd uchel |

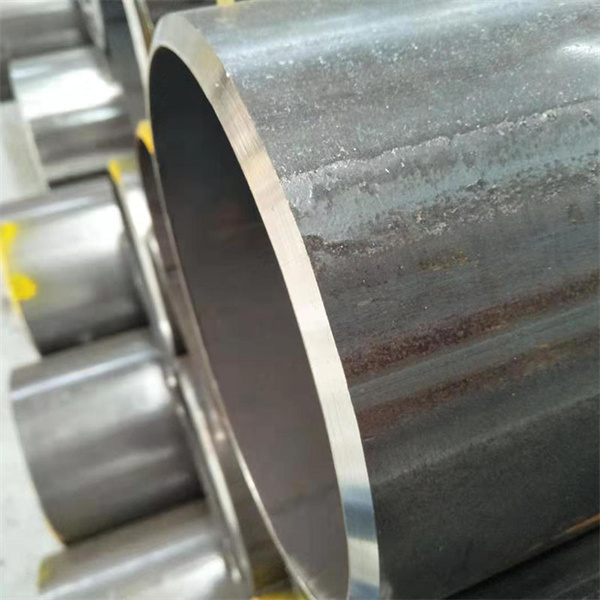

Bevelio Pen Pibell

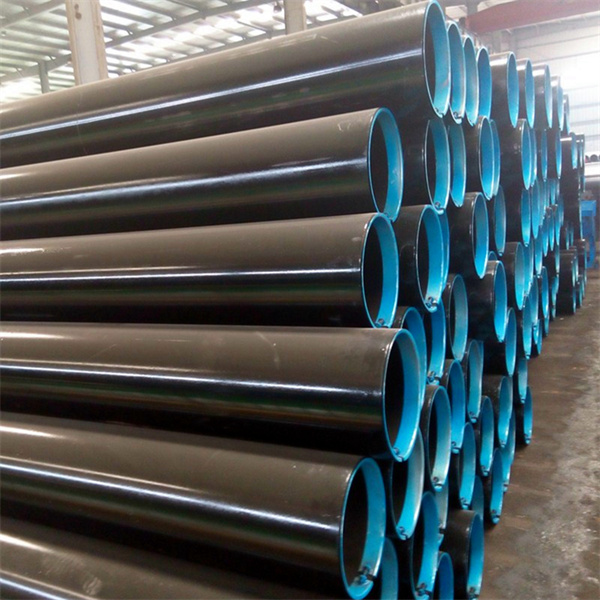

Peintio Du gyda Marcio

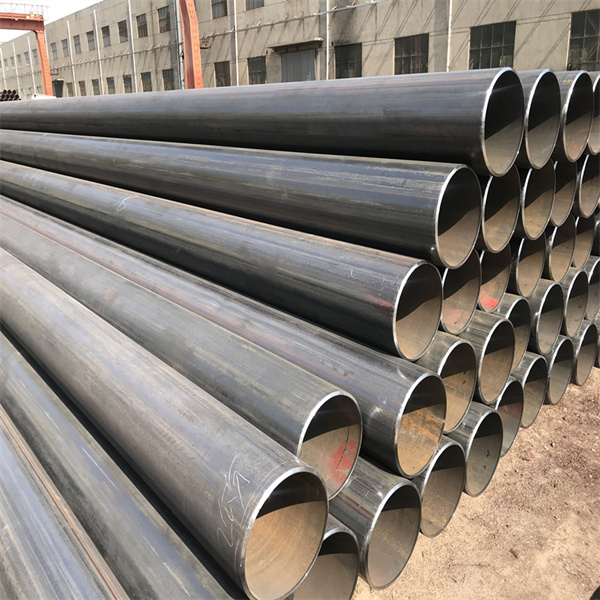

Bwndelu a Slingio

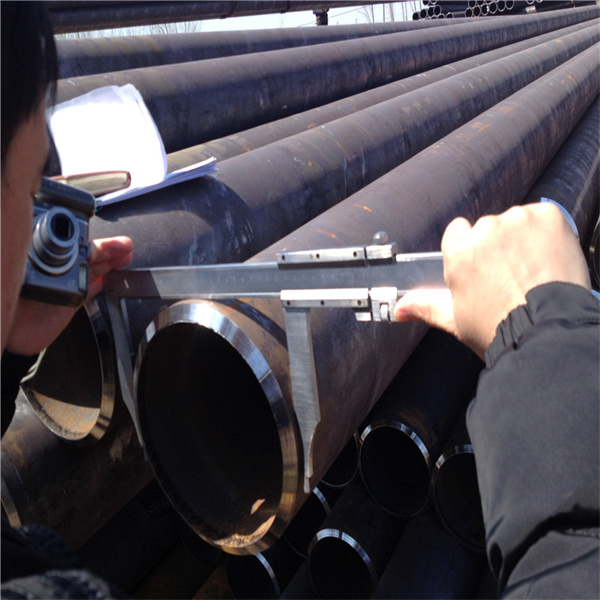

Archwiliad Diamedr Allanol

Archwiliad Trwch Wal

Diwedd yr Arolygiad

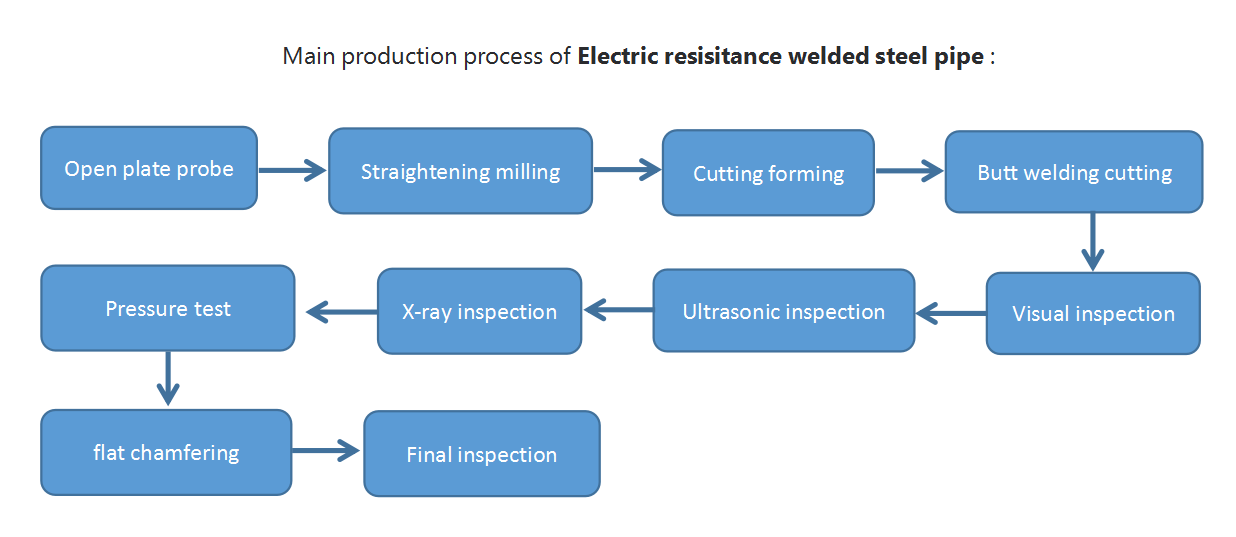

Weldio gwrthiant trydan (Y dull gweithgynhyrchu yw weldio gwrthiant trydan neu weldio pen-ôl. Gall y dull gorffen fod yn boeth neu'n oer. Rhaid anelio'r pibellau gorffenedig oer ar ôl eu gweithgynhyrchu.)

Goddefgarwch OD a WT

| Adran | Goddefgarwch ar OD | Goddefgarwch ar WT | |

| Pibell Dur ERW | 10.5mm≤D≤48.6mm | ±0.5 mm | -12.5% + Heb ei nodi |

| D=60.5mm | ±0.5 mm | ||

| D=76.3mm | ±0.7 mm | ||

| 89.1mm≤D≤139.8mm | ±0.8 mm | ||

| D=165.2mm | ±0.8 mm | ||

| D=190.7mm | ±0.9 mm | ||

| D=216.3mm | ±1.0 mm | ||

| D=241.8mm | ±1.2 mm | ||

| D=267.4mm | ±1.3 mm | ||

| D=318.5mm | ±1.5mm | ||

| 355.6mm≤D≤508.0mm | - | ||

| Pibell ERW ASTM A252 | Pibell ERW Gron |

| Pibell ERW ASTM A53 B | Pibell Dur Weldio ERW |

| Pentwr Pibell Dur ERW | Pibell Dur Du ERW |

| Pibell ERW Dur Ysgafn | Pibell Dur Carbon ERW |

Pibell Dur Carbon ERW ASTM A53 Gr.A a Gr. B ar gyfer Tymheredd Uchel

PIBELL DUR STRWYTHUROL ERW EN10210 S355J2H

Gwasanaeth Pwysedd Pibell Dur Carbon ERW JIS G3454

Pibellau Dur Carbon ERW JIS G3452 ar gyfer Pibellau Cyffredin

Pibell Dur ERW STRWYTHUROL EN10219 S275J0H S275J2H / S275JRH